Thanks for sharing.

I didn't see the diagram, but from the description, I got an impression it's very similar to the oblique slices on Scan-speak Revelator midwoofers, or the presses on Lowthers.

Identical or at least similar concepts, aren't they?

I didn't see the diagram, but from the description, I got an impression it's very similar to the oblique slices on Scan-speak Revelator midwoofers, or the presses on Lowthers.

Identical or at least similar concepts, aren't they?

No, the concept is totally different, and we did have to defend this new invention in the application process. They may look similar from drawings, but application of basic physics is a different approach.

Beryllium still has a higher specific stiffness than magnesium.Hello whgeiger

Have you looked at Magnesium at all?? I have a pair of JBL 476Mg's and they measure very well. Much lower cost than the Be.

Rob🙂

You keep calling it electric steel. Wouldn't that term normally be reserved for magnetic circuits with AC fields, not DC?WhGeiger,

I see on this point we are in agreement. I am planning on using the electric steel for my pole piece, it has a definite advantage in this area of my design. I am not sure that you don't have enough mass and thickness in the pole piece of a compression driver without doing the modeling and checking this in a magnetics analysis program. I my instance it was obvious while doing the modeling and analysis that it was the way to increase the flux density and also because of saturation in that area of the motor. I wouldn't however use the material for the rest of the motor as it showed no improvement in the gap energy to use the higher dollar material.

454Casull,

Electric steel is the term that is used in the specialty steel industry. That is the general term used where you would look for the specific alloy you may want. Yes this is the same category of steel that would be used for transformer laminate steel, we are looking for the same type of properties. Basically it is a specialty steel that has extremely low carbon and has other trace elements. Some of these steels will be listed as stainless steels and other types. They are available in bar form and can be machined. To achieve the ultimate properties the material needs to be annealed at high temperature after machining to very specific temperatures for set times. These metals are fairly expensive because of the purity and specific elements add into the alloy. Look at Carpenter Steel electric steel alloys.

Electric steel is the term that is used in the specialty steel industry. That is the general term used where you would look for the specific alloy you may want. Yes this is the same category of steel that would be used for transformer laminate steel, we are looking for the same type of properties. Basically it is a specialty steel that has extremely low carbon and has other trace elements. Some of these steels will be listed as stainless steels and other types. They are available in bar form and can be machined. To achieve the ultimate properties the material needs to be annealed at high temperature after machining to very specific temperatures for set times. These metals are fairly expensive because of the purity and specific elements add into the alloy. Look at Carpenter Steel electric steel alloys.

Beryllium still has a higher specific stiffness than magnesium.

Hi 454,

Please excuse my ignorance and/or if this has been already answered somewhere else. But, will the stiffness property actually matter (audibly) if the required frequency for the material to produce is in the midrange band? Wouldn't this material be of better use if it was implemented as a mid bass or even a bass driver (though very expensive)? Since driver wobbling (distortion) is happening more in the lower vs. higher frequencies?

Thanks,

Ian

YES!

Stiffness of and sound velocity in the material are related.

For a tweeter, we are trying to minimize mass of the moving system to avoid an early onset of HF roll-off due to it. To meet this mission objective, we are looking for a low density, high stiffness material.

The wobbling (and rocking) modes are relative: it is only the frequency set at which they occur that changes, which is a function of diaphragm size and the sound velocity within it and the suspension as well.

The lower frequency modes directly involve the suspension. (At higher frequencies it is the impedance miss-match that is at issue.) For the spider-less tweeter, this, plus its inherent excursion limit, determine the lowest 'safe' frequency of operation. Most high performance, low frequency drivers have two spiders for good reason, the poor tweeter has none!

Mode suppression is determined by resistance (impedance) parameters of the diaphragm and surround materials. These have yet to be addressed here.

To explain the physics of the moving system of a driver takes several hundred pages of detailed text and math. Do not expect that to be provided here. That also makes the pros here, due to necessary brevity, 'easy pickings'.

The best path to information on subjects acoustic, is through AES and ASA memberships, followed by a lot of reading. From there you will be directed to important texts, one of which is provided here:

Acoustics: Sound Fields and Transducers is a thoroughly updated version of Leo Beranek's classic 1954 book that retains and expands on the original's detailed acoustical fundamentals while adding practical formulas and simulation methods.

Acoustics: Sound Fields and Transducers - Leo L. Beranek, Tim Mellow - Google Books

Regards,

WHG

Hi 454,

Please excuse my ignorance and/or if this has been already answered somewhere else. But, will the stiffness property actually matter (audibly) if the required frequency for the material to produce is in the midrange band? Wouldn't this material be of better use if it was implemented as a mid bass or even a bass driver (though very expensive)? Since driver wobbling (distortion) is happening more in the lower vs. higher frequencies?

