As do I, about 2.1 to 2.2 litre per driver, almost fully stuffed.

This needs a Linkwitz transform to play bass. Or better yet FIR filters.

This needs a Linkwitz transform to play bass. Or better yet FIR filters.

Thanks for the input Fluid, Halair, and Wesayso!

My mind is blown. I've always used WinISD and always thought that Qtc can never go below Qts. I've believed this for YEARS. Looks like I'm going to have to buy BassBoxx Pro...

And no worries, I'm planning on buying a MiniDSP. I'm just undecided on going the no-bar-holds Wesayso route and learn everything possible about DSP, or just use DIRAC Live for quick and easy results, lol.

My mind is blown. I've always used WinISD and always thought that Qtc can never go below Qts. I've believed this for YEARS. Looks like I'm going to have to buy BassBoxx Pro...

And no worries, I'm planning on buying a MiniDSP. I'm just undecided on going the no-bar-holds Wesayso route and learn everything possible about DSP, or just use DIRAC Live for quick and easy results, lol.

Last edited:

More routing today

The hardwood bases are the right shape and have a little chamfer added

The window braces have had roundover's put on to reduce any chance of creating small resonators!

The hardwood bases are the right shape and have a little chamfer added

The window braces have had roundover's put on to reduce any chance of creating small resonators!

Attachments

A heavy rainstorm prevented much being done today, I managed to complete a strange task which was to file the threaded inserts I have for the bases to the same size, some of them were almost 1.5mm bigger than the other's. I wondered why the wood had seemed to lift on some corners when the nuts were flush, now I know why.

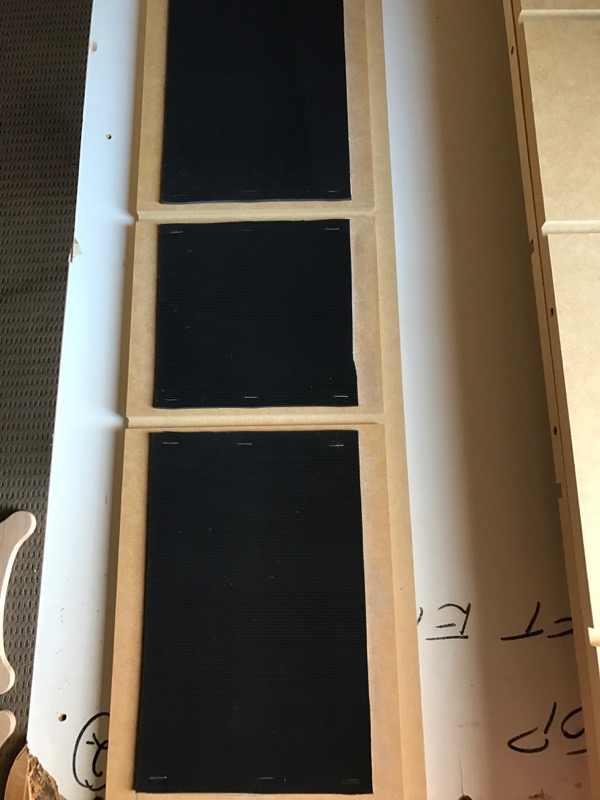

The rubber sections have been glued and stapled to the sides. I had forgotten how much I hate using a caulking gun and I seemed to get a few hit and miss staples but in the end it is all done. Not the prettiest work ever but they won't be coming off any time soon.

The bases have been finish sanded to 400 grit and are ready for a finish to be applied.

I have tested using a Tung oil mixture Feast Watson 'Floorseal Oil'. When wiped on it leaves a very nice finish, leaves a slightly darker finish than bare wood be doesn't darken it too much either. The oil really highlights the figure in the timber. Not too easy to see on a small test piece in photos.

The bases have been finish sanded to 400 grit and are ready for a finish to be applied.

I have tested using a Tung oil mixture Feast Watson 'Floorseal Oil'. When wiped on it leaves a very nice finish, leaves a slightly darker finish than bare wood be doesn't darken it too much either. The oil really highlights the figure in the timber. Not too easy to see on a small test piece in photos.

Attachments

It won't be too long now before I need to start cutting the fibreglass stuffing.

