For me - we have to take cost and time out of the equation. $1,000 is cheap to one person and expensive to another. Same with time (do you have better things to do? etc...)

With that out of the way, then law of diminishing returns applies with outright quality. I don't know what the "knee" is on that curve.

If we look at the highest end speakers, what do we get?

1. Aesthetics. I can't match what can be achieved here. I lack the skills and tools even if I could source or make the same materials

2. Scale and size including well built cabinetry. We can certainly equal this in the DIY market

3. Component quality. We can source equivalent quality drivers and passive and active crossover and amplifier components

If I could imagine up the best workshop and cabinet maker and crossover designer. I can't see why a collaborative DIY effort couldn't match the highest end speakers you could commercially buy.

With that out of the way, then law of diminishing returns applies with outright quality. I don't know what the "knee" is on that curve.

If we look at the highest end speakers, what do we get?

1. Aesthetics. I can't match what can be achieved here. I lack the skills and tools even if I could source or make the same materials

2. Scale and size including well built cabinetry. We can certainly equal this in the DIY market

3. Component quality. We can source equivalent quality drivers and passive and active crossover and amplifier components

If I could imagine up the best workshop and cabinet maker and crossover designer. I can't see why a collaborative DIY effort couldn't match the highest end speakers you could commercially buy.

I was pondering this the other day: "How good are our what we build compared to what the giants build?"

I am sure there are many that are quite good and just as many are not. You can't ignore the advantage the real manufacturers have. The ability order custom drivers and a tool box we would all die for. Not getting into really talented pro's who have skin in the game and have earned a reputation and respect of their colleagues. That is no easy challenge.

Are we fooling ourselves that our builds are anywhere near the polished unit of these are they just doing the exact same thing in an incredibly fancy box (in this case, enclosure)?

Let me know you thoughts on the topic and especially let me know if you've listened to a DIY right next to a high end off the shelf unit.

An easy thing to do is have a couple of well regarded speakers on hand to compare. Now the choice of what you choose and your DIY may not be someone else's choices but they don't have to be.

Bottom line is even if they are not you can't forget just how much fun you have, The fun alone can be worth it.

Rob 🙂

I am aware. I run a custom fabrication shop for robotics, automation equipment, and all forms of test and measurement equipment. We do a lot of prototypes and R&DThere is a lot more to the manufacturing costs of a product than just what the parts cost.

Facility rent, insurance, salaries, test equipment, advertising, financing, etc.

Anything in a retail hifi shop has a 5 x markup on cost post covid. Thats well know in the industry. Freight and everything has gone up.

There are a lot of very good insights in this thread.

I will add that some online businesses are selling kits that are well engineered at the price point using either known brand drivers or their own. CCS comes to mind.

On the parallel with the Pass and other Solid state electronics kits that has taken time to evolve on Diyaudio.com. 20 years ago it was quite different.

It’s about developing and closing the capability gap. One of the key aspects that fools diy loudspeakers builders is that a free space simulation is not how any loudspeaker interacts in a living room. This aspect of the design process takes experience, modifications, listening and te testing.

Otherwise the diy builder is flying blind. This is why a reputable brand can outperform a diy first attempt for under RRP $1000, less for a small nearfield monitor with dsp active electronics.

I find some of the best tools are the late Jeff Bagby excell spreadsheet diffraction and boundary simulatior which can give the net effect of baffle step, boundary and room loading on a baffle shape.

This is very different to measure at home.

The other jewel in the diy tool box is REW which can tell you quite accurately how a loudspeaker woofer location will behave in a room.

These tools allow some baseline assumptions that can then be incorporated into modelling - simulation programs.

My point is often what you see on a simulation is not what you get in the room unless it’s accounted for.

