I had a moment this morning and changed the Rsense to 0.135 Ohm, and Amp output 1 Volt.

Works in Arta-Limp, but cleanest result with Stepped Sine.

The Fr drops ~2Hz for the PTT4.0 but these are extensively burned in so 45 46 Hz, so quite ok.

So i have a setup that measures in cases comparable to real use for music.

Progress !

Works in Arta-Limp, but cleanest result with Stepped Sine.

The Fr drops ~2Hz for the PTT4.0 but these are extensively burned in so 45 46 Hz, so quite ok.

So i have a setup that measures in cases comparable to real use for music.

Progress !

I can imagine a sense resistor of 0,1Ohm will lead to unexact measurements, since the voltage drop over it is quite low compared to values a hundred times higher. Ivo Matejan advises 27Ohm and your results are pretty spot on with that measurement.

@markbakk , this is a continuing discussion ;-)

My take:

With the 0.1(35) ohm i measure like purifi does. So my results can be compared with theirs. They keep a record of each driver, quite assuring. My experience with other manufacturers in the past was quite horrible in that respect.

The other main advantage is i measure the behaviour under normal operating condition.

Especially for the bass region. Which is anything but a small signal condition, and for sure is more constant voltage and not a constant current case

Also i can add a series resistor representing the dc resistance of the filter inductors (f.i. 0.5 ohm), which can have an impact.

Outside of that region it is in my experience insignificant.

But indeed the signal is not very strong, but with stepped sine it is quite good actually. Time consuming though compared to periodic pink noise ;-)

My take:

With the 0.1(35) ohm i measure like purifi does. So my results can be compared with theirs. They keep a record of each driver, quite assuring. My experience with other manufacturers in the past was quite horrible in that respect.

The other main advantage is i measure the behaviour under normal operating condition.

Especially for the bass region. Which is anything but a small signal condition, and for sure is more constant voltage and not a constant current case

Also i can add a series resistor representing the dc resistance of the filter inductors (f.i. 0.5 ohm), which can have an impact.

Outside of that region it is in my experience insignificant.

But indeed the signal is not very strong, but with stepped sine it is quite good actually. Time consuming though compared to periodic pink noise ;-)

The 0.135 Ohm by the way is outcome of calibration iteration process with a 6.9 Ohm resistor as a dut.

It is thus what arta-limp sees as Rsense!

It is thus what arta-limp sees as Rsense!

PTT4.0M04-NAC03 driver is a midrange right?

As you don't care about low end extension or bass tuning, just put it in a several liters and you're done!

As you don't care about low end extension or bass tuning, just put it in a several liters and you're done!

The PTT4.0M04-NAC04 is indeed a midrange, but a fs of 48Hz. Means it is critical in cabinet volume and the damping i apply. Not only for the in box fs of ~90- 100Hz, also for the cabinet modes which are all in the midrange region.

Too large a cabinet volume will lead to overdamping.

Too large a cabinet volume will lead to overdamping.

Been some time since last post here. Mainly occupied with my work and private matters. In between in process of finding proper sealed box volume for the PTT4.0M04 which is around 1.0 L as also indicated by Purifi and by enclosure tool of Vituixcad. Given the small size and the enclosure construction og the GAYA boxes i am designing the option of magnet support including isolation of basket mount to baffle.

Also experimented with measuring panel resonances and use of constrained layer damping in panels. CLD for sure helps, but not enough, the bending mode suppression needs damping acting normal to the panel. So some form of bracing is needed with damping like f.i. KEF is using.

When i have more time i will compile measurements to present here.

Also experimented with measuring panel resonances and use of constrained layer damping in panels. CLD for sure helps, but not enough, the bending mode suppression needs damping acting normal to the panel. So some form of bracing is needed with damping like f.i. KEF is using.

When i have more time i will compile measurements to present here.

Been working lately intermittendly on my project. First the bass-unit.

The cabinet panel resonances of the testbox i delt with by glueing an extra layer of MDF on the sides and top and bottom. The rear panel was already stiffened by braces.

So what remains mostly is the modes , and that should be dealt with with the wool.

