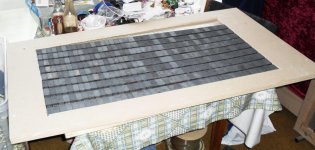

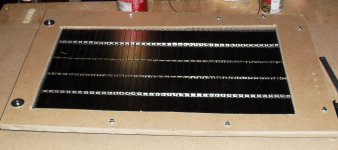

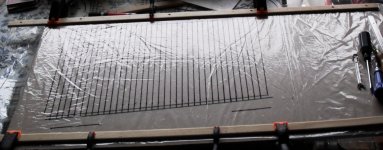

these are my latest rebuilds.

I have decided not to build any more push pull designs, because it is not worth the extra magnets or weight. I will just be rebuilding my old designs, using 23 micron mylar A polyester in the future.

I have decided not to build any more push pull designs, because it is not worth the extra magnets or weight. I will just be rebuilding my old designs, using 23 micron mylar A polyester in the future.

Attachments

Some more pictures for all those asking.

Afew more pictures showing neo and ferrite designs over the last 20 years.😎

Afew more pictures showing neo and ferrite designs over the last 20 years.😎

Attachments

-

SAM_0519.JPG224.2 KB · Views: 206

SAM_0519.JPG224.2 KB · Views: 206 -

SAM_0518.JPG249 KB · Views: 230

SAM_0518.JPG249 KB · Views: 230 -

SAM_0517.jpg508.1 KB · Views: 984

SAM_0517.jpg508.1 KB · Views: 984 -

SAM_0523.JPG399.3 KB · Views: 268

SAM_0523.JPG399.3 KB · Views: 268 -

SAM_0522.JPG191.1 KB · Views: 264

SAM_0522.JPG191.1 KB · Views: 264 -

SAM_0525.JPG210.6 KB · Views: 211

SAM_0525.JPG210.6 KB · Views: 211 -

SAM_0539.jpg489 KB · Views: 424

SAM_0539.jpg489 KB · Views: 424 -

SAM_0531.JPG819.5 KB · Views: 378

SAM_0531.JPG819.5 KB · Views: 378 -

SAM_0526.JPG242.2 KB · Views: 214

SAM_0526.JPG242.2 KB · Views: 214 -

SAM_0540.JPG292.6 KB · Views: 348

SAM_0540.JPG292.6 KB · Views: 348

DITTO

Even more pictures for your perusal.😎

Even more pictures for your perusal.😎

Attachments

-

SAM_0541.jpg490.8 KB · Views: 257

SAM_0541.jpg490.8 KB · Views: 257 -

SAM_0542.JPG255 KB · Views: 140

SAM_0542.JPG255 KB · Views: 140 -

SAM_0547.JPG182.9 KB · Views: 166

SAM_0547.JPG182.9 KB · Views: 166 -

SAM_0545.JPG553.2 KB · Views: 154

SAM_0545.JPG553.2 KB · Views: 154 -

SAM_0544.JPG622 KB · Views: 133

SAM_0544.JPG622 KB · Views: 133 -

SAM_0549.JPG133.7 KB · Views: 133

SAM_0549.JPG133.7 KB · Views: 133 -

SAM_0550.JPG146.1 KB · Views: 138

SAM_0550.JPG146.1 KB · Views: 138 -

SAM_0551.JPG220.9 KB · Views: 142

SAM_0551.JPG220.9 KB · Views: 142 -

SAM_0558.JPG875.5 KB · Views: 269

SAM_0558.JPG875.5 KB · Views: 269 -

SAM_0560.jpg520.3 KB · Views: 153

SAM_0560.jpg520.3 KB · Views: 153

Same again

Even more for you.😱

Even more for you.😱

Attachments

-

SAM_0562.JPG268.4 KB · Views: 315

SAM_0562.JPG268.4 KB · Views: 315 -

SAM_0563.JPG569.3 KB · Views: 245

SAM_0563.JPG569.3 KB · Views: 245 -

SAM_0564.JPG211.5 KB · Views: 180

SAM_0564.JPG211.5 KB · Views: 180 -

SAM_0567.JPG954.6 KB · Views: 220

SAM_0567.JPG954.6 KB · Views: 220 -

SAM_0571.JPG648.6 KB · Views: 175

SAM_0571.JPG648.6 KB · Views: 175 -

SAM_0570.JPG825.5 KB · Views: 162

SAM_0570.JPG825.5 KB · Views: 162 -

SAM_0569.JPG666 KB · Views: 183

SAM_0569.JPG666 KB · Views: 183 -

SAM_0572.jpg503 KB · Views: 190

SAM_0572.jpg503 KB · Views: 190 -

SAM_0573.JPG360.9 KB · Views: 179

SAM_0573.JPG360.9 KB · Views: 179 -

SAM_0574.JPG321.6 KB · Views: 174

SAM_0574.JPG321.6 KB · Views: 174

PHEW!

