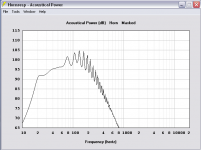

Here you go. 18 - 100 hz full size horn shown at 1 watt. 105 db sensitivity right down to the low knee. And only 22000 liters.

Nope, haven't bothered to check anything for sub 20. You are right its a trivial matter though. I'm getting too old to hear that stuff anyway. I'll drop that idea for the lack of value in it.

The high pass filter wasn't simmed because I probably won't need one active while indoors. Getting loud outdoors its possible though. I wasn't thinking about that last night, probably cause I don't have a sim that I'm ready to commit to.

I did increase the rear chamber volume a bit more than I wanted to already. Last night I had it at 75 initially, then later on I raised it to 90, then 110, said nah... put back to 90. Didn't help enough... Thats about 3 cu ft I'm guessing?

The high pass filter wasn't simmed because I probably won't need one active while indoors. Getting loud outdoors its possible though. I wasn't thinking about that last night, probably cause I don't have a sim that I'm ready to commit to.

I did increase the rear chamber volume a bit more than I wanted to already. Last night I had it at 75 initially, then later on I raised it to 90, then 110, said nah... put back to 90. Didn't help enough... Thats about 3 cu ft I'm guessing?

I thought your first 550 liter version was fine. But if you want more low end sensitivity there's only one way to get it.

You can try tapped horn too. But unless it's significantly larger it won't beat the flh much if at all. What it will do is allow you to go smaller if you want (at the cost of sensitivity) and use up your usable excursion with less power. The higher frequencies won't be as strong as the flh so it will appear to not have such a rising response but the low bass will be ~ the same spl.

You can try tapped horn too. But unless it's significantly larger it won't beat the flh much if at all. What it will do is allow you to go smaller if you want (at the cost of sensitivity) and use up your usable excursion with less power. The higher frequencies won't be as strong as the flh so it will appear to not have such a rising response but the low bass will be ~ the same spl.

Ok then maybe I won't quit yet. I'll work down another FLH to around 500-600 liters but without that unreasonably low knee. If I can get a decent response from a knee near high 20s-low 30s area I'll build it. Maybe a higher knee if I have to... OSB is cheap and the driver is ready.

I'll be ready too after taking a long nap. Thanks for hanging in there, for making all these design issues clearer to me.

later...zzz

I'll be ready too after taking a long nap. Thanks for hanging in there, for making all these design issues clearer to me.

later...zzz

Specd--not sure how well your driver will play with a FLH, given its rather high Qts (for the application). There's nothing magical about an FLH (as you're gathering), and it's probably best to set a volume budget and see what alignment works best. FLH's are great if you have the room and a tweener sealed/vented 12" is going to need a LOT of it.

My bet is a tapped horn/tapered tapped quarter wave tube/pipe (TQWT) will probably achieve the best middle ground.

My bet is a tapped horn/tapered tapped quarter wave tube/pipe (TQWT) will probably achieve the best middle ground.

Ok then maybe I won't quit yet. I'll work down another FLH to around 500-600 liters but without that unreasonably low knee. If I can get a decent response from a knee near high 20s-low 30s area I'll build it. Maybe a higher knee if I have to... OSB is cheap and the driver is ready.

I'll be ready too after taking a long nap. Thanks for hanging in there, for making all these design issues clearer to me.

later...zzz

With the 550 liter flh it takes about 1000 watts to hit xmax. If you raise the tuning it's going to take a lot more power to hit xmax. And the driver won't handle a whole lot more power than that with a demanding signal for any length of time before it melts.

If your driver really does have 22 mm one way xmax you really do need a low tuning to hit xmax with a reasonable amount of power in a flh.

....If you raise the tuning it's going to take a lot more power to hit xmax.

If your driver really does have 22 mm one way xmax you really do need a low tuning to hit xmax with a reasonable amount of power in a flh.

