In danish HighFidelity in the late 70s there was a guy that build closed boxes for his Tannoy 15" drivers. I think they were 200-300L each and he lined the inside with ceramic tiles, not the wall tiles but the thick ones that you have on the floor, they weigh two to three times as much. They must have tipped the scale way above 100 kg.

My current plan on lossy boxes is slightly enlarged Spendor BC1 (300x630x300) using OSB 350x700x350 and line them with bitumen impregnated softboard (asfaboard) and then line the board with 10mm felt. Every layer glued with accoustic quality silicon glue.

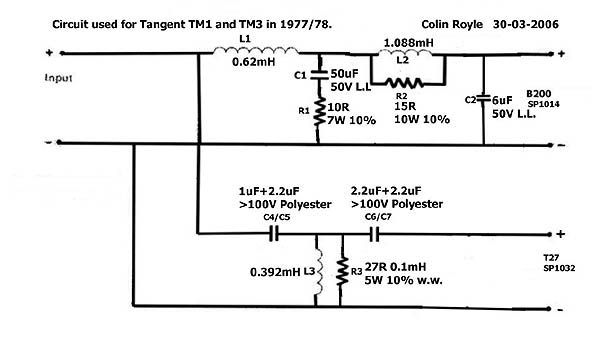

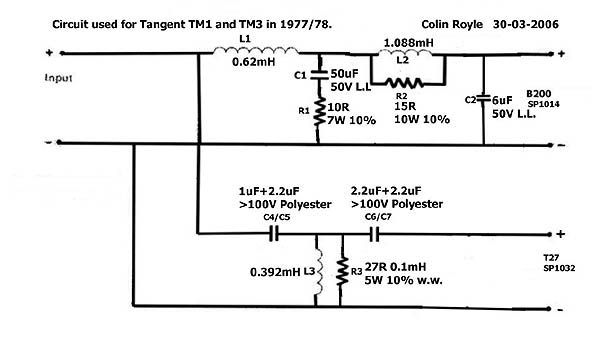

Drivers will be KEF B200 and T27 to get that vintage bextrene sound. But I will skip the bass reflex and use a third order closed box instead.

My current plan on lossy boxes is slightly enlarged Spendor BC1 (300x630x300) using OSB 350x700x350 and line them with bitumen impregnated softboard (asfaboard) and then line the board with 10mm felt. Every layer glued with accoustic quality silicon glue.

Drivers will be KEF B200 and T27 to get that vintage bextrene sound. But I will skip the bass reflex and use a third order closed box instead.

Vinyl tile in commercial grade is thicker...more mass... than residential grade. Call it mineral loaded vinyl damping, if you wish.

An alternate is 40 mil pvc sheets, sold as shower pan liner, it is the water barrier used under ceramic tile shower floors.

Silicone caulk has very good adhesive properties. I use it for the same purpose as "green glue". Local availability and cheaper.

NOISEPROOF YOUR LIFE® | Green Glue

An alternate is 40 mil pvc sheets, sold as shower pan liner, it is the water barrier used under ceramic tile shower floors.

Silicone caulk has very good adhesive properties. I use it for the same purpose as "green glue". Local availability and cheaper.

NOISEPROOF YOUR LIFE® | Green Glue

Investigating constrained layer damping. Consider aluminum roll flashing.

http://www.sciencebuddies.org/science-fair-projects/project_ideas/ApMech_p040.shtml#makeityourown

http://www.sciencebuddies.org/science-fair-projects/project_ideas/ApMech_p040.shtml#makeityourown

Last edited:

Silicone caulk is not similar to Green Glue in terms of acoustic properties....Silicone caulk has very good adhesive properties. I use it for the same purpose as "green glue". Local availability and cheaper.

NOISEPROOF YOUR LIFE® | Green Glue

When I was a kid, there're a pair of speakers at home which we considered quite a luxury item for us. There're a 3/4" dome and a 8" cone on the ported cabinet with a mark of "Tangent" IIRC. By my unscientific and naive ears/brain, the speakers sounded so wonderful in my untrustful memory. The piano played from it sounded just like the real thing in the same room.

I learned the drivers are KEF in later years.

No dimensions on hand, but it's quite big for loading a single 8" (more than 2 ft high and more than 1 ft wide and deep), and the construction is very similar to those in OP -- it has 3/4" removable front baffle by particle board, and 1/2" side walls (maybe plywood but not sure).

A simple "T" shape bracing connecting 2 side walls, with that fore-aft stick proping the rear panel and the magnet of midwoofer. Ordinary looking foam pads on 5 of the inner walls. Quite simple in any means.

After I got older and hooked on audio, among other things, I started to 'improve' this old speaker by what I learned (or mis-guided) from magazines or books etc.

I made more damping and bracings to the cabinet, but it just sounded worse as I did more. Sometimes new resonances popped up, sometimes it sounded just dull. Never improved. Eventually I gave up.

Similar things happened in some other experiences afterward. And I've heard similar stories from others.

Before I found the nirvana of building a proper speaker box, I gave up and turned to OB and horns...

