That van/RV kitchenette made from XPS and brown paper facing was way cool. It even sort of looks like wood. (Paper is wood fiber). Looks really strong and durable with the facing.

I am using foam board for a test baffle for impedance and frequency response measurements. It is 1" Owens Corning "foamular" board, Menards sells it in 2x2 panels and full size sheets.

https://www.diyaudio.com/forums/multi-way/343831-sb-acoustics-textreme-54.html#post6393377

If it works well for this application, I will update this thread...

https://www.diyaudio.com/forums/multi-way/343831-sb-acoustics-textreme-54.html#post6393377

If it works well for this application, I will update this thread...

I have made a lot of audio projects from 1in thick Foamular. The 2x2 size is convenient when you don’t need a 4x8 ft sheet. If you face it with thin 1/8in plywood it can hold heavy drivers well.

Your tweeter project looks very nice - looking forward to seeing your results.

Your tweeter project looks very nice - looking forward to seeing your results.

Last edited:

The foam board worked out really well for a test baffle. Even with the 6 inch driver I did not need any additional stiffening.

Attachments

Last edited:

I remember way back when I loitered on the now defunct Single Driver Website by James Melhuish, there was a lot of interest in "inert" speaker enclosures using foam insulation board with varying degrees of success. the main exponent being to reduce/eliminate fabric colouration. The ingenuity of some enclosures was quite something. The fact its rarely mentioned these days suggests it never caught on? Shame really.

The other spin off was constructing with small sections of wood rather than one large piece, attempting to prevent particular resonant frequencies from doing the same. As well as thin walls with `dedshete' adhesive damping to do likewise? Cool stuff that really got you thinking 🙂

The other spin off was constructing with small sections of wood rather than one large piece, attempting to prevent particular resonant frequencies from doing the same. As well as thin walls with `dedshete' adhesive damping to do likewise? Cool stuff that really got you thinking 🙂

Anyone have suggestions for designs with directivity and physical size of the JBL LSR 306? Nice speakers but the hiss from the cheap amps is bothersome, I imagine something in foam core could be a nice replacement for my desk. Thanks.

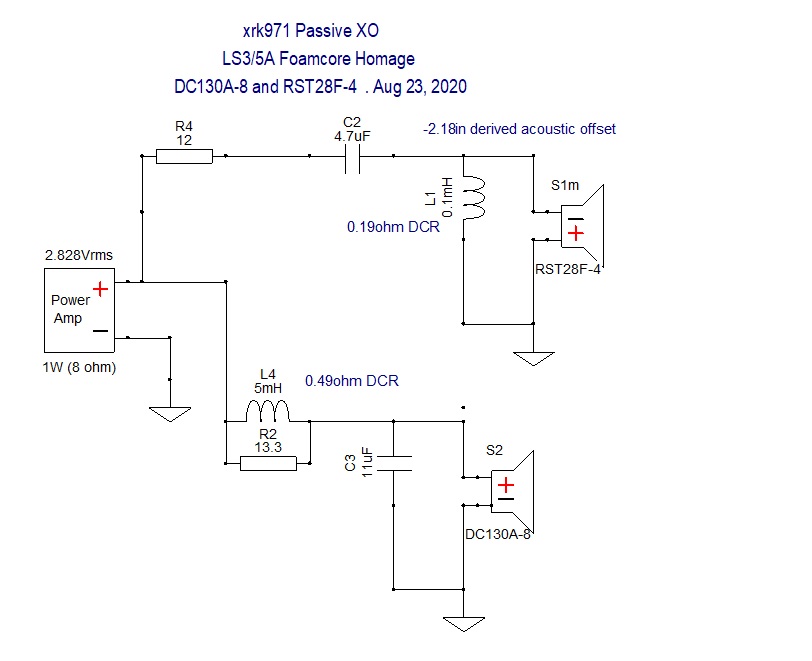

I really like how this speaker sounds as a desktop speaker. Works well with 50w Class D amp.

RST28F and DC130A Foamcore Homage to LS3/5A

RST28F and DC130A Foamcore Homage to LS3/5A

I really like how this speaker sounds as a desktop speaker. Works well with 50w Class D amp.