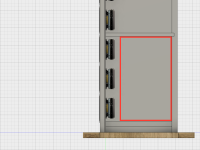

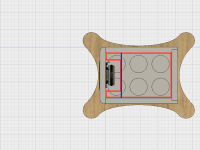

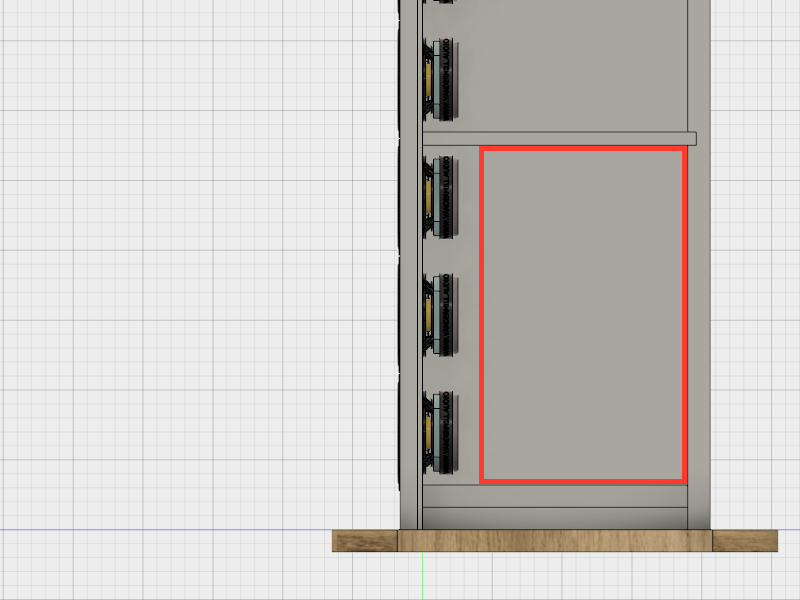

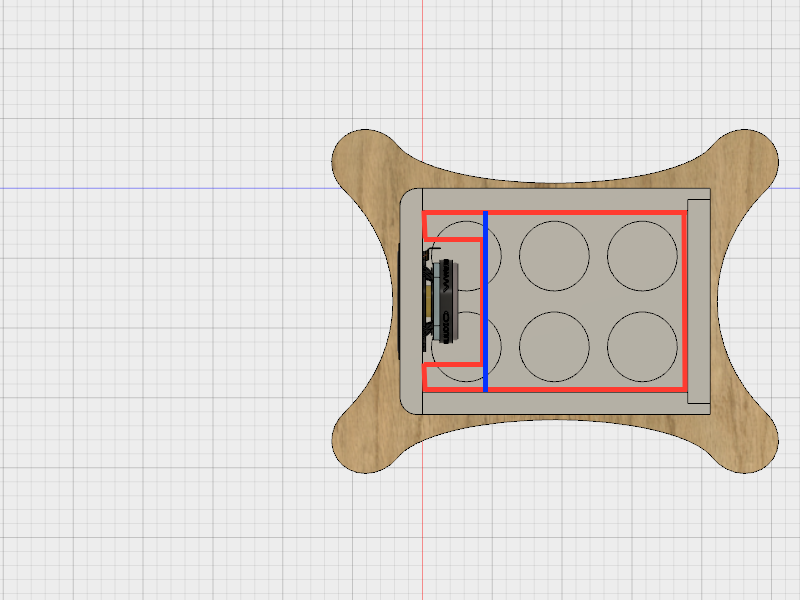

I asked some questions over on the Twin Towers thread but I am still unsure just how close to the rear of the driver I want the stuffing to be. I am still undecided if using some to either side drivers to go right up to the baffle is a good idea. Like the red line in this image or to just cut off at the blue line.

Any experience or opinions would be welcome 🙂

I asked some questions over on the Twin Towers thread but I am still unsure just how close to the rear of the driver I want the stuffing to be. I am still undecided if using some to either side drivers to go right up to the baffle is a good idea. Like the red line in this image or to just cut off at the blue line.

Any experience or opinions would be welcome 🙂

Attachments

At the side of the drivers I only used wool felt. The distance looks fine to me this way.

It looks like you could place it out into those corners. Are you planning to put something between the fiberglass and the back of the drivers? Just to prevent the driver from sucking in loose fibres trough it's vent.

Can you build a test box holding one driver? Some impedance tests could tell you a lot! It doesn't need to be pretty, just the same size 😉.

It looks like you could place it out into those corners. Are you planning to put something between the fiberglass and the back of the drivers? Just to prevent the driver from sucking in loose fibres trough it's vent.

Can you build a test box holding one driver? Some impedance tests could tell you a lot! It doesn't need to be pretty, just the same size 😉.

At the side of the drivers I only used wool felt. The distance looks fine to me this way.

It looks like you could place it out into those corners. Are you planning to put something between the fiberglass and the back of the drivers? Just to prevent the driver from sucking in loose fibres trough it's vent.

Thanks for the response, I was going to use some acrylic damping material (that I have plenty of) to create a barrier between the fibreglass and the drivers. Perhaps I can create a shallow U shape and fill in the sides with the acrylic and cover the fibreglass at the same time. When I have a basic enclosure glued together I can test to see how it moulds and if it will stay in place.

