Standard Honeycomb Panels, OEM Product Manufacturing Panels

neat stuff too bad there doesn't seem to be a ready made solution for finishing panel edges though,other wise as it's available in a three quarter and 1/2 inch thicknesses i'd certainly love to build some boxes and put them through a trial by fire...if the market returns....damn covid...where's me scotch!!

neat stuff too bad there doesn't seem to be a ready made solution for finishing panel edges though,other wise as it's available in a three quarter and 1/2 inch thicknesses i'd certainly love to build some boxes and put them through a trial by fire...if the market returns....damn covid...where's me scotch!!

Last edited:

Penn Elcom Double Angle Extrusion Supplied in 3.66m/12ft Lengths 3070 PennElcomOnline.com

hmmm this may make that idea possible....

hmmm this may make that idea possible....

That would look the part of a pro tour rig. Nice double angle edges - didn’t even know they sell stuff like that.

There are very thin plywood and bendy plywood products out there that might be useful covering smaller projects. Makers Stock has a number of options including quality sheet goods that they will cut to order, reducing shipping costs.

MakerStock acrylic, plywood, sheet goods for laser cutting

Cool project. Back in the day I built a bunch of KEF kits. There is something of an imprinting that occurs when one grows up with certain speakers. When I am an outlier in shared listening groups it is almost always predicated on early exposure.

You are likely aware of Falcon Acoustics and the old published specs of the LS3/5A.

The Unofficial LS3/5A Support Site

MakerStock acrylic, plywood, sheet goods for laser cutting

Cool project. Back in the day I built a bunch of KEF kits. There is something of an imprinting that occurs when one grows up with certain speakers. When I am an outlier in shared listening groups it is almost always predicated on early exposure.

You are likely aware of Falcon Acoustics and the old published specs of the LS3/5A.

