There could be other issues with the DATS - poor connections are possible. This could affect your results.

I'd try a different set of leads at a minimum, and a different USB a-b cable to start. Perhaps even try a different USB port or different computer as well.

I have seen the magnetizer at Acoustic Elegance and toured the shop. Last time I was there and spoke with John, all of his steel was sourced from the US. Baskets are imported. Coils are US sourced from a winder out of state that manufactures very high temperature coils, both flatwound and round wound.

Regarding your 15M impedance blips in the 450 hz area, I have noted a dip in the 400-600 hz area that is in the driver itself, not sure of the source. I didn't investigate any further, it was a borrowed driver.

I'd try a different set of leads at a minimum, and a different USB a-b cable to start. Perhaps even try a different USB port or different computer as well.

I have seen the magnetizer at Acoustic Elegance and toured the shop. Last time I was there and spoke with John, all of his steel was sourced from the US. Baskets are imported. Coils are US sourced from a winder out of state that manufactures very high temperature coils, both flatwound and round wound.

Regarding your 15M impedance blips in the 450 hz area, I have noted a dip in the 400-600 hz area that is in the driver itself, not sure of the source. I didn't investigate any further, it was a borrowed driver.

Regarding the poor connection...The DATS has a calibration procedure. If the DATS was defective, the software would let us know...

Its strange how all of a sudden people are at a loss, concerning the DATS...what are you guys using to test thiele specs?!

I may be possible that the DATS is not able to measure large woofers?

Its strange how all of a sudden people are at a loss, concerning the DATS...what are you guys using to test thiele specs?!

I may be possible that the DATS is not able to measure large woofers?

Who is at a loss here?

Your dats is giving lower Bl than expected on multiple drivers.

It is possible that your dats is defective and you seem to be ignoring that option...

In a previous profession I used LMS while at home I used ARTA and they always seemed to agree with one another. Never used a DATS.

Your dats is giving lower Bl than expected on multiple drivers.

It is possible that your dats is defective and you seem to be ignoring that option...

In a previous profession I used LMS while at home I used ARTA and they always seemed to agree with one another. Never used a DATS.

Finally!