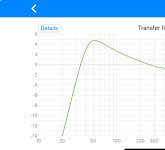

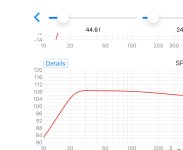

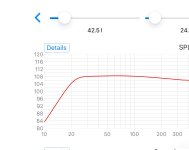

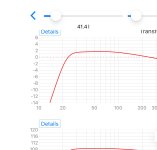

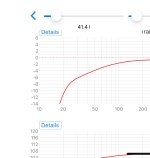

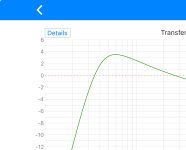

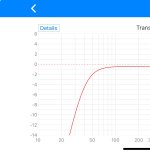

I have attached a simple bass reflex simulation comparing a free space low frequency response with the effect of a room boundary using a 3 db low frequency shelf EQ 100 hertz.

By modifying the enclosure size and tuning frequency of the port a more acceptable low frequency response can be simulated.

This is the sort of experimentation that a diy builder need to invest in. Don’t let driver ego overshadow your success.

Unfortunately some diy builders then resort to a sealed enclosure on the basis that it must have tighter base without further investigation

There are a lot of very good insights in this thread.

I will add that some online businesses are selling kits that are well engineered at the price point using either known brand drivers or their own. CCS comes to mind.

On the parallel with the Pass and other Solid state electronics kits that has taken time to evolve on Diyaudio.com. 20 years ago it was quite different.

It’s about developing and closing the capability gap. One of the key aspects that fools diy loudspeakers builders is that a free space simulation is not how any loudspeaker interacts in a living room. This aspect of the design process takes experience, modifications, listening and te testing.

Otherwise the diy builder is flying blind. This is why a reputable brand can outperform a diy first attempt for under RRP $1000, less for a small nearfield monitor with dsp active electronics.

I find some of the best tools are the late Jeff Bagby excell spreadsheet diffraction and boundary simulatior which can give the net effect of baffle step, boundary and room loading on a baffle shape.

This is very different to measure at home.

The other jewel in the diy tool box is REW which can tell you quite accurately how a loudspeaker woofer location will behave in a room.

These tools allow some baseline assumptions that can then be incorporated into modelling - simulation programs.

My point is often what you see on a simulation is not what you get in the room unless it’s accounted for.

I have attached a simple bass reflex simulation comparing a free space low frequency response with the effect of a room boundary using a 3 db low frequency shelf EQ 100 hertz.

By modifying the enclosure size and tuning frequency of the port a more acceptable low frequency response can be simulated.

This is the sort of experimentation that a diy builder need to invest in. Don’t let driver ego overshadow your success.

Unfortunately some diy builders then resort to a sealed enclosure on the basis that it must have tighter base without further investigation

Attachments

One thing I have observed for a long time is that commercially produced audio electronics have been locked into a fairly narrow range of 'acceptable' style since the market moved to separates and away from consoles in the '50s and early '60's. Moreso with the change from exposed tubes to enclosed solid state. Some quite attractive, most fairly unremarkable and some barely industrial. Silver and black boxes (some fewer goldish). Diy lets us design the appearance of our units if we don't simply buy or reuse older chassis/enclosures. I think those of us who like to design and make the outside too have an opportunity to create our on look and fit/match our room's decor. Good fun.

Skip

Skip

As mentioned before making an inexpensive DIY loudspeaker box does not save you money. Large volume items can be obtained by a manufacturer at much lower cost. So even with all the overhead factored in it will sound better, because the manufacturer has build and tested many prototypes. A better deal is building the most expensive or second most expensive speaker design say by Scanspeak, Focal or Dynaudio. They will have done all the research and measurement to make their high-end driver sound as good as they can.

Those Tad drivers are expensive but people still buy them. The power of belief seems a strong influencer in either a retail purchase or a diy build. The later with exotic parts upgrades.

Interestingly l read Douglas Self’s article on capacitor distortion related to Sallen Key filters. His research revealed some interesting findings.

Only certain capacitors in a Sallen Key filter are sensitive to dielectric types as far as thd is concerned.