The Unofficial LS3/5A Support Site

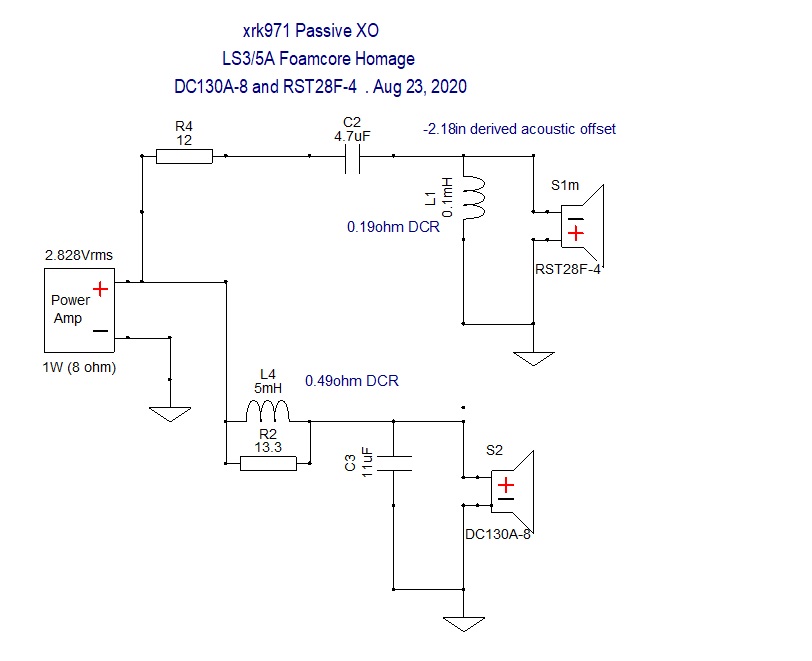

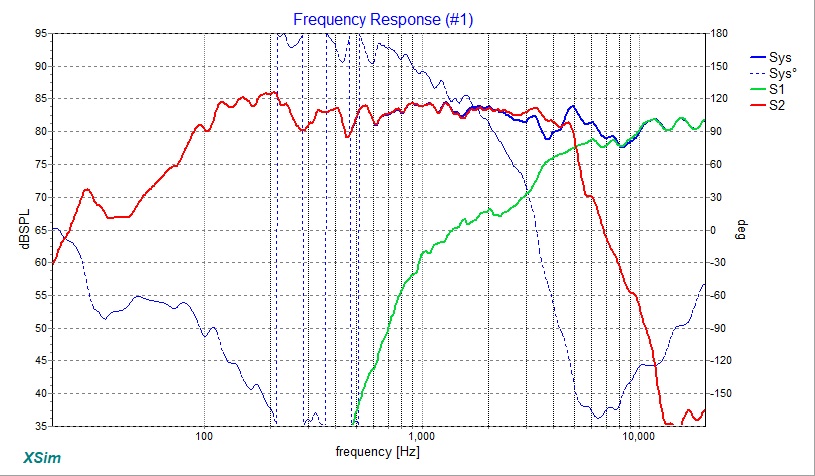

Here is the resulting foamcore homage to the LS3/5A with measurements:

RST28F and DC130A Foamcore Homage to LS5/3A

RST28F and DC130A Foamcore Homage to LS5/3A

its fascinating just to see the bracing technique and sculptured foam ! With one side removed the cabinet could pass as modern art.

Question - is Super Tuff-R 1/2" foam insulation board (~$12.25 per 4' x 8' sheet) too tough/wonky (foil on one side) to cut accurately? That's a lot of board for the money at Home Depot.

https://www.homedepot.com/p/Super-TUFF-R-1-2-in-x-4-ft-x-8-ft-R-3-3-Foam-Insulation-268413/100322369

Thanks, Freddi! I don't know about the foam insulation board you linked but probably can work. It looks a lot like the thinner version of the pink XPS panels.

X take a look around on the Penn Elcom site lots of interesting stuff for a diy'er, connectors, raw cable, rack and enclosure hardware up to and including panel cutout services.

Last edited:

The foamcore LS3/5A homage is finally in stereo and with permanent crossover:

RST28F and DC130A Foamcore Homage to LS3/5A

RST28F and DC130A Foamcore Homage to LS3/5A

Hello XRK,

Getting into this amazing world of building foam board speakers and learning a lot from your & others here.

I have received my Vifa TC9FDs last week and hoping to build a couple of designs from your photos and drawings.

Reading the forum but it is like drinking from a fire hose at the moment. So just a few questions -

1. What thickness of foam board I should buy from dollar stores?

2. Are the TC9FDs mounted with its flange outside or over the baffle? I thought they come with a padding to create a seal when mounted to the back side of the baffle?

