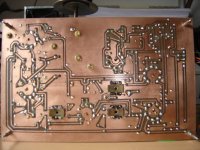

The PSU has been finished!

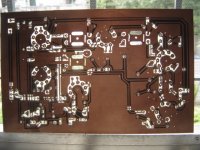

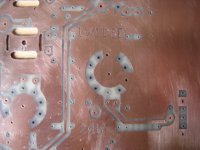

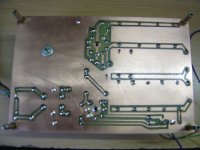

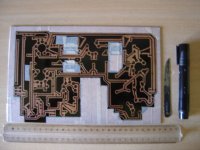

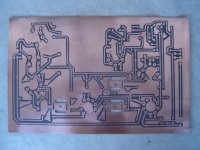

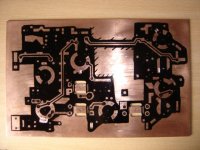

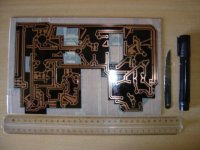

Here is the PCB of the PSU, now, finished.

Here is the PCB of the PSU, now, finished.

Attachments

-

Power Supply 01.JPG153.9 KB · Views: 221

Power Supply 01.JPG153.9 KB · Views: 221 -

Power Supply 07a.JPG53.7 KB · Views: 116

Power Supply 07a.JPG53.7 KB · Views: 116 -

Power Supply 07.JPG140.1 KB · Views: 109

Power Supply 07.JPG140.1 KB · Views: 109 -

Power Supply 06.JPG134.5 KB · Views: 104

Power Supply 06.JPG134.5 KB · Views: 104 -

Power Supply 05.JPG150.9 KB · Views: 212

Power Supply 05.JPG150.9 KB · Views: 212 -

Power Supply 04.JPG137.4 KB · Views: 211

Power Supply 04.JPG137.4 KB · Views: 211 -

Power Supply 03.JPG147.5 KB · Views: 216

Power Supply 03.JPG147.5 KB · Views: 216 -

Power Supply 02.JPG148.7 KB · Views: 230

Power Supply 02.JPG148.7 KB · Views: 230

Looking good! You are much more intrepid than I am, I would have built that P2P on a little metal chassis. I can't remember the last time I hand laid out a PCB and etched it myself, it must be getting close to 30yrs ago.

Demonstrates that you are very resourceful and it's interesting to watch you make progress.

Demonstrates that you are very resourceful and it's interesting to watch you make progress.

Hi Kevin‼ Many thanks for your comments, always very positive.

I have an old HP laser printer 4L and the stuff to make professional PCBs (Autotrax 1.61). What happens to me is that It takes much more time than a hand made PCB like this, and also I doubt about the process of to transfer from the sheet to the material. I had brought negative UV films, and sensitive PCBs, but I doubt about the finished results.

I have an old HP laser printer 4L and the stuff to make professional PCBs (Autotrax 1.61). What happens to me is that It takes much more time than a hand made PCB like this, and also I doubt about the process of to transfer from the sheet to the material. I had brought negative UV films, and sensitive PCBs, but I doubt about the finished results.

I had a 4L that died just a couple of years ago after 17yrs of faithful service.. The replacement, an Epson Workforce Inkjet, higher resolution, is much faster, has a duplexer, prints in photographic quality color, prints on any standard size of paper to 13 x 19 inches, and actually cost less than the Laserjet 4L. It also scans, faxes, and copies. (works with my phone, tablet, linux and windows boxes and windows laptops over wifi or ethernet)

I have used a laser printer with printable film and UV sensitive PCB material which I exposed to strong sunlight for some period of time and it worked, sort of.

The results were acceptable but it took a lot of time to expose, develop, and etch the board, then I had to drill it. Vector board would have been so much faster, I think that was the last pcb board I ever fabricated by hand.

Given some care I think the results can be fairly good.

I have used a laser printer with printable film and UV sensitive PCB material which I exposed to strong sunlight for some period of time and it worked, sort of.

The results were acceptable but it took a lot of time to expose, develop, and etch the board, then I had to drill it. Vector board would have been so much faster, I think that was the last pcb board I ever fabricated by hand.

Given some care I think the results can be fairly good.

I brought two of them a couple of years ago, because my 486's only suport parallel ports, not USB.

There are some specialized paces here that repair at low costs, cylinders, toner, etc, of printers, buy they have certain delays and I still have doubts in respect to the process itself and the final quality of the finished PCB.

In fact, manual results are not too bad, neither.

There are some specialized paces here that repair at low costs, cylinders, toner, etc, of printers, buy they have certain delays and I still have doubts in respect to the process itself and the final quality of the finished PCB.

