It seems like the tractrix curve has everything going for it, uses less horn length and mouth, helps with low frequencies, directiveity, smooth phase alignment etc..

But has anyone attempted to fold one? or would the folds inherently destroy the curve no matter what? I can barely draw a tractrix curve unfolded at this point, but im fairly sure I could CNC one with a lot of scoring for bending material. Im even open to alternative materials and methods that could wrap the horn path around the main larger horn mouth itself in a spiral for example.

So far GPT said (with a grain of salt) that I could get down to 60/70Hz with a 20 db gain and 3 times the thow as compared to un-vented.. LOL

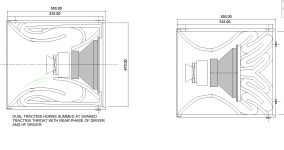

Attached are some "very" rough ideas for comment.

But has anyone attempted to fold one? or would the folds inherently destroy the curve no matter what? I can barely draw a tractrix curve unfolded at this point, but im fairly sure I could CNC one with a lot of scoring for bending material. Im even open to alternative materials and methods that could wrap the horn path around the main larger horn mouth itself in a spiral for example.

So far GPT said (with a grain of salt) that I could get down to 60/70Hz with a 20 db gain and 3 times the thow as compared to un-vented.. LOL

Attached are some "very" rough ideas for comment.

Attachments

That depends of how you define 'works'. Yes, something will come out. No, you will not like the result. The vast compression will cause very high distortion and non-linearity and the non-existant phase compensation will cause additonal severe FR unlinearity and bandwidth limitation. Or in other words: Utterly crap.

Folding can be done successfully if you understand the limitations. These are complex and can be difficult to explain in a simple post.

You'll find that builders are reluctant to use folding for a horn that plays through the mid and higher frequencies.

You'll find that builders are reluctant to use folding for a horn that plays through the mid and higher frequencies.

First of all, you need to understand that this contraption has to work in the midrange, LF can't be reproduced because the horn mouth is too small. For the midrange, you'll experience severe phase changes at multiple frequencies and that in a range that's very sensitive to the human ear. It will sound horrible, even to the lowest standards. The fact that on the 2nd picture the 'horn' goes a lot narrower shortly before its final expansion shows there's NONE of the theoretical or practical knowledge applied. It even happens several times on the horn path. I've never ever seen such a bad horn design even from 1st time builders. the first design is even asymmetrical, leaving the cone with asymmetrical load and tumbling motions! If that's what AI is able to design today, you need to wait for 30-50 years to come to something working.

No, folding it like that will not be a TracTrix, it will be more like a rear loaded horn only amplifying lower register, without using the drivers front radiation capacity.

Will not work very well

There have been occasional attempts to save space by gently bending the curve. Specially in the early days when amplifier power was very limited.

Some still like it and use it out of interest and hobby. Some of these designs have pretty decent performance with low distortion output.

I would say that this picture, showing Western Electric horns from early days of cinema, tells you a lot about where limits goes when discussing bending a front loading horn.

Lowther have made some bent front horns but have designed them for drivers that have a severe lift in amplitude for the higher registers.

So it's more an attempt to handle the otherwise excessive high registers that would result in a too bright sound character.

You can try as a learning experience, but I think it will be waste of time.

And, forget about TracTrix, it's a horn as any other horn with no special funtionality. It's a marketing name.

Every design of horn needs to be adjusted to the driver it will coupled with.

A wave guide for a tweeter is also a horn, adjusted to suite the specific driver.

Will not work very well

There have been occasional attempts to save space by gently bending the curve. Specially in the early days when amplifier power was very limited.

Some still like it and use it out of interest and hobby. Some of these designs have pretty decent performance with low distortion output.

I would say that this picture, showing Western Electric horns from early days of cinema, tells you a lot about where limits goes when discussing bending a front loading horn.

Lowther have made some bent front horns but have designed them for drivers that have a severe lift in amplitude for the higher registers.

So it's more an attempt to handle the otherwise excessive high registers that would result in a too bright sound character.

You can try as a learning experience, but I think it will be waste of time.