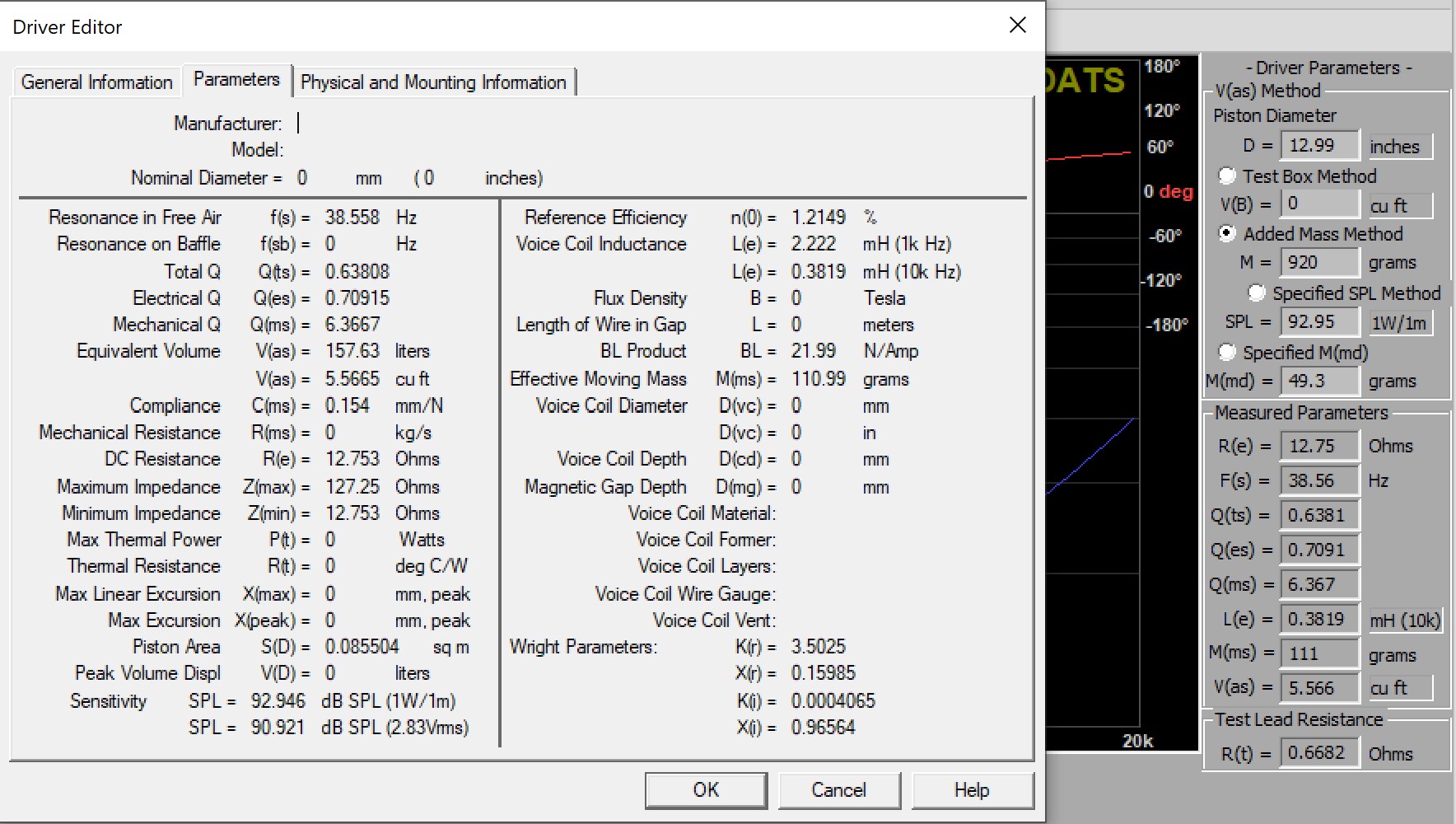

I added more mass and this is what happened...but now mms is off....If I lower the added mass...I get correct MMS but BL is off

And what about Q specs? No input information is needed for the DATS to calculate Q specs, not to mention the Qts reads fine on the 18h+s....I really don't know what to say about spl and efficiency specs

I added more mass and this is what happened...but now mms is off....If I lower the added mass...I get correct MMS but BL is off

And what about Q specs? No input information is needed for the DATS to calculate Q specs, not to mention the Qts reads fine on the 18h+s....I really don't know what to say about spl and efficiency specs

Attachments

Last edited:

I use Woofer Tester 2. Works fine. Makes no sense it can't measure a woofer. Do you have another driver set from another manufacturer you can measure to see if both measurement sets seem skewed?

If motor strength is low you should see a drop in sensitivity. Has anyone else had a similar issue? It's possible the magnets may not have been charged properly.

I don't know that much about your drivers but if these are made to order I can't imagine them not being tested. If they have serial numbers it may not hurt to ask them to review the factory data if available. They could batch test as well but you would need significant volume to justify that approach.

Rob 🙂

If motor strength is low you should see a drop in sensitivity. Has anyone else had a similar issue? It's possible the magnets may not have been charged properly.

I don't know that much about your drivers but if these are made to order I can't imagine them not being tested. If they have serial numbers it may not hurt to ask them to review the factory data if available. They could batch test as well but you would need significant volume to justify that approach.

Rob 🙂

I added more mass and this is what happened

Which brings you back to possible measurement error...

Measurement error for BL... Q has not changed no matter the method...no input is needed for Q. Q measured out correctly within range for the 18H+'s....its just the 15m that is double the expected amount.

