(you mean that other Irish fag)

Tsk, tsk, tsk ... these days of political correctness we do not say "fag", we say "gay". Doesn't change a thing, but still ... 😀

A faggot of wood is a bundle about 3 feet long that fits in your arms. Meaning a diameter of around 2 feet.

AudioExpress used to edit my wood references a bit!

A stick is a piece of wood to be used in making furniture.

Lumber is used by carpenters. Planks are used by shipbuilders.

A cord is 4x8x4 feet of small timber pieces. Timber still has the bark and is rough stacked.

A cunit is 100 cubic feet of lumber.

A unit of wood varies according to type but for 3/4" plywood it is often 44 pieces. 3/8" plywood is 88 pieces. Note it is just under 3' not 4' for a cord.

A board foot lacks a bit of circulation err is 144 cubic inches before drying, about 90% of that dry. Except you can often get 144 cubic inches per board foot when buying furniture grade sticks.

That is all American usages, elsewhere other funny terms.

AudioExpress used to edit my wood references a bit!

A stick is a piece of wood to be used in making furniture.

Lumber is used by carpenters. Planks are used by shipbuilders.

A cord is 4x8x4 feet of small timber pieces. Timber still has the bark and is rough stacked.

A cunit is 100 cubic feet of lumber.

A unit of wood varies according to type but for 3/4" plywood it is often 44 pieces. 3/8" plywood is 88 pieces. Note it is just under 3' not 4' for a cord.

A board foot lacks a bit of circulation err is 144 cubic inches before drying, about 90% of that dry. Except you can often get 144 cubic inches per board foot when buying furniture grade sticks.

That is all American usages, elsewhere other funny terms.

Last edited:

You're welcome.Lucky

I was surprised when i saw your TL cantilever model (*), Next I was even more surprised reading about the dispersion in your last post.

This clings 'guided waves testing' to me

Dispersion is not due to material inherent properties ( -almost- isotropic materials are -almost- non dispersive acoustically) but due to accumulated wave mode changes when relatively long waves interfere obliquely with structural geometry upon multiple passes (resonance) along a long solid structure.

The combination of long wavelength and small thickness is favorite for thinking that guided wave theory is applicable to a cartridge cantilever case.

Allow me to express my concerns over the validity of the application of this theory due to the minimal cantilever length when compared to excitation's wavelength.

I haven't the means to test or simulate the scenario. If you are in position to do so, please check what happens at such a small distance from the excitation point (single excitation point, not comb excitation)

In any case, thank you very much for the fresh look you provide on this old problem. That was a stimulus for me reading further on an interesting topic.

........

Lucky, just a question. What propagation velocity did you chose for the cartridge cantilever TL sims?

BTW, transverse vibrations apply generally to rods and tubes, and resonant modes apply to tonearms as well as cantilevers. There is not one resonant frequency, but a whole series of them corresponding to multiples of propagation times that exactly fit mutiples of wavelengths - and they are not equally spaced because of dispersion. This is why tubular bells and windchimes can sound pleasant or unpleasant depending on geometry and material - the spacing of transverse eigenfrequency resonant series depends on dispersion.

It's complex as to why, but unless mass per length is zero transverse vibrations travel faster with increasing frequency. This means that all non-sinusoidal waveshapes are altered as they propagate along the tube, they 'disperse' hence the term 'dispersion'.

In the case of a cantilever, roughly the propagation time at the 'mid dip' around 4kHz corresponds to a phase shift of 90 deg, a minimum for mechanical impedance to stylus motion when the cantilever readily flexes. This tallies with calculations based on tube structures, suggesting at 4kHz propagation time of about 250uS being 90 deg in TL terms. Getting shorter as frequency rises.

Oooops, that is to say cantilever propagation time for flex waves is 1/4 cycle at c 4kHz, ie about 63uS.This tallies with calculations based on tube structures, suggesting at 4kHz propagation time of about 250uS being 90 deg in TL terms. Getting shorter as frequency rises.