For me (and probably most DIYers), it's very hard to catch the magic recipe of proportions, materials and constructions etc, especially if we want unique and original in our works, no cloning.

It's a very good thing to use simple-looking material and construction in commercial products, because of cost saving. Meantimes it's excellent engineering which is hard to obtain by amatures. I think there must be quite a lot of trial & error activities to get those excellent results. It's OK for RD department of big companies, but I guess I can never get that kind of "zen" before my house is full of the failed boxes. Or still can't after.

Agressively armed products like the types of Wilson or Avalon are well-built and almost free of box resonances, but that's not an easy way for most DIYers, either. I myself don't like cutting all those boards etc. And I don't think it's good engineering.

Since the major goal -enjoying music- can be obtained by other techniques, so I give up boxes for good. Not missing them, no regret.

I learned the drivers are KEF in later years.

No dimensions on hand, but it's quite big for loading a single 8" (more than 2 ft high and more than 1 ft wide and deep), and the construction is very similar to those in OP -- it has 3/4" removable front baffle by particle board, and 1/2" side walls (maybe plywood but not sure).

A simple "T" shape bracing connecting 2 side walls, with that fore-aft stick proping the rear panel and the magnet of midwoofer. Ordinary looking foam pads on 5 of the inner walls. Quite simple in any means.

After I got older and hooked on audio, among other things, I started to 'improve' this old speaker by what I learned (or mis-guided) from magazines or books etc.

I made more damping and bracings to the cabinet, but it just sounded worse as I did more. Sometimes new resonances popped up, sometimes it sounded just dull. Never improved. Eventually I gave up.

Similar things happened in some other experiences afterward. And I've heard similar stories from others.

Before I found the nirvana of building a proper speaker box, I gave up and turned to OB and horns...

For me (and probably most DIYers), it's very hard to catch the magic recipe of proportions, materials and constructions etc, especially if we want unique and original in our works, no cloning.

It's a very good thing to use simple-looking material and construction in commercial products, because of cost saving. Meantimes it's excellent engineering which is hard to obtain by amatures. I think there must be quite a lot of trial & error activities to get those excellent results. It's OK for RD department of big companies, but I guess I can never get that kind of "zen" before my house is full of the failed boxes. Or still can't after.

Agressively armed products like the types of Wilson or Avalon are well-built and almost free of box resonances, but that's not an easy way for most DIYers, either. I myself don't like cutting all those boards etc. And I don't think it's good engineering.

Since the major goal -enjoying music- can be obtained by other techniques, so I give up boxes for good. Not missing them, no regret.

...ported cabinet with a mark of "Tangent"

I learned the drivers are KEF in later years.

No dimensions on hand, but it's quite big...

Tangent TM1 from your description, the more upscale mode substitutued an Audax 8" (RS4), Quite a good loudspeaker in its day.

Tangent Speakers TM-1

dave

In my opinion the Tangent TM1 and TM3 were about the only decent-sounding speakers ever made with the KEF B200 SP1014. That woofer has a "quack" in its upper range that's hard to get rid of. Linn never managed that with their Sara, but Tangent got it.

In my opinion the Tangent TM1 and TM3 were about the only decent-sounding speakers ever made with the KEF B200 SP1014.

+1

dave

This is a perfect example for a big problem in HiFi: detecting an error (coloration) in the sound of a device (box) which reminds of something (wood, paper), and making probably false assumptions where this error comes from.

Please have a look at the measurements from Stereophile: Harbeth M40.1 loudspeaker Measurements | Stereophile.com

I don't know if this is the speaker you've heard but I bet that all of those Harbeth speakers are comparable.

The CSD of the back panel's vibrations looks awful, sure. But above 250 Hz there is no problem. BBC research indicates that these low resonances are less audible than resonances higher in frequency. But without a measurement at the listening position this CSD gives only a peek on the behaviour of the panels, so we cannot tell if these low resonances are below the audibility threshold found by the BBC....

It's likely that the accelerometer that they used also had limited bandwidth. Otherwise, why limit the graph to 1kHz?

When it comes to "box sound", I can think of at least 3 different sources:

-- pistonic dipole movement as the speaker motor pushes and pulls the entire box at low frequencies. You can probably sense it with a touch test.

-- partial oscillations that ripple across the baffle and any other panels connected to it.

-- and the main one, standing waves that resonate in the air cavity inside the box, which try to escape through the obvious weak spot, the diaphragm. If you've ever heard people talking on the other side of an apartment wall, think of the speaker as a giant hole in that wall and the cone is not much more than a privacy curtain.

OK, I exaggerated a bit with the 3rd point because speakers are usually extremely good at producing >~100dB bass inside a box, while keeping the outside level at a more comfortable 60dB, ish. That's 40dB attenuation! You can thank the cone stiffness, strong motor, low Qes etc. But at high frequencies, that is, mid-woofers attempting 500Hz - 5kHz with controlled cone break-up, the voice-coil is driven by the amp while the outer parts of the cone (with the most surface area) are basically blowing in the wind. Hard cone drivers aren't a perfect fix either because of their problematic bell modes, and the soft rubber surrounds.