Thanks,

Ian

Stiffness of and sound velocity in the material are related.

For a tweeter, we are trying to minimize mass of the moving system to avoid an early onset of HF roll-off due to it. To meet this mission objective, we are looking for a low density, high stiffness material.

The wobbling (and rocking) modes are relative: it is only the frequency set at which they occur that changes, which is a function of diaphragm size and the sound velocity within it and the suspension as well.

The lower frequency modes directly involve the suspension. (At higher frequencies it is the impedance miss-match that is at issue.) For the spider-less tweeter, this, plus its inherent excursion limit, determine the lowest 'safe' frequency of operation. Most high performance, low frequency drivers have two spiders for good reason, the poor tweeter has none!

Mode suppression is determined by resistance (impedance) parameters of the diaphragm and surround materials. These have yet to be addressed here.

To explain the physics of the moving system of a driver takes several hundred pages of detailed text and math. Do not expect that to be provided here. That also makes the pros here, due to necessary brevity, 'easy pickings'.

The best path to information on subjects acoustic, is through AES and ASA memberships, followed by a lot of reading. From there you will be directed to important texts, one of which is provided here:

Acoustics: Sound Fields and Transducers is a thoroughly updated version of Leo Beranek's classic 1954 book that retains and expands on the original's detailed acoustical fundamentals while adding practical formulas and simulation methods.

Acoustics: Sound Fields and Transducers - Leo L. Beranek, Tim Mellow - Google Books

Regards,

WHG

Is sound velocity in the material a good comparison for selecting HF diaphragms?

If so then the table in post6815 shows Aluminimum, Magnesium, Titanium all to be similar.

Alumina is significantly higher. Is anodised aluminium approximately equal to Alumina?

Does anyone have a figure for anodised magnesium?

Beryllium and diamond show as very significantly higher speed.

The two plastic come out particularly poorly on speed, but maybe damping helps with these.

If so then the table in post6815 shows Aluminimum, Magnesium, Titanium all to be similar.

Alumina is significantly higher. Is anodised aluminium approximately equal to Alumina?

Does anyone have a figure for anodised magnesium?

Beryllium and diamond show as very significantly higher speed.

The two plastic come out particularly poorly on speed, but maybe damping helps with these.

Last edited:

Notes:

Selection of a diaphragm material is a multi-dimensional problem. For a tweeter, moving mass, the onset frequency and severity of the break-up modes, cost, and reliability, are all competing considerations. Plastics do not heat sink the voice coil very well. Given the typical venues a compression driver 'sees', anodizing magnesium diaphragms is pretty much a given.

Regards,

WHG

Is sound velocity in the material a good comparison for selecting HF diaphragms?

If so then the table in post6815 shows Aluminimum, Magnesium, Titanium all to be similar.

Alumina is significantly higher. Is anodised aluminium approximately equal to Alumina?

Does anyone have a figure for anodised magnesium?

Beryllium and diamond show as very significantly higher speed.

The two plastic come out particularly poorly on speed, but maybe damping helps with these.

Selection of a diaphragm material is a multi-dimensional problem. For a tweeter, moving mass, the onset frequency and severity of the break-up modes, cost, and reliability, are all competing considerations. Plastics do not heat sink the voice coil very well. Given the typical venues a compression driver 'sees', anodizing magnesium diaphragms is pretty much a given.

Regards,

WHG

Yes and no. Transformer steel and DC magnetic circuit steel need different properties. Transformer steel needs excellent permeability and low core loss whereas DC steel needs (usually) high saturation induction, so on and so forth.454Casull,

Electric steel is the term that is used in the specialty steel industry. That is the general term used where you would look for the specific alloy you may want. Yes this is the same category of steel that would be used for transformer laminate steel, we are looking for the same type of properties. Basically it is a specialty steel that has extremely low carbon and has other trace elements. Some of these steels will be listed as stainless steels and other types. They are available in bar form and can be machined. To achieve the ultimate properties the material needs to be annealed at high temperature after machining to very specific temperatures for set times. These metals are fairly expensive because of the purity and specific elements add into the alloy. Look at Carpenter Steel electric steel alloys.

Specific stiffness (or stiffness over density squared) determines how stiff something can be for a given mass or volume, or vice versa three-ways.Hi 454,

Please excuse my ignorance and/or if this has been already answered somewhere else. But, will the stiffness property actually matter (audibly) if the required frequency for the material to produce is in the midrange band? Wouldn't this material be of better use if it was implemented as a mid bass or even a bass driver (though very expensive)? Since driver wobbling (distortion) is happening more in the lower vs. higher frequencies?

Thanks,

Ian

This article explains it somewhat well:

Specific modulus - Wikipedia, the free encyclopedia

There is a handy chart which can be sorted by column. You can derive (with some patient thinking) which of the columns to use, given which constraints (fixed mass, fixed thickness/volume, etc.)