I could and I have considered it more than once! The thing against it at the moment is where and how I would have to make it.Can you build a test box holding one driver? Some impedance tests could tell you a lot! It doesn't need to be pretty, just the same size 😉.

I don't have that many choices in terms of damping as I only have the fibreglass and acrylic so I have been weighing up whether it is worth the effort. Maybe I need to get a roll of that thin underfelt I found and build a test box... or just go with what I've got 😉

Perhaps I can create a shallow U shape and fill in the sides with the acrylic and cover the fibreglass at the same time.

Well I think I can already discount that idea as the damping material is too thick to fit nicely in the side gap without almost touching the magnet.

If I cut it in half then it fits much better.

I am thinking that getting the thin felt might actually work well because then I can use it to press everything down into place a bit like wesayso did. Except mine will be in two or three drivers groups due to my bracing structure and the felt will be thinner.

Attachments

fluid,

Check for wool underlay for carpets - 6mm-12mm should work, something like the item listed below:

https://www.amazon.co.uk/d/DIY-Tools/Wilson-Underlays-12mm-Thick-Insulation/B00EZMY0LE/

Check for wool underlay for carpets - 6mm-12mm should work, something like the item listed below:

https://www.amazon.co.uk/d/DIY-Tools/Wilson-Underlays-12mm-Thick-Insulation/B00EZMY0LE/

Last edited:

fluid,

Check for wool underlay for carpets - 6mm-12mm should work, something like the item listed below:

https://www.amazon.co.uk/d/DIY-Tools/Wilson-Underlays-12mm-Thick-Insulation/B00EZMY0LE/

Thanks for the idea but unfortunately there is nothing like that available where I am and the cost of postage makes bulky items expensive. The closest I have found is automotive felt underlay that is much thinner.

If I still lived in the UK I wouldn't have this problem, but I'm not going back just to get carpet underlay 😉

I am going to a bigger town next week so maybe I will hit up the carpet shops to see what kind of underlay they have 🙂

Edit: Called them and they only have foam, maybe I can go to the removalists and see if they will sell or give me one of their felt blankets 🙂

Last edited:

If I still lived in the UK I wouldn't have this problem, but I'm not going back just to get carpet underlay 😉

LOL!

Edit: Called them and they only have foam

Yes, this trend is quite alarming... even here most carpet places have gone to selling rubber/foam type underlays only. It's very tough to source jute felt at my place nowadays.

Thanks for the idea but unfortunately there is nothing like that available where I am and the cost of postage makes bulky items expensive. The closest I have found is automotive felt underlay that is much thinner.

If I still lived in the UK I wouldn't have this problem, but I'm not going back just to get carpet underlay 😉

I am going to a bigger town next week so maybe I will hit up the carpet shops to see what kind of underlay they have 🙂

Edit: Called them and they only have foam, maybe I can go to the removalists and see if they will sell or give me one of their felt blankets 🙂

Check out daleys.com.au

They have a WA branch. Truly, an Aladin's cave of stuff for speaker-builders.

Doug

Be careful with fiberglass. It is hazardous...

Will do 😉

More clamps! Nice project

Thanks! Only the two pieces on the ends are being glued so I would have struggled to fit more clamps in!

Thanks for the thought, the tricky part is finding an auto/marine store, I should have thought to look harder when I was in Perth in January but I had decided against it at that point. I asked when I was at the felt dealer about their bulk remolvalist felt but they would only sell a large amount which was too costly.You may find wool felt in auto/marine part shops as it is used to sound dampening.

Still 1200km from me though 😉 I will check it out the next time I am in Perth.Check out daleys.com.au

They have a WA branch. Truly, an Aladin's cave of stuff for speaker-builders.

Doug

I wish I found this thread earlier. I jumped on the same sale at PE for the TC9. Saw it in my email and I got them to go down to $10.50 from their $11 sale price. I am young so I devoted a lot of time in 2-3 weeks to build them. I guarantee you will enjoy them when you are done! (Don't know how to post pics from my phone.. will later)

I could and I have considered it more than once! The thing against it at the moment is where and how I would have to make it.

I don't have that many choices in terms of damping as I only have the fibreglass and acrylic so I have been weighing up whether it is worth the effort. Maybe I need to get a roll of that thin underfelt I found and build a test box... or just go with what I've got 😉

Don't assume, measure... 😀

It's way easier to find a recipe with a single speaker box and repeat that than having regrets later on.

- Home

- Loudspeakers

- Full Range

- Full Range TC9 Line Array CNC Cabinet