The other finding is that the impedance reactance of an electrolyte capacitance in the signal path causes a voltage drop across the capacitor. This gives rise to significant thd. The simple change is to multiple the value 4 x or more. Ironically diy builders put faith in small value expensive electrolytic capacitors thinking they sound better.

There are lots of sins diy builders make while at the same time being oblivious to what factually matters because they rarely measure and test their diy loudspeakers.

Below l have re posted the two different bas reflex tuning scenarios

A Satori MW 19P-8

Free field versus in room boundary effects using a 3 db shelf filter at 100 hertz

From top to bottom attachments

Maximally flat alignment 21 L Fb 35 hertz

Effect of room boundary

Custom alignment over damped 44L Fb 24 hertz

Effect of room boundary

Of course if the diy builder understands this he can always EQ the low frequency response. But this requires in room measurement with REW or room correction like Dirac.

I think it’s more appropriate to understand these phenomena and design around it to produce a a better end result. It’s important to still test all assumptions as all rooms and loudspeaker placements are different. That said the room simulator in REW is quite accurate in predicting the low frequency response at the listening position based on the specific location of the woofer x,y, z co ordinates.

Interestingly l read Douglas Self’s article on capacitor distortion related to Sallen Key filters. His research revealed some interesting findings.

Only certain capacitors in a Sallen Key filter are sensitive to dielectric types as far as thd is concerned.

The other finding is that the impedance reactance of an electrolyte capacitance in the signal path causes a voltage drop across the capacitor. This gives rise to significant thd. The simple change is to multiple the value 4 x or more. Ironically diy builders put faith in small value expensive electrolytic capacitors thinking they sound better.

There are lots of sins diy builders make while at the same time being oblivious to what factually matters because they rarely measure and test their diy loudspeakers.

Below l have re posted the two different bas reflex tuning scenarios

A Satori MW 19P-8

Free field versus in room boundary effects using a 3 db shelf filter at 100 hertz

From top to bottom attachments

Maximally flat alignment 21 L Fb 35 hertz

Effect of room boundary

Custom alignment over damped 44L Fb 24 hertz

Effect of room boundary

Of course if the diy builder understands this he can always EQ the low frequency response. But this requires in room measurement with REW or room correction like Dirac.

I think it’s more appropriate to understand these phenomena and design around it to produce a a better end result. It’s important to still test all assumptions as all rooms and loudspeaker placements are different. That said the room simulator in REW is quite accurate in predicting the low frequency response at the listening position based on the specific location of the woofer x,y, z co ordinates.

Attachments

The driver components we have access to these days is amazing. There's definitely something for everyone to be had, for every taste and style of music. There is one type of gear that is only available in the diy world, which is the combination of pro audio and hifi. There's nothing really out there which caters to both areas. I really love high end pro audio which doesn't have the typical dynamic range, bandwidth and headroom restrictions of typical low sensitivity smaller bookshelf speakers. Its almost like a drug being able to enjoy listening to recordings at realistic volume levels and with the full range of low frequency extension. It makes a special event out of listening to your favorite albums and hearing those tiny details which were otherwiss buried and obscured. The available dynamic range can be addicting, making you jump when a transient comes through.

High sensitivity speakers with lots of resolution, detail AND decent power handling aren't common place in the hifi world these days, especially not with any of the typical better brands. Its a very niche product area with only a handful of companies, like studio monitor manufacturers ie. ATC, Volt, PMC, etc. Many years ago we still had the older, more mainstream Klipsh horn loaded designs and various copies of it in our living rooms, but the Bose fad pretty much wiped all that out in the 90s. Klipsh now mostly builds these boring looking, poor sounding ugly black boxes with those fake bronze looking cones. Since the early 90s, the typical home audio speaker just shrank more and more until we ended up with those stupid little Bose cubes and soundbars playing background level over-compressed streaming music.

