Hi.Sorry to post here if it is a mistake.I know how to use winisd but I tried Hornresp but it seems very complicated to me and i did not understand it well.I could not simulate my subwoofers.I want to build a TL tower stereo subwoofers.

Double driver for each cabinet.I will try different bookshelf speakers.It is for multi use purpose.

I already have 4pcs of Easttech FSB12A065-1401 woofers.6,5 inch drivers.

Sd: around 110cm2

D: 13cm

Rmax:37 ohms

Re: 3,8 ohm

Rx: 11,857

Fs: 50Hz

f1:39Hz

f2:63Hz

Qts:0,667

Vas:11,16

ebp: 57

I measured TS parameters myself.They may not be very accurate but it is ok for me.

Cabinet size should be around 80cm tall,40cm deep and max 23cm wide.(sorry it is for waf)

I want deep and tight bass as much as possible.And cabinet size as small as possible.

Regards Ümit

Double driver for each cabinet.I will try different bookshelf speakers.It is for multi use purpose.

I already have 4pcs of Easttech FSB12A065-1401 woofers.6,5 inch drivers.

Sd: around 110cm2

D: 13cm

Rmax:37 ohms

Re: 3,8 ohm

Rx: 11,857

Fs: 50Hz

f1:39Hz

f2:63Hz

Qts:0,667

Vas:11,16

ebp: 57

I measured TS parameters myself.They may not be very accurate but it is ok for me.

Cabinet size should be around 80cm tall,40cm deep and max 23cm wide.(sorry it is for waf)

I want deep and tight bass as much as possible.And cabinet size as small as possible.

Regards Ümit

Neither of the 'constant something' methods will give you a complete picture of horn and driver behavior, as none of them model the behavior of the driver properly.

Some basics:

A driver is resistance controlled in a frequency range about its diaphragm mass/compliance resonance. This is not necessarily where the largest peak in the impedance curve is when the driver is used on a horn, because the horn+driver forms a double resonance system (like BR), and the main peak typically occurs at the resonance between driver compliance and horn acoustic mass. The diaphragm mass/compliance resonance occurs about midband, and you can see it if you load the horn by a plane wave tube. In the resistance controlled range, the driver operates at approximately constant velocity. This will give flat power response.

Below this frequency range, the driver is stiffness controlled. Above, it is mass controlled, and operating in constant acceleration mode. This produces the natural rolloff you see with typical drivers (in the power response, modified by directivity of course). This is not a natural rolloff of the horn, but of the driver on the horn.

The driver also has an internal source impedance that feeds the horn load impedance. The driver impedance is complex, but the main point is that it is an impedance, roughly of the same order of magnitude as the horn impedance. This causes the ripples in the response to be reduced compared to if the horn was driven by a 'constant something'. Which in either case implies that the horn is driven by a piston that moves the same velocity or acceleration or displacement regardless of the horn impedance. Which again implies that the drive impedance is infinite. So regardless of what kind of movement this piston has, it will not represent the driver, nor the interaction between driver and horn.

It is much simpler with a direct radiator, because its source impedance is has a much higher than the acoustic load. But with horns source and load are about equal. That makes a big difference in how important the source impedance is for the resulting response.

Keele described a method where the horn was driven through a source impedance matched to the horn impedance, rho*c/Sth. This is somewhat more realistic in terms of the response of the driver to horn impedance ripples, but still leaves out the behavior of the mass and compliance on the response.

My point is, these 'constant xyz' methods are all for comparing differences between the horns. You look at the differences in performance, and how the performance changes as you modify the horn. This is what it is useful for, and I have used that a lot myself. And in this case I mainly look at the throat impedance and directivity, not the frequency response, because the response will be quite different with a driver.

The pressure response with constant velocity at the throat is called the Transfer Impedance of the horn, BTW.

If you try to guess from the results how the horn will behave with a driver, all you get is different flavors of wrong. They all lack important bits to make the response a believable horn-driver response.

Perhaps a simplification could be to drive the horn with a pressure source through a source impedance that consists of a resistive part that is rho*c/Sth, and a mass reactance scaled to give a mass corner frequency of 2.5kHz, which is close to where a typical compression driver has the mass corner. Or it could be a selectable value. But then you may want to add the suspension compliance to see how it behaves at low frequencies, and before you know it, you have added the entire driver...

PS: Be careful when comparing directivity simulations in ABEC and Hornresp. ABEC uses BEM, Hornresp uses a 1D directivity model, which cannot give all the detail of BEM.