And, forget about TracTrix, it's a horn as any other horn with no special funtionality. It's a marketing name.

Every design of horn needs to be adjusted to the driver it will coupled with.

A wave guide for a tweeter is also a horn, adjusted to suite the specific driver.

Last edited:

Bending a horn is a lot different than folding it.

There are a lot of 'mythtical' theories about TracTrix and spherical horns. TBH, that's all BS since either of them have still HOMs and vastly inferior directivity, which also influences the energy in the room and therefore diminishes the reproduction fidelity and FR a lot. Some High-Enders swear on them but they also buy 15k€ speaker cables that are 1,5m long and cinch cables of 30cm length that are above 1k€.

Sure, if you only listen at one single spot, that might be fine but since these horns don't even provide more linear responses, even the 'oh so bad' diffraction horns perform on a so much better level, it's not even funny anymore. Nothing against big or bent horns, some of them perform exceptionally but if you are bound to more realistically room dimensions or like to move in the room, other horn types are your friend.

If you doubt it, ask for angle measurements of the horn and look how extremely narrow they become at the top. The only horns which follow a certain horn geometry philosophy that also perform good are some of the JMLC horns. There are still a lot of commercially available horns which perform equally good (or better) for a fraction of the cost.

There are a lot of 'mythtical' theories about TracTrix and spherical horns. TBH, that's all BS since either of them have still HOMs and vastly inferior directivity, which also influences the energy in the room and therefore diminishes the reproduction fidelity and FR a lot. Some High-Enders swear on them but they also buy 15k€ speaker cables that are 1,5m long and cinch cables of 30cm length that are above 1k€.

Sure, if you only listen at one single spot, that might be fine but since these horns don't even provide more linear responses, even the 'oh so bad' diffraction horns perform on a so much better level, it's not even funny anymore. Nothing against big or bent horns, some of them perform exceptionally but if you are bound to more realistically room dimensions or like to move in the room, other horn types are your friend.

If you doubt it, ask for angle measurements of the horn and look how extremely narrow they become at the top. The only horns which follow a certain horn geometry philosophy that also perform good are some of the JMLC horns. There are still a lot of commercially available horns which perform equally good (or better) for a fraction of the cost.

Rear loaded horns also benefits from benign bending. I find this builder of Hedlund Horn have created a very successful combination with Lowthers PM2A silver coil. Folding is too much of a compromise IMHO.

Last edited:

Rear loaded horns also benefits from benign bending. I find this builder of Hedlund Horn have created a very successful combination with Lowthers PM2A silver coil.

That's right but they work in a much lower range than the proposed horns. Bent rear loaded horns have a more smooth response but folded BL horns got the advantage of less midrange dispersied off-phase. Depending on the horn, driver and damping that might or might not a big advantage. As in so many horns, such details matter immensely. To strictly say one type is superior ist just wrong, it depends so much on the horn in question. I've tried several ACR/Fostex BL horns with bends and with the original straight or angled turns and the bends always sounded a lot worse. I've also tried the Cornu horn, which sounded better with the rounded horn path but since the expanding foam of it was such a horrible mess I've never ever again built a horn again with expanding PU foam and never will again.

@ICG

Why would less midrange from the horn be a advantage?

Don't mind the "theoretical" out-of-phase output from the horn. It has very little impact IRL.

I say it will benefit the overall tonality and harmonic distortion structure.

A rear loaded horn is like a music instrument that needs to be tuned in harmony with the driver.

When done right it can give a spectacular result, but it's like balancing on a knives edge.

Another example of rear loaded horn with benign bends, that I find to sound really good...

Sound quite nice with the Western Electric type of bended horns too. This is my cup of tea.

Why would less midrange from the horn be a advantage?

Don't mind the "theoretical" out-of-phase output from the horn. It has very little impact IRL.

I say it will benefit the overall tonality and harmonic distortion structure.

A rear loaded horn is like a music instrument that needs to be tuned in harmony with the driver.

When done right it can give a spectacular result, but it's like balancing on a knives edge.

