I will, Rob. I am on the road in Philly on a mobile device.

Maybe even more people will read it and related studies if we problematize the issue and we can hack away at the question some.

Keep the references coming...

Maybe even more people will read it and related studies if we problematize the issue and we can hack away at the question some.

Keep the references coming...

<snip>

If I just have to listen to another record before I go to sleep in the evening, it's good.

If I have no problem turning everything off and go to sleep, something is wrong.

<snip>

I like this, explains why I am frequently still up at 1:30AM forcing myself to shut off the stereo. 😀

I've heard a number of field coils, mostly of the RCA theater system variety and thought they sounded very good, and were rather interesting generally speaking.

No issue either with severe duty induced demagnetization that you may experience with alnico woofers and other drivers with alnico magnets subjected to high power operation. Tinkering with FC current probably has a measurable effect on both BL and QES/QTS particularly if you try various combinations of CCS versus VS power supplies to the FC. Field coils can be tuned electrically to some extent to match their box tuning.

In any event this is a hobby and an area of endeavor/discovery whether or not there is significant discernible difference in objective or even subjective metrics. Look at the choice we have in automobiles - most will competently get you from point A to B, but some are a lot more fun than others, I suspect the choice of FC versus PM magnets not to mention neo, alnico, or ferrite on the PM side at minimum can be rationalized the same way. (Even if none of them have any particular advantage over the other) In any event who does this hurt if someone finds a different path to enjoyment, I hope you are not going to dictate to me what car I should drive. Choice, tolerance and some semblance of an open mind ...

FWIW I'm glad I moved the thread to where it has finally seen the light of day.

I'd love some diy FC project to materialize out of this - possibly based on some inexpensive 1" eBay driver?

We did a lot of testing on voice coil heating at KEF. I worked on the protection circuitry of the KM1 where voice coil temperature was constantly measured via monitoring the DC resistance. In effect the thermal conditions are of cascaded RC circuits. You dump heat into the voice coil and its temperature rises. It has light thermal mass so it will have a short time constant, perhaps 2 seconds for a tweeter and 5 to 10 seconds for a woofer. At a constant power it will run up to a fairly constant temperature but will meanwhile be transfering heat to the surrounding magnet structure. This is through the air gap, a highish resistance, to the large thermal mass of the magnet and steel. Those two factors give the magnet a very long thermal time constant of, say, a half an hour. As the magnet heats up it very slowly transfers its heat to the cabinets and so on and so on.

The thermal resistance between the coil and the magnet structure means that the structure isn't very good at regulating the VC temperature. It will rise and fall regularly as the music power ebbs and flows. Of course it only falls back to thr local ambient, which is the temperature of the surrounding magnet.

As for a warm field coil being the "cause of these units sounding so good" (I love the presumptions here), the resistivity of copper rises and reduces current, so sensitivity drops, Qe rises, etc. no different than putting a couple of ohms in series with a woofer. F=Bli, so more resistence just reduces i and so reduces force or SPL output.

VC heating causes a fairly benign power compression. I've seen about 3 dB of sensitivity sag during testing. It rises and falls at the VC time constant so it would sound like a gentle hand on the volume control, turning back the loudest music by a couple of dB. If you get much more sag than 3 dB then you are getting the VC up to a temp where you are risking burnout.

Interestingly, you can add ferrofluid and the thermal conductivity to the motor will improve. The VC will run cooler but the maximum temperature that you should get the ferrofluid too is less than most modern voice coils will stand, so it is a tradeoff.

David S

The thermal resistance between the coil and the magnet structure means that the structure isn't very good at regulating the VC temperature. It will rise and fall regularly as the music power ebbs and flows. Of course it only falls back to thr local ambient, which is the temperature of the surrounding magnet.

As for a warm field coil being the "cause of these units sounding so good" (I love the presumptions here), the resistivity of copper rises and reduces current, so sensitivity drops, Qe rises, etc. no different than putting a couple of ohms in series with a woofer. F=Bli, so more resistence just reduces i and so reduces force or SPL output.

VC heating causes a fairly benign power compression. I've seen about 3 dB of sensitivity sag during testing. It rises and falls at the VC time constant so it would sound like a gentle hand on the volume control, turning back the loudest music by a couple of dB. If you get much more sag than 3 dB then you are getting the VC up to a temp where you are risking burnout.

Interestingly, you can add ferrofluid and the thermal conductivity to the motor will improve. The VC will run cooler but the maximum temperature that you should get the ferrofluid too is less than most modern voice coils will stand, so it is a tradeoff.

David S

I love the presumptions here

Think of it as a loose hypothesis for evaluation, brainstorming, if that makes it more palatable!

Thanks for the input, SD.

What temperatures are we talking about at the vc? Field coils do not usually get very hot...certainly not to where you need kapton undershorts.

I'm thinking more about effects of magnet heating than vc heating. Electromagnets are naturally warm whereas PM is not at low dissipation. Further, maybe electromagnets are relatively immune to minor temperature shifts so it doesn't matter?

Say, I take a magnet and heat the center near the gap with a hot VC, does this create a measurable long time-constant transient effect? Does heating the permanent magnet evenly by 40 or 50 degrees matter?