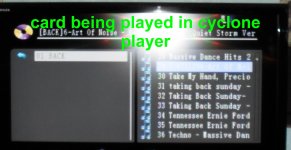

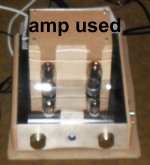

Still some more, hope I'm not boring you!?

The amp is no longer being used the left hand channel packed in. So I am using one I built years ago. Still running good, unlike the one I bought.

Still some more, hope I'm not boring you!?

The amp is no longer being used the left hand channel packed in. So I am using one I built years ago. Still running good, unlike the one I bought.

Attachments

-

SAM_0582.JPG539 KB · Views: 184

SAM_0582.JPG539 KB · Views: 184 -

SAM_0577.JPG639.8 KB · Views: 180

SAM_0577.JPG639.8 KB · Views: 180 -

SAM_0576.JPG303 KB · Views: 204

SAM_0576.JPG303 KB · Views: 204 -

SAM_0583.jpg485 KB · Views: 162

SAM_0583.jpg485 KB · Views: 162 -

SAM_0595.JPG165.2 KB · Views: 194

SAM_0595.JPG165.2 KB · Views: 194 -

SAM_0596.JPG86.7 KB · Views: 233

SAM_0596.JPG86.7 KB · Views: 233 -

SAM_0597.JPG387.8 KB · Views: 241

SAM_0597.JPG387.8 KB · Views: 241 -

SAM_0598.JPG498.5 KB · Views: 246

SAM_0598.JPG498.5 KB · Views: 246 -

SAM_0599.JPG572 KB · Views: 330

SAM_0599.JPG572 KB · Views: 330 -

SAM_0600.JPG729.3 KB · Views: 325

SAM_0600.JPG729.3 KB · Views: 325

Last edited:

I think this is all!!??

I hope so.😕

I hope so.😕

Attachments

-

SAM_0603.JPG785.5 KB · Views: 217

SAM_0603.JPG785.5 KB · Views: 217 -

SAM_0602.JPG768.2 KB · Views: 217

SAM_0602.JPG768.2 KB · Views: 217 -

SAM_0601.JPG632.5 KB · Views: 256

SAM_0601.JPG632.5 KB · Views: 256 -

SAM_0604.JPG918.5 KB · Views: 210

SAM_0604.JPG918.5 KB · Views: 210 -

SAM_0605.JPG729.2 KB · Views: 187

SAM_0605.JPG729.2 KB · Views: 187 -

SAM_0606.JPG529.5 KB · Views: 189

SAM_0606.JPG529.5 KB · Views: 189 -

SAM_0609.JPG864 KB · Views: 273

SAM_0609.JPG864 KB · Views: 273 -

SAM_0608.JPG895.7 KB · Views: 237

SAM_0608.JPG895.7 KB · Views: 237 -

SAM_0607.JPG863.3 KB · Views: 193

SAM_0607.JPG863.3 KB · Views: 193 -

SAM_0610.JPG846.3 KB · Views: 234

SAM_0610.JPG846.3 KB · Views: 234

OH DEAR OOPS!

Even more!

Even more!

Attachments

-

SAM_0611.JPG639.1 KB · Views: 187

SAM_0611.JPG639.1 KB · Views: 187 -

SAM_0612.JPG905.7 KB · Views: 132

SAM_0612.JPG905.7 KB · Views: 132 -

SAM_0613.JPG897.6 KB · Views: 135

SAM_0613.JPG897.6 KB · Views: 135 -

SAM_0616.JPG699.4 KB · Views: 178

SAM_0616.JPG699.4 KB · Views: 178 -

SAM_0615.JPG965.8 KB · Views: 172

SAM_0615.JPG965.8 KB · Views: 172 -

SAM_0614.JPG968.1 KB · Views: 149

SAM_0614.JPG968.1 KB · Views: 149 -

SAM_0617.JPG327.8 KB · Views: 170

SAM_0617.JPG327.8 KB · Views: 170 -

SAM_0618.JPG362.5 KB · Views: 165

SAM_0618.JPG362.5 KB · Views: 165 -

SAM_0619.JPG748.4 KB · Views: 131

SAM_0619.JPG748.4 KB · Views: 131 -

SAM_0620.JPG853.2 KB · Views: 154

SAM_0620.JPG853.2 KB · Views: 154

And more.