Another example of rear loaded horn with benign bends, that I find to sound really good...

Sound quite nice with the Western Electric type of bended horns too. This is my cup of tea.

Last edited:

@ICG

Why would less midrange from the horn be a advantage?

Don't mind the "theoretical" out-of-phase output from the horn. It has very little impact IRL.

Exactly because it does have impact IRL! Phase differences above ~120 Hz are bothersome to the human ear and become really annoying above ~200 Hz. So you really want to avoid to have phase differences there and above. Since bent horns don't reduce these frequencies, you don't want unlinearities and even less big phase problems. So many BL horns would benefit from not having bends but instead folds. Just look at development and construction reports "uh, I had to move the damping sheets so many times" etc - that's because they've got too much mid garbage from the horn mouth.

@ICG

You are a theoretical kind of designer and have decided that your "truth" is the only truth.

Please rest your efforts to convince me...

That's not theoretical nor want I convince you.

I have designed my share of nice horns and know what's important.

Me too. If you decide to stay ignorant, that's fine by me unless you try to convince others. Don't you want to share your bent BL horn measurements? Esp from the horn mouth? That will clear things up very quickly.

This is beginning to get out of hand. There is much here that will not assist turboblast in answering the original question.

@ICG

Oh, I can't help you with measurements since I sold my last design some 15-18 years ago and don't have any records left in my computer. Lost them.

At the time I used LMS for measurements.

If it matters, the last design I sold was the original Hedlund Horn design I sold to a gentleman in Paris.

Listen to the soundclips I included. One of them is a design of mine.

Why so angry and protective. It's a hobby...

AllenB

Yes, you are right, it's getting out of hands so I will stop here.

Hopefully we have enlighted turboblast where the limits are for folding or bending a front horn are. Helped him on his journey to great sound.

Oh, I can't help you with measurements since I sold my last design some 15-18 years ago and don't have any records left in my computer. Lost them.

At the time I used LMS for measurements.

If it matters, the last design I sold was the original Hedlund Horn design I sold to a gentleman in Paris.

Listen to the soundclips I included. One of them is a design of mine.

Why so angry and protective. It's a hobby...

AllenB

Yes, you are right, it's getting out of hands so I will stop here.

Hopefully we have enlighted turboblast where the limits are for folding or bending a front horn are. Helped him on his journey to great sound.

Last edited:

Ok lets check this off as a fail. It seems like the trend for a small speaker is a beefy driver and a lot of power and unvented.. was hoping to avoid that but it seems inevitable. synergy is patented. bass reflex is ehh whatever.. But Im open to suggestions to get more db for the buck from a small box if it exists.

But yes there are much more I need to learn. Thats why I appreciate the guidance of this community on my exploratory sketches..

A main take away from this, is that the horn mounth is too small for lower end frequencies, GPT indicated that if the total horn length inceased, then the mouth opening size could decrease, and there would be the same frq cut off. Hense my trying to extend the lenght. Turns out not true GPT.. LOL

ICG: I appreciate your feedback. One thing I want to point out regarding the provided schematic, it that its just that, a loose schematic out of 30 iterations, roughly sketched to show general intention, and non-symmetrical in parts to indicate different design options, with the assumption that as co-collaborative interpreters, we all know that the horn is supposed to not be more narrow as it expands.. But Ill make that more clear next time I submit a design for feedback. The funny thing is that any more work drafting on my end would have been pointless because it turns out that this design " concept" is a dud.First of all, you need to understand that this contraption has to work in the midrange, LF can't be reproduced because the horn mouth is too small. For the midrange, you'll experience severe phase changes at multiple frequencies and that in a range that's very sensitive to the human ear. It will sound horrible, even to the lowest standards. The fact that on the 2nd picture the 'horn' goes a lot narrower shortly before its final expansion shows there's NONE of the theoretical or practical knowledge applied. It even happens several times on the horn path. I've never ever seen such a bad horn design even from 1st time builders. the first design is even asymmetrical, leaving the cone with asymmetrical load and tumbling motions! If that's what AI is able to design today, you need to wait for 30-50 years to come to something working.