Some basics:

A driver is resistance controlled in a frequency range about its diaphragm mass/compliance resonance. This is not necessarily where the largest peak in the impedance curve is when the driver is used on a horn, because the horn+driver forms a double resonance system (like BR), and the main peak typically occurs at the resonance between driver compliance and horn acoustic mass. The diaphragm mass/compliance resonance occurs about midband, and you can see it if you load the horn by a plane wave tube. In the resistance controlled range, the driver operates at approximately constant velocity. This will give flat power response.

Below this frequency range, the driver is stiffness controlled. Above, it is mass controlled, and operating in constant acceleration mode. This produces the natural rolloff you see with typical drivers (in the power response, modified by directivity of course). This is not a natural rolloff of the horn, but of the driver on the horn.

The driver also has an internal source impedance that feeds the horn load impedance. The driver impedance is complex, but the main point is that it is an impedance, roughly of the same order of magnitude as the horn impedance. This causes the ripples in the response to be reduced compared to if the horn was driven by a 'constant something'. Which in either case implies that the horn is driven by a piston that moves the same velocity or acceleration or displacement regardless of the horn impedance. Which again implies that the drive impedance is infinite. So regardless of what kind of movement this piston has, it will not represent the driver, nor the interaction between driver and horn.

It is much simpler with a direct radiator, because its source impedance is has a much higher than the acoustic load. But with horns source and load are about equal. That makes a big difference in how important the source impedance is for the resulting response.

Keele described a method where the horn was driven through a source impedance matched to the horn impedance, rho*c/Sth. This is somewhat more realistic in terms of the response of the driver to horn impedance ripples, but still leaves out the behavior of the mass and compliance on the response.

My point is, these 'constant xyz' methods are all for comparing differences between the horns. You look at the differences in performance, and how the performance changes as you modify the horn. This is what it is useful for, and I have used that a lot myself. And in this case I mainly look at the throat impedance and directivity, not the frequency response, because the response will be quite different with a driver.

The pressure response with constant velocity at the throat is called the Transfer Impedance of the horn, BTW.

If you try to guess from the results how the horn will behave with a driver, all you get is different flavors of wrong. They all lack important bits to make the response a believable horn-driver response.

Perhaps a simplification could be to drive the horn with a pressure source through a source impedance that consists of a resistive part that is rho*c/Sth, and a mass reactance scaled to give a mass corner frequency of 2.5kHz, which is close to where a typical compression driver has the mass corner. Or it could be a selectable value. But then you may want to add the suspension compliance to see how it behaves at low frequencies, and before you know it, you have added the entire driver...

PS: Be careful when comparing directivity simulations in ABEC and Hornresp. ABEC uses BEM, Hornresp uses a 1D directivity model, which cannot give all the detail of BEM.

Hi Bjorn,

Thanks for giving the clear comments on driver-horn interactions. Very helpful (at least to me).

KR,

Christoph

Thanks for giving the clear comments on driver-horn interactions. Very helpful (at least to me).

KR,

Christoph

Hi David !

To help interpretation of group delay while tweaking in wizard, should it be possible to have a time delay slider to interpret in desired bandwith ?

There is really too much free space above width slider ^^

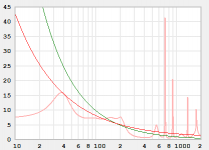

See really specific GD case below.

Thanks a lot,

David

To help interpretation of group delay while tweaking in wizard, should it be possible to have a time delay slider to interpret in desired bandwith ?

There is really too much free space above width slider ^^

See really specific GD case below.

Thanks a lot,

David

Attachments

Last edited:

Hi Don,

The constant acceleration option could certainly be added, but it is still not clear to me how it would be used in practice to help in designing a loudspeaker system. Do you have a process in mind, perhaps?

A special build - I am not that prescient, unfortunately 🙂.

Calculating the results is the easy part - what would take the time would be setting up the user interface and fully integrating the feature into Hornresp. I am quite happy to undertake the work though, provided that someone can give me a tangible reason to do so 🙂.

Kind regards,

David

Would you consider adding constant acceleration drive.

The constant acceleration option could certainly be added, but it is still not clear to me how it would be used in practice to help in designing a loudspeaker system. Do you have a process in mind, perhaps?

The constant acceleration graph appears to already be in hornresp. Is that a special build or foresight 🙂?

A special build - I am not that prescient, unfortunately 🙂.

Calculating the results is the easy part - what would take the time would be setting up the user interface and fully integrating the feature into Hornresp. I am quite happy to undertake the work though, provided that someone can give me a tangible reason to do so 🙂.

