I did a comparison again between the Cornu and the Karlsonator with the reduced stuffing. Now I like the Karlsonator better. Lol. The Cornu had more bass, but seemed to sound a little hollow on male vocals. I put a little stuffing in the horn mouths and that improved it, so maybe I need to remove the driver and play with stuffing in it a little.

But given the cost and ease of build, that 0.4 Karlsonator is a gem.

Glad it worked out. There is a reason why it’s such a popular speaker. Easy to make and sounds great.

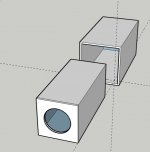

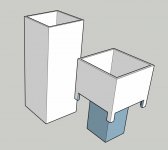

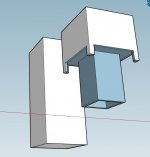

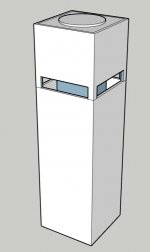

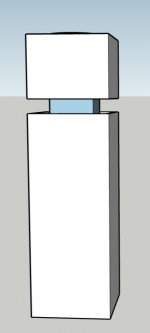

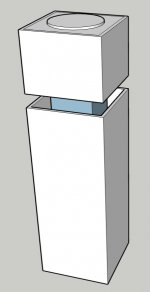

Would you care to look at these drawings? Being playing with left over cardboard. Maybe would work well with foam core. It is one box inside another, one that goes in smaller than the other, held in such a way, so there would be a surround reflex vent around the smaller box. The drawings are sketches, not to scale, just the idea.

Attachments

The rear of the outer box appears to be open. Is this intended? How about the inner box, open or closed rear?

The rear of the outer box appears to be open. Is this intended? How about the inner box, open or closed rear?

The rear of the outer box is closed, the rear of the inner box is open. There should be some ribs between them to keep the vent intact. Not shown in the drawings. The boxes doesn't have to be long, can be fat and short. 🙂

I would like to use some tubes, but can't get them, because of the lock down.

Last edited:

I'm sure it's been tried somewhere (most everything has), but that doesn't mean you shouldn't absolutely build a set and report how they sound! 🙂

Roughly what size drivers are you thinking?

Roughly what size drivers are you thinking?

Yes, that can work and it has the advantage of using the narrow cross section wall flow friction vs regular port constriction cross section alone to effect pressure drop. This will be different than equivalent cross section of a tube alone as port. Similar to an Onken type reflex box but those have two walls with slot ports. Yours is a 4 wall Onken. A square baffle will result in more diffraction anomalies (dips and peaks due to constructive and destructive interference). A rectangular box is better.

Vintage Altec Onken:

Vintage Altec Onken:

Last edited:

Onken build article; http://www.planet10-hifi.com/downloads/Hiraga-Onkens-English.pdf

I can see some drawer action experimentation w/regard to tuning. Then adjust depths and try again before finalizing. The ports on the Onken look kinda neat, but hands down (or up) the wesayso towers are the neatest design I have ever seen.

I can see some drawer action experimentation w/regard to tuning. Then adjust depths and try again before finalizing. The ports on the Onken look kinda neat, but hands down (or up) the wesayso towers are the neatest design I have ever seen.

Last edited:

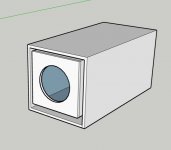

This is more or less the idea, for the vents to come up most of the way, and go out from all 4 sides, that is, if we build a square, tall speaker box. The driver will be up firing.

Attachments

You actually have something closer to a back loaded horn than a reflex box. Totally different simulation. If going horn route, the low frequency depends on length. For 60Hz reach thats 112in long or 56in of folded in half. You could do 4 concentric squares and get 28in long speaker.

Whatever the name we give to this, the sound from the back of the audio driver would hit the back wall/bottom of the longer box, and reflect back and hit the back of the top box, and deflect out. The smaller mouth of the top box doesn't have to go all the way to the bottom of the longer box. The bottom of that box would be stuffed with loose sound absorbing material. Maybe with an old goose feather pillow, or from its contents. The inner sides of the box can be lined, if needed. The top one too. It'd be interesting, if the top box can be held by the bottom box, without the 4 little columns at the corners, so that the top would look like floating.

The gap between the top box and the bottom doesn't have to be that large as shown in the drawings. The same with the gap inside the longer box. It would look nicer with a thinner gap.

Once the lock down is over, I hope to look for pipes. Most probably in the spring. Why pipes? Because they are stiff radially and won't give out resonance.

By the way, if anyone can try this, it would be nice. 🙂

The gap between the top box and the bottom doesn't have to be that large as shown in the drawings. The same with the gap inside the longer box. It would look nicer with a thinner gap.