Thats right! And its a BIG point you've made! One of my reasons for trying an FLH box in the first place was the lower power requirement. And the main reason I want to use my IDMAX is for the Xmax headroom where its needed below 20 Hz. That and it is a good SQ woofer. And I own it already so less costs.

After sleeping on it I'm thinking maybe I'll try out a box between 600-700 liters. I'll keep the low tuning but not obsess over it. I'll try to let the driver and horn tell me more about whats best. Probably take me a while to get it right, but I'm thinking I'll just build it and be happy with it.

Fl and Fh are fine for a 18 - 60 hz bandwidth but you get weird results with Leach's math when requesting that bandwidth, a very low flare T and an enormous throat.

No, it's a 'make-do' driver just as you noted.

What can I say? I simmed one with a mouth and net Vb that should fit his box size, but whether it's extra performance is worth it to him in his app? Obviously I don't have a clue.

What I do know is that greater acoustic efficiency and lower CR makes more peak SPL at high power due to a lower thermal power compression, so for a typical HIFI/HT app, no way since the room will dominate and he probably can't use but a fraction of its power handling, but in a very large space/outdoors, 'BIB' [bigger is better] rules as you well know, so yes and ideally he'd have an attachable 'end correction' extension.

WRT to your high power comparison sim, you don't show Xmax limited or probable thermal power compression differences, but with no actual data to use about all I can say is that from limited experience and long gone Altec measured data, the gap between the two will be greater, but won't be proportionately greater based on net Vb.

FWIW, I initially simmed a much smaller horn similar to yours, but then he posted his size constraints, so deleted it since by then you'd already done a small one and went bigger because it's what he wanted.

GM

If low power is a goal you want a tapped horn, not flh. The tapped horn doesn't have the sealed chamber so it can get to xmax with less power applied. This also has implications for the high pass filter as well. The flh has the excursion max INSIDE the passband so the hpf (if/when used) will cost 2-4 db at the low knee. The tapped horn has the excursion max BELOW tuning so the hpf doesn't affect the low knee much if at all.

It's time to sim both a tapped horn and a ported box and compare it to the flh sims. Keep it to 550 liters or less and compare to your first 550 liter flh. And if you plan to use a hpf at all, sim both with the hpf in place.

Do the ported box sim just so you can see how much advantage it has over the horns. You might find that unless you make the horns really large there's not much advantage. The ported box will have higher port compression and likely higher power compression too, and that will not be reflected in the sims so even if they look ~ equal in terms of max spl the horn will still win. But it's nice to see a horn having a large simulated advantage over a ported box, otherwise it might not make sense to build a horn with the extra cost and complexity.

It's time to sim both a tapped horn and a ported box and compare it to the flh sims. Keep it to 550 liters or less and compare to your first 550 liter flh. And if you plan to use a hpf at all, sim both with the hpf in place.

Do the ported box sim just so you can see how much advantage it has over the horns. You might find that unless you make the horns really large there's not much advantage. The ported box will have higher port compression and likely higher power compression too, and that will not be reflected in the sims so even if they look ~ equal in terms of max spl the horn will still win. But it's nice to see a horn having a large simulated advantage over a ported box, otherwise it might not make sense to build a horn with the extra cost and complexity.

No, it's a 'make-do' driver just as you noted.

For the 18 -60 hz bandwidth it's obviously not ideal, but it looks great in for 18 - 100 hz. The large horn sim I posted is the output straight from Leach's math. The throat is sized for ~ 2:1 compression ration (if the driver is offset so it's a few cm down the line), the flare T is a very reasonable .51 and the rear chamber volume is a comfortable 64 liters. The frequency response looks great and all other performance metrics are right on the mark. And as I noted, the calculated Fl and Fh for the driver are well within the 18 - 100 hz bandwidth.

So I would say it's a fine driver for the 18 - 100 hz bandwidth. It just doesn't look good at all when you apply Leach's math to the 18 - 60 hz bandwidth.