Tsk, tsk, tsk ... these days of political correctness we do not say "fag", we say "gay". Doesn't change a thing, but still ... 😀

I once knew an Avon Lady whose name was Gaye Rhea - no, I am not kidding and I won't try to explain.

Well since this is the place to get useful answers, except of course from the three who know who you are, a bit of a new problem has popped up.

I am building some new test equipment, that should stick around. So the question is what should the cases look like?

For those unaware, 3D plastic printing, sheet metal, milling metal and wood working facilities are all in my back room. (It actually isn't that large a room. It is only 1/2 of an acre. But it is heated and air conditioned.)

So if anyone has any ideas on style for test equipment pictures please!

In a similar vein there are bar graph style nixie tubes available on eBay. I am sorely tempted to use them to make an RTA!

Now the test equipment is intended to be a series of small modular boxes, fully shielded that interconnect for various test set-ups. In the past I have used thin brass sheet to make Faraday shielded enclosures for various tests. I also keep a decent stock of small steel boxes for adapters such as direct boxes etc.

Not yet clear if they are to be AC powered directly, from a remote supply or battery powered. I just got in my sample of the lithium ION batteries and they are looking quite nice.

I expect this series to be painted aluminum or maybe the EPA legal version of chromate conversion coated (Alodine.)

So please nominate what you think is decent looking test equipment!

I am building some new test equipment, that should stick around. So the question is what should the cases look like?

For those unaware, 3D plastic printing, sheet metal, milling metal and wood working facilities are all in my back room. (It actually isn't that large a room. It is only 1/2 of an acre. But it is heated and air conditioned.)

So if anyone has any ideas on style for test equipment pictures please!

In a similar vein there are bar graph style nixie tubes available on eBay. I am sorely tempted to use them to make an RTA!

Now the test equipment is intended to be a series of small modular boxes, fully shielded that interconnect for various test set-ups. In the past I have used thin brass sheet to make Faraday shielded enclosures for various tests. I also keep a decent stock of small steel boxes for adapters such as direct boxes etc.

Not yet clear if they are to be AC powered directly, from a remote supply or battery powered. I just got in my sample of the lithium ION batteries and they are looking quite nice.

I expect this series to be painted aluminum or maybe the EPA legal version of chromate conversion coated (Alodine.)

So please nominate what you think is decent looking test equipment!

Last edited:

I can't help as I need lots of knobs, either vernier or steampunk style and big 19" racks with forbidden planet style dials to make things look serious. A bad affliction I know 🙂.

Ed,

Are you planning to make serial production or just a one off type of thing? If it is only for your own use why try and make it look fancy, but if it isn't then with the 3D printing you could do something interesting and metal spray the inside of the plastic to give yourself some shielding if you can't just put a box or sheet inside. What type of printer do you have. if it is FDM then you are limited in tolerances and also in the type of materials you can use. Photopolymers are the best that you can do but not many have those types of machines.

Are you planning to make serial production or just a one off type of thing? If it is only for your own use why try and make it look fancy, but if it isn't then with the 3D printing you could do something interesting and metal spray the inside of the plastic to give yourself some shielding if you can't just put a box or sheet inside. What type of printer do you have. if it is FDM then you are limited in tolerances and also in the type of materials you can use. Photopolymers are the best that you can do but not many have those types of machines.

"...raised almost literally to the power of infinity". (Dr. Morbius, Forbidden Planet)I can't help as I need lots of knobs, either vernier or steampunk style and big 19" racks with forbidden planet style dials to make things look serious. A bad affliction I know 🙂.

Ed,

Are you planning to make serial production or just a one off type of thing? If it is only for your own use why try and make it look fancy, but if it isn't then with the 3D printing you could do something interesting and metal spray the inside of the plastic to give yourself some shielding if you can't just put a box or sheet inside. What type of printer do you have. if it is FDM then you are limited in tolerances and also in the type of materials you can use. Photopolymers are the best that you can do but not many have those types of machines.

Just one offs for me. Have no trouble spraying metal.

