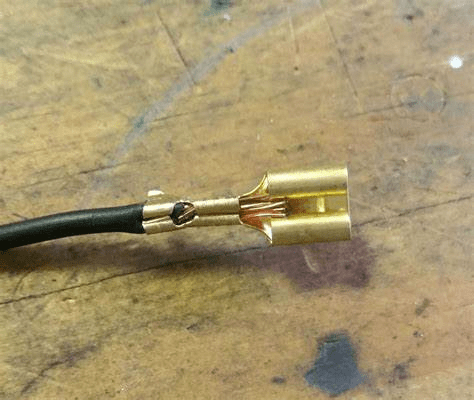

Those connectors are only suitable for joining wire to wire, not wire to tweeter terminal.

Post a photo of the terminals on the new tweeters, or wait for @6thplanet to tell us if crimp connectors are applicable to them.

I understand your reluctance to solder wire directly to the tweeter terminals as it must be done quickly to avoid potential damage.

P.S. The British say sole-der. Americans say sod-der!

Post a photo of the terminals on the new tweeters, or wait for @6thplanet to tell us if crimp connectors are applicable to them.

I understand your reluctance to solder wire directly to the tweeter terminals as it must be done quickly to avoid potential damage.

P.S. The British say sole-der. Americans say sod-der!

My mistake, I don't know why I mentioned those solder connectors for wire to speaker terminal.

Anyway, I will wait for @6thplanet to comment on the connectors to the tweet terms.

Anyway, I will wait for @6thplanet to comment on the connectors to the tweet terms.

6thplanet could be busy.

Describe what the terminals look like or post a photo. Are they wire wrap posts by any chance?

Was the image you attached in post #13 that of the original Bose 401 tweeter or of the mismatching 8 ohm replacement?

Just a thought, if it was you who fitted that mismatching tweeter you had no difficulty with the soldering process - right?

Describe what the terminals look like or post a photo. Are they wire wrap posts by any chance?

Was the image you attached in post #13 that of the original Bose 401 tweeter or of the mismatching 8 ohm replacement?

Just a thought, if it was you who fitted that mismatching tweeter you had no difficulty with the soldering process - right?

The connections on the new tweets are wire-wrap posts. Yes, I soldered the mismatched tweeter. I have done a lot of electrical work and have no problem soldering, but @6thplanet was so helpful with these new tweets, I am being extra careful so as not to damage them in any way!

Attachments

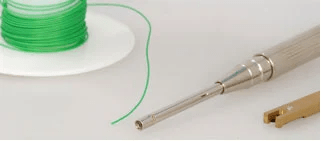

You won't have access to a wire wrapping tool.

So wrap several turns of the single core wire around the post as tightly as possible by hand.

Then heat the wrap and apply solder.

So wrap several turns of the single core wire around the post as tightly as possible by hand.

Then heat the wrap and apply solder.

If I may, that way the quantity of metal increases with no a real reason and proportionally the heat necessary to melt the proportionally increased quantity of tin alloy will increase in an unwanted manner. IMOSo wrap several turns of the single core wire around the post as tightly as possible by hand.

Then heat the wrap and apply solder.

IF tweeters were mine I would heat the posts just as much as necessary for a modest amount of tin to cover their let's say 1 cm long reclined on one side horizontally to avoid the tin dripping vertically onto the post support.

Then I would do the same with a small length of stripped wire.

And then simply by bringing them closer and holding them firmly with a any "tool" capable of keeping them firmly in place, I would bring the tip of the soldering iron (which I would not use with a power higher than 30W) closer just that short period of time to fuse them together.

Done.

IMO Much safer (and effective).

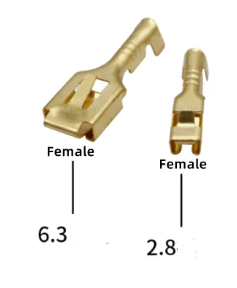

Just as second thought, I can't determine width and thickness of the posts, but if they were of the "right" size could use a 2.8 mm female faston as in the following picture leaving the post unscathed with no trace of molten tin.