What can I say? I simmed one with a mouth and net Vb that should fit his box size, but whether it's extra performance is worth it to him in his app? Obviously I don't have a clue.

What I do know is that greater acoustic efficiency and lower CR makes more peak SPL at high power due to a lower thermal power compression, so for a typical HIFI/HT app, no way since the room will dominate and he probably can't use but a fraction of its power handling, but in a very large space/outdoors, 'BIB' [bigger is better] rules as you well know, so yes and ideally he'd have an attachable 'end correction' extension.

WRT to your high power comparison sim, you don't show Xmax limited or probable thermal power compression differences, but with no actual data to use about all I can say is that from limited experience and long gone Altec measured data, the gap between the two will be greater, but won't be proportionately greater based on net Vb.

FWIW, I initially simmed a much smaller horn similar to yours, but then he posted his size constraints, so deleted it since by then you'd already done a small one and went bigger because it's what he wanted.

GM

I did note that yours would beat mine in every performance metric, especially with power compression factored in. But one of the goals was to be able to wheel this thing around, and I'm just guessing but I think that trumps the modest gains of the 3x larger size.

At 1500 liters and several hundred pounds, his stated max dimensions would be impossible for a single person to move it through a door or around a hallway corner even with a fridge cart. And since it's unlikely that two people could lift it, moving it through a doorway or a hall corner would likely be a 4 man job. None of this was discussed but it's stuff that has to be considered when a major goal is portability.

For the 18 -60 hz bandwidth it's obviously not ideal, but it looks great in for 18 - 100 hz.

But one of the goals was to be able to wheel this thing around......

Still can't 'see the forest for the trees' even after you've stated the facts that prove my point, so we'll have to agree to disagree.

OK, but he set the box size, not us, and we've no clue what his plans/options are, yet you've decided there's not enough performance gains to justify what he asked for. Seems like that's for him to decide, don't you think?

FWIW, as large speakers go, his proposed size isn't much smaller than the 32x48x84" 210 horn cabs [~495 lbs per Altec] I had and me and a neighbor [both of us on the small side back then, though both young, fit] use to dolly them from my 'great'/family room down a couple of steps to the patio, then roll them across a sloped back lawn over cheap exterior grade plywood sheathing to the cul-de-sac for 'block' parties, so we'll have to agree to disagree that he de facto probably is 'biting off more than he can chew' size/weight wise.

GM

Still can't 'see the forest for the trees' even after you've stated the facts that prove my point, so we'll have to agree to disagree.

From where I'm standing I'm pretty sure I can see both the forest and the trees. I stated the facts that prove my point, not yours.

Playing around with Leach's math, even just with Hornresp's System Design tool, it's extremely obvious that the ideal driver t/s parameter for different bandwidths are incredibly different. Even if you just change the high knee (like for example from 60 to 100 hz) and leave the low knee alone (like 18 hz for example) everything changes dramatically. The ideal throat size alone (for a given set of t/s parameters) is a difference of several times larger for the 60 hz high end vs 100 hz.

I could break this down and go step by step through Leach's math but it would take a long time and I'm definitely not going to do that if your only argument is "agree to disagree". This driver is just fine for a 18 - 100 hz passband as Leach's math shows in the large horn sim I provided.

OK, but he set the box size, not us, and we've no clue what his plans/options are, yet you've decided there's not enough performance gains to justify what he asked for. Seems like that's for him to decide, don't you think?

FWIW, as large speakers go, his proposed size isn't much smaller than the 32x48x84" 210 horn cabs [~495 lbs per Altec] I had and me and a neighbor [both of us on the small side back then, though both young, fit] use to dolly them from my 'great'/family room down a couple of steps to the patio, then roll them across a sloped back lawn over cheap exterior grade plywood sheathing to the cul-de-sac for 'block' parties, so we'll have to agree to disagree that he de facto probably is 'biting off more than he can chew' size/weight wise.