It is an area of difference between PM and FC operation, so it deserves at least a look.

By the way, Speaker Dave, the guys from KEF are our neighbors in Munich and they are great fans of our field coil theater gear demos! Yeah, we upstaged the KEF Blade but they didn't seem to mind.

I'm not a magnetics expert, but all I remember about magnetic heating is the Curie effect where magnetism goes away. I believe this is reversable so that full strength comes back when the magnet cools. There is an issue with extreme cold though, where a magnetic circuit that is poorly designed can be frozen to the point where it "falls below he knee" and permanently demagnetizes. I've heard stories of trucks parked overnight in Minnesota winters and the woofers losing most of their strength, etc.

Most voice coils are good up to 200 degrees C or more. I think one of those JBL papers mentioned 270 degrees. I remember overnight power tests where we needed heavy gloves to pick up the woofer. The magnets were over 100 C, hot enough to boil water. I suspect that most field coils run at the "moderately warm" region of 30 or 40 C. Not enough to impact the performance greatly.

To clear up the crystal oven notion, warming the motor structure doesn't regulate the VC temperature, it just sets the environment it starts in. If a give wattage raise it 40 degrees over ambient then it wil still rise that much over a warmer ambient. the crystal oven was initally for tube radios where the warm up of the radio cause lots of drift from turn on. Instead the crystal is put in an oven (compartment) that is regulated to be a little warmer than the outside tube radio would have gotten it to. As the radio heats up the thermostat turns down the oven's heating element and keeps the temperature constant. Its not the heat but the regulation that is important.

David

Most voice coils are good up to 200 degrees C or more. I think one of those JBL papers mentioned 270 degrees. I remember overnight power tests where we needed heavy gloves to pick up the woofer. The magnets were over 100 C, hot enough to boil water. I suspect that most field coils run at the "moderately warm" region of 30 or 40 C. Not enough to impact the performance greatly.

To clear up the crystal oven notion, warming the motor structure doesn't regulate the VC temperature, it just sets the environment it starts in. If a give wattage raise it 40 degrees over ambient then it wil still rise that much over a warmer ambient. the crystal oven was initally for tube radios where the warm up of the radio cause lots of drift from turn on. Instead the crystal is put in an oven (compartment) that is regulated to be a little warmer than the outside tube radio would have gotten it to. As the radio heats up the thermostat turns down the oven's heating element and keeps the temperature constant. Its not the heat but the regulation that is important.

David

To clear up the crystal oven notion, warming the motor structure doesn't regulate the VC temperature,

I was thinking of magnet temperature, fc power losses as power source for ovenizing the magnet...I don't see any advantage in keeping the vc warm.

If VCs can go up to 100 even 200C without ill effect, a FC will not get that hot.

With most FC designs being highly sensitive transducers, you would be deaf and the cops would be knocking on the door before dissipating that much power in the vc!!

Yeah, the Curie effect. Glad I read more of the last few posts before saying anything.

But that is how the Weller WTPC range of soldering irons (and other brands) do their temperature control. When the magnetic element gets too hot it drops its field and the magnetic circuit that holds a relay finger opens, turning off the powah to the heating elephant.

My understanding is that Alnico does this, not just neo and ferrite. For most home apps the temperature where it goes limp could not be reached. But, I don't recall if there is a variation in the flux levels with temperature or not.

I vote for the peltier cooled FC units myself...

😀

_-_-bear

But that is how the Weller WTPC range of soldering irons (and other brands) do their temperature control. When the magnetic element gets too hot it drops its field and the magnetic circuit that holds a relay finger opens, turning off the powah to the heating elephant.

My understanding is that Alnico does this, not just neo and ferrite. For most home apps the temperature where it goes limp could not be reached. But, I don't recall if there is a variation in the flux levels with temperature or not.

I vote for the peltier cooled FC units myself...

😀

_-_-bear

Last edited:

I'm not a magnetics expert, but all I remember about magnetic heating is the Curie effect where magnetism goes away. I believe this is reversable so that full strength comes back when the magnet cools. There is an issue with extreme cold though, where a magnetic circuit that is poorly designed can be frozen to the point where it "falls below he knee" and permanently demagnetizes. I've heard stories of trucks parked overnight in Minnesota winters and the woofers losing most of their strength, etc.

I hope you were trying to be sarcastic because I am really laughing.

dave

Don't hold you breath. This is all about speculation and arguing. We'd be lucky to get an actual listening test of FC vs PM just to find a preference.I'd love some diy FC project to materialize out of this - possibly based on some inexpensive 1" eBay driver?

I doubt anyone* here actually wants to build anything. Talking about it is so much more fun.

..

*Except Dave Slagle - he has actually built some.

Here's a relevant article from my favorite science journal, Stereophile

🙄 "Science journal"? Pseudo-science perhaps. They mix measurements alongside flakey "Oh you MUST try this wonderful power cable because I just did and it lifted 15 veils from the music and made for blacker backgrounds" Sheesh 😛

Soooooooo it got quiet in here , what's the matter no meaningful measurements pop up yet? 😉

You could use ARTA to measure frequency and distortion and post them for those that do have a Field coil and non modified driver of the same make and model. or perhaps