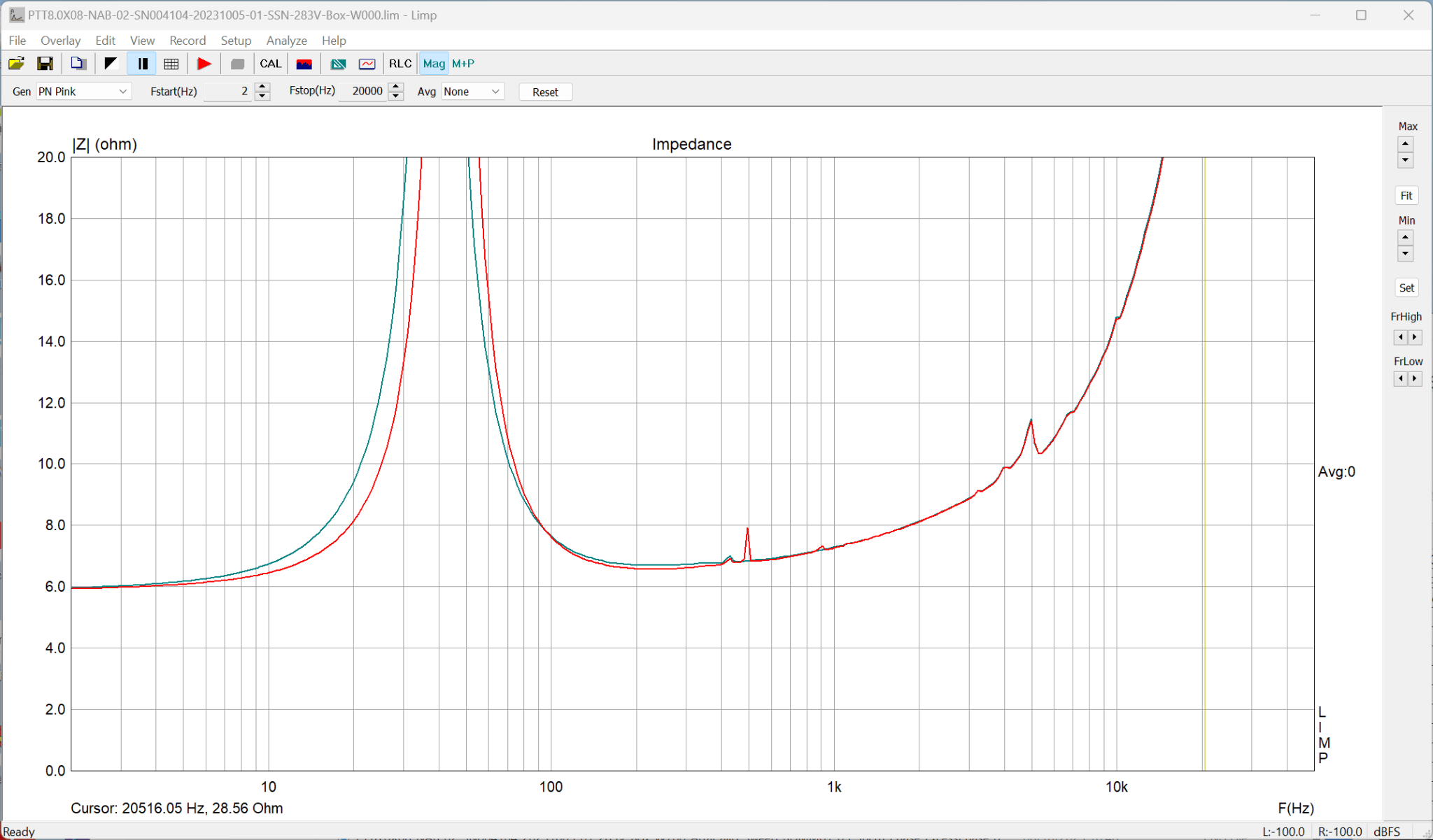

Impedance mesurement, in stiffened testbox with no wool (W000 - Red curve) and with 700gr wool (W700 - grey/blue curve)):

The internal modes show up in the red W000 curve, but no longer in the W700 curve. Except for something at ~ 420hz, possibly the spider resonance?