GM

Absolutely OP should decide what he can move and what he can't and how many people he can get to help him.

Let's break this down. Google says the average doorway height is 2040 mm, just over 6.5 feet. Lots of doorways are even less, but let's go with 6.5 feet.

Your big cab that you used to move around is 4 feet wide by 7 feet tall. Your proposed cab (if it fills OP's max dimensions) is 4 feet wide by 8 feet tall.

To get either of these (but especially the taller one) through a 6.5 ft high doorway (assuming the doorway width is less than 4 feet) it's going to need to be almost horizontal. And since a fridge cart's handles are usually about 4 feet high, you would have to be crouching below the cab as you move it through the door.

If you can do that by yourself that's fantastic since it's almost impossible. You could get a specialty extra long fridge cart and not have to crouch below the cab but that would be several hundred dollars. You could also buy a bunch of towalongs and strap the cab to the cart and hope like hell that it stays tightly secured and doesn't move, and then you could maybe get away with lifting the far end of the cab and not crouching under the cab. Even then, you would need at least one extra person to lift it over the bump at the threshold unless you plan to risk taking a run at it and hoping it can make it over the bump without tipping.

Illustration - since I'm not going to say that you can't do this almost impossible feat, I've drawn myself into this crappy not to scale picture. As you can see I am very very sad because in a couple of seconds I'm going to die when the cab falls on me. It's pretty easy for even a single person to cart something this size and weight around even on rocky terrain. But when you have to fit it through a doorway or around a corner in a hallway (when you can't use the cart) things get a lot more tricky.

EDIT - oops, I forgot to put wheels on my cart. That's going to make things even more difficult, more angle to get through the doorway. The only practical way to get this through a doorway is to have 4 people carry it in horizontal position. Even with a dolly so a single person could push it in horizontal position you will have to lift it over the bump at the threshold, that's going to be really tough for a single person.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

I'll build whatever works the best, as long as I can fold it up. Tapped horn, FLH, TL, doesn't matter to me. Keep in mind that I'm totally green and ignorant and tend to make bad decisions until you guys set my mind straight. There is a performance vs size matter to consider though, since least lumber and least mass can look pretty inviting when its only a couple Db SPL difference in cabs. That said, I'm willing to do whatever will work because this is going to be a very cheap project for me to complete materials-wise.

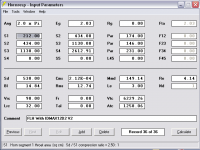

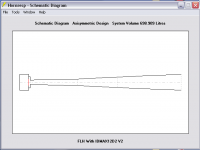

I just tried another sim with a goal to keep the horn under 700 liters. Barely made it... I don't have enough experience to know when its going to be oversize in Hornresp, so I'm lucky to have made the cut tonight.

There are errors in this sim I'm certain, cause the throat adapter isn't made right and probably other errors in there too. I'm a rookie, first saw Hornresp just over a month ago. Keep that in mind as you view the result.

Anyway, while working on this I discovered that I have been screwing up the designs previously, so I hope I've done a better job this time. Also, as I was working on this I realized that I had taken more off the bottom end than I had to... so next time I expect to have a similar looking sim but with greater low extension. I screwed it up. Maybe, just maybe the next one will be smaller as well!

No HPF was in place for Xmax, reached a bit out of band at 253 watts. As I said I think I can fix it. I expect about a 19 Hz knee at 92 db when its corrected. Maybe...

Shoot holes in it for me please!

THANKS!

I just tried another sim with a goal to keep the horn under 700 liters. Barely made it... I don't have enough experience to know when its going to be oversize in Hornresp, so I'm lucky to have made the cut tonight.

There are errors in this sim I'm certain, cause the throat adapter isn't made right and probably other errors in there too. I'm a rookie, first saw Hornresp just over a month ago. Keep that in mind as you view the result.