Its hard to believe that in our immediate neighborhood, I'm really the only one who has a dedicated larger 2 channel audio system, playing physical media. The other day a guy I often see walking by the house asked me if I played drums and several other instruments, commenting on how good it sounded. I told him it was just pre-recorded music played back, then saw the surprised look on his face in disbelief. Lol

I think DIY speaker building won't ever die out as long as we have decent drivers and related components available to buy. I think the 2 common stores like Madisound and Parts Express are the only ones left who sell dedicated raw drivers of several brands. Its important we keep the hobby going, so companies continue carrying the raw ingredients to make it possible. It would be a shame if it disappeared. Thats why when people ask questions on here for the first time as newer members, its important to give them some basic, guiding answers to help them get closer to their goals if we potentially have the answers to some of their questions. Some other forums have very rude or brash people who often talk down to newer people with basic questions. I find this very sad and hope this forum remains to be a productive place for help and answers. Back in the late 70s to early 80s, I started out with a copy of the louspeaker cookbook, a subscription to speaker builder magazine, a FET DVM and Radio Shack SPL meter. There was no internet or other retail store to answer my questions. It was trial and error, but I could still end up with a very good sounding speaker with excellent soundstage, balance and for a much lower cost than most other speakers well past its price range.

High sensitivity speakers with lots of resolution, detail AND decent power handling aren't common place in the hifi world these days, especially not with any of the typical better brands. Its a very niche product area with only a handful of companies, like studio monitor manufacturers ie. ATC, Volt, PMC, etc. Many years ago we still had the older, more mainstream Klipsh horn loaded designs and various copies of it in our living rooms, but the Bose fad pretty much wiped all that out in the 90s. Klipsh now mostly builds these boring looking, poor sounding ugly black boxes with those fake bronze looking cones. Since the early 90s, the typical home audio speaker just shrank more and more until we ended up with those stupid little Bose cubes and soundbars playing background level over-compressed streaming music.

Its hard to believe that in our immediate neighborhood, I'm really the only one who has a dedicated larger 2 channel audio system, playing physical media. The other day a guy I often see walking by the house asked me if I played drums and several other instruments, commenting on how good it sounded. I told him it was just pre-recorded music played back, then saw the surprised look on his face in disbelief. Lol

I think DIY speaker building won't ever die out as long as we have decent drivers and related components available to buy. I think the 2 common stores like Madisound and Parts Express are the only ones left who sell dedicated raw drivers of several brands. Its important we keep the hobby going, so companies continue carrying the raw ingredients to make it possible. It would be a shame if it disappeared. Thats why when people ask questions on here for the first time as newer members, its important to give them some basic, guiding answers to help them get closer to their goals if we potentially have the answers to some of their questions. Some other forums have very rude or brash people who often talk down to newer people with basic questions. I find this very sad and hope this forum remains to be a productive place for help and answers. Back in the late 70s to early 80s, I started out with a copy of the louspeaker cookbook, a subscription to speaker builder magazine, a FET DVM and Radio Shack SPL meter. There was no internet or other retail store to answer my questions. It was trial and error, but I could still end up with a very good sounding speaker with excellent soundstage, balance and for a much lower cost than most other speakers well past its price range.

those selling commercial branded gears have the bottom line in mind.....

at the mercy of bean counters, that is why the high price...

diy'ers do not necessarily think along those lines.

at the mercy of bean counters, that is why the high price...

diy'ers do not necessarily think along those lines.

Hi prodigy,

I hear you.

You can clone these Jbl systems from parts available on the used market or from after sales replacement parts (M2 clone)

I have personally been involved in supporting the build of dozens of JBL 4344 clones all over from Croatia, Berlin, London, Sydney, India, Thailand, LA, Montreal. Not one dissatisfied diy builder. The Pass active crossover is used to bi amp these systems giving massive dynamic headroom. The M2 Clone commands even more headroom.