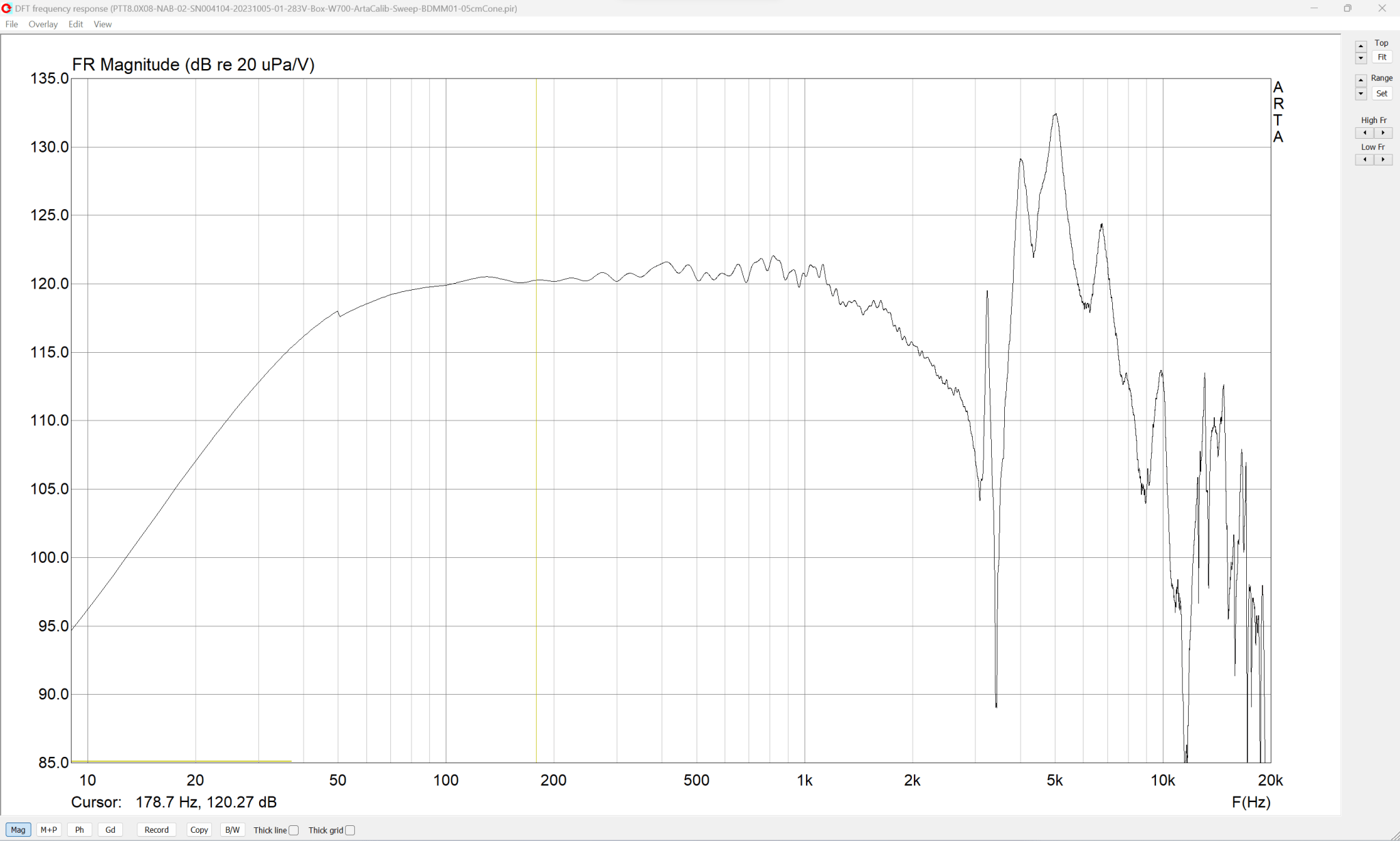

The frequency response is also as expected.