In fact, manual results are not too bad, neither.

Hi Oslvado, sorry I asked over on the tubes side of the forum about your FM design. I didn't realise how hard at work you have been with this AM tuner.

Truly excellent work and I do think that AM can have really quite good retrieved audio quality.

As others have mentioned I too prefer it for spoken word broadcasts, its just a shame that here in the UK the actual quality of transmitted media is poor and getting worse. I believe they are going to turn off Radio 4 from Droitwich at some point.

Cheers

Matt

Truly excellent work and I do think that AM can have really quite good retrieved audio quality.

As others have mentioned I too prefer it for spoken word broadcasts, its just a shame that here in the UK the actual quality of transmitted media is poor and getting worse. I believe they are going to turn off Radio 4 from Droitwich at some point.

Cheers

Matt

Thanks Matt for your concepts.

This project comes from large time ago. This is why I saved the 3 section brass plates gang and the IF transformers, plus tubes, sockets, etc. In fact, it was not a hard job, I did it to prove myself that I'm capable of making something away from classic designs and I did it in the free time, fortunately I live alone. I have a txt file what I use as a spread sheet, where I saved calculus, experiences, an so on, but it is in Spanish and in CP437, so, once again offer it to those who want to investigate how did I arrived to such a result. As I said in other thread, to make a good project, IMHO it is not a good idea to mix some schematics and see what happen. This is a very meditated project using some previous concepts, I read all I could get at hand (the Radiotron mainly, but also some patents from Google Patents, and more).

The audio quality is really pleasant. When wright tuned in the top of the IF's Q curve on good station, audio very resembles a FM station. Good bass response without being tiring, and good trebles without being harsh.

I really didn't measure it using laboratory instrument to show us real figures of my tuner, because I still didn't finished it (Still working in the double sided PCB project) and its ugly and feeble form makes it difficult to transport to a laboratory, but when I finish it probably I´ll carry it to the UTN FRA's laboratory, and with the help of a professor, for make overwhelming tests.

Once again, thanks for reading this thread, and I apologize about my RF topics.

This project comes from large time ago. This is why I saved the 3 section brass plates gang and the IF transformers, plus tubes, sockets, etc. In fact, it was not a hard job, I did it to prove myself that I'm capable of making something away from classic designs and I did it in the free time, fortunately I live alone. I have a txt file what I use as a spread sheet, where I saved calculus, experiences, an so on, but it is in Spanish and in CP437, so, once again offer it to those who want to investigate how did I arrived to such a result. As I said in other thread, to make a good project, IMHO it is not a good idea to mix some schematics and see what happen. This is a very meditated project using some previous concepts, I read all I could get at hand (the Radiotron mainly, but also some patents from Google Patents, and more).

The audio quality is really pleasant. When wright tuned in the top of the IF's Q curve on good station, audio very resembles a FM station. Good bass response without being tiring, and good trebles without being harsh.

I really didn't measure it using laboratory instrument to show us real figures of my tuner, because I still didn't finished it (Still working in the double sided PCB project) and its ugly and feeble form makes it difficult to transport to a laboratory, but when I finish it probably I´ll carry it to the UTN FRA's laboratory, and with the help of a professor, for make overwhelming tests.

Once again, thanks for reading this thread, and I apologize about my RF topics.

what is the frequency response you are able to get. Many AM tuners roll off over 3khz while FM can go to 15khz. FM is near CD quality if they did not compress it so much.

HA1197 AM tuner chip can get to 6khz if you back off sensitivity ( and Q ) a bit

Sound quality is really pleasant and full

HA1197 AM tuner chip can get to 6khz if you back off sensitivity ( and Q ) a bit

Sound quality is really pleasant and full

Last edited:

what is the frequency response you are able to get.

I can't say you exactly as I haven't measure it with instrumental, but its high ends are very interesting. I presume that 5-6KHz perhaps.

The past two weeks, I was in vacations time, and in between other things I did, I finished the project. Here I will post some photos of the hand-made double sided PCB for the tuner.