Troels was inspired by the 4344 so he designed a version using modern pro drivers. He said at the time it was his best project. He called it The Loudspeaker One.

They aren’t for everyone but once you experience them there is no going back.

Subjectively it’s being there, complete immersion.

This is a premium diy loudspeaker project.

The four way system is complex to implement but with some support builders make it through with a smile on their faces. I built the 18 inch woofer version. It uses the JBL2245H woofer. It was designed by Greg Timbers for the L250 subwoofer called the B460 back in the 1980’s. It’s in a league of its own for music playback.

http://www.troelsgravesen.dk/The-Loudspeaker.htm

Either of these systems will fulfill realistic recording levels.

To be honest nothing even comes close.

I hear you.

You can clone these Jbl systems from parts available on the used market or from after sales replacement parts (M2 clone)

I have personally been involved in supporting the build of dozens of JBL 4344 clones all over from Croatia, Berlin, London, Sydney, India, Thailand, LA, Montreal. Not one dissatisfied diy builder. The Pass active crossover is used to bi amp these systems giving massive dynamic headroom. The M2 Clone commands even more headroom.

Troels was inspired by the 4344 so he designed a version using modern pro drivers. He said at the time it was his best project. He called it The Loudspeaker One.

They aren’t for everyone but once you experience them there is no going back.

Subjectively it’s being there, complete immersion.

This is a premium diy loudspeaker project.

The four way system is complex to implement but with some support builders make it through with a smile on their faces. I built the 18 inch woofer version. It uses the JBL2245H woofer. It was designed by Greg Timbers for the L250 subwoofer called the B460 back in the 1980’s. It’s in a league of its own for music playback.

http://www.troelsgravesen.dk/The-Loudspeaker.htm

Either of these systems will fulfill realistic recording levels.

To be honest nothing even comes close.

Attachments

Last edited:

I see DIY being more about the journey, enjoyment and satisfaction. One thing I really like is being able to voice and get sonics to suit my tastes and application. Most times it will end up more expensive than a commercial speaker especially at the budget speaker end which has some great bargains to be had.

When you add in time, tools, components, shipping and not to mention errors and fine tuning it can add up rapidly but over a couple of decades I feel it's been money well spent. I've spent a small fortune on this hobby but it only works out about A$50 per week which also includes commercial gear.

My advice is if you only want one pair of speakers, then buy commercial, but if you want a good hobby for the long term then DIY.

When you add in time, tools, components, shipping and not to mention errors and fine tuning it can add up rapidly but over a couple of decades I feel it's been money well spent. I've spent a small fortune on this hobby but it only works out about A$50 per week which also includes commercial gear.

My advice is if you only want one pair of speakers, then buy commercial, but if you want a good hobby for the long term then DIY.

I was pondering this the other day: "How good are our what we build compared to what the giants build?"

There is clearly a wide range of talent here. With me being right smack at at the bottom and I'm sure some titans of DIY right up there at the top.

Having myself only heard a couple of actually high end units in my life (one was a $30k system and one was $110k) I am definitely not the best to answer this posed question. I also listened to those systems many years ago. Long before I ever built one.

I was watching the highlights reel on the High End Munich show and saw, to my amazement, that most of the featured units use the same drivers that are available to me. I see Peerless woofers, Seas Mids, etc. I did see quite a few custom drivers which I am sure are made bespoke for those builds.

Are we fooling ourselves that our builds are anywhere near the polished unit of these are they just doing the exact same thing in an incredibly fancy box (in this case, enclosure)?

Let me know you thoughts on the topic and especially let me know if you've listened to a DIY right next to a high end off the shelf un

As a fairly realistic diyer, I would say that the fancy enclosure / sepaker construction is exactly what diyer generally falls short compared to the good summit-fi speaker from Magico, Rockport, Martens, Avalon, Estalon,... you see in hifi show like Munich Highend. The more I know about speaker design, the more I value the speaker cabinet. Those cabinet maybe look fancy but not only for cosmetic reason. You can see the same pattern like large beveled baffle or generous roundover/curve, sandwich layer of materal for speaker baffle, heavy bracing in woofer section, heavy cabinet. All of them in my knowledge is technically correct, and contribute to superior qualities in imaging, "disappear" quality of speaker and bass quality in high volume.