With mic close to mid-point of dome:

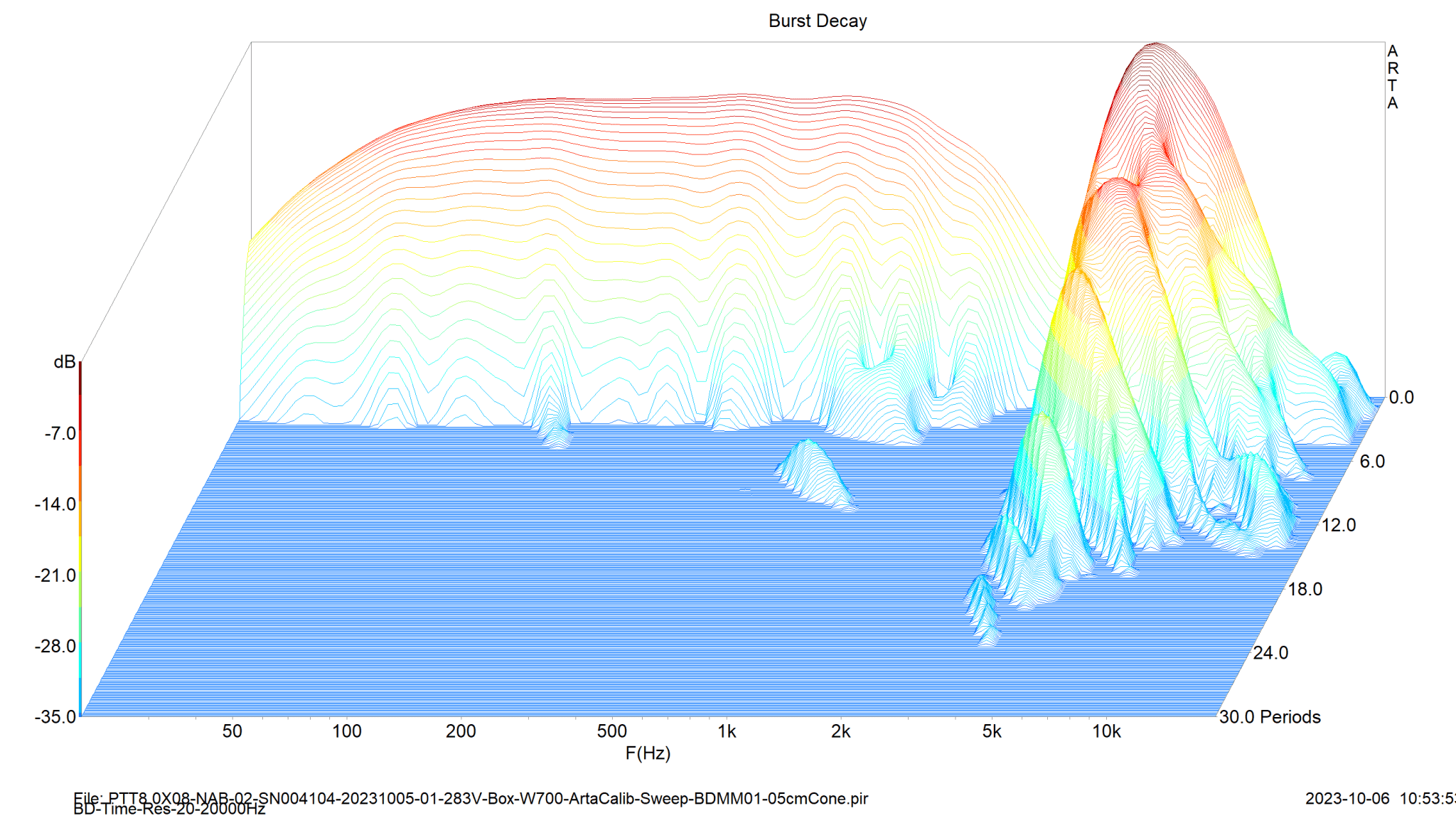

The Burst Decay also looks ok to me:

Note the response measurements were done in a small and furnished room, so quite some reflections.