Attachments

-

PCB 07.JPG157.4 KB · Views: 92

PCB 07.JPG157.4 KB · Views: 92 -

PCB 08.JPG141.4 KB · Views: 85

PCB 08.JPG141.4 KB · Views: 85 -

PCB 09.JPG145.8 KB · Views: 94

PCB 09.JPG145.8 KB · Views: 94 -

PCB 10.JPG147 KB · Views: 95

PCB 10.JPG147 KB · Views: 95 -

PCB 06.JPG157 KB · Views: 93

PCB 06.JPG157 KB · Views: 93 -

PCB 05.JPG151.2 KB · Views: 183

PCB 05.JPG151.2 KB · Views: 183 -

PCB 04.JPG156 KB · Views: 180

PCB 04.JPG156 KB · Views: 180 -

PCB 03.JPG157.3 KB · Views: 181

PCB 03.JPG157.3 KB · Views: 181 -

PCB 02.JPG122.4 KB · Views: 182

PCB 02.JPG122.4 KB · Views: 182 -

PCB 01.JPG137.6 KB · Views: 190

PCB 01.JPG137.6 KB · Views: 190

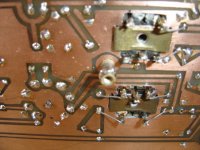

Once the PCB is finished, then it will receive the components.

Attachments

-

AM Receiver Project 29.JPG146.2 KB · Views: 101

AM Receiver Project 29.JPG146.2 KB · Views: 101 -

AM Receiver Project 28.JPG149.7 KB · Views: 102

AM Receiver Project 28.JPG149.7 KB · Views: 102 -

AM Receiver Project 27.JPG146.3 KB · Views: 102

AM Receiver Project 27.JPG146.3 KB · Views: 102 -

AM Receiver Project 26.JPG140.1 KB · Views: 104

AM Receiver Project 26.JPG140.1 KB · Views: 104 -

AM Receiver Project 25.JPG150.9 KB · Views: 110

AM Receiver Project 25.JPG150.9 KB · Views: 110 -

AM Receiver Project 24.JPG148.7 KB · Views: 109

AM Receiver Project 24.JPG148.7 KB · Views: 109 -

AM Receiver Project 23.JPG142.3 KB · Views: 104

AM Receiver Project 23.JPG142.3 KB · Views: 104 -

AM Receiver Project 22.JPG140.2 KB · Views: 95

AM Receiver Project 22.JPG140.2 KB · Views: 95 -

AM Receiver Project 21.JPG134.2 KB · Views: 105

AM Receiver Project 21.JPG134.2 KB · Views: 105 -

AM Receiver Project 20.JPG146.2 KB · Views: 115

AM Receiver Project 20.JPG146.2 KB · Views: 115

High Audio Quality AM Tuner

Finally, the tuner is singing successfully, and the tittle of the thread can be modified, getting rid of the parenthesis and now I can say "High Audio Quality AM Tuner".

Thanks to the boys who participated on the thread.

Finally, the tuner is singing successfully, and the tittle of the thread can be modified, getting rid of the parenthesis and now I can say "High Audio Quality AM Tuner".

Thanks to the boys who participated on the thread.

I'm not good making cabinets, nor I have sufficient tools, I live in a little house (only 40m²) and also I have usually little time to enjoy my projects. Then, for a time, the AM Tuner Project will look as in the pic below. Now, I'll continue working in an old project, also published here long time ago (http://www.diyaudio.com/forums/tubes-valves/224046-neutralizing-amplifier.html), and finish it. Perhaps, before it, I make a single box for both, the amplifier and the tuner.

Attachments

I didn't realize the house was quite that small, about twice to three times the size of what we call "tiny houses" here in the U.S. which are a popular trend now - many are trailerable. Very green environmentally speaking is the intent in many cases. I know you use solar power for some stuff so there are similarities.

Surprised that your considerable skills don't yet extend to making cabinets for your projects. I do OK in metal, but not so great in wood. 😛

Surprised that your considerable skills don't yet extend to making cabinets for your projects. I do OK in metal, but not so great in wood. 😛

OK, sometimes I say that I have "manos de manteca" (Butter hands), which menas that almost everything I get in hands, in a relatively short time they drop from them 🙂 I believe that it is not an ill, simply a bit stupid with my hands: in fact I must rectify several times a text because in the firsts two checks, most of the words are bad wroten. Too many errors or mistake in the keyboard.

Returning to the project, yes, I am not skilled in the art of making boxes, and I luck of sufficient space and tools to make them good finished.

Sincerely (Also), I prefer spent time making electronic design over wood or metal jobbing.

Returning to the project, yes, I am not skilled in the art of making boxes, and I luck of sufficient space and tools to make them good finished.

Sincerely (Also), I prefer spent time making electronic design over wood or metal jobbing.

<snip>

Sincerely (Also), I prefer spent time making electronic design over wood or metal jobbing.

We refer to it as butter fingers.. I am notorious for dropping and breaking things. I also break expensive little taps and drill bits from time to time.

I too, much prefer doing electronic design to the practical aspects of packaging, but have been badly embarrassed enough times in the past that I am now a bit of a maniac about it. My stuff mostly is not pretty, but it is well built and packaged.

- Home

- Source & Line

- Analogue Source

- High (Audio) Quality AM Tuner