Yay! Huge milestone! Well done.

Thanks! I had just been reading the two towers thread again where someone asked if the towers stood up by themselves without support. I thought I needed to check before I went any further 😀

Quite a while ago I ran poor man's spikes. Basically round top nuts that were resting on the floor. That didn't provide me the peace of mind I needed. When I replaced them with industrial type damping feet the arrays became a lot more stable.

My front foot rests are spaced 270 mm apart, just a FYI. The back ones are a little closer together to be able to place one of the arrays closer to the chimney.

My front foot rests are spaced 270 mm apart, just a FYI. The back ones are a little closer together to be able to place one of the arrays closer to the chimney.

Quite a while ago I ran poor man's spikes. Basically round top nuts that were resting on the floor. That didn't provide me the peace of mind I needed. When I replaced them with industrial type damping feet the arrays became a lot more stable

My front foot rests are spaced 270 mm apart, just a FYI. The back ones are a little closer together to be able to place one of the arrays closer to the chimney.

Always good to know more information. My base has the spikes about 205mm apart in width and 270mm apart front to back.

In the first instance the arrays will be used on carpet and the spikes do a good job of holding them in place while cutting through to the concrete for support. I also have the metal pads to rest the spikes in for solid floors which is probably what will be used for the long term if they prove stable enough.

I can always recut the hardwood bases to make them wider if needed.

The threaded inserts are also a standard 6mm internal thread so it would be easy to use similar feet to yours in the future.

Aesthetically speaking I'm liking the spikes with the wood 😉

I've used a piece of damping material that I have that is like MLV but with a fabric backing (also used used to fill in the 2mm gap left in the back dados) between the cabinet and base.

Attachments

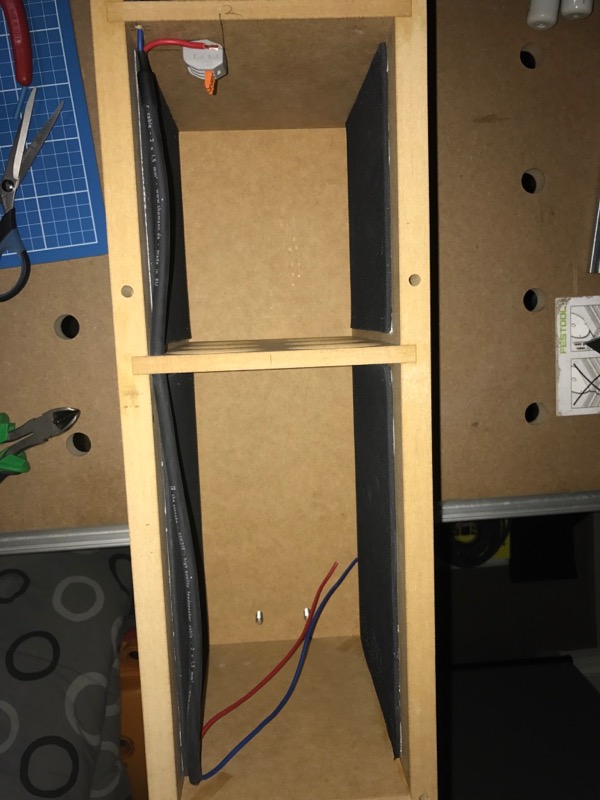

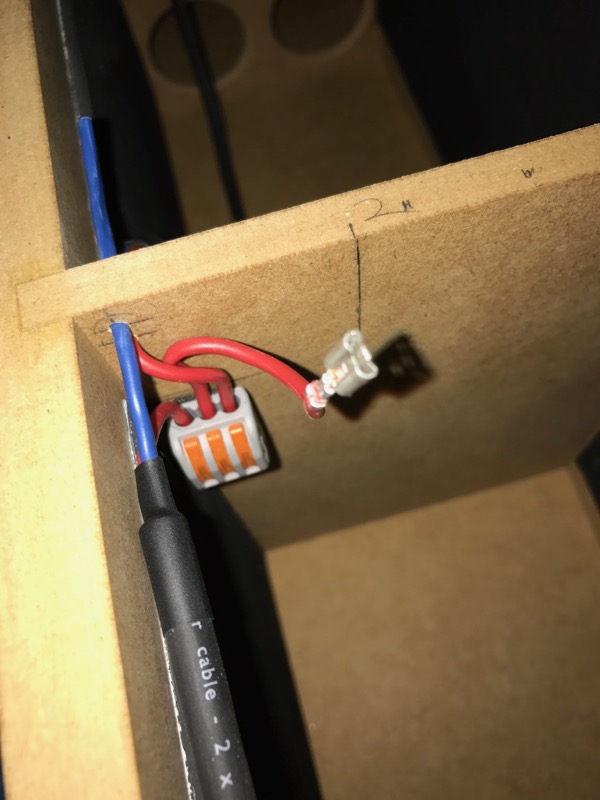

Started preparing the wiring. I have drilled some holes through the braces to help keep the wiring in place, I will use some of the silicone glue to secure it properly when it is ready to be closed up.