If you can make cabinet as good as the speaker, our own diy speaker can be equal, even superior to those high end speaker in terms of tonality, directivity if we put good amount of time and effort on it. Knowledge about speaker design and testing now is fairly tranparent, we have access to great quality drivers, we have dsp to spped up the design process,...

DIY vs commercial depends on what type of speaker you are pursuing. If high efficiency (eg the JBL clones mentioned above), PA (eg synergy clones and subs) or single driver designs (lowther er al), diy is so much cheaper than commercial and there are a wide range of off the shelf plans that suit all situations, unlike commercial designs which have to fit a certain market. But if you are after traditional low-ish efficiency column type speakers or bookshelfs, diy has tough competition with the used market. Commercial speakers can be resold, the resale value of diy speakers is parts at best. DIY can outperform commercial designs at a given retail price point though. Some commercial designs are unclonable for most diyers, eg Magico speakers, and if this is what you want, diy is not the way to go.

Yes of course, it is called the Ikea effectAre we fooling ourselves

https://en.wikipedia.org/wiki/IKEA_effect

Doesn't mean that DIY can't be better though

Brian

As a fairly realistic diyer, I would say that the fancy enclosure / sepaker construction is exactly what diyer generally falls short compared to the good summit-fi speaker from Magico, Rockport, Martens, Avalon, Estalon,... you see in hifi show like Munich Highend. The more I know about speaker design, the more I value the speaker cabinet. Those cabinet maybe look fancy but not only for cosmetic reason. You can see the same pattern like large beveled baffle or generous roundover/curve, sandwich layer of materal for speaker baffle, heavy bracing in woofer section, heavy cabinet. All of them in my knowledge is technically correct, and contribute to superior qualities in imaging, "disappear" quality of speaker and bass quality in high volume.

Summit-fi? I think you will find a fair few disagree with you about that and place most, though not all, of the speakers you list in the same category as expensive designer handbags.

Why do you think speakers offering the highest technical performance in an objective sense (e.g. measurements, blind listening tests,...) tend to have relatively straightforward cabinets? (i.e. ones using mass, stiffness and damping to address the engineering requirements rather than visual/marketing ones).

If you can make cabinet as good as the speaker, our own diy speaker can be equal, even superior to those high end speaker in terms of tonality, directivity if we put good amount of time and effort on it.

The cabinet is something we have full control over and I would agree that with an understanding of sound radiation and vibration control it can be designed and built to a high standard by DIYers. This is rarely done though because the relevant engineering is not widely followed/understood and a number of poorish practises have become adopted due to being guided by what other DIYers have done (particularly those with extensive websites) rather than engineering requirements. It is improving though as detailed 3D simulations becomes more widely used (e.g. BEM for waveguides/external geometry) but it has yet to really take hold for cabinet design although I expect it soon will.

Perhaps I should add that following common speaker DIY practises is most likely going to result in a speaker cabinet that performs fairly well rather than badly. It is the next step to a cabinet that is audibly inert and guides the sound optimally to achieve the desired radiation pattern that has yet to be taken in any numbers.

Knowledge about speaker design and testing now is fairly tranparent, we have access to great quality drivers, we have dsp to spped up the design process,...

Toole's book has helped a lot on the sound perception side but there isn't really an equivalent on the engineering side. There is mixture of good and bad information floating about which is difficult to identify for those without a background in the relevant engineering disciplines which is of course most DIYers.

DSP opens up a range of possibilities such as better control over the sound radiation pattern but this has yet to be widely adopted by DIY folk. It is fairly widely used in consumer audio and so it is likely a question of time. Many DIYers still prefer to use passive crossovers so there is still a fair way to go before active crossovers become the norm and then the next step is taken to use DSP in a way that have no analogue equivalent.