But yes there are much more I need to learn. Thats why I appreciate the guidance of this community on my exploratory sketches..

A main take away from this, is that the horn mounth is too small for lower end frequencies, GPT indicated that if the total horn length inceased, then the mouth opening size could decrease, and there would be the same frq cut off. Hense my trying to extend the lenght. Turns out not true GPT.. LOL

Last edited:

The tractrix is able to offer many things because it channels all it's compromise into continuously opening. If a widening directivity is something you're looking for.. which you'll see less with tweeters and more with lower mids.It seems like the tractrix curve has everything going for it, uses less horn length and mouth, helps with low frequencies, directiveity, smooth phase alignment etc..

The tractrix is probably as popular as it is because it is so similar to the JMLC (LeCleach) family of horns, which are optimised versions of the exponential horn. Of course you can't just run loading style horns below their cutoff unless they meet certain criteria. Jean-Michel LeCleach showed how with some curvature factors and chosen frequencies this was possible.

Your ChatGPT input was entertaining, thank you.

You can see with the pictures of horns shown above, take for example the far right horn in post #5, the curved early section was kept narrow in that dimension (the height of the duct) as this was to protect the higher frequency wavefronts.

Here is a better design objective question: how would one capture the rear 1/4 wave phase of the driver in a traditional tracxtic horn and combine it with the main horn? For a reasonable full range or mid/high response, in a reasonable sized box?

For example how could these beauties integrate the rear phase of the driver? Also lets assume they were designed as are coaxial semi-full range 🙂

http://volvotreter.de/pics/04070002.jpg

For example how could these beauties integrate the rear phase of the driver? Also lets assume they were designed as are coaxial semi-full range 🙂

http://volvotreter.de/pics/04070002.jpg

Here is a better design objective question: how would one capture the rear 1/4 wave phase of the driver in a traditional tracxtic horn and combine it with the main horn? For a reasonable full range or mid/high response, in a reasonable sized box?

It needs a very small compression chamber. You can achieve that with a phase plug that's the opposite shape of the membrane.

-> DIY phase plugs <-

Here is a better design objective question: how would one capture the rear 1/4 wave phase of the driver in a traditional tracxtic horn and combine it with the main horn? For a reasonable full range or mid/high response, in a reasonable sized box?

For example how could these beauties integrate the rear phase of the driver? Also lets assume they were designed as are coaxial semi-full range 🙂

http://volvotreter.de/pics/04070002.jpg

I'm The King of Overcomplicating Things, and I can tell you: you're overcomplicating things 🙂

While there are certainly horns that leverage the output from the front and the back of the diaphragm (like tapped horns) they're only useful over a narrow bandwidth. They're (mostly) for sub duty. If you're clever you could probably get a back loaded horn to work, but then you wouldn't get any of the directivity control benefits of a horn or waveguide.

The clear answer is yes, it can be folded.It seems like the tractrix curve has everything going for it, uses less horn length and mouth, helps with low frequencies, directiveity, smooth phase alignment etc..

But has anyone attempted to fold one? or would the folds inherently destroy the curve no matter what? I can barely draw a tractrix curve unfolded at this point, but im fairly sure I could CNC one with a lot of scoring for bending material. Im even open to alternative materials and methods that could wrap the horn path around the main larger horn mouth itself in a spiral for example.

So far GPT said (with a grain of salt) that I could get down to 60/70Hz with a 20 db gain and 3 times the thow as compared to un-vented.. LOL

Attached are some "very" rough ideas for comment.

Every horn that relies on a 2 dimensional surface area expansion could be folded. But the result will not be as good as for a straight horn because in a folded horn the path length for higher frequencies will be longer and you get phase shifts. So you have to limit the pass band to about 1-2 octaves. Another problem is that you may get reflections inside the folded construction back to the throat. The snail horns are better wrt because they have no abrupt changes in the profile.

Simply use a round tractrix as reference and calculate the 2D surface area at each path length and then transform this to maybe rectangular.

- Home

- Loudspeakers

- Multi-Way

- insane question: can a tractrix horn be folded?