RST28F and DC130A Foamcore Homage to LS3/5A

That looks really good, I'll give that thread a thorough read, thanks. I have a MiniDSP sitting around for the crossovers.

The passive crossover is really good on this one and not complicated or expensive. If you go miniDSP, be sure to try to get the similar filter for a 5.5kHz crossover with an apparent transient perfect step response.

I am thinking of something like this for a 168mm (6.5") full range driver, only not yet sure of the box dimensions, yet. The hole is 144mm diameter. It could be placed with the vent on top, or bottom, or upward firing with a half a sphere over the driver.

Maybe, someone had done this here before.

Maybe, someone had done this here before.

Attachments

Last edited:

^Looks like a subwoofer box to me. 🙂

I like the design. Of course, I know nothing about evaluating acoustic properties by sight, but it looks plausible. Mock it up in foamcore and see how it sounds!

It reminds me a lot of this design, which worked quite well. Of course, that was a highly-modeled design, and a much smaller driver, but still.... 😀

I like the design. Of course, I know nothing about evaluating acoustic properties by sight, but it looks plausible. Mock it up in foamcore and see how it sounds!

It reminds me a lot of this design, which worked quite well. Of course, that was a highly-modeled design, and a much smaller driver, but still.... 😀

To really take advantage of the TL design it would be important to see what the TS parameters of the driver it was designed for and what kind of predicted response this gives. Just putting a random 6.5in driver in there may or may not work well. Ideally it should be simulated before building. Hornresp or similar programs can be very beneficial here.

To really take advantage of the TL design it would be important to see what the TS parameters of the driver it was designed for and what kind of predicted response this gives. Just putting a random 6.5in driver in there may or may not work well. Ideally it should be simulated before building. Hornresp or similar programs can be very beneficial here.

I am thinking of using foam pipe length(s) to find out the optimal length of the TL. These tubes can be made from 2mm foam mats left after floor repairs. 2mm foam mats are too flimsy for walls, but as tubes they are stiff enough. Can't get thicker mats, as there's some sort of a lock down. 🙂

I am also thinking of this dual side back loaded horns for flat wall box, thickness about 10cm. There's another idea about using triple or quadruple Fibonacci spiral. What do you think?

This doesn't have to be this wide, but can be thin and tall.

Attachments

Last edited:

Why make tubes out of the foam core and encase in a rectangular box when rectangular cross section channels are just as good. There is no advantage to round cross section other than if you start with tubes like PVC piping.

Sounds like you are a looking a for a foam core project to build.