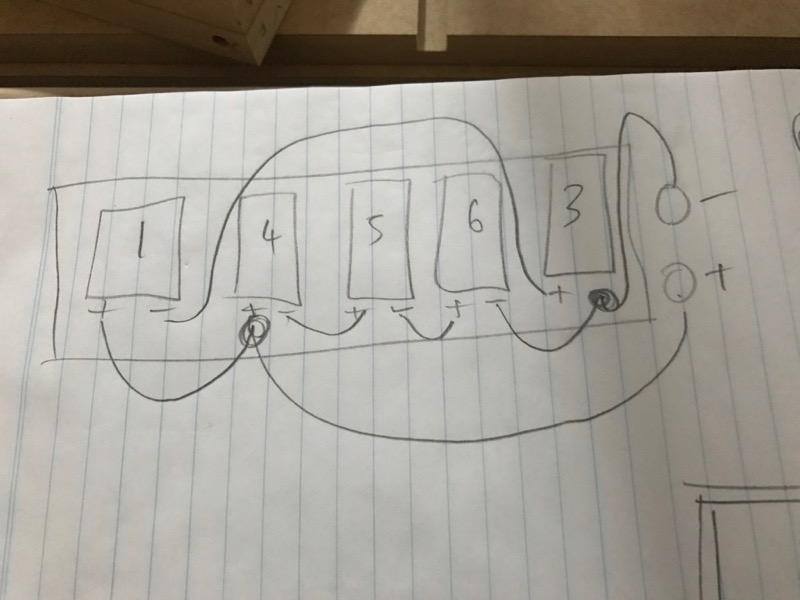

Wiring scheme for the test drivers to get 9.6 Ohms.

I decided to just buy some of the underfelt I found on ebay, at least then I will have something different to test 🙂

Wiring scheme for the test drivers to get 9.6 Ohms.

I decided to just buy some of the underfelt I found on ebay, at least then I will have something different to test 🙂

Attachments

Last edited:

fluid,

Just fyi, another option (similar size and price) for underlay in Australia on eBay:

UNDERLAY TO SUIT MOULDED CAR CARPET FRONT AND REAR | eBay

Look forward to your updates when the stuff comes. 🙂

Just fyi, another option (similar size and price) for underlay in Australia on eBay:

UNDERLAY TO SUIT MOULDED CAR CARPET FRONT AND REAR | eBay

Look forward to your updates when the stuff comes. 🙂

That is a good example of why I find it difficult to get to me at a reasonable price. The cost of the carpet is the same and they are the same size but the postage has gone from $12.95 to $56. Probably free shipping if you are in Melbourne.

When you multiply it by every item you need for a build like this checking the shipping costs becomes the first thing you do!

When you multiply it by every item you need for a build like this checking the shipping costs becomes the first thing you do!

An internal shot of the wiring test, I moved the terminal block to be further away from the driver. Chamfering the back of the driver hole helps to leave room for the terminals.

The chamfering has left a small gap where they overlapped. A little bit of sealant might be needed after the glue up to keep the 5 sections totally separate.

I have made a temporary gasket to allow me to use the actual cabinet as a test box.

The chamfering has left a small gap where they overlapped. A little bit of sealant might be needed after the glue up to keep the 5 sections totally separate.

I have made a temporary gasket to allow me to use the actual cabinet as a test box.

Attachments

Do you plan to fill in the gap created by the chamfer? Where did you get the "terminal block" from?

Do you plan to fill in the gap created by the chamfer? Where did you get the "terminal block" from?

Yes I do at least on the sections that are meant to be separate

A little bit of sealant might be needed after the glue up to keep the 5 sections totally separate.

The terminal blocks were bought from china on ebay, search 'terminal block lever' you will find lots 🙂

I put some information about them earlier

http://www.diyaudio.com/forums/full-range/303417-full-range-tc9-line-array-cnc-cabinet-2.html#post4980682

Solid progress on what appear to be a good quality tower.. I think you will like how they sound... 😀

Looking good!!! I've been following your build. They should have good solid impact with all those drivers.

I hope so, enough others have gone before for me to follow 😀 My progress is similar to yours in that I need to fit it in where I can and when I get a whole day to go at a lot can be done. I have tried to get as much ready for the second tower at the same time as I can. Have you ever done more processing with your towers, the graphs in your thread stopped after you seemed to get a reasonable response?Solid progress on what appear to be a good quality tower.. I think you will like how they sound... 😀

Thanks! The line array concept is intriguing so I wanted to find out if it would work for meLooking good!!! I've been following your build. They should have good solid impact with all those drivers.

I have finished the wiring for the 5 speaker test setup. Hard to measure voice coil resistance with a standard multimeter, but I get a figure around 6.6 ohms on my meter which when wired as before should give 7.92 ohms and I measure about 7.9 so I am happy that it works.

Attachments

Now I know what people must have felt like waiting for me to finish my long journey 🙂

You have no idea!

Now I know what people must have felt like waiting for me to finish my long journey 🙂

It's only been 2 months since I started posting information, I thought I was doing OK..... seems like I need to step it up 😉

Even though the current testing phase is mostly due to your prompting 🙂

Once these are built it is going to take much longer to get them measured and EQ'd inside due to family restrictions, I apologise in advance to anyone waiting for that 😱

...it is going to take much longer to get them measured and EQ'd inside due to family restrictions, I apologise in advance to anyone waiting for that 😱

We hear you! At least, God bless her, she let you get this far!

Ha Ha, I had a table saw and router table where the dining table should have been for 6 months in another house so the arrays are nothing to her 😱We hear you! At least, God bless her, she let you get this far!

When we get to move into our own home in the near future then things like that probably won't go down so well. One of the reasons I am building these to be unobtrusive 🙂

- Home

- Loudspeakers

- Full Range

- Full Range TC9 Line Array CNC Cabinet