Or even a smaller terminal like this.

Or even a smaller terminal like this.

I advised, just strip about 1.5" and hand wrap as tight as you can. You can add heatshrink if you'd like. Really doesn't need solder.

And remember to allow for the fact that two wires (the red and the grey) must be wrapped on the positive post.

Please note that I wasn't aware of this simply because it is not written in any post here and as matter of fact I quoted @Galu just because who recommended also to add welding ("apply solder"). 🙄I advised

With due respect, I disagree with the above just because I'm almost "fanatic" of accuracy and I would never be sure of the contact resulting from wrapping done by hand with no tool also because we ignore the OP's manual skill in attempting to do this with 2 tweeters which he rightly considers precious.just strip about 1.5" and hand wrap as tight as you can.

Furthermore hand wrapping a wire "as tight as you can" with no tool around a thin post means only one thing IMO: bending it 99% of cases and possibly even breaking it, I would never take that risk IF they were mine.

Please also note that in my replies I always said "IF the tweeters were mine" and "IMO". 😉

Really doesn't need solder.

Since wrapping by hand does not produce the huge pressure of a wire wrap tool I suggested the application of solder to seal out the air and produce a corrosion-free joint.

@ulogon Your method is quite appropriate (and safe!) in this situation, but wherever possible I make a sound mechanical connection before soldering.

Last edited:

Please note that this, wanting, can be solved easily and elegantly by crimping or soldering two wires together in a single terminal without even touching the tweeter posts. 😉And remember to allow for the fact that two wires (the red and the grey) must be wrapped on the positive post.

Also because if I didn't agree with a single wire hand wrapping with no tool, than much more with one made with even two wires by those who have never done it before and want to rightly protect their precious tweeters at all costs.

Please let's not joke.

Last edited:

I would never be sure of the contact resulting from wrapping done by hand with no tool.

I agree.

