I might have a pair I can check later today when I get homeDoes anyone have any EL34 boards for a stereo set left? I’d love a set!

Hi Yes I have a set. Will be in Las Vegas and of August and could post them from there if you wish

Regards

Christoph

Regards

Christoph

Hi everyone, I would like to know if anyone has a PCB set for the PP EL34 available (€uropa)? Thanks in advance if that's the case🙂 (@GenuineFrenchNoob, second DIY project 🙂 )

Hi

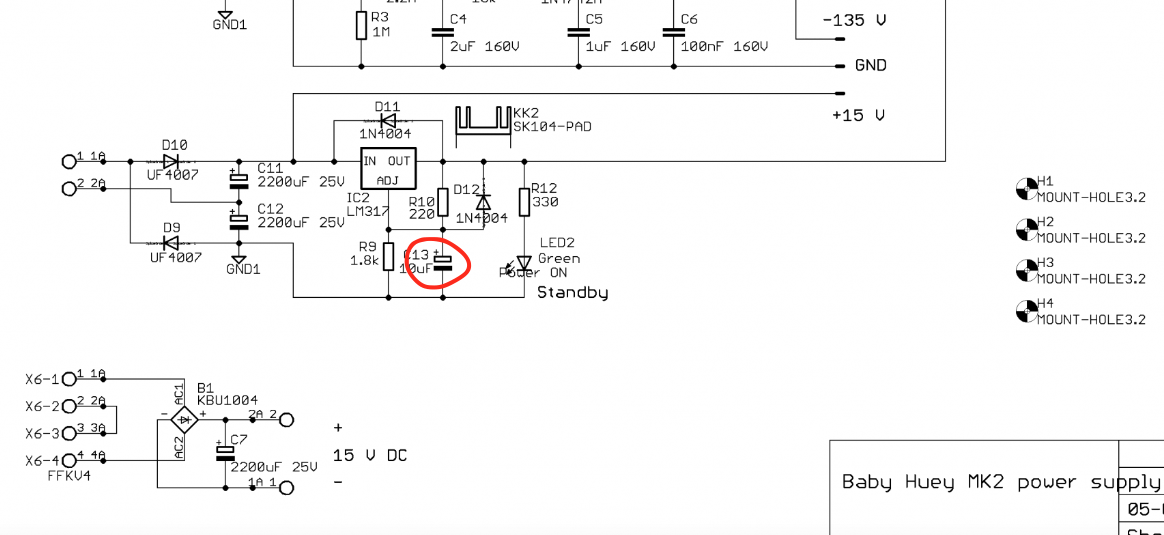

The power module is not working properly for me with this(C13) capacitor.

with this cap. I have 3V at the output of LM317.

so, I removed capacitor and now I have 12V, which is OK, and relay is working properly.

any ideas?

The power module is not working properly for me with this(C13) capacitor.

with this cap. I have 3V at the output of LM317.

so, I removed capacitor and now I have 12V, which is OK, and relay is working properly.

any ideas?

I had a small issue with the PCB. Mine is revision 1.51 but I see that it is similar to the current board in the drawings at the start of this thread.

I refitted one of the coupling capacitiors, C2, heating the socket side of the board where the lead comes out, and managed to lift the pad on the other side. The pad seems to be a bit small and with a tight hole for a part like a coupling capacitor, where some of the more esoteric examples have bigger leads and footprints, and also swapping is not out of the question. Am I the only clumsy solderer?

I refitted one of the coupling capacitiors, C2, heating the socket side of the board where the lead comes out, and managed to lift the pad on the other side. The pad seems to be a bit small and with a tight hole for a part like a coupling capacitor, where some of the more esoteric examples have bigger leads and footprints, and also swapping is not out of the question. Am I the only clumsy solderer?

Hi OldHector,

Your complaint about mounting hole size and footprint are pretty common things I see the results from on the service bench.

We are conditioned to believe more expensive parts are better. This is often not true, it isn't uncommon for those "audiophile approved" parts to perform worse than the parts normally available. Of course, without reason, these audiophile approved parts have to be larger as well. So, larger and don't fit, lead size too large, more expensive. All very good reasons not to use them even if their performance is on par.

