My experience only, it is good contact, but also variable geometry depending heavily on Oring diameter (that reduces as belt stretches)I was wondering about your use of a round belt with a pulley that has a V-Groove. Wouldn't a rounded groove in the pulley maintain more intimate contact with the belt? What's industry practice here

Everything is dependent on everything else, I get it. The stretching of the belt however, had better not be a factor unless the tension of the belt is so high that it is indeed distorting the geometry of the belt. At that point, other issues would become more important, such as the added side force to the main bearing.

@Trzalica For a more complete view of your situation, consider adding a description of your WOW measurement method. Graph/screenshot of the measurements can be helpful as well.wow is between 1% and 3%

@Trzalica you could insert a hard metal disc at the bottom of the spindle, so that it sits on the steel ball. The aluminium might have an indent that increases friction.

The fact that the wow 1-3% problem makes me believe that something is sort of friction sticking at some interval. Reminds me of something that might be out of round too. The spindle is the assumed center of the bearing, but upon viewing the stylus in play, is there a back-and-forth slow motion as the record is being played? I could see where a hard spot in the aluminum bearing could cause something to happen as well. Keen mechanical observation is needed.

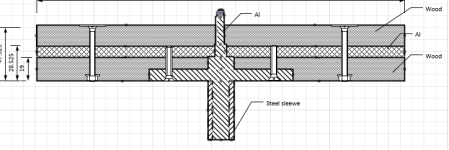

Steel ball is at the bottom of the bearing and the spindle has a flat (aluminum) bottom. I already asked my friend mechanic to reduce a diameter of bearing and spindle by adding a steel insert in bearing. He will polish both steel bearing and sintered brass spindle, as best as possible as well. I will also add a teflon insert at the bottom of a spindle so that there is no direct contact between steel ball and aluminum spindle.@Trzalica you could insert a hard metal disc at the bottom of the spindle, so that it sits on the steel ball. The aluminium might have an indent that increases friction.

... Diameter of the bearing shaft usually, for a platter about 5 Kg is 13 to 15mm, 30 mm is by far too big in my opinion. ....

I was just about making yet another BIG mistake by reducing a spindle to 9mm. After Adelmo recommendation i increase it to 14mm. Hopefully it is going to be good enough B)

HI,

About 20 years ago I made a DIY TT that is still working well, pic in my avatar. The platter is 4.6 Kg, on top of it I have a puc 500gr( just over 5 Kg the total weight ) and the diy bearing was made as follow:

Shaft 13mm made with hard steel and well polished

House made from solid bronze with tight allowance between bush and shaft. Bottom thrust plate from solid bronze too

Steel sphere 5mm

Oil lubrication

In 20 years I changed the bottom thrust plate once just because I wanted to change it but the bearing was still working well.

TT still running well, therefore my suggestion.

I would not use aluminum in any of the following part of the TT bearing:

Shaft

Bushes in contact with the shaft

Thrust plate in contact with sphere

Rgds

Adelmo

About 20 years ago I made a DIY TT that is still working well, pic in my avatar. The platter is 4.6 Kg, on top of it I have a puc 500gr( just over 5 Kg the total weight ) and the diy bearing was made as follow:

Shaft 13mm made with hard steel and well polished

House made from solid bronze with tight allowance between bush and shaft. Bottom thrust plate from solid bronze too

Steel sphere 5mm

Oil lubrication

In 20 years I changed the bottom thrust plate once just because I wanted to change it but the bearing was still working well.

TT still running well, therefore my suggestion.

I would not use aluminum in any of the following part of the TT bearing:

Shaft

Bushes in contact with the shaft

Thrust plate in contact with sphere

Rgds

Adelmo

My experiences to date of learning about a cause of Wow, is that a eccentric rotation of the Platter Spindle can be a cause of a measured speed fluctuation.

A Standalone Strobe such as Keystrobe will easily show Speed Fluctuation, especially where the Kookiness of the Spindles rotation might be the cause.

A Standalone Strobe such as Keystrobe will easily show Speed Fluctuation, especially where the Kookiness of the Spindles rotation might be the cause.

I would check that before remachining the bearing. Is the circle where the o-ring is running on concentric with the bearing? Ask your friend that does machining to come round with a dial gauge and put it on the surface the o-ring is running. Turn the table by hand and see if the dial moves.My experiences to date of learning about a cause of Wow, is that a eccentric rotation of the Platter Spindle can be a cause of a measured speed fluctuation.

Hi Ralf,Hi Trzalica,

How well does the motor pulley fit the motor shaft?

Ralf

This is a DARN good question, and probably right to the point. There is some wobbling when pulley (made not by my friend but by "professional machine shop" that I paid dearly) spins. I'll try to stabilize it by two set screws. If I can't I'll see if my friend can make a better fitting one.

THANKS, Trzi

Hello Trzi,

More set screws won't help. It is the degree of looseness between the pulley and the motor shaft that could be the problem. All that the set screw does, is that, it pulls the pulley off center to the motor shaft. The fit between the pulley and the motor shaft must be a slip-fit measured in increments of .0001".

You must measure the shaft diameter accurately with a quality micrometer caliper and give that dimension to the machinist. Dealing with a business is not a good idea, because there will be a supervisor who will be all over the machinist to "get her done". you might also include a tiny hole at the bottom of the pulley bore to "vent" the air when fitting the parts. Use a little grease when fitting the parts so they won't cease to each other when fitting. Last but not least, the bore in the pulley and the feature of the pulley that drives the belt, should be machined in the same set-up to ensure concentricity.

Sincerely,

Ralf

More set screws won't help. It is the degree of looseness between the pulley and the motor shaft that could be the problem. All that the set screw does, is that, it pulls the pulley off center to the motor shaft. The fit between the pulley and the motor shaft must be a slip-fit measured in increments of .0001".

You must measure the shaft diameter accurately with a quality micrometer caliper and give that dimension to the machinist. Dealing with a business is not a good idea, because there will be a supervisor who will be all over the machinist to "get her done". you might also include a tiny hole at the bottom of the pulley bore to "vent" the air when fitting the parts. Use a little grease when fitting the parts so they won't cease to each other when fitting. Last but not least, the bore in the pulley and the feature of the pulley that drives the belt, should be machined in the same set-up to ensure concentricity.

Sincerely,

Ralf

Thanks AGAIN Ralf,

I am not going to add more set screws B) I'll just try to tight them evenly (if possible) to reduce a wobble. Now I am taking a spare motor to friend so that he can make pulley as tight as possible. He will make a smaller (15mm) bearing with sintered (oiled) bronze in the base and spindle of polished SS as well.

With best,

Trzi

I am not going to add more set screws B) I'll just try to tight them evenly (if possible) to reduce a wobble. Now I am taking a spare motor to friend so that he can make pulley as tight as possible. He will make a smaller (15mm) bearing with sintered (oiled) bronze in the base and spindle of polished SS as well.

With best,

Trzi

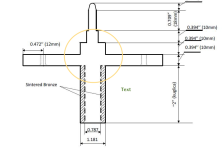

Probably too late to the party to be any help but I'm curious, What's the spindle detail inside the circle , and where does the platter sit?

Thanks

It is never too late B) This is a whole platter, with oversized spindle, that is going to be reduced from 30mm to 15mm.

Cheers,

Trzi

Attachments

Thanks SP,Hi, I wouldn't use aluminium for a bearing surface, you will get a slip-stick effect and that will react with the spring of the belt.

That was one of my mistakes, and it is going to be addressed shortly. Housing will be of sintered bronze and the spindle will have an SS sleeve.

Last edited:

- Home

- Source & Line

- Analogue Source

- Huge wow on diy turntable