Drivers available to DIYers is a growing issue as more manufacturers opt not to bother with the ever shrinking market sector. It's not too serious yet although finding an appropriate and reasonably priced midrange driver is becoming difficult. On the other hand it has become relatively cheap and straightforward to have ones own driver manufactured (subject to one or two constraints) so perhaps we will see one or two DIY group projects aimed at this in the future. Or perhaps the few remaining active DIYers will be focused mostly on very expensive drivers where the margins are sufficient to sell into the DIY market. Don't know but it is a concern for those of us that don't see much value in very expensive drivers for their hobby.

+1M times yes....i believe there are many of us here...I see DIY being more about the journey, enjoyment and satisfaction.

I've built lots of diy kits in the last 10 years or so, most of them in the range of 1-2k eur.

Some from troels gravesen and other well known diy kits, some I tried to design myself.

Sadly not one of them have sounded better when compared to of the shelf speakers in the same price range.

Couple a months ago I decided to give it a last try, going all in, using high end components, hypex amps, beryllium tweeters and accuton mid and woofer.

I've spent hundreds of hours trying to fine tune the crossover and I think that I've finally made them the best they can sound.

They do sound better than my Marten Django xl, BUT, the material cost is more than what a pair of used Django cost.

With today's prices my build is nearly 7000eur.

So, my next speaker will definitely not be diy,

It's fun but I don't have the time anymore to spend hundreds of hours trying to make them the best I can.

Some from troels gravesen and other well known diy kits, some I tried to design myself.

Sadly not one of them have sounded better when compared to of the shelf speakers in the same price range.

Couple a months ago I decided to give it a last try, going all in, using high end components, hypex amps, beryllium tweeters and accuton mid and woofer.

I've spent hundreds of hours trying to fine tune the crossover and I think that I've finally made them the best they can sound.

They do sound better than my Marten Django xl, BUT, the material cost is more than what a pair of used Django cost.

With today's prices my build is nearly 7000eur.

So, my next speaker will definitely not be diy,

It's fun but I don't have the time anymore to spend hundreds of hours trying to make them the best I can.

For me, many of them are not expensive designer handbags since measurement of them in Stereophile (Magico M2, Tidal Akira, Rockport Avior II) is very good. And even when hearing in audio shows that while some of them have problem with frequency response due to crossoverr like Avalon they all exhibite some serious quality in "disappear" quality and bass quality, especially in high volume, which can contributed by good cabinet design to minimize edge diffraction and cabinet resonance.Summit-fi? I think you will find a fair few disagree with you about that and place most, though not all, of the speakers you list in the same category as expensive designer handbags.

Why do you think speakers offering the highest technical performance in an objective sense (e.g. measurements, blind listening tests,...) tend to have relatively straightforward cabinets? (i.e. ones using mass, stiffness and damping to address the engineering requirements rather than visual/marketing ones).

Problem is that many objective sense like standard measurements or blind listening test don't test in extreme case, but that is the situation where many problem occurs. For example is edge diffraction, which according to Geddes is more audible with higher SPL. The same can be said about cabinet vibration at high volume with bass materials. Personally I think the 5% THD of woofer at 60Hz is not really audible, but the cabinet vibration due to high SPL is audible, since it affects the tweeter and/or midrange as well. And for blinding test, I'm not sure about which other speakers they include in the test. Can you specify one for me?

Yes, cabinet is which we can have full control over with, but most diy-speaker do not pay enough attention to it. I agree that common speaker diy practises is farly well rather than badly, but we talk here is the highest performance possible rather than trying to be bang-for-buck approach.The cabinet is something we have full control over and I would agree that with an understanding of sound radiation and vibration control it can be designed and built to a high standard by DIYers. This is rarely done though because the relevant engineering is not widely followed/understood and a number of poorish practises have become adopted due to being guided by what other DIYers have done (particularly those with extensive websites) rather than engineering requirements. It is improving though as detailed 3D simulations becomes more widely used (e.g. BEM for waveguides/external geometry) but it has yet to really take hold for cabinet design although I expect it soon will.