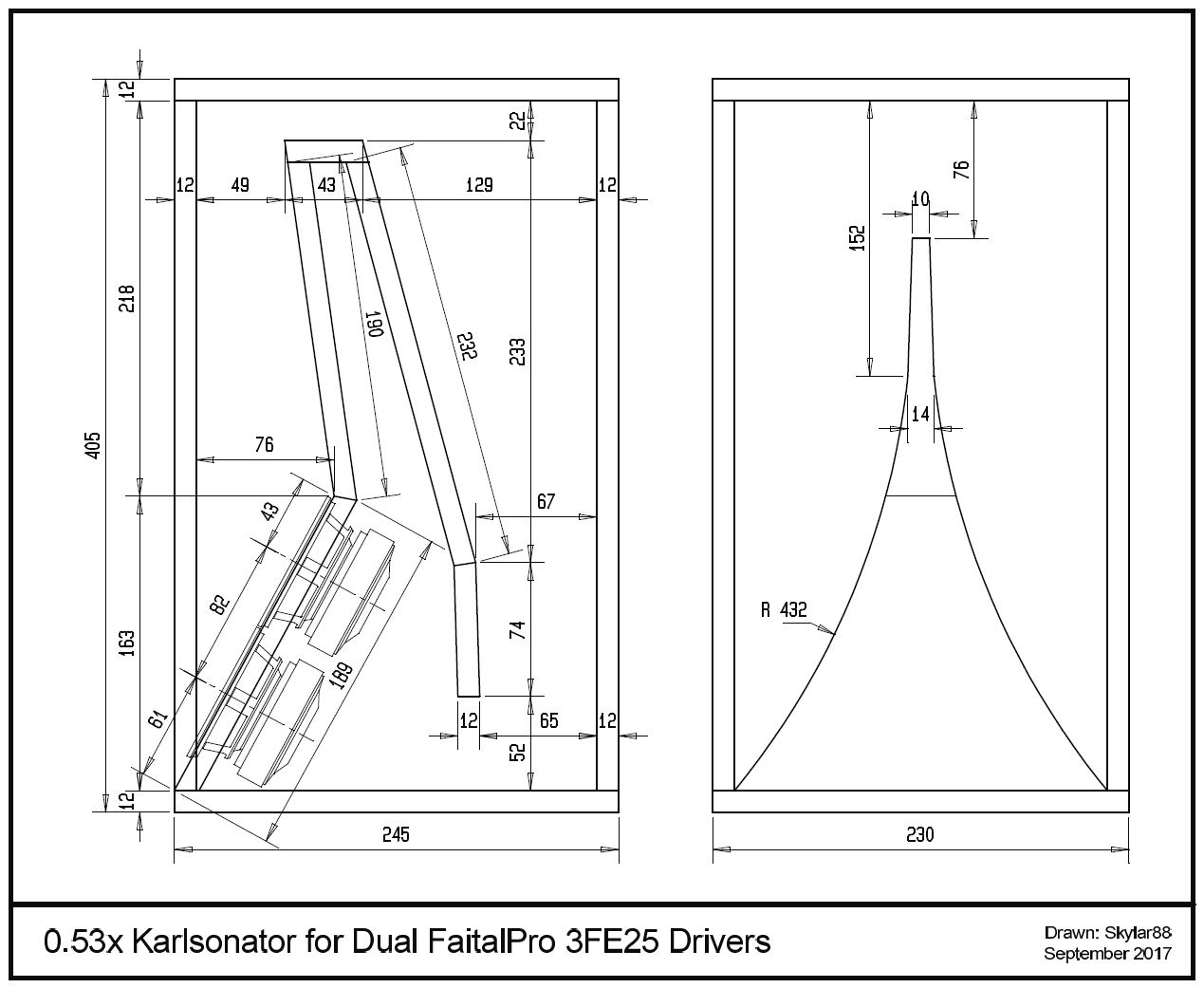

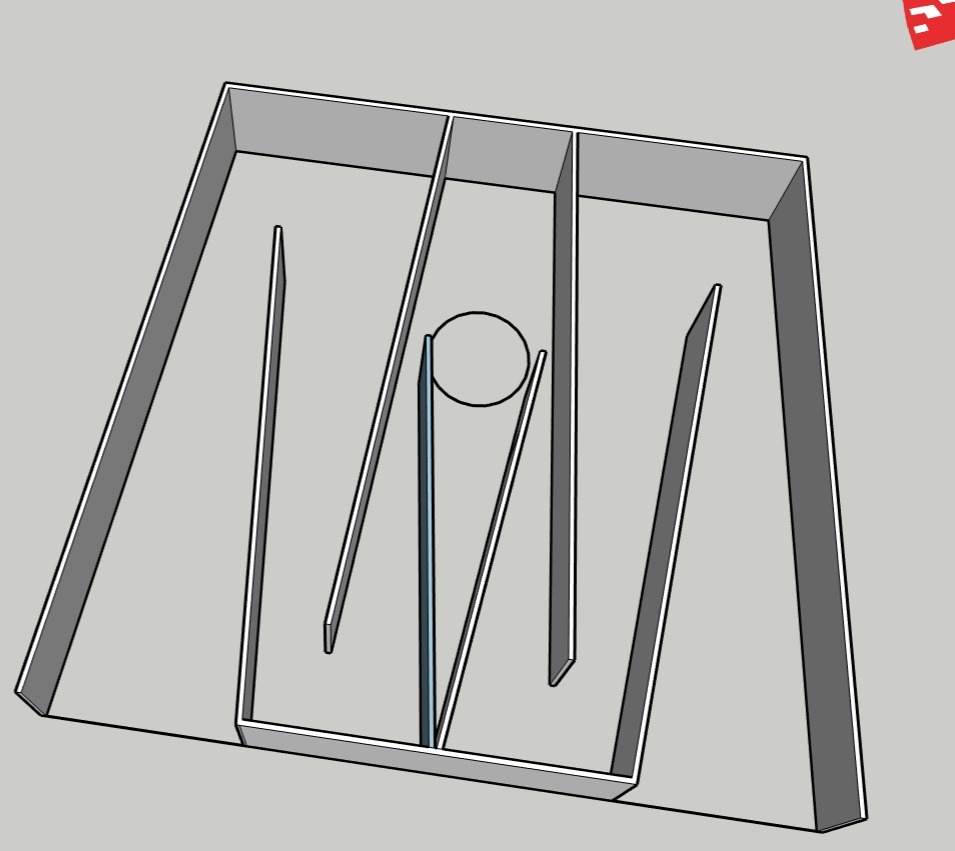

You really should try the Karlsonator in foam core. It’s a well proven design that’s easy to build (mass loaded quarter wave TL with Karlson aperture output acoustic lens) and is scalable you whatever driver you have. Get me the TS parameters and I will model it for you and you can follow basic plans.

Hundreds of variations have been built and everyone likes the sound.

Mini Karlsonator (0.53X) with Dual TC9FDs

If you don’t have a driver in mind, try the dual TC9FD and 0.53x scale Karlsonator. Or PA130-8 single driver with 0.53x scale Karlsonator.

Here is one for dual 3FE25-16 drivers:

Here is a completed one in foam core with wood aperture for PA130-8:

Or tell me what driver you have and I’ll see what I can do.

The Karlsonator will sound better than something like this:

Sounds like you are a looking a for a foam core project to build.

You really should try the Karlsonator in foam core. It’s a well proven design that’s easy to build (mass loaded quarter wave TL with Karlson aperture output acoustic lens) and is scalable you whatever driver you have. Get me the TS parameters and I will model it for you and you can follow basic plans.

Hundreds of variations have been built and everyone likes the sound.

Mini Karlsonator (0.53X) with Dual TC9FDs

If you don’t have a driver in mind, try the dual TC9FD and 0.53x scale Karlsonator. Or PA130-8 single driver with 0.53x scale Karlsonator.

Here is one for dual 3FE25-16 drivers:

Here is a completed one in foam core with wood aperture for PA130-8:

Or tell me what driver you have and I’ll see what I can do.

The Karlsonator will sound better than something like this:

Last edited:

Well, because it is easy and I have these 2mm foam sheets available. Putting them in a box would be the last thing I'd do as it would be a finished job. Until then, I am just experimenting. By the way, I've read practically all your threads. The Karlsonator won't do as I got veto on that. 🙂 The pipes would never be allowed in the house, so have to go in a box.Why make tubes out of the foam core and encase in a rectangular box when rectangular cross section channels are just as good...

I have some Jensen hf-223 coax in HealthKit ae-40 cabinets (large untuned ported enclosures) very sensitive, sound amazing at low volume but they get boomy very quickly when power is added. No driver t/s. The way I see it I have a few options:

1.) Remove the port and make a sealed box.

2.) tune the port by cutting/stuffing /listening/testing

3.) build foam-core karl-somethings for the jensens

How would I go about sizing/picking a Karlson type enclosure for these 12” jensens?

1.) Remove the port and make a sealed box.

2.) tune the port by cutting/stuffing /listening/testing

3.) build foam-core karl-somethings for the jensens

How would I go about sizing/picking a Karlson type enclosure for these 12” jensens?

Well, because it is easy and I have these 2mm foam sheets available. Putting them in a box would be the last thing I'd do as it would be a finished job. Until then, I am just experimenting. By the way, I've read practically all your threads. The Karlsonator won't do as I got veto on that. 🙂 The pipes would never be allowed in the house, so have to go in a box.

You can cover the whole front aperture with grill cloth if your significant other doesn’t like the K slot curve. It will look like any other “box” speaker.

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?