Bl is supposed to be about 23tm....I just got a 21.99, when can say motor strength is there for the 15m. Likely to be very close with the 18H+. Its just a matter of Q for the 15m....

Bl is supposed to be about 23tm....I just got a 21.99, when can say motor strength is there for the 15m. Likely to be very close with the 18H+. Its just a matter of Q for the 15m....

- According to data-bass.comAn amplifier and voltage divider network is used in order to provide a strong signal of about 1.5 volts to the drivers. Based on previous experiences: Large, heavy mms, stiff suspension sub drivers, need a significant input signal to pull accurate parameters.

Last edited:

Regarding your 15M impedance blips in the 450 hz area, I have noted a dip in the 400-600 hz area that is in the driver itself, not sure of the source.

Hmm, ~13560"/2/450 = ~15", so likely an eigenmode plus its harmonics across the front of any typical 15" driver as part of the diaphragm's acoustic 'pipe' end correction with really tall surrounds skewing this simple calculation somewhat.

Measurement error for BL...

Hmm, at this point my recommendation is to do what I've recommended to others that had this type problem with the original PE Woofer Tester, which is to do it the old fashioned way and 'it is what it is', so with 100% successful results to date 😉: Measuring Loudspeaker Driver Parameters

@camplo

Have you checked that the sample rate of the DATS audio interface in Win settings is the same as the program expects?

Have you checked that the sample rate of the DATS audio interface in Win settings is the same as the program expects?

@ camplo:

I have witnessed a 'technician' change an engine out of a pickup that had no oil pressure, only to find out that the replacement engine also had no oil pressure.

The culprit was a faulty engine oil pressure sending unit which of course was transferred to the new engine. A manual oil pressure gauge could have been installed in an oil galley to rule out the possibility of a faulty reading.

As suggested, trying a different usb port, a different cable, a different computer can help to rule out these things.

Also, are you laying the driver on the rear plate ( with cone facing up ) to measure, or is the driver clamped in the normal vertical position?

I have witnessed a 'technician' change an engine out of a pickup that had no oil pressure, only to find out that the replacement engine also had no oil pressure.

The culprit was a faulty engine oil pressure sending unit which of course was transferred to the new engine. A manual oil pressure gauge could have been installed in an oil galley to rule out the possibility of a faulty reading.

As suggested, trying a different usb port, a different cable, a different computer can help to rule out these things.

Also, are you laying the driver on the rear plate ( with cone facing up ) to measure, or is the driver clamped in the normal vertical position?

Keep in mind, he is using it in a ~110db/w multi way horn system, and crossed it at 500hz in a larger horn for testing

I have read that link before, and I think it is the lack of stored energy/resonance that makes the peerless driver sound so good compared to the others. From first hand experience it goes lower and sounds better than the HF108R, even if it may have more harmonic distortion

Evidently, I was aware of POOH's application of the Tymphany.

Don't get me wrong, I think the Tymphany is great value for money, but I don't think it's suitable for a 2 way that somewhat lives up to the thread title.

Until this year I considered the HF108(R) to be one of the most interesting 1" drivers and almost bought a pair.

By "stored energy" you are probably specifically referring to the (ketone polymer) diaphragm?

This is also a subject of my doubts. While a lossy diaphragm material prevents serious resonances, it may also blur the input signal, causing the treble in particular to sound muffled.

This phenomenon manifests itself in (direct) comparison with other drivers and the extent to which this is experienced as disruptive may also depend on personal preferences.

If the driver has a vented pole piece, I could imagine getting a bad reading if the driver is placed cone facing up and the vent blocked.

I think I would revert to less automated testing. If the drivers are good, I would bet Windows is at fault. The sound drivers are known to do bad things when not expected.

An aside, if you se a windows based tone generator, confirm it produces the right frequency. You could compare 60 hz with with a low voltage AC source.

I think I would revert to less automated testing. If the drivers are good, I would bet Windows is at fault. The sound drivers are known to do bad things when not expected.