My engineering compromise for the above is to make the box oversized. Bring the Qtc down as low as practical, e.g. 0.5 instead of that mythical 0.707. The driver may look awkwardly small, but the SPL inside the box is significantly reduced. I don't know whose crazy idea it was that Qtc = 0.707 was something people should actually aim for. It's only ever going to be correct for outdoor applications where there's no room gain.

My engineering compromise for the above is to make the box oversized. Bring the Qtc down as low as practical, e.g. 0.5 instead of that mythical 0.707. The driver may look awkwardly small, but the SPL inside the box is significantly reduced. I don't know whose crazy idea it was that Qtc = 0.707 was something people should actually aim for. It's only ever going to be correct for outdoor applications where there's no room gain.

A 4th order system so Qtc = 0.707 doesn't apply.

I'm not sure reducing pressure in the box would reduce cabinet wall breakthrough. At KEF when we were using vibration isolation mounts, the wall vibration dropped quite a bit. It was the direct reaction force driven mechanically through the chassis that was the larger factor. Once the units were decoupled then in-box pressure became the dominate factor but it was 10 to 20 dB lower than the direct excitation had been.

David

A 4th order system so Qtc = 0.707 doesn't apply.

I'm not sure reducing pressure in the box would reduce cabinet wall breakthrough. At KEF when we were using vibration isolation mounts, the wall vibration dropped quite a bit. It was the direct reaction force driven mechanically through the chassis that was the larger factor. Once the units were decoupled then in-box pressure became the dominate factor but it was 10 to 20 dB lower than the direct excitation had been.

David

Cool, that's good to know. For experimenting, I'm looking at making the entire front panel detachable, perhaps with some kind of rubber gasket.

I think the KEF technique of using soft foam seal and rubber grommets in the mounting holes is likely going to be more effective than decoupling the entire baffle, plus it's easier...

Cool, that's good to know. For experimenting, I'm looking at making the entire front panel detachable, perhaps with some kind of rubber gasket.

Cork can be had at art'n craft supply. Various thicknesses and in self adhesive sheets are available for not much money. Cut, stick and trim. Done.

For experimenting, I'm looking at making the entire front panel detachable, perhaps with some kind of rubber gasket.

Its worth trying.

Harwood in his paper talks about some "reject" cabinets with poor corner rigidity. They actually sounded better in their tests. Maybe it is "poor coupling" instead of decoupling.

The thing to be aware of with all decoupling schemes is that a few rigid cross points, such as screws across the rubber, can largely defeat the effect. The KEF rubber grommets had underlying metal rivets to make sure that the screws weren't overtightened and everything was truly floating.

David

FWIW, industrial strength Velcro is what I'd try first to somewhat decouple a speaker baffle and if I needed it airtight, then I'd 'ring' it with NEMA type 5-12 rated neoprene.

GM

GM

If the goal is to float the driver in the box, then the normal screw holes on frame are no longer good fixing points.

When front mounted, the magnet droops, lower portion of frame pops out and pulls the screw head(s). Available areas for spreading pressure on these positions are all too tiny and not effective over time. Materials soft enough are not able to resist that kind of pressure and would be compressed into a thin hard layer in no time.

So it should be supported at the magnet. Some internal bracings for this are essential.

When front mounted, the magnet droops, lower portion of frame pops out and pulls the screw head(s). Available areas for spreading pressure on these positions are all too tiny and not effective over time. Materials soft enough are not able to resist that kind of pressure and would be compressed into a thin hard layer in no time.

So it should be supported at the magnet. Some internal bracings for this are essential.

This all stems from a post in another thread about capacitors which I didn't want to derail.

And then we also get:

My point really is why "rigid"? What exactly is the purpose of a speaker cabinet? Other than supporting the drivers, need it be rigid at all? I guess that this is where Open Baffles come in?

<snip>

Huge debates about cabinet bracing at these sort of forums. It's a double-edged sword. Overly rigid and braced front panels stress drive units and chassis into ringing.

<snip>

System7 said:". . . it should be noted that MDF and chipboard are both little better than thick cardboard acoustically."

"Spendor and Harbeth both advocate rigid, light and strong 12mm plywood cabinets."

And then we also get:

As a corollary to Harwood's "bell" analogy I would say that a duvet doesn't ring at all so one could perhaps build a speaker out of cardboard (or MDF / Chipboard but let's not go there 😉).Alan Shaw of Harbeth Audio said:What underpins the BBC's thin-wall cabinet philosophy (and I was surprised to read that exact word in one of Harwood's papers recently) is the observation that a perfectly cast bell will ring on for many seconds. Conversely, a bell with a hairline crack will sound leaden and hardly ring at all.

My point really is why "rigid"? What exactly is the purpose of a speaker cabinet? Other than supporting the drivers, need it be rigid at all? I guess that this is where Open Baffles come in?

- Home

- Loudspeakers

- Multi-Way

- Interesting read I found on Lossy Cabinet designs by Harbeth