Anyway, while working on this I discovered that I have been screwing up the designs previously, so I hope I've done a better job this time. Also, as I was working on this I realized that I had taken more off the bottom end than I had to... so next time I expect to have a similar looking sim but with greater low extension. I screwed it up. Maybe, just maybe the next one will be smaller as well!

No HPF was in place for Xmax, reached a bit out of band at 253 watts. As I said I think I can fix it. I expect about a 19 Hz knee at 92 db when its corrected. Maybe...

Shoot holes in it for me please!

THANKS!

Attachments

One of the obvious errors I made in that sim is I made the S2-S3 segment shorter than I intended to and that screwed up the expansion for the entire horn from S2-S4. After I was done with it I realized the mistake there. Its got some crazy FTA going on in there... sorry about that.

From where I'm standing I'm pretty sure I can see both the forest and the trees. I stated the facts that prove my point, not yours.

Nope, you've restated and elaborated on my proof, so again, we'll have to agree to disagree.

No need to 'break in down' for me, I already understand it, but not convinced you do. 😉

If the driver was 'fine', it would have specs close enough to optimal for a 18-60 Hz pass-band and yes, it and the alignment would be quite different since it's not even two octaves, so overall, better to build a ~two octave TH with it.

No, it was 32" wide x 48" deep x 84" tall, so laid down on its back and motorcycle tie-down strapped to two cheap DIY dollies it fit through an [American] standard 36" entry doorway and easily enough pushed/pulled by two [then] average size guys.

His is only 24" wide, so could even fit through an [American] spec interior doorway. Of course you're right in that hopefully he has enough presence of mind not to build it where he can't get it out.

GM

I'll build whatever works the best, as long as I can fold it up. Tapped horn, FLH, TL, doesn't matter to me. Keep in mind that I'm totally green and ignorant and tend to make bad decisions until you guys set my mind straight. There is a performance vs size matter to consider though, since least lumber and least mass can look pretty inviting when its only a couple Db SPL difference in cabs. That said, I'm willing to do whatever will work because this is going to be a very cheap project for me to complete materials-wise.

You can't take the overlaid sims as definitive performance guidelines. GM's horn took 700 watts to reach xmax while my 3x smaller horn took 1000. As we have all be saying there will be differences in power compression that the sim can't show.

There is no completely accurate model for power compression so I don't even attempt to simulate the effects.

And power compression depends VERY heavily on the voltage level and also the type of music that you play. if you play music with very little bass, and what little bass that's there is very sporadic and dynamic then power compression isn't going to be a big issue and the sims should pretty accurately reflect what's going to happen. But if you play music that has constant bass similar to sine waves, and the frequencies of the bass line correspond to the frequencies where the driver is using the most power then there are going to be huge power compression problems and possible outright thermal failure.

This shows the actual power vs frequency that the driver is consuming when voltage is 49.84 V and power level is "600 watts". You can see that the driver is consuming VERY little power at 25 and 60 hz. But if you play a 48 hz sine wave at this power level for a few hours the driver will exhibit severe power compression and the voice coil will likely melt even though it's rated for 1000 watts RMS.

(This is driver power for the tapped horn sim shown below.)

An externally hosted image should be here but it was not working when we last tested it.

I just tried another sim with a goal to keep the horn under 700 liters.

I think at this point you have more than enough flh sims of various sizes so you have a pretty good picture of how a flh of various sizes is going to perform. Now it's time to do some tapped horn and ported box sims and see how they compare.

To get things started, here is an ultra simple tapped horn with a constant PAR expansion rate. If you reduced the last segment length to equal the first segment length this could be folded into a super simple single fold by just folding it in half, but changing the last segment length will make the dip at 70 hz very deep. Still, with the first and last segment unequal lengths it's pretty easy to fold.

This is shown at 600 watts with a high pass filter in place. Overlaid is the small flh sim I showed previously shown at 1000 watts, also with the required high pass filter in place. Excursion levels are not exactly the same but this is just a quick 2 minute sim.