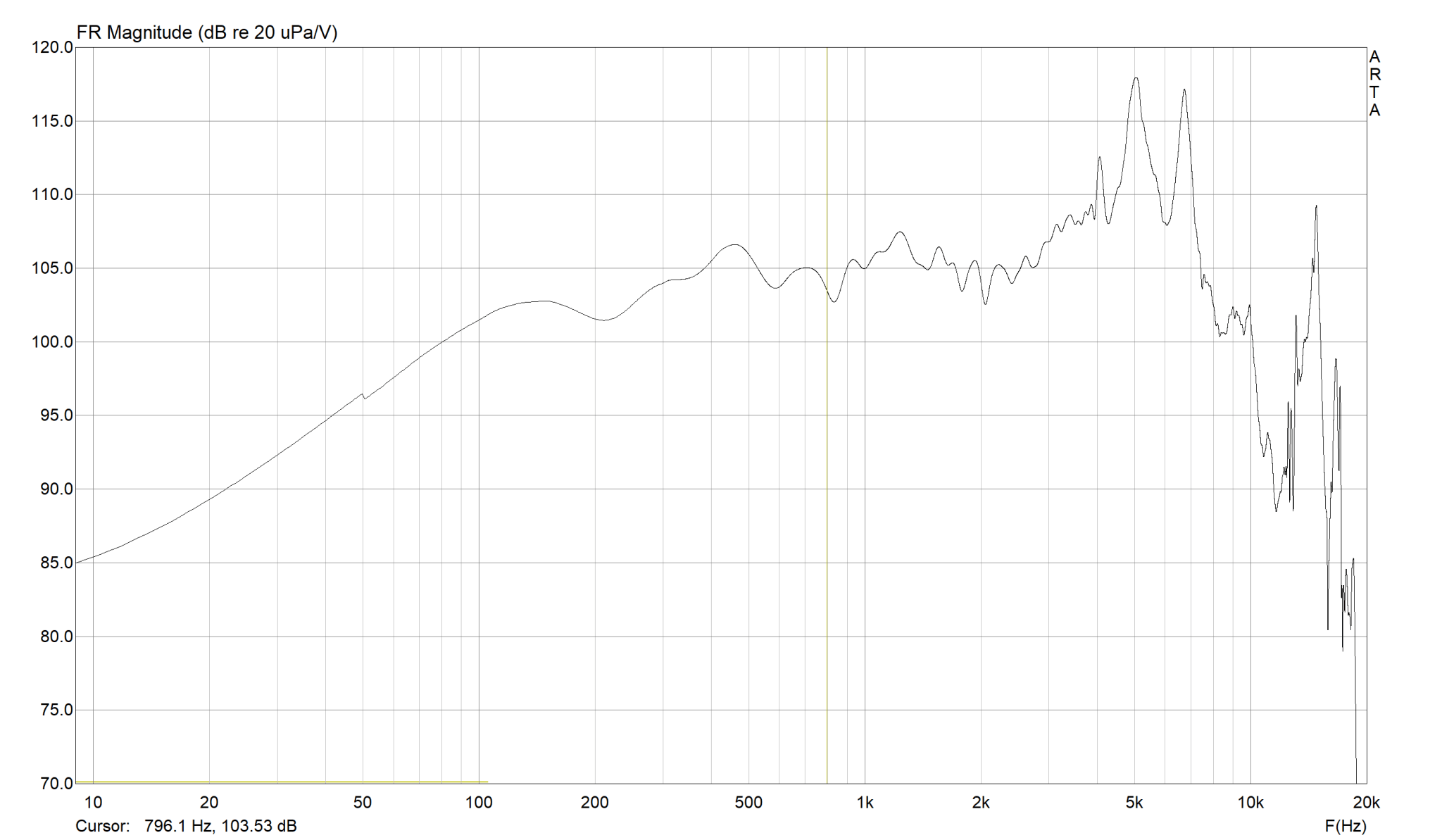

But at 30cm from baffle it is still doable:

It shows a rather flat mid region and an strong breakup effect above 2 kHz, as expected from the Purifi datasheets.

Listening to it off-axis with music shows a clear and engaging sound, i am happy.

The midranges (PTT4.0M04-NAC04) unfortunately had to be returned as they developed a ticking sound, with low frequencies (20-70Hz) clearly audible and turned out to be a batch problem in one of the glueing joints. So replaced under RMA , and the new ones are mechanically silent ;-)

Now testing the box volume and wool content after a few hours of break-in.

Thusfar indeed about 1L volume needed.

As a sidenote: Still struggling with Arta to get a calibration with correct SPL levels, it measures too high for given voltage on speaker (2,83Vrms) so working on that now.

To be continued

The cabinet panel resonances of the testbox i delt with by glueing an extra layer of MDF on the sides and top and bottom. The rear panel was already stiffened by braces.