Am I missing something here?

Your complaint about mounting hole size and footprint are pretty common things I see the results from on the service bench.

the more esoteric examples have bigger leads and footprints, and ...

- and therefore do not fit. If the part doesn't fit, do not use it.

- The more esoteric examples do not perform any better, and often worse than the good industrial parts available.

- Often causes PCB damage when forced into place (modified to fit).

We are conditioned to believe more expensive parts are better. This is often not true, it isn't uncommon for those "audiophile approved" parts to perform worse than the parts normally available. Of course, without reason, these audiophile approved parts have to be larger as well. So, larger and don't fit, lead size too large, more expensive. All very good reasons not to use them even if their performance is on par.

Am I missing something here?

@OldHector, I agree with you completely. I have Rev 1.6 PCBs from @prasi and I would have appreciated slightly bigger pads and holes for the coupling caps, C5 and a few other places. To self, note lesson for future reference.The pad seems to be a bit small and with a tight hole for a part like a coupling capacitor

So, no, you are not the only clumsy solderer. In fact, you may not be one! Let’s blame the PCB.

@anatech, oldHector is not chasing/pushing esoteric parts here.

Hi Francois G,

Thanks, I am aware of that. But he was wondering about using these larger parts. There is good reason not to do that which I tried to outline. He isn't a clumsy solderer, the part simply didn't fit.

Thanks, I am aware of that. But he was wondering about using these larger parts. There is good reason not to do that which I tried to outline. He isn't a clumsy solderer, the part simply didn't fit.

The problem I experienced, and I think @OldHector who called it a “small issue” too, was that the PCB offers the same, tiny soldering pad and hole for 1/4 watt resistors as it does for larger coupling capacitors. Some capacitors and even some box capacitors that fit the spacing provided, feature a larger wire size, and larger soldering pad and holes would have accommodated that variation better.

Last edited:

Hi Francois,

I haven't built one of these, but having ordered PCBs of my own design, it's easy to end up with pads and holes that are smaller than you wanted. I know exactly what you are talking about.

If so, an issue for the next run of boards.

I haven't built one of these, but having ordered PCBs of my own design, it's easy to end up with pads and holes that are smaller than you wanted. I know exactly what you are talking about.

If so, an issue for the next run of boards.

Hi @anatech , I had fitted some Russian K40 (I think, it was a while ago) and the leads fitted through the holes fine (probably a snug fit), but when I came to do the final assembly onto the top plate I thought I could have made a better job of the lead dress so I decided to resolder it with a shorter lead. I actually thought all had gone well, but then I noticed a tiny bit of copper in the solder on the capacitor lead and realised I had lifted the pad that is ringed above, which was on the other side of the board to where I had aplied heat.

There would seem to be a lot of real estate in that area where the coupling caps are fitted, hence the suggestion of a more substantial pad and slightly larger hole.

Hi @Francois G , thanks for your comments!

In the end I had to run a jumper from the lead of the capacitor to the lead of another resistor to fix the issue, a bit quick and dirty but I could not see another way to do it with the tiny trace to the cap.

I have plumbed in the new boards now and am being rewarded with sweet music, so it was not a disaster.

I have recapped a few old Tandberg tape recorders with philips tripod electrolytics that span multiple tracks, and it has been a long time since I had a problem with a track on a PCB, so I don't consider myself the least experienced doing this type of rework.

Cheers, Richard

There would seem to be a lot of real estate in that area where the coupling caps are fitted, hence the suggestion of a more substantial pad and slightly larger hole.

Hi @Francois G , thanks for your comments!

In the end I had to run a jumper from the lead of the capacitor to the lead of another resistor to fix the issue, a bit quick and dirty but I could not see another way to do it with the tiny trace to the cap.

I have plumbed in the new boards now and am being rewarded with sweet music, so it was not a disaster.

I have recapped a few old Tandberg tape recorders with philips tripod electrolytics that span multiple tracks, and it has been a long time since I had a problem with a track on a PCB, so I don't consider myself the least experienced doing this type of rework.

Cheers, Richard

- Home

- Group Buys

- GB for Baby Huey PCB