The tapped horn is about 200 liter smaller than the flh. 568 liters vs 368 liters. The dramatically different power level to bring these designs to xmax will mean much less power compression for the tapped horn.

As it stands, ignoring power compression the low knee is almost identical but the flh has a couple db advantage at the dip above the low knee and a LOT of extra output at the top of the passband. With room gain this tapped horn might be a bit too strong at low frequencies but it would be pretty ideal outside.

Much smaller size, much less power required, the compromises are up to you.

An externally hosted image should be here but it was not working when we last tested it.

I'll build whatever works the best, as long as I can fold it up.

TH makes the most sense to me for your intended driver, BW [file attached]. ~511 L net.

WRT designing a truncated FLH, the way we did it before simming programs was to design true full range horn where its Fc = Fs, so technically a BLH since the rear chamber size approached infinity for all practical purposes, then 'sliced' a section out that had the right throat [HF limit] and mouth [LF] area that was at least 1/8 WL. Normally, the CR was 1:1 or less and never > 2:1 AFAIK to keep from needing a phase plug, front filter chamber.

Anyway, the main thing is that as the BW shifts down, so goes efficiency, ergo if you want efficiency in the sub-bass then either the horn has to be long, huge or use multiple and/or very large drivers with the appropriate specs to shorten it and it must be acoustically 1/2 WL long to get down to its tuning [Fp] with any 'authority'.

GM

Attachments

Nope, you've restated and elaborated on my proof, so again, we'll have to agree to disagree.

No need to 'break in down' for me, I already understand it, but not convinced you do. 😉

If the driver was 'fine', it would have specs close enough to optimal for a 18-60 Hz pass-band and yes, it and the alignment would be quite different since it's not even two octaves, so overall, better to build a ~two octave TH with it.

Ok, let me retract this statement "Playing around with Leach's math, even just with Hornresp's System Design tool, it's extremely obvious that the ideal driver t/s parameter for different bandwidths are incredibly different.

- and replace it with this -

This driver might not have ideal specs for the requested passband but using Leach's math it's easy to see that it can be used extremely effectively for 18 - 100 hz bandwidth. Furthermore, almost any set of driver specs can be used with Leach's math to provide extremely effective response over SOME bandwidth.

Clearly I should have chosen my words much more carefully.

No, it was 32" wide x 48" deep x 84" tall, so laid down on its back and motorcycle tie-down strapped to two cheap DIY dollies it fit through an [American] standard 36" entry doorway and easily enough pushed/pulled by two [then] average size guys.

His is only 24" wide, so could even fit through an [American] spec interior doorway. Of course you're right in that hopefully he has enough presence of mind not to build it where he can't get it out.

GM

Fine, the point was that a fridge cart won't work and it's not possible for one person to move. It's going to require at least two people to lift the dollies over the bump at the doorway threshold.

The harder it is to move the less likely that it's going to be moved. Clearly OP can decide for himself how much is too much and like I've said at least twice now, your horn beats the smaller horn in every performance metric, especially when power compression is considered. But it's massive and depending on where performance vs portability lies on OP's list of goals, might not be worth the size.

FWIW, our tapped horns overlaid.

GM's, 511 liters, 535 watts. Mine, 368 liters, 600 watts.

The extra 143 liters buys you a couple hz lower extension and slightly less power to hit xmax. For GM's sim you could make the last segment a bit longer (without changing the overall length of the horn) to reduce that 60 hz dip a bit if you wanted to. Danley does this on at least some of his low tuned tapped horns to keep that dip from getting to deep.

GM's, 511 liters, 535 watts. Mine, 368 liters, 600 watts.

The extra 143 liters buys you a couple hz lower extension and slightly less power to hit xmax. For GM's sim you could make the last segment a bit longer (without changing the overall length of the horn) to reduce that 60 hz dip a bit if you wanted to. Danley does this on at least some of his low tuned tapped horns to keep that dip from getting to deep.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- FLH design basics for a dummy