Sorry. The sewing is the hardest bit for me.😡

Sorry. The sewing is the hardest bit for me.😡

Attachments

-

SAM_0621.JPG642.4 KB · Views: 181

SAM_0621.JPG642.4 KB · Views: 181 -

SAM_0622.JPG685.2 KB · Views: 170

SAM_0622.JPG685.2 KB · Views: 170 -

SAM_0623.jpg403.8 KB · Views: 170

SAM_0623.jpg403.8 KB · Views: 170 -

SAM_0626.JPG963.6 KB · Views: 212

SAM_0626.JPG963.6 KB · Views: 212 -

SAM_0625.jpg725.4 KB · Views: 218

SAM_0625.jpg725.4 KB · Views: 218 -

SAM_0624.JPG827.3 KB · Views: 222

SAM_0624.JPG827.3 KB · Views: 222 -

SAM_0643.JPG692.6 KB · Views: 232

SAM_0643.JPG692.6 KB · Views: 232 -

SAM_0644.JPG757.4 KB · Views: 197

SAM_0644.JPG757.4 KB · Views: 197 -

SAM_0645.JPG827.9 KB · Views: 168

SAM_0645.JPG827.9 KB · Views: 168 -

SAM_0646.JPG433.1 KB · Views: 144

SAM_0646.JPG433.1 KB · Views: 144

Nearly there.

Not much longer.This is it for now got to crop some more and quite a lot of rebuilds, made the cover too small on the blue ones, need a lot more practise on the sewing machine.

Not much longer.This is it for now got to crop some more and quite a lot of rebuilds, made the cover too small on the blue ones, need a lot more practise on the sewing machine.

Attachments

Hi there Henry: Your work, as depicted in the photos, is inspiring. Can you post photos of your method of tensoning the membrane. (I read your previous post for tensoning, but did not understand it.) I'm looking at 16 gage (0.0598-inches) 63% open perforated steel plate. Many thanks for the photos and information. ... regards, Michael

tensioning

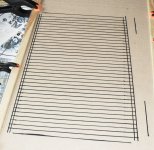

Place membrane in position over magnets making sure the tape is along the N/S axis. Cut holes where the screws or bolts go to hold the wood, which holds the membrane in position.

Place 3 screws or bolts in each piece of the 4 spread out, carefully introduce the points into the holes marked on the MDF base, and gently lower the wood into position, making sure you can still move the membrane easily.

Position the membrane and tighten the screws gradually, whilst at the same time gently taking up the slack in the membrane. Working your way round and placing more screws or bolts in position. Gradually removing the ripples in the membrane.Tapping the membrane round the edges to check that it is taut all the way round. The middle should not be touching the magnets.If the membrane touches the magnets this will probably cause problems with the sound.

I hope this helps and the best of luck, patience is paramount when putting tape on membrane It is easily broken.Also be careful with magnets they can easily trap your fingers. I only use 3 mm thick neos. The total weight of the membrane is important the lower the better!😉

Place membrane in position over magnets making sure the tape is along the N/S axis. Cut holes where the screws or bolts go to hold the wood, which holds the membrane in position.

Place 3 screws or bolts in each piece of the 4 spread out, carefully introduce the points into the holes marked on the MDF base, and gently lower the wood into position, making sure you can still move the membrane easily.

Position the membrane and tighten the screws gradually, whilst at the same time gently taking up the slack in the membrane. Working your way round and placing more screws or bolts in position. Gradually removing the ripples in the membrane.Tapping the membrane round the edges to check that it is taut all the way round. The middle should not be touching the magnets.If the membrane touches the magnets this will probably cause problems with the sound.

I hope this helps and the best of luck, patience is paramount when putting tape on membrane It is easily broken.Also be careful with magnets they can easily trap your fingers. I only use 3 mm thick neos. The total weight of the membrane is important the lower the better!😉

my last pictures

I have to do all my rebuilds next for more pictures. I shall probably cover them with material, better get practising with the sewing machine..😱

I have to do all my rebuilds next for more pictures. I shall probably cover them with material, better get practising with the sewing machine..😱