An aside, if you se a windows based tone generator, confirm it produces the right frequency. You could compare 60 hz with with a low voltage AC source.

Came here to suggest what was just mentioned above; I use DATS and take all my V(as) measurements with the driver oriented vertically (ie as if it were mounted on an enclosure). You just have to find a way to support the magnet in such an orientation. See if that helps, along with switching USB ports (also mentioned above). If you hear back from John he’s just going to ask you if you tried all these methods anyway.

I tried the added mass using ~400grams and the BL comes out to be 18tm still....when using 920grams the mmd did not come to correct figure, somehow that throws the measurement off.

Last edited:

Did you use an ordinary good ohm meter to measure the DC resistance of the coil?

Whats the reading?

//

Whats the reading?

//

From first hand experience it goes lower and sounds better than the HF108R, even if it may have more harmonic distortion

There are some distinct differences between the HF108 and HF108R:

Compared to the HF108 compression driver, the HF108R incorporates a more rigid clamping system on the diaphragm. This creates a more subtle listening experience when the distance between the enclosure and the target audience is limited (as in a bar / club / restaurant or for a home listening situation) since it is typical for the compression drivers to be somewhat overwhelming when listened to in the near field. This requires additional machining in the gap as well as the alternative clamping method.

As a result, the diaphragms of the HF108 and HF108R are not interchangeable.

It seems the consensus is that the HF108 (not R) is generally preferred and goes lower, although member tuyen loves his HF108Rs.

In the last 20 years, a number of manufacturers (notably RCF and 18Sound) have considerably refined and improved titanium diaphragms, especially the suspension.

Some info on diaphragm resonances:

There are three principal structural resonances associated with the diaphragm assembly:

1) fo, the resonance caused by the total effective moving mass, M, of the diaphragm assembly against the compliance of the surround Cs.

2) fs, the second "cantilever" resonance frequency of the surround.

3) fh, the dome resonance frequency.

Typically fo is of the order of 1 kHz or less, and affects the response below this frequency.

Typically fs and fh are above 5kHz.

When we consider the system's control over resonances, at high frequencies this is largely related to the diaphragm and coil mass, while at low frequencies the mass plays a relatively small role. So, at the low end the driver works directly against the air column in the horn. When the mass is reduced, almost nothing happens. Whereas when the power factor is increased, things happen, not only with the level but also the modal tendency decreases and the phase response changes. In other words, motor power means everything at low frequencies. This explains (partly) why few 1" drivers play low (and loud) without bothersome distortion figures.

A couple of descriptions of polymer membranes:

" - They sound comfortable, but the snare drum sounds like a softie roaring in the asphalt "

and

" - Plastic membranes sound like a sleeping bag "

The trend in midrange drivers is to have high internal attenuation for one reason or another. Either in the diaphragm itself and / or as a result of mechanical damping in suspension, eddy current brake in coil form, etc. As a result a larger proportion of the energy supplied to the driver is stored for a certain time in the mechanical and electromagnetic system and emitted distributed in time. This effect is non-harmonic in the sense that the energy emitted does not follow any tonal system that relates directly to the signal. It is more "a lot of energy as in a lot of noise, little energy as in little noise", so that a non-harmonic noise always makes up a certain proportion of what we hear.

But there is also an advantage of this damping. In modal systems (something all parts of a driver are) we can control the modes by means of damping. An increase in attenuation automatically implies a reduction in modal behavior.

Last edited:

I tried the added mass using ~400grams and the BL comes out to be 18tm still....when using 920grams the mmd did not come to correct figure, somehow that throws the measurement off.

Forgot to mention the pioneer's used a 2 ft^3 sealed box for 15", don't forget to add the volume the driver displaces for accurate calculations.

Camplo, you measured resistance at the terminals I assume?

It looks like you've 8 Ohm drivers.

It looks like you've 8 Ohm drivers.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Is it possible to cover the whole spectrum, high SPL, low distortion with a 2-way?