For example, for any given sensitivity, you can go with a stiffer material (modulus over density squared) and have a higher breakup frequency, or keep the same breakup frequency and use less mass to increase sensitivity.

The NA12 size will be its biggest advantage. I do not expect it to be quite as good as the NS15 because of the way I have to shoehorn the waveguide into the smaller cabinet. The current Abbey will remain unchanged.

By the way, I was able to fix the early problem in the MS15 at crossover in later development. You can see this at NS15

A 1" driver is just fine even down to 800 Hz as in the NS15 simply because this is for a home and the SPLs are just not so high as to cause a problem with excursion. I have been using a 1" driver in the Summa for more than ten years and never saw a problem as long as they were used in a home.

Back in the AI days we did see problems with the 1" drivers when used in clubs, but that was full power for hours on end.

I used a single Summa as the PA system at my wedding.

Worked really well, but it was capable of going way louder than I'd ever need it to go. I was using about fifty watts of solid state power.

Larger throat compression drivers will always need a second driver to get up to 15 kHz. The 1" just gets there. Going to a 1.5" but having to add another HF driver is simply not a good trade off unless, because of power handling requirements, one has no other choice. The DIY community always believes that bigger is better and sometimes it is, but not always.

Going to have to disagree with you here.

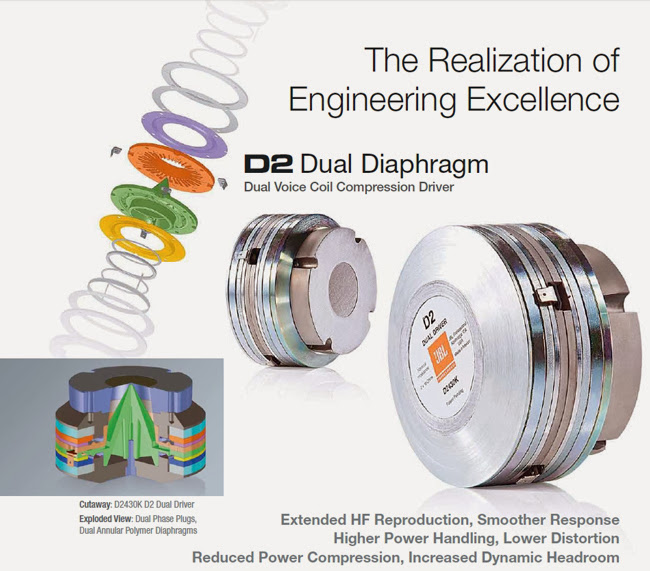

Check out the patents on these new JBL drivers; they've done a really good job of extending the bandwidth of a compression driver by using a number of innovations:

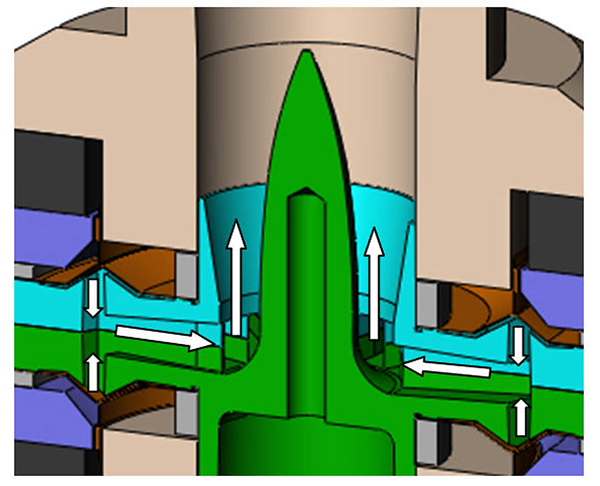

1) push-push ring radiators. Basically more displacement by taking advantage of the fact that you can place two rings face to face. Try doing *that* with a dome!

2) The phase plug is asymmetrical. I believe this is one of the reasons that the response is so smooth.

3) All of these advancements aren't particularly expensive; no needy for Beryllium or anything exotic. I am personally using a relative of the M2 driver, that I purchased online for $105. (http://reconingspeakers.com/product/jbl-2408h-1-high-frequency-driver/) At that price, I seriously can't see why anyone would use anything else at that price range.

That giant compression driver from the M2, the one with the 1.5" throat, can't be bought new. But you *can* find them regularly on eBay, as it's not only used in the M2, it is also used in JBL's arrays. And due to that, they're surprisingly cheap, about $400.

Is it three times better than a DE250? No. But it's a significant improvement, and the law of diminishing returns always rears it's ugly head.

Obviously, the compression driver from the M2 wouldn't be a good candidate for your speakers because it would require a new waveguide, but check out the 1" variant, it is very very good. I sold all of my B&C and Selenium compression drivers and I am using BMS, JBL and Celestion exclusively now.