Attachments

-

SAM_0552.jpg689.8 KB · Views: 979

SAM_0552.jpg689.8 KB · Views: 979 -

SAM_0553.jpg515.1 KB · Views: 922

SAM_0553.jpg515.1 KB · Views: 922 -

SAM_0556.jpg465.7 KB · Views: 879

SAM_0556.jpg465.7 KB · Views: 879 -

SAM_0557.jpg532.3 KB · Views: 837

SAM_0557.jpg532.3 KB · Views: 837 -

SAM_0559.jpg512.7 KB · Views: 823

SAM_0559.jpg512.7 KB · Views: 823 -

SAM_0578.JPG733.5 KB · Views: 198

SAM_0578.JPG733.5 KB · Views: 198 -

SAM_0568.JPG766.5 KB · Views: 182

SAM_0568.JPG766.5 KB · Views: 182 -

SAM_0565.JPG900.4 KB · Views: 211

SAM_0565.JPG900.4 KB · Views: 211 -

SAM_0579.JPG191.3 KB · Views: 193

SAM_0579.JPG191.3 KB · Views: 193 -

SAM_0580.jpg410 KB · Views: 191

SAM_0580.jpg410 KB · Views: 191

Hi Henry,

my greatest respect.... this is great and very inspiring!! I am tempted to build a couple myself.....

just a question - the electrostatics guys use clear (kitchen) film used for covering food, and that stuff apparently can be tensioned with a little bit of hot air from a hairdryer, have you ever looked into doing that? My guess would be that as the aluminum would not be shrinking, this might cause wrinkles. (or you would have to put the aluminum after tensioning the film....)

keep it up!

my greatest respect.... this is great and very inspiring!! I am tempted to build a couple myself.....

just a question - the electrostatics guys use clear (kitchen) film used for covering food, and that stuff apparently can be tensioned with a little bit of hot air from a hairdryer, have you ever looked into doing that? My guess would be that as the aluminum would not be shrinking, this might cause wrinkles. (or you would have to put the aluminum after tensioning the film....)

keep it up!

membrane shrinkage

Never tried shrinking with or without the aluminium foil, so cannot say whether it would work.You can tighten up by going round with the screws holding the 4 wood clamps as I have. Although they all corrugate the foil for ribbon speakers. If heating the membrane with foil on causes the foil to corrugate who knows it might work. But if it doesn't you can always do another membrane, as it doesn't cost much, only time and effort.🙂

Never tried shrinking with or without the aluminium foil, so cannot say whether it would work.You can tighten up by going round with the screws holding the 4 wood clamps as I have. Although they all corrugate the foil for ribbon speakers. If heating the membrane with foil on causes the foil to corrugate who knows it might work. But if it doesn't you can always do another membrane, as it doesn't cost much, only time and effort.🙂

Hi there Henry: I'm planning on using 16 gage (1.519 mm thick) preforated steel plate (63% open). What thicknes plate you using? Have you experimented with different thckness plates? How are your rebuilds going? ...regards, Michael

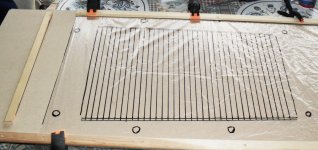

perforated thickness

I use .25 mm, If you use thicker plate it would probably increase the field strength, although I have not tried it myself. I have enough rebuilds at the moment, if I did use a thicker sheet, that would mean even more rebuilds!!!😡I am in the process of rebuilding one of my original designs using ferrites, and I am trying different ideas in the rebuild. Have cut the MDF to size and shape, and will be putting the magnets on today. I stripped the old design yesterday, weight 80 lbs, too heavy for a man of my age to move about. Will be taking photos.😎

I use .25 mm, If you use thicker plate it would probably increase the field strength, although I have not tried it myself. I have enough rebuilds at the moment, if I did use a thicker sheet, that would mean even more rebuilds!!!😡I am in the process of rebuilding one of my original designs using ferrites, and I am trying different ideas in the rebuild. Have cut the MDF to size and shape, and will be putting the magnets on today. I stripped the old design yesterday, weight 80 lbs, too heavy for a man of my age to move about. Will be taking photos.😎

Hi there Henry: Thanks for the advice on the plate thickness. Your willingness to help others is admirable and your posts will be a long time contribution to DIY audio for permanent magnet flat panels.

Your posts indicate that the NEO magnets you are using (50 mm x 12.7mm x 3mm) are magnetized through the 12.7mm sides, so that the columns are arranged ns-ns-ns-ns...ns. (Am I correct ?) With this arrangement, the magnets will attract each other as well as the preforated steel plate, leading to inherant magnet stability on the plate, (and no glue required) very cleaver design on your part! ...regards, Michael