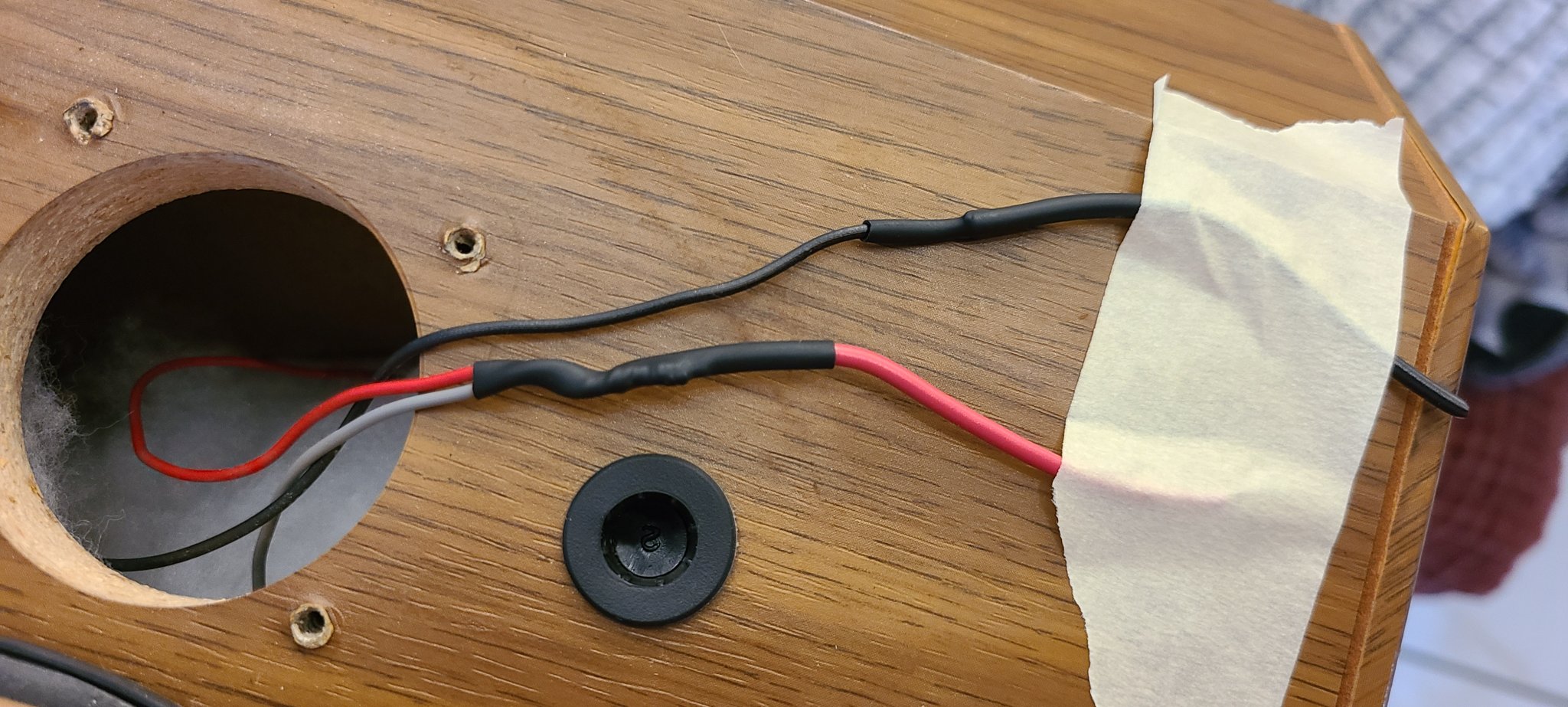

[Upper image] The right tower's tweeter is the original, but it doesn't have a grey wire; just red to positive term and black to black term. Should I replace this one anyway or leave it be since it is original?

Replace it and keep it as a spare.

P.S. The soldering on that original tweeter is none too neat!

And the red wire of the upper image is stranded wire - not single core.

P.S. The soldering on that original tweeter is none too neat!

And the red wire of the upper image is stranded wire - not single core.

@SpineyNorman When positioning the tweeters, be careful not to bend the posts with the movement of the cables.

Edit to add: I know you can't wait to listen to your beloved speakers, but don't rush.

Be control and calm, please. 😉

I really don't know why he bent the wire and used a lot of tin. 🙄

Edit to add: I know you can't wait to listen to your beloved speakers, but don't rush.

Be control and calm, please. 😉

I agree.The soldering on that original tweeter is none too neat!

I really don't know why he bent the wire and used a lot of tin. 🙄

...

P.S. The British say sole-der. Americans say sod-der!

You're cramping my style now.

My new car has a Bose system. Maybe if I rip out that Bose logo ON TOP OF THE TWEETERS by the base of the A pillars... and change the cross over capacitors it might sound reasonable?

I mean, who in he!! thinks it's a good thing to put a 2 inch Bose logo on top of a 2 and a half inch tweeter? Marketing gone nuts.

It is Bose after all. Somethings never change.

Last edited:

This is odd. I cut the wires about two inches away from the terminals and found that the grey wire had been spliced with the red and then shrinkwrapped. The black wire also has shrink wrap. Something tells me this is not a factory Bose connection.

I am not rushing. I took my time and was gentle with the soldering. The terminals are still solid.@SpineyNorman When positioning the tweeters, be careful not to bend the posts with the movement of the cables.

Edit to add: I know you can't wait to listen to your beloved speakers, but don't rush.

Be control and calm, please. 😉

I agree.

I really don't know why he bent the wire and used a lot of tin. 🙄

Something tells me this is not a factory Bose connection.

According to your upper image in post #134, it wasn't an original Bose tweeter!

The wires have been extended by the person putting in this tweeter.

- Home

- Loudspeakers

- Multi-Way

- Information request for modifying Bose 401s