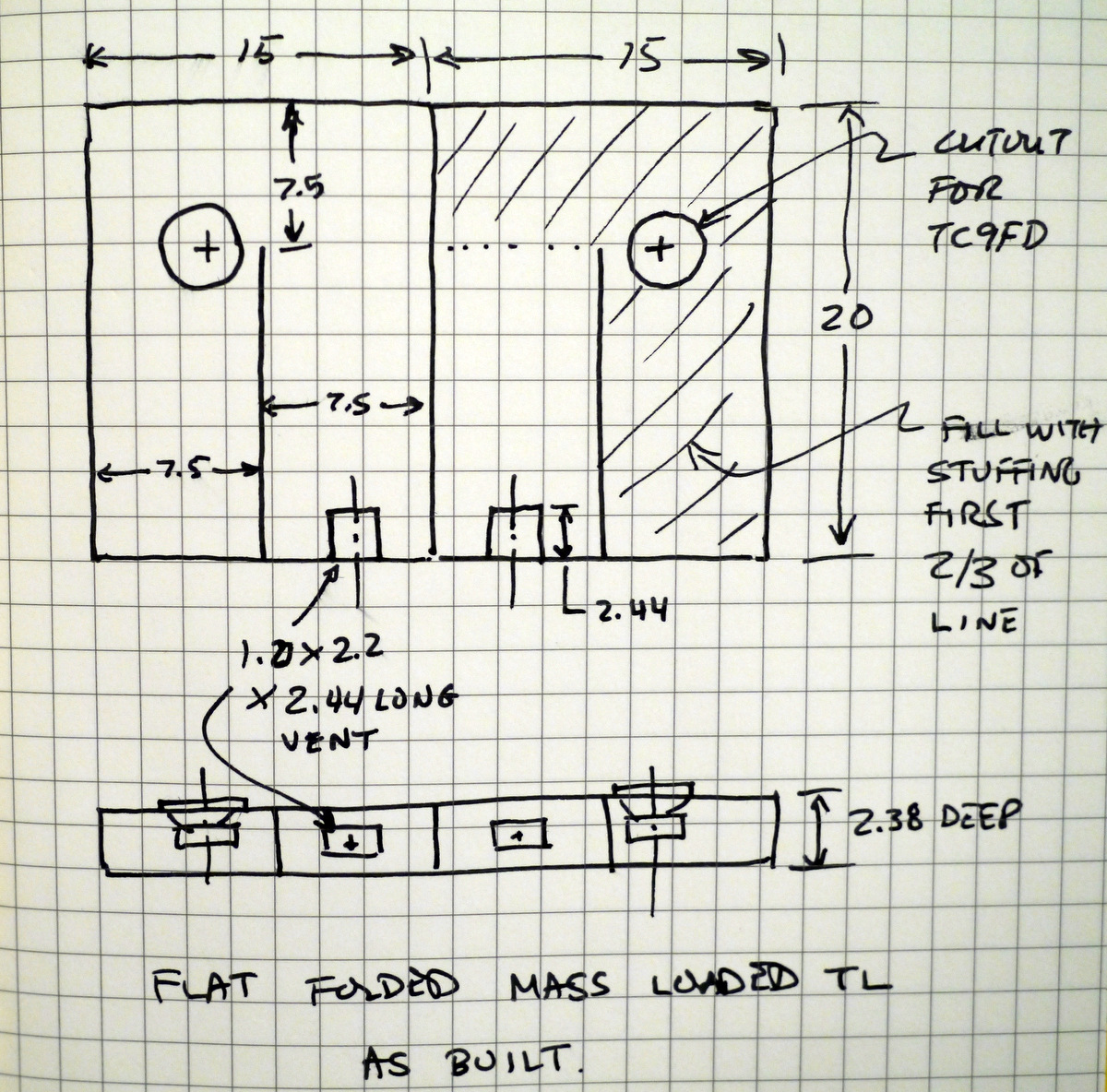

3. Do you have the driver location or position details for this design? Also what does fill up to 2/3 of the line means? Is it 2/3 of the height ? - Foam Core Board Speaker Enclosures?

4. Do you have a drawing for the 20" X 20" Cornu spiral design for the Vifa TC9FDs?

Sorry for the trouble but too excited to build something with my son and still trying to go through this long thread to find pertinent information.

Thanks a bunch and hoping to learn a lot,

NG

Getting into this amazing world of building foam board speakers and learning a lot from your & others here.

I have received my Vifa TC9FDs last week and hoping to build a couple of designs from your photos and drawings.

Reading the forum but it is like drinking from a fire hose at the moment. So just a few questions -

1. What thickness of foam board I should buy from dollar stores?

2. Are the TC9FDs mounted with its flange outside or over the baffle? I thought they come with a padding to create a seal when mounted to the back side of the baffle?

3. Do you have the driver location or position details for this design? Also what does fill up to 2/3 of the line means? Is it 2/3 of the height ? - Foam Core Board Speaker Enclosures?

4. Do you have a drawing for the 20" X 20" Cornu spiral design for the Vifa TC9FDs?

Sorry for the trouble but too excited to build something with my son and still trying to go through this long thread to find pertinent information.

Thanks a bunch and hoping to learn a lot,

NG

Welcome NG!

Dollar store foamcore only comes in 3/16in thick and 30in x 20in Sheets. The heavier stuff made by Elmer’s at art craft stores like Michaels or Hobby Lobby is also 3/16 bit stronger.

Most of my stuff is mounted from front. I have actually never rear mounted them to use the foam gasket. I think that was for some OEM TV speaker application? Or for something g like a line array cabinet?

