I'd think the JA6603's phenolic diaphragm, not the FE magnet would be responsible for "the hf weakness".

You missunderstood why I do it on the 6603.

I don't want to ruine my 6681. The 6603 has as most drivers from the H51Xx cabinets shifted Magnets. Even the bass drivers have shifted Magnets. I want to convert those to ND too.

I don't want to ruine my 6681. The 6603 has as most drivers from the H51Xx cabinets shifted Magnets. Even the bass drivers have shifted Magnets. I want to convert those to ND too.

Sorry but i do not. I have for quiet some time had them on a shortlist but never got around to actually buy them. I have had offers but always without healthy diaphragms so making new suspensions to old ones really woke up my interest again. Today I run JBL 2451 with Radian Be and as good as they are the old Yamahas have stayed as something I want to try.Bappe

Do you have a pair of JA6681 as well or are you just nice to us?

//Anders

OK time for some questions:

Was it just a mental excercise or are we willing to master the challenge?

Are we in agreement that this is a combined effort and will be treated as Open Source?

If the answer is yes the assigning of tasks needs to be determined after ones acces to the necessary Tools.

rewind are you willing to sonically evaluate each Iteration? (no time pressure)

Anders you got a access to measuring Equipment and may be ready by winter to do some things here and there?

The deassembling measuring procedure discribed by rewind makes good sense and we should go about it.

Rewind do you have a defect diaphragm you could try to dissasemble and send the parts to Anders?

I need to check if I still have my defect Aluminium diaphragms somewhere (it's been 13years since) to send them to you or Anders.

One of my 6603 can be the motor to be inspected.

To be continued..,.

Was it just a mental excercise or are we willing to master the challenge?

Are we in agreement that this is a combined effort and will be treated as Open Source?

If the answer is yes the assigning of tasks needs to be determined after ones acces to the necessary Tools.

rewind are you willing to sonically evaluate each Iteration? (no time pressure)

Anders you got a access to measuring Equipment and may be ready by winter to do some things here and there?

The deassembling measuring procedure discribed by rewind makes good sense and we should go about it.

Rewind do you have a defect diaphragm you could try to dissasemble and send the parts to Anders?

I need to check if I still have my defect Aluminium diaphragms somewhere (it's been 13years since) to send them to you or Anders.

One of my 6603 can be the motor to be inspected.

To be continued..,.

Yes, sure. I am listening to JA6681B almost every day and know how they should sound. I also have a umik-1 to measure. Presence of small children might delay testing to weekends.

I have two broken diaphragms that I can donate for science. One blown/crushed aluminium dome, but maybe complete otherwise. And one with skewed fingers, but complete aluminium dome.

Whoever is willing and competent to try and duplicate them can have them.

I have two broken diaphragms that I can donate for science. One blown/crushed aluminium dome, but maybe complete otherwise. And one with skewed fingers, but complete aluminium dome.

Whoever is willing and competent to try and duplicate them can have them.

Anders you got a access to measuring Equipment and may be ready by winter to do some things here and there?

I most probably have time, come winter 🙂

//Anders

There is probably much less Beryllium in the copper than I thought.

Does anybody remember how thick these S fingers where?

Does anybody remember how thick these S fingers where?

Found it

thickness is 0.16mm

The Beryllium is probably not to save weight but for lasting elasticity

thickness is 0.16mm

The Beryllium is probably not to save weight but for lasting elasticity

Did some extensive research on copper beryllium.

I'm 99.9% certain that I found the exakt foil that has been used by Yamaha for the 6681.

Materion is the main supplier of this material worldwide. It's called C17200. To achieve these properties the beryllium content only needs to be 1.8 to 2.0 %.

It is mainly used in Relais as its conductivity is fairly high while its "springy" properties is even longer lasting than spring steel.

I have ordered this material and hopefully can come up with a methode to get these fine S- fingers etched, milled, punched ect. out.

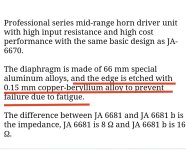

This is the description of the surround:

I'm 99.9% certain that I found the exakt foil that has been used by Yamaha for the 6681.

Materion is the main supplier of this material worldwide. It's called C17200. To achieve these properties the beryllium content only needs to be 1.8 to 2.0 %.

It is mainly used in Relais as its conductivity is fairly high while its "springy" properties is even longer lasting than spring steel.

I have ordered this material and hopefully can come up with a methode to get these fine S- fingers etched, milled, punched ect. out.

This is the description of the surround:

Attachments

Thanks Eggg3r,

I will look into those options.

When I look at the fine routing on circuit boards I wonder if etching might work.

I don't know how much the 2% beryllium will hinder this process and if the 0.15 mm thickness will be a problem. Many things to try and very little time.

I will look into those options.

When I look at the fine routing on circuit boards I wonder if etching might work.

I don't know how much the 2% beryllium will hinder this process and if the 0.15 mm thickness will be a problem. Many things to try and very little time.

Please chime in if you have any objection, suggestion, for the following procedure:

1. Cut the copper beryllium foil into 100mm x100mm shape.

2. Put for 30minutes in 300° Celsius pre heated oven, between milled 100mm x100mm iron blocks to get an absolotley flat piece.

3. Clamp foil between appropatate diameter disks with 5mm over hang and route outer diameter.

4. Clamp foil on Donut shaped milled disks of 70mm inner hole to mill inner diameter.

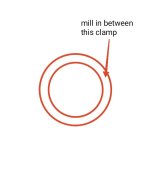

5. Mill S-shaped fingers in between the kind of clamp as seen in picture

1. Cut the copper beryllium foil into 100mm x100mm shape.

2. Put for 30minutes in 300° Celsius pre heated oven, between milled 100mm x100mm iron blocks to get an absolotley flat piece.

3. Clamp foil between appropatate diameter disks with 5mm over hang and route outer diameter.

4. Clamp foil on Donut shaped milled disks of 70mm inner hole to mill inner diameter.

5. Mill S-shaped fingers in between the kind of clamp as seen in picture

Attachments

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Info on the Yamaha JA-6681 compression driver