Perhaps I should add that following common speaker DIY practises is most likely going to result in a speaker cabinet that performs fairly well rather than badly. It is the next step to a cabinet that is audibly inert and guides the sound optimally to achieve the desired radiation pattern that has yet to be taken in any numbers.

In my opinion, the good cabinet for multiway speaker at least have:

1. Very well and heavy bracing, especially for woofer section. Ideally should be seperated cabinet for woofer section and isolated to mid-treble section with damping material. The gap in baffle between two section can be filled with foam.

2. Non-parallel cabinet side wall.

3. Generous roundover (4cm minimum) or heavy beveled baffle.

4. Waveguide on tweeter (if dome tweeter is used)

5. Thick composite baffle construction (MDF, HDF, Aluminium)

6. Slopped baffle if passive crossover is used.

Yes, Toole's book is not for speaker design. It only provides some criteria need to be considered when designing speakers. And that's why I said above that diyer needs to put time and effort to design. Not only time and effort when building or fine tuning crossover but also for studying to understand the usefulness of information and the trade-off when using the information and planing what to do. There are nothing in the world, especially the hard one, can be achieve without big effort.Toole's book has helped a lot on the sound perception side but there isn't really an equivalent on the engineering side. There is mixture of good and bad information floating about which is difficult to identify for those without a background in the relevant engineering disciplines which is of course most DIYers.

I would put an example why critical thinking is needed rather than blindly follow exactly word-by-word. In Tooles's book, it said that the good speaker should have flat on-axis freuqnecy response, (and smooth off-axis frequency repsonse). But this information should not be taken to every speakers since it works for conventional box speaker with directivity fall off, so the in-room response can be slope downward. If you are using this criteria for speakers with nearly constant directivity , then the sound you receive will be bright, since the in-room response will be near flat.

Yes, some manufacturer is pulling out of diy sector. But there are always other alternatives. We don't have Peerless anymore but we still have Dayton, SB Acoustics, which are still offer great value drivers. About midrange driver, then there are always SB15NABC or SB17NBAC at reasonable price. Or you can go with pro driver like B&C 6MDN44 or the likes.Drivers available to DIYers is a growing issue as more manufacturers opt not to bother with the ever shrinking market sector. It's not too serious yet although finding an appropriate and reasonably priced midrange driver is becoming difficult. On the other hand it has become relatively cheap and straightforward to have ones own driver manufactured (subject to one or two constraints) so perhaps we will see one or two DIY group projects aimed at this in the future. Or perhaps the few remaining active DIYers will be focused mostly on very expensive drivers where the margins are sufficient to sell into the DIY market. Don't know but it is a concern for those of us that don't see much value in very expensive drivers for their hobby.

Just look at measurements from Erin's Audio Corner.

I know many diy projects that will surpass many of those "big brands" easily by a big margin.

I am far from impressed what "quality" some of those brands deliver.

Especially when you consider the price.

I never was impressed when I started this hobby many many years ago, it was actually one of the reason why I started building stuff myself.

And I am still not impressed after working in this industry as a professional for more than 15 years, designing and developing loudspeakers as well as electronics.

I know many diy projects that will surpass many of those "big brands" easily by a big margin.

I am far from impressed what "quality" some of those brands deliver.

Especially when you consider the price.

I never was impressed when I started this hobby many many years ago, it was actually one of the reason why I started building stuff myself.

And I am still not impressed after working in this industry as a professional for more than 15 years, designing and developing loudspeakers as well as electronics.

- Home

- Loudspeakers

- Multi-Way

- How good are our DIY units compared to off the shelf stuff?