Kind regards,

David

Cabinet size should be around 80cm tall,40cm deep and max 23cm wide.(sorry it is for waf)

I want deep and tight bass as much as possible.And cabinet size as small as possible.

Hi Ümit,

For help with a specific design it is probably best to set up separate dedicated thread.

Otherwise this thread could quickly become a lot longer than it already is... 🙂.

Kind regards,

David

To help interpretation of group delay while tweaking in wizard, should it be possible to have a time delay slider to interpret in desired bandwith ?

Hi Damien,

Sorry, the group delay chart is complicated enough already, with the group delay per period option and the ability to add 1/f and Claus Futtrup limit guidelines.

Kind regards,

David

Neither of the 'constant something' methods will give you a complete picture of horn and driver behavior

Some basics: ................................

Be careful when comparing directivity simulations in ABEC and Hornresp.

Thanks Bjørn 🙂.

Thanks Bjørn 🙂.

^2 Bjørn

A good explanation. I was visualizing the differences in impedance as I read your explanation. Simulation land has it's uses and it's pitfalls.

Hi trying to get the latest version of hornresp to run on an old XP system and as a digital neanderthal could someone hopefully help?

this should work straight forward, I have several XP machines (updated to SP3 which you should do anyways, regardless of running hornresp) and it works fine..

Download it, install it, use it...

Of course, sometimes there are hickups (missing fonts in your system or so), but this is not "normal" - in case you run into problems, report them and we/I can help your here.

Download it, install it, use it...

Of course, sometimes there are hickups (missing fonts in your system or so), but this is not "normal" - in case you run into problems, report them and we/I can help your here.

ah ok..

The default path (directory) where hornresp is installed is:

c:\hornresp

so far you did:

- download setup.exe

- start setup.exe

- hit "unzip" (top button)

After hitting "unzip", the setup routine quickly un-zipps a few files, If nothing goes wrong, you get a message:

"4 files unzipped correctly..."

that´s basicaly it... Unless you manually changed the path where to put the files, you now have a new folder in drive C named "hornresp" - open it and you can start "hornresp.exe"

To open the folder, you are best of using the "explorer", which can be found in the start menu - or use the "my computer" icon on the desktop (which basically starts the explorer)...

hornresp has no "setup routine" like most other programms and therefore it puts no icon on the desktop or the start-menu. Its wonderfully small and clean and lean 🙂

If you would like to add a desktop icon to start hornresp from the desktop - or a shortcut in the start menu - please ask, we can do that manually with a few clicks - lets do this over PN then..

Hope this helps.

The default path (directory) where hornresp is installed is:

c:\hornresp

so far you did:

- download setup.exe

- start setup.exe

- hit "unzip" (top button)

After hitting "unzip", the setup routine quickly un-zipps a few files, If nothing goes wrong, you get a message:

"4 files unzipped correctly..."

that´s basicaly it... Unless you manually changed the path where to put the files, you now have a new folder in drive C named "hornresp" - open it and you can start "hornresp.exe"

To open the folder, you are best of using the "explorer", which can be found in the start menu - or use the "my computer" icon on the desktop (which basically starts the explorer)...

hornresp has no "setup routine" like most other programms and therefore it puts no icon on the desktop or the start-menu. Its wonderfully small and clean and lean 🙂

If you would like to add a desktop icon to start hornresp from the desktop - or a shortcut in the start menu - please ask, we can do that manually with a few clicks - lets do this over PN then..

Hope this helps.

you can check on the website (see my signature):

4920-190331

David always puts the latest version online.

Updating is very easy - simply run setup again and overwrite the old files...

If you wanna be safe, make a backup before installing a new version. I simply zip the whole folder - you also can simply make a copy of the folder.

4920-190331

David always puts the latest version online.

Updating is very easy - simply run setup again and overwrite the old files...

If you wanna be safe, make a backup before installing a new version. I simply zip the whole folder - you also can simply make a copy of the folder.

Download setup.exe from the website in my signature and start all over.

If you never used it before, you have no saved designs, so no need for a backup at this point.

If you never used it before, you have no saved designs, so no need for a backup at this point.

i'm lost after downloading and trying to unzip and install...

Navigate mouse with knuckles to c:/Hornresp/hornresp.exe and double click to open 😀

not that i had any designs worth saving but it seems i'm stuck with an old version...? i must be doing something wrong...?

- Home

- Loudspeakers

- Subwoofers

- Hornresp