Your posts indicate that the NEO magnets you are using (50 mm x 12.7mm x 3mm) are magnetized through the 12.7mm sides, so that the columns are arranged ns-ns-ns-ns...ns. (Am I correct ?) With this arrangement, the magnets will attract each other as well as the preforated steel plate, leading to inherant magnet stability on the plate, (and no glue required) very cleaver design on your part! ...regards, Michael

magnet layout on steel sheet

Yes the neo magnets don't need any glue, you have to slide them off and no chance of them moving unless you about 100G force!. Yes they are placed NSNSNSNS Next to each other, in columns or rows, so you can place the foil vertically or horizontally.It is slightly easier vertically as you don't have to make so many turns when placing the foil on the membrane.I didn't get round to putting the ferrites in position today. I planted some potatoes instead!Thank you for your kind words. I still have many neos left as I have turned the push pull designs into normal ones as I found out there was no difference in the sensitivity.😎

Yes the neo magnets don't need any glue, you have to slide them off and no chance of them moving unless you about 100G force!. Yes they are placed NSNSNSNS Next to each other, in columns or rows, so you can place the foil vertically or horizontally.It is slightly easier vertically as you don't have to make so many turns when placing the foil on the membrane.I didn't get round to putting the ferrites in position today. I planted some potatoes instead!Thank you for your kind words. I still have many neos left as I have turned the push pull designs into normal ones as I found out there was no difference in the sensitivity.😎

Big planar

Hi Henry,

I have been reading back through your many posts with great interest. I would really like to make a couple of fullrange planar speakers myself but don't have the time right now.

May I ask whether you got good bass from your 48 inchers? Enough to play dance music? What sort of SPl's are possible? 100DB ?

I realise that planars are normally considered to be suited to HIFI applications but I am wondering if more is possible.

If I could get up to Leicester could we do some tests with a meter if you haven't already?

Would you be interested in building some large ones? or maybe you know somone else in the UK?

Thx Eric

Hi Henry,

I have been reading back through your many posts with great interest. I would really like to make a couple of fullrange planar speakers myself but don't have the time right now.

May I ask whether you got good bass from your 48 inchers? Enough to play dance music? What sort of SPl's are possible? 100DB ?

I realise that planars are normally considered to be suited to HIFI applications but I am wondering if more is possible.

If I could get up to Leicester could we do some tests with a meter if you haven't already?

Would you be interested in building some large ones? or maybe you know somone else in the UK?

Thx Eric

BIG PLANARS

Dear Eric, Have already built big planars up to 7' tall.Am in the process of rebuilding a 4' X 2' using ferrites which I built about 15 years ago. I have reduced the weight somewhat and used a thinner membrane and half the aluminium foil. This increases the sensitivity. I did build 4' ones using neos but have reduced the size to 60 x 40 cm.After using 23 um mylar A, and reducing the foil width. This gave the same results or even better than the 4' design, with the old membrane design. I have used a frequency meter to measure spot frequencies which I had on the HI- FI WORLD CD. Although I did find this very time consuming and boring. Not knowing how accurate the meter was didn't help! I prefer to listen than measure the ear is the best meter, although my upper frequency hearing stops at 10khz, being 72 years old.I am quite happy with the bass response of the 60 x 40 size and won't be building any more bigger ones with my remaining neo magnets, which I have plenty. Taking all my p/p designs apart as it wasn't worth the extra weight and work. I hope this helps with your decision. Bye the way, I play all types of music from classical to trance, dance, electronic, jazz, heavy metal garage, pop etc, etc. The bass is very tight and clean unlike the bass on the esl 57 & 63 which is plummy and resonant in comparison.😉

Dear Eric, Have already built big planars up to 7' tall.Am in the process of rebuilding a 4' X 2' using ferrites which I built about 15 years ago. I have reduced the weight somewhat and used a thinner membrane and half the aluminium foil. This increases the sensitivity. I did build 4' ones using neos but have reduced the size to 60 x 40 cm.After using 23 um mylar A, and reducing the foil width. This gave the same results or even better than the 4' design, with the old membrane design. I have used a frequency meter to measure spot frequencies which I had on the HI- FI WORLD CD. Although I did find this very time consuming and boring. Not knowing how accurate the meter was didn't help! I prefer to listen than measure the ear is the best meter, although my upper frequency hearing stops at 10khz, being 72 years old.I am quite happy with the bass response of the 60 x 40 size and won't be building any more bigger ones with my remaining neo magnets, which I have plenty. Taking all my p/p designs apart as it wasn't worth the extra weight and work. I hope this helps with your decision. Bye the way, I play all types of music from classical to trance, dance, electronic, jazz, heavy metal garage, pop etc, etc. The bass is very tight and clean unlike the bass on the esl 57 & 63 which is plummy and resonant in comparison.😉

Last edited:

- Home

- Loudspeakers

- Planars & Exotics

- Full range planar speaker using neo magnets