So what remains mostly is the modes , and that should be dealt with with the wool.

Impedance mesurement, in stiffened testbox with no wool (W000 - Red curve) and with 700gr wool (W700 - grey/blue curve)):

The internal modes show up in the red W000 curve, but no longer in the W700 curve. Except for something at ~ 420hz, possibly the spider resonance?

The frequency response is also as expected.

With mic close to mid-point of dome:

The Burst Decay also looks ok to me:

Note the response measurements were done in a small and furnished room, so quite some reflections.

But at 30cm from baffle it is still doable:

It shows a rather flat mid region and an strong breakup effect above 2 kHz, as expected from the Purifi datasheets.

Listening to it off-axis with music shows a clear and engaging sound, i am happy.

The midranges (PTT4.0M04-NAC04) unfortunately had to be returned as they developed a ticking sound, with low frequencies (20-70Hz) clearly audible and turned out to be a batch problem in one of the glueing joints. So replaced under RMA , and the new ones are mechanically silent ;-)

Now testing the box volume and wool content after a few hours of break-in.

Thusfar indeed about 1L volume needed.

As a sidenote: Still struggling with Arta to get a calibration with correct SPL levels, it measures too high for given voltage on speaker (2,83Vrms) so working on that now.

To be continued

Been quiet a while .

My fine art printing business end of year peak is a main reason not being able to do the actions i planned.

In spare moments i focused on stable, reproducable distortion measurments with Arta. Should have read the manual more carefully (used to call this RTFM).

Ran into limited low end of frequency response, i understand now why. So redo needed, focus is on effect of the wool filling on cavity mode reductions and impact on non-linear distortions in the bass region.

Also after some contemplation decided to follow @hifijim approach for hybrid active-passive. Purchased purifi eval1 based amp for use for the bass speakers, so i can focus on the midrange and tweeter as that part also requires carefull shaping of baffle to control the diffraction impact.

Want to get it in a final and enjoyful state beginning of spring.

Best wishes for Xmas and New Year.

My fine art printing business end of year peak is a main reason not being able to do the actions i planned.

In spare moments i focused on stable, reproducable distortion measurments with Arta. Should have read the manual more carefully (used to call this RTFM).

Ran into limited low end of frequency response, i understand now why. So redo needed, focus is on effect of the wool filling on cavity mode reductions and impact on non-linear distortions in the bass region.

Also after some contemplation decided to follow @hifijim approach for hybrid active-passive. Purchased purifi eval1 based amp for use for the bass speakers, so i can focus on the midrange and tweeter as that part also requires carefull shaping of baffle to control the diffraction impact.

Want to get it in a final and enjoyful state beginning of spring.

Best wishes for Xmas and New Year.

A new year, with more time to spend on purification of my GAYA2's ;-)

A quick and brief recap: The challenge is not so much the woofers aka bass, it is the midrange tweeter baffle shape. The main enclosure shape is a given, so room to play is pretty limited, nice challenge. The deadline is Spring 2024. Balancing time vs cost made me decide for a hybrid active concept. The purifi eval1 amp parts arrived and will be assembled and tested this week.

The past week i had some more time ;-)

So i started making a foam replication of the GAYA2 cabinetshape as a platform for the M-T baffle shape testing. Also modeled the cabinet platform in Fusion 360, and did a first mesh in F360 to see if it would give issues. The goal is to simulate baffle shapes to find the best fitting compromise, simulation without real-world correlations has little meaning, so a foam replica is made (the originals weigh ~ 75-80kilo a piece).

In the foam replica the small midrange testbox will be fitted, so i can test acoustically.

My wife and i are also rearranging our house, as "collateral damage" i will have a room avilable of 5.3x3x2.45 m size, great for testing ;-)

Joerg Panzer of RandDTeam.de just (as writing this post) granted me a student license for AKABAK, great, thanks Joerg!

@augerpro pointed me to posts in DIYAudio for some support in using BEM simulation, thanks !