We just finished a project where the architect specified an interior ceiling beam and loudspeaker color of a PPG silver paint. Since they are local I picked up a gallon and a nice note to the architect that the paint was not suitable for wood.

Used a tiny bit of the gallon to check the finish and it turned out Rustoleum silver paint was a perfect match. Good thing as the specified silver paint was $435.00 a gallon. Yes SILVER paint. Also requires a catalyst and supplied air when spraying it. (Have that gear also!)

So I now have quite a bit of nice conductive paint!

I can't help as I need lots of knobs, either vernier or steampunk style and big 19" racks with forbidden planet style dials to make things look serious. A bad affliction I know 🙂.

That would be the nixie tube RTA. Real black wrinkle finish, painted brass handles, engraved serif font letter or white decals, 3/16" steel face plate, you know the standard monster in the lab look.

Brad,

I only have two of the Weston style meters in my collection. I think the ultra-sensitive projection ones are niftier!

I imagine that is either a urethane or epoxy based paint if it needs a catalyst. If you have an idea I could do a Solidworks drawing that you could I can convert to an SLS file for your printer. Just need some dimensions and a basic idea of what you want where.

It's interesting to see how long projection galvanometers were still providing useful measurements. I recall a discussion of their intrinsic noise levels.I only have two of the Weston style meters in my collection. I think the ultra-sensitive projection ones are niftier!

And then there are vibrating reed electrometers.

I imagine that is either a urethane or epoxy based paint if it needs a catalyst. If you have an idea I could do a Solidworks drawing that you could I can convert to an SLS file for your printer. Just need some dimensions and a basic idea of what you want where.

Modified urethane. Looking for ideas!

Folks please post pictures of not horrible looking electrical gear.

On of these days I will build some completely black cubes that puzzle box style contain the gear.

It's interesting to see how long projection galvanometers were still providing useful measurements. I recall a discussion of their intrinsic noise levels.

And then there are vibrating reed electrometers.

I have a 5 uA unit. Hold the leads and watch your heartbeat! I did lay in a stock of the light bulbs as I think they may be hard to get in the future.

I also like to buy the clunky Russian surplus black bakelite meters. 50 ua are ideal for just about everything.

Very VERY old fab equipment for discretes

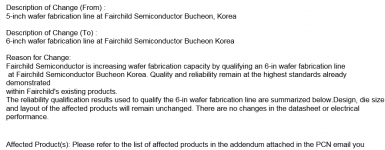

I just got a notice from Mouser that there's a Product Change Notification on a Fairchild "Soft Recovery diode" I recently purchased. It's a fairly new and fairly high tech diode

The PCN says that they are upgrading the fab, from 5 inch wafers to 6 inch wafers. Oh by the way, MOS LSI made the 5 inch to 6 inch transition in the late 1980s -- twenty five years ago!! I imagine Fairchild's capital equipment must be fully depreciated by now.

_

I just got a notice from Mouser that there's a Product Change Notification on a Fairchild "Soft Recovery diode" I recently purchased. It's a fairly new and fairly high tech diode

- 30 amps

- 200 volts

- Recovery softness factor (tb/ta) is spec'd and guaranteed: 0.6

The PCN says that they are upgrading the fab, from 5 inch wafers to 6 inch wafers. Oh by the way, MOS LSI made the 5 inch to 6 inch transition in the late 1980s -- twenty five years ago!! I imagine Fairchild's capital equipment must be fully depreciated by now.

_

Attachments

That would be the nixie tube RTA. Real black wrinkle finish, painted brass handles, engraved serif font letter or white decals, 3/16" steel face plate, you know the standard monster in the lab look.

Yup that would get my vote 🙂

I'm still using a Dana voltmeter with nixies. I need to take it apart to clean the switches, but otherwise it works well.

In an AES paper I lied inadvertently that it was true rms---and later realized that it was the old average-responding but calibrated for rms. But it has a pretty decent ~50kHz bandwidth that sustains down to rather low levels. Someone knew what they were doing.I'm still using a Dana voltmeter with nixies. I need to take it apart to clean the switches, but otherwise it works well.

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II