Drawing for 20in cornu is in Cornu thread - just scale the pdf plan (27in) down to 20in using the print scale function when printing. Use a ruler to measure print and adjust accordingly.

Stuffing is usually from closed end to where driver is on a MLTL. So that’s the first 1/3rd.

My stuffing plan for this one went a little father than usual and went past the driver down to first 2/3rd from closed end. I am not convinced that this is best now. Adjust it by ear. It may be too much. The first 1/3rd rule is much more universal.

Dollar store foamcore only comes in 3/16in thick and 30in x 20in Sheets. The heavier stuff made by Elmer’s at art craft stores like Michaels or Hobby Lobby is also 3/16 bit stronger.

Most of my stuff is mounted from front. I have actually never rear mounted them to use the foam gasket. I think that was for some OEM TV speaker application? Or for something g like a line array cabinet?

Drawing for 20in cornu is in Cornu thread - just scale the pdf plan (27in) down to 20in using the print scale function when printing. Use a ruler to measure print and adjust accordingly.

Stuffing is usually from closed end to where driver is on a MLTL. So that’s the first 1/3rd.

My stuffing plan for this one went a little father than usual and went past the driver down to first 2/3rd from closed end. I am not convinced that this is best now. Adjust it by ear. It may be too much. The first 1/3rd rule is much more universal.

Last edited:

I recently remembered that I have a bunch of these old PE buyout Tang Band W3-881si drivers from a long dead vision I’ve since forgotten.

https://www.parts-express.com/pedocs/specs/299-113-factory-buyouts-w3-881si-specifications.pdf

I also remembered that I was enthralled by the old thread regarding Elias’ stereophonic single speaker.

Stereophonic Sound from a Single Loudspeaker

So I want to give the SSS a try, and have a powered sub to add to the mix. I think my room and option for placement above and behind my TV would be a good experiment.

I think I have enough standard dollar store foam core to make the cabinet for the three drivers. What would be a good volume to use for three of these?

Or, am I better off with a dual wall mount flat TL like above?

https://www.parts-express.com/pedocs/specs/299-113-factory-buyouts-w3-881si-specifications.pdf

I also remembered that I was enthralled by the old thread regarding Elias’ stereophonic single speaker.

Stereophonic Sound from a Single Loudspeaker

So I want to give the SSS a try, and have a powered sub to add to the mix. I think my room and option for placement above and behind my TV would be a good experiment.

I think I have enough standard dollar store foam core to make the cabinet for the three drivers. What would be a good volume to use for three of these?

Or, am I better off with a dual wall mount flat TL like above?

Just look up the specs for the driver and see what they recommend as the volume for one. Multiply by three and make the port scaled up accordingly. I made one out of foamcore for the TC9FD. It’s interesting sounding (more like for use as a clock radio or kitchen speaker) but I liked the sound of the flat wall MLTL better.

Thanks, X.

In that case, can I make estimates of flat wall TL dimensions (volume and length) based on the other TLs designed for this driver in the past?

I may play around with the matrix three driver box, too, because what else are we gonna do in the pandemic? 😀

In that case, can I make estimates of flat wall TL dimensions (volume and length) based on the other TLs designed for this driver in the past?

I may play around with the matrix three driver box, too, because what else are we gonna do in the pandemic? 😀

Yes, look at the AMLTL thread. That’s basically one way of designing an approximate TL. Make the length at least 30in for line and tune it as if it were a bass reflex. Place driver 1/3rd from closed end and vent at the other end. Add stuffing from closed end to the driver.

Dear XRK,Welcome NG!

Dollar store foamcore only comes in 3/16in thick and 30in x 20in Sheets. The heavier stuff made by Elmer’s at art craft stores like Michaels or Hobby Lobby is also 3/16 bit stronger.

Most of my stuff is mounted from front. I have actually never rear mounted them to use the foam gasket. I think that was for some OEM TV speaker application? Or for something g like a line array cabinet?

Drawing for 20in cornu is in Cornu thread - just scale the pdf plan (27in) down to 20in using the print scale function when printing. Use a ruler to measure print and adjust accordingly.