Some pictures:

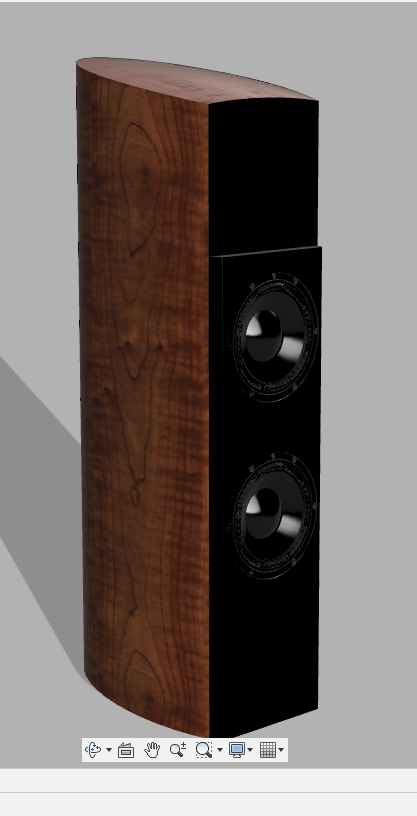

A rendering of my GAYA2 platform with Purifi PTT8 woofers:

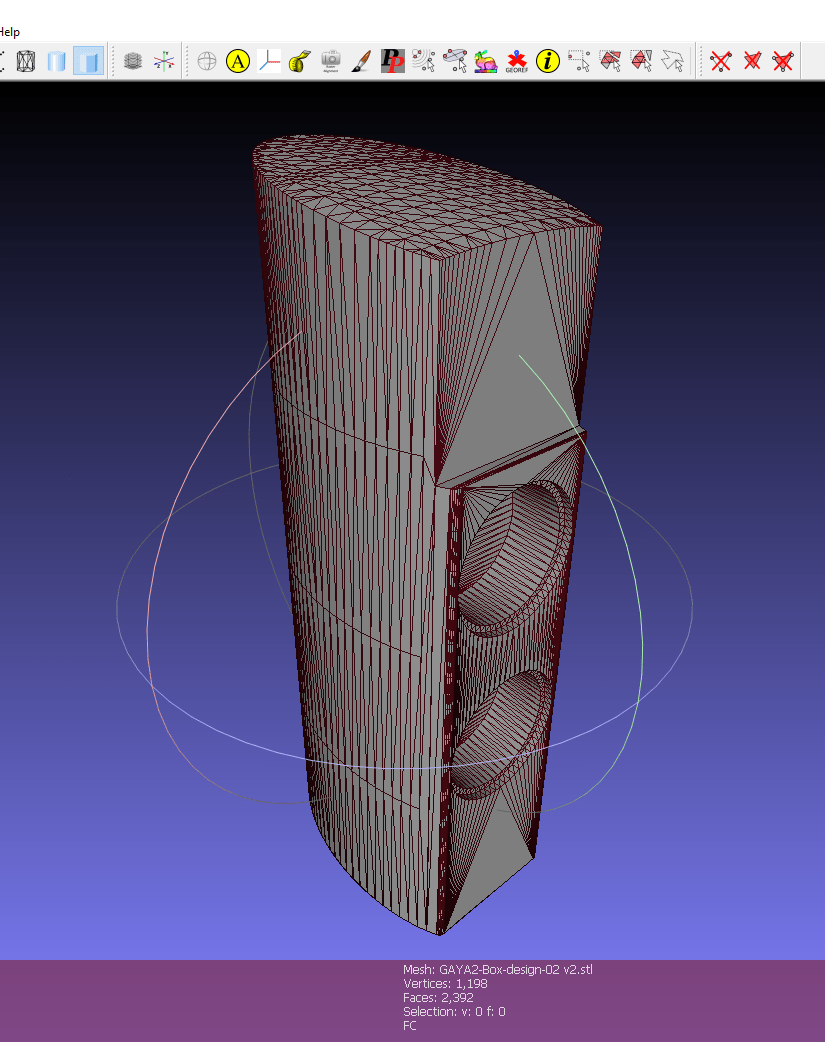

Just the outside, meshed with F360:

The testcabinets for PTT8 and PTT4 and the foam replica under development stacked away to make room for overnight guests:

Now comes the difficult part, learning curve AKABAK for BEM simulation ;-)

A quick and brief recap: The challenge is not so much the woofers aka bass, it is the midrange tweeter baffle shape. The main enclosure shape is a given, so room to play is pretty limited, nice challenge. The deadline is Spring 2024. Balancing time vs cost made me decide for a hybrid active concept. The purifi eval1 amp parts arrived and will be assembled and tested this week.

