Once you've sourced all the parts, and a pick & place fab shop, can you give an estimate on the cost to buy an assembled amp? Thanks!

Of coursse! I need to build a prototype to make sure it works as designed and check for ease of use, battery life, etc. it goes without saying that the sound quality needs to be super. My concern is the apparent lack of interest as you are the only one at this point. Maybe once people see a real product that is not vaporware and has a price tag, more interest will bubble up?

Or perhaps a good review on HeadFi or Headfonics will stir up the interest?

If interest does arise, this discussion will move over to the GB section. The technical aspects will be discussed here.

Or perhaps a good review on HeadFi or Headfonics will stir up the interest?

If interest does arise, this discussion will move over to the GB section. The technical aspects will be discussed here.

My concern is the apparent lack of interest as you are the only one at this point.

Not sure about anyone else but I am personally watching this thread with interest, so you aren't on your own in this thread!

There just isn't much to say until the prototype has been created and you give an account of how this one sounds. It is looking good so far though.

I think a lot of previous customers, like me, are looking with interest!Hi Avtech,

Cool, thanks for letting me know.

X

Ciao

@XRK71 -

After building the PCAs, I've been living vicariously through your threads to watch how a product evolves from idea to prototype and onward.

My own love is the "therapy" of the parts sourcing, and assembly vs. purchase of finished products. Given the correct price / performance ratio, I could be swayed to buying my first "finished product" in a very long time. I haven't quite picked up the final balance of what will be DIY for this particular project.

Still watching with interest.

After building the PCAs, I've been living vicariously through your threads to watch how a product evolves from idea to prototype and onward.

My own love is the "therapy" of the parts sourcing, and assembly vs. purchase of finished products. Given the correct price / performance ratio, I could be swayed to buying my first "finished product" in a very long time. I haven't quite picked up the final balance of what will be DIY for this particular project.

Still watching with interest.

Thanks for all the notes of support guys. I was feeling g like the Hakuin was a bit neglected for while.

IAIMH: you have a PM that might help put your need for “therapy” to work 🙂

IAIMH: you have a PM that might help put your need for “therapy” to work 🙂

I'm very interested, provided I don't have to solder anything or drill holes in altoid tins. (DIY electronics are very much outside my wheelhouse.)

This was planned to be a fully built and tested amp. You just need to install the boards into the 3D printed case. No hole drilling needed. ( Actually, we use paper hole punches for the Altoid tins as drills rip the metal. The amp has the optional Altoid tin option - that’s why there are two different volume pots.

Just wanted to thank member IAIMH for his help with the BOM - it’s been invaluable and will help me to get to build the prototype much sooner than later.

Soldering and mounting stuff in cases is np here...my DIY interest is in the design and the performance.

I do like an accurate BOM and parts layout and things to do when initially setting up or biasing, voltage checks...

Thanks for doing these projects!!

Much Appreciated!

Alex

Merry Christmas and Happy Holidays and New Year!

I do like an accurate BOM and parts layout and things to do when initially setting up or biasing, voltage checks...

Thanks for doing these projects!!

Much Appreciated!

Alex

Merry Christmas and Happy Holidays and New Year!

We will have a nice accurate BOM with this one thanks to IAIMH. I didn’t realize there were folks willing to DIY this all SMT amp - it’s got some tricky VSON parts that only can be done with paste and a hot plate or hot air. Nothing smaller than 0603 though.

Will keep a DIY version in mind then rather than all robo-built.

Will keep a DIY version in mind then rather than all robo-built.

With the super help from IAIMH, I have now ordered the BOM (mostly Mouser and a few items from Digikey). There are some interconnect pieces from Samtec that had to be ordered directly from the manufacturer. We should be able to build the prototype soon.

You're too kind. It was a pleasure to help. I learned quite a bit. Can't wait to see how the prototype turns out.

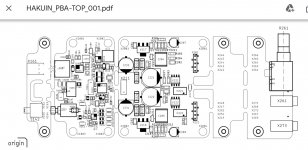

I was honored that XRK971 allowed me to try building an amp from prototype boards. The amplifier section went off without a hitch (I hope) hand soldering the components with some careful planning. The power supply and battery management system requires a whole new skill set for me with paste and a heat gun. With a bit of coaching, I think I can manage to learn how to better solder with paste, hot plate, and heat gun. At the moment, I am paused. I have to take a step back and rethink the plan.

Anyway... here is a picture of the progress so far 😀. Incredibly fun. Now I need a proper scope. LOL!

#SMTChallenge

More to come...

Anyway... here is a picture of the progress so far 😀. Incredibly fun. Now I need a proper scope. LOL!

#SMTChallenge

More to come...

Attachments

IAIMH,

Nice work! Thanks so much for helping. You are doing great - and you are very careful, ask all the right questions, and you pick things up very quickly. Super skills for a prototype tester.

This project has moved forward a lot faster with your help.

Thanks again,

X

Nice work! Thanks so much for helping. You are doing great - and you are very careful, ask all the right questions, and you pick things up very quickly. Super skills for a prototype tester.

This project has moved forward a lot faster with your help.

Thanks again,

X

....Anyway... here is a picture of the progress so far 😀. Incredibly fun. Now I need a proper scope. LOL!

#SMTChallenge

More to come...

Wow!! Your progress looks great, IAIMH 😉

Looking forward to your next move.....

This project might be the one that pushes me to acquire a set of headphones

Do you have any stats on what loads this amp can drive? Minimum/maximum impedance. What is the power / current handling like? (Sorry if I missed it in the thread already)

I've acquired a pair of ortho headphones that need a good class A amp but they are a bit power hungry..

I've acquired a pair of ortho headphones that need a good class A amp but they are a bit power hungry..