Stuffing is usually from closed end to where driver is on a MLTL. So that’s the first 1/3rd.

My stuffing plan for this one went a little father than usual and went past the driver down to first 2/3rd from closed end. I am not convinced that this is best now. Adjust it by ear. It may be too much. The first 1/3rd rule is much more universal.

Thank you so much for a quick response. Learning something each time from your posts

So here is my interpretation of your drawing. Specifically the driver will be centered at 3.75" from the sides and 12.5" from the bottom. Also, the 12.5" from the driver to the bottom will be filled with pillow stuffing 🙂

Hope I got that right. Will have something to share by Sunday night.

Thanks once again

Attachments

Yes, that’s about right. The lateral position is flexible. You can move it closer towards the divider wall - clearance for the basket provided though.

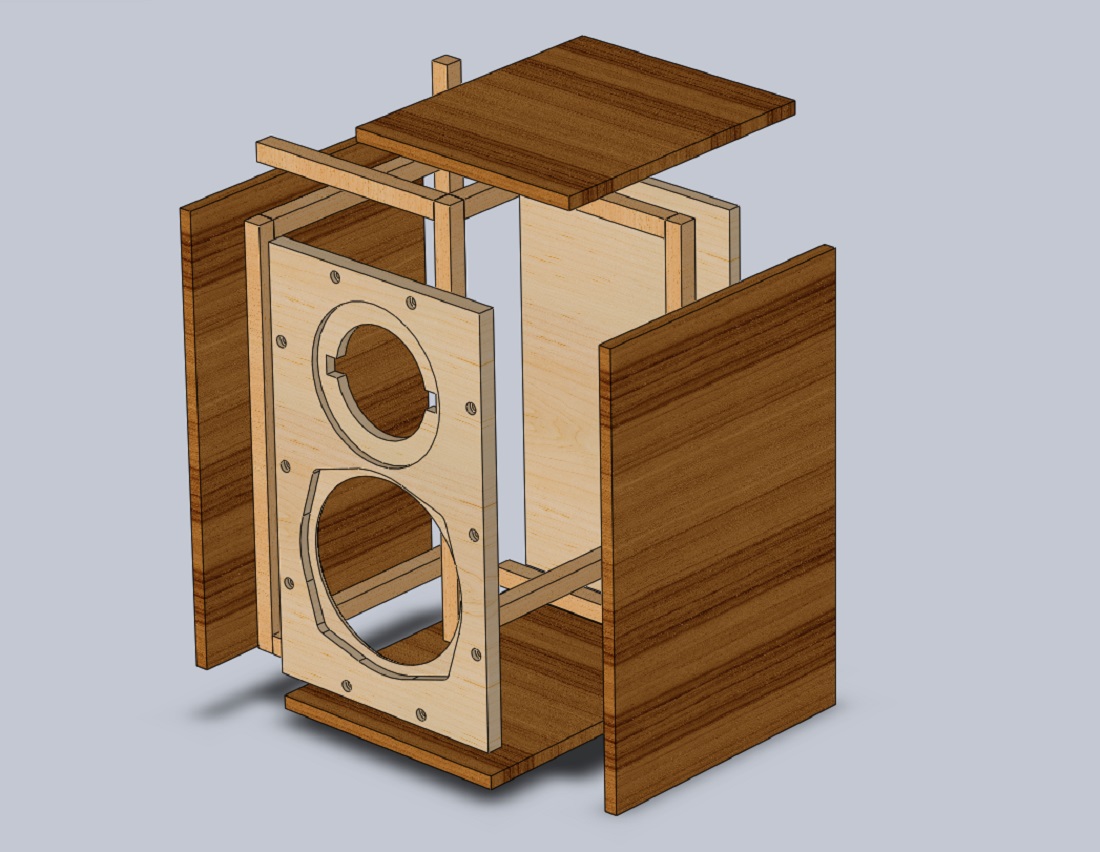

FoamClone LS3/5A mini monitors are working out really well. They are graduating to wood and here’s the design with 9mm and 12mm BB ply and beech battens.

FoamClone:

Wood:

FoamClone:

Wood:

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?