The past week i had some more time ;-)

So i started making a foam replication of the GAYA2 cabinetshape as a platform for the M-T baffle shape testing. Also modeled the cabinet platform in Fusion 360, and did a first mesh in F360 to see if it would give issues. The goal is to simulate baffle shapes to find the best fitting compromise, simulation without real-world correlations has little meaning, so a foam replica is made (the originals weigh ~ 75-80kilo a piece).

In the foam replica the small midrange testbox will be fitted, so i can test acoustically.

My wife and i are also rearranging our house, as "collateral damage" i will have a room avilable of 5.3x3x2.45 m size, great for testing ;-)

Joerg Panzer of RandDTeam.de just (as writing this post) granted me a student license for AKABAK, great, thanks Joerg!

@augerpro pointed me to posts in DIYAudio for some support in using BEM simulation, thanks !

Some pictures:

A rendering of my GAYA2 platform with Purifi PTT8 woofers:

Just the outside, meshed with F360:

The testcabinets for PTT8 and PTT4 and the foam replica under development stacked away to make room for overnight guests:

Now comes the difficult part, learning curve AKABAK for BEM simulation ;-)

Start by using whatever symmetry you can to split the model up, export it to STEP and use GMSH to mesh it, exporting the .msh at version 2 for use with AKABAK.Now comes the difficult part, learning curve AKABAK for BEM simulation ;-)

Yes only the outside surface for exterior radiation problems. You can mesh the solid and only select the tagged faces for the outside in AKABAK or create a copy of your model and split the solid into surface faces then mesh that.

If it is only the mid you are looking at you might want to make a cut down model that you can use quarter symmetry with. Otherwise the solving time gets quite long or the resolution has to be low.

If it is only the mid you are looking at you might want to make a cut down model that you can use quarter symmetry with. Otherwise the solving time gets quite long or the resolution has to be low.

The baffle for midrange and tweeter is pretty assymetric in vertical direction. So i will half the cabinet vertically. I use a 12 core pc with 128gb of mem and ssd drives. Even still if it takes some time, it will be less than modeling physically by hand the baffle shapes to test.

Working to get fusion 360 to give me the shape of the baffle as i want it. Bit hard, in the past i went through all generations of 3D mondeling tools of Intergraph, modeling from bottles to ships to aircraft parts. But even then i was unable to get to grips the same way with Autocad, same with fusion 360 ;-(

Anyhow i will get there.

In the mean time studying the video's on the akabak site.

Expect to load a first model into Akabak this weekend.

Working to get fusion 360 to give me the shape of the baffle as i want it. Bit hard, in the past i went through all generations of 3D mondeling tools of Intergraph, modeling from bottles to ships to aircraft parts. But even then i was unable to get to grips the same way with Autocad, same with fusion 360 ;-(

Anyhow i will get there.

In the mean time studying the video's on the akabak site.

Expect to load a first model into Akabak this weekend.

Making a good mesh that solves well can be quite tricky. One of the real benefits of Ath is that it is hard to make a truly bad mesh with it.

Starting small in quarter symmetry is a good way to cut your teeth. I know what I am doing and I almost never make full half symmetry models of large baffles at high frequencies because of the number of elements it takes. Full baffles for low frequency drivers is no problem because at lower frequencies the mesh can be that much coarser and still give a good result. At mid to high frequencies this changes quickly. The solving time becomes exponentially longer as the element number increases.

If you have a sketch of the baffle you want I can try and help you model it in Fusion.

Starting small in quarter symmetry is a good way to cut your teeth. I know what I am doing and I almost never make full half symmetry models of large baffles at high frequencies because of the number of elements it takes. Full baffles for low frequency drivers is no problem because at lower frequencies the mesh can be that much coarser and still give a good result. At mid to high frequencies this changes quickly. The solving time becomes exponentially longer as the element number increases.

If you have a sketch of the baffle you want I can try and help you model it in Fusion.

- Home

- Loudspeakers

- Multi-Way

- GAYA2-Final, finishing the unfinished after 15 years