Last edited:

I have failed to see any "waveguide" discussion in the last few pages, only a bunch of hypotheses about how to make the "best" compression drivers. Having used and measured a lot of them my conclusion is that they are all about the same, basically they are a commodity. Except that I have yet to see a dual diaphragm unit that I would consider useing. There simply is no way to get two diaphragms into a single device that will have a flawless transition between them. And this flaw always occurs in the worst possible frequency range.

I have failed to see any "waveguide" discussion in the last few pages, only a bunch of hypotheses about how to make the "best" compression drivers. Having used and measured a lot of them my conclusion is that they are all about the same, basically they are a commodity. Except that I have yet to see a dual diaphragm unit that I would consider useing. There simply is no way to get two diaphragms into a single device that will have a flawless transition between them. And this flaw always occurs in the worst possible frequency range.

But all of the ring radiators kill the domes on the CSD measurements.

I can see the advantage of a B&C DE250 over a BMS 4550. The BMS costs 33% more, and the audibility of the superior CSD and extension is open to debate.

But the JBL 2408H-1? It costs 8% more, is more extended, and will likely have superior CSD.

Then again, you may be able to get the DE250 for less than $110, so that would change things.

Basically, I can't see any reason to use a DE250 over a 2408H-1 at their current retail prices.

Geddes,

Good point. We have to consider if that (dual) was really an evolution (in engineering/hypotheses again) or maybe only in some cases of applications only, I don' know.

Good point. We have to consider if that (dual) was really an evolution (in engineering/hypotheses again) or maybe only in some cases of applications only, I don' know.

" Except that I have yet to see a dual diaphragm unit that I would consider useing. There simply is no way to get two diaphragms into a single device that will have a flawless transition between them. And this flaw always occurs in the worst possible frequency range."

Will you please elaborate? I am quite interested in these drivers and would sincerely like to know how and where you believe they are flawed.

Thank you,

Barry.

Will you please elaborate? I am quite interested in these drivers and would sincerely like to know how and where you believe they are flawed.

Thank you,

Barry.

But all of the ring radiators kill the domes on the CSD measurements.

I can see the advantage of a B&C DE250 over a BMS 4550. The BMS costs 33% more, and the audibility of the superior CSD and extension is open to debate.

But the JBL 2408H-1? It costs 8% more, is more extended, and will likely have superior CSD.

Then again, you may be able to get the DE250 for less than $110, so that would change things.

Basically, I can't see any reason to use a DE250 over a 2408H-1 at their current retail prices.

Hi John

I don't look at CSD, I don't give it much credence. It doesn't really show anything that plane old frequency response doesn't. Two drivers with the same frequency response will virtually always have the same CSD.

I am not at all driven by price, but I am also not driven by hype either. Given that Compression Drivers are a commodity I find that people are making huge claims about performance enhancements that just aren't there. All in an effort to reduce cost and differentiate themselves in the marketplace, just as any commodity does.

" Except that I have yet to see a dual diaphragm unit that I would consider useing. There simply is no way to get two diaphragms into a single device that will have a flawless transition between them. And this flaw always occurs in the worst possible frequency range."

Will you please elaborate? I am quite interested in these drivers and would sincerely like to know how and where you believe they are flawed.

Thank you,

Barry.

To minimize HOMs and diffraction, the throat aperture must be driven uniformly. This is difficult to impossible to do when there are two diaphragms operating over different frequency ranges (the only real reason that one would do that.) In every dual diaphragm driver that I have measured there is a distinct and significant polar response degradation at the crossover between these two diaphragms. This is to be expected and it appears to always be there. To make matters worse it is always in the critical 1 kHz - 5 KHz region where we are most sensitive to errors of this type.

There is simply no comparison between a dual diaphragm driver and a single diaphragm driver as long as the single can provide the required bandwidth as many many can. But to differentiate themselves several manufacturers make large claims (unsupported I might add.)

But the JBL driver is two identical ring diaphragms firing toward each other, isn't it?....This is difficult to impossible to do when there are two diaphragms operating over different frequency ranges (the only real reason that one would do that.)

But the JBL driver is two identical ring diaphragms firing toward each other, isn't it?

Yes it is. It's basically like taking a 2408H-1, mirroring it across the x axis. It takes advantage of the fact that a ring can work face-to-face. So you can get the small size necessary for extension to 20khz, along with the high displacement necessary for extension to 500hz.

From reading the papers of Alex Voishvillo, it looks like these designs are intended for a wide range of drivers. We'll likely see larger and smaller versions of this driver. (Hopefully cheaper!) As an example of this, the D2430K from the $5000 M2 has already found it's way into a speaker that sells for half as much. Looks like an Econowave to me!

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Geddes on Waveguides