Once the lock down is over, I hope to look for pipes. Most probably in the spring. Why pipes? Because they are stiff radially and won't give out resonance.

By the way, if anyone can try this, it would be nice. 🙂

Attachments

Happy Xmas everyone! Hope you all have a wonderful Xmas and a safe and exciting new year building audio projects in foam core or whatever you like to use.

I finally completed my first foam core build as a prototype to see how my Seas H1597-08 - FA22RCZ full rangers sound before building a permanent box. They are built to the specs recommended by Seas in their Application Note.

These sound way better than I expected! So good in fact, that I'm in no hurry to build a wood box.

I beefed up construction by doubling the sides, top, bottom and back. The front baffle is 3 ply with a plywood ring inside for added strength at the mounting points and the driver recessed into the front ply. I also placed 3 additional horizontal supports with holes offset to inhibit standing waves. Finally, I stuffed with nylon Acousta Stuff before installing the drivers.

Because of my tendency to overbuild, this project took way longer than I expected and assembly evolved along the way. I'm currently driving them with my SIT 2 and very happy with the result. 🙂

These sound way better than I expected! So good in fact, that I'm in no hurry to build a wood box.

I beefed up construction by doubling the sides, top, bottom and back. The front baffle is 3 ply with a plywood ring inside for added strength at the mounting points and the driver recessed into the front ply. I also placed 3 additional horizontal supports with holes offset to inhibit standing waves. Finally, I stuffed with nylon Acousta Stuff before installing the drivers.

Because of my tendency to overbuild, this project took way longer than I expected and assembly evolved along the way. I'm currently driving them with my SIT 2 and very happy with the result. 🙂

Attachments

Because of my tendency to overbuild...

I'd say so! 😀

That looks really nice!

Is that 1/2" foam core?

What's your source for it? I used to work at a place that sold it, but sadly I no longer have a good source. It was amazing stuff. The paper backing was more like glossy cardstock. You could build all sorts of cool stuff out of it.

look closer it seems constrained layer damping is afoot...it looks like doubled run of the mill foamcore to me.

WBS nice build, kudos!

WBS nice build, kudos!

If one were to suggest an obtainable constrained layer for such a doubled up layup -

paper-foam-paper-"X"-paper-foam-paper

What would "X" be?

Cardboard?

Formica?

Linoleum floor?

Plastic sheet?

Pink foam?

Felt?

Tyvek?

Cloth?

Rubber sheet?

Carpet backing foam?

Anti-static mat?

Yoga mat?

A coat of elastomeric roof coating on each?

A coat of driveway sealer on each?

Perhaps the foamcore could be turned into a metamaterial by constraining a layer of somethin' between, with even better properties than just the two boards.

paper-foam-paper-"X"-paper-foam-paper

What would "X" be?

Cardboard?

Formica?

Linoleum floor?

Plastic sheet?

Pink foam?

Felt?

Tyvek?

Cloth?

Rubber sheet?

Carpet backing foam?

Anti-static mat?

Yoga mat?

A coat of elastomeric roof coating on each?

A coat of driveway sealer on each?

Perhaps the foamcore could be turned into a metamaterial by constraining a layer of somethin' between, with even better properties than just the two boards.

Last edited:

What would "X" be?

why can't it simply be the glue between the two "pFp" layers?

baltic birch isn't a magic cabinet material by virtue of the material's properties, it's that in it's 8 layers of dense wood bound by 7 layers of glue, to me that's CLD on steriods,no?

Last edited:

I'd say so! 😀

That looks really nice!

Is that 1/2" foam core?

What's your source for it? I used to work at a place that sold it, but sadly I no longer have a good source. It was amazing stuff. The paper backing was more like glossy cardstock. You could build all sorts of cool stuff out of it.

Thanks Elmojo!

It's 3/16" 32X40 Blick foamboard. I bought a box of 25 and cutting them down on my Fletcher mat cutter made it pretty straightforward.

Turk 182, first I tried gluing the layers together using 3M High Strength 90 spray adhesive. That was a pain, so I switched to using good old Titebond 2 and adding weight on top to cure the bond.

jjasniew, due to the size of the panels, layering something in between crossed my mind as well. But I finally asked myself just how much effort I wanted to put into a trial concept.

yatr98, thanks! Being full range, there is no need for a crossover. However these drivers were a bit "shouty" by themselves, as whizzer cones tend to be. So I added an adjustable EQ given to me by a friend. That turned these into one of the top 3 FR drivers I've ever heard, close to Cubes and the Seas 6 inch version. I think they sound better than the Feastrex OBs I heard at Burning Amp years ago!!!

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?