After 10-ish years in planning and working I (with help of my friend machinist) built my TT. It looks good but does not work good. When it turns, both 33 and 45 PRP, it is running unstable - wow is between 1% and 3%.

Here are what I have so far:

PLEASE can you point me to what is wrong, how to improve it and make it finally work.

Here are what I have so far:

- TT bearing is made of aluminum

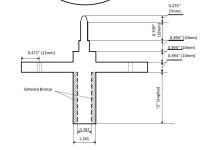

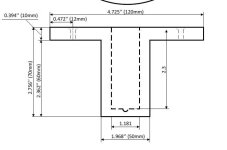

- Spindle is made of aluminum, with sintered bronze "sleeve" and it is sitting on steel ball at the bottom of the bearing

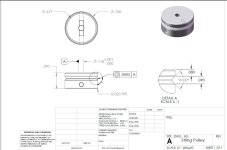

- Both base and platter are made of several layers of "butcher block" wood and aluminum parts (yes, they are heavy)

- Motor is Maxon A-max 110191

- Mark Kelly speed controller sets speed

- 3-IN-ONE oil is lubricating

- I am using a Chemical-Resistant Round Belt, 2 mm Diameter belt from McMaster-Carr.

PLEASE can you point me to what is wrong, how to improve it and make it finally work.

Attachments

If you can actually hear the wow, does the wow go away if you remove the belt and spin the splatter by hand?

Yes, it is made of aluminum (the "good one" though)TT bearing is made of aluminium?

As @rayma suggested, remove the belt, give the platter a spin, and measure the time until it stops rotating. If it is minutes, the bearing is OK. My next advice would be to replace the O-ring belt to dental floss or some other material that is not elastic.

Bearing shaft should be hardened steel. Aluminum is too soft, if that's what you are using. Housing made from Al. would be ok.Spindle is made of aluminum,

It's not very good. I would remove it asap. Even plain old Mobil 1 or Castrol Syntec 10-30w motor oil is better.3-IN-ONE oil is lubricating

jeff

Last edited:

Let me clarify myself B)

Housing is made of AL and shaft is made of AL, with sintered bronze sleeve so it is bronze inside AL.

3-IN-ONE was recommended by few members here, that's why I used it. Also, in the same thread, it was stated NOT to use motor oil because it contains detergent. Other recommendation for oil was a plain Compressor Oil, which I'll try next.

Housing is made of AL and shaft is made of AL, with sintered bronze sleeve so it is bronze inside AL.

3-IN-ONE was recommended by few members here, that's why I used it. Also, in the same thread, it was stated NOT to use motor oil because it contains detergent. Other recommendation for oil was a plain Compressor Oil, which I'll try next.

Check to see how much wobble there is at the platter rim when it is spinning. There should be no detectable vertical or lateral change in platter position. If there is, it adds to wow/flutter... And both main bearing & platter balance/machining then need to be examined.

Here's a super simple jig to test the vertical wobble --

Here's a super simple jig to test the vertical wobble --

Last edited:

That doesn't sound very long to me, especially if the platter is heavy.With removed belt it stops spinning in about 20 seconds

The bearing shaft should be hard steel. Is there a ball and thrust pad at the bottom?shaft is made of AL,

Really? It's crap. Try something else.3-IN-ONE was recommended by few members here

I've got Syntec in my LP12 bearing, works great.

jeff

What do you thing about size of shaft/spindle? Diameter is 1.18 inch (30mm), would it be better if it is smaller?

It does not wobble, but platter balancing might be needed.Here's a super simple jig to test the vertical wobble --

Before I go back to machining shop and reduce a shaft diameter I would change the oil, add a Teflon between steel ball at the bottom and shaft and try to balance a platter. Will post results.

THANK YOU ALL!!!

THANK YOU ALL!!!

Hi. Imo huge bearing is nothing wrong as long as it is precise.

Drag is also no issue if motor is right.... And motor is what I suspect, but have not enough info

Drag is also no issue if motor is right.... And motor is what I suspect, but have not enough info

HI,

A bearing shaft usually is not made with aluminum but rather hardened steel and super polished. Diameter of the bearing shaft usually, for a platter about 5 Kg is 13 to 15mm, 30 mm is by far too big in my opinion.

Balanced platter help.

Motor and speed controller is another story.

Rgds

Adelmo

A bearing shaft usually is not made with aluminum but rather hardened steel and super polished. Diameter of the bearing shaft usually, for a platter about 5 Kg is 13 to 15mm, 30 mm is by far too big in my opinion.

Balanced platter help.

Motor and speed controller is another story.

Rgds

Adelmo

- Home

- Source & Line

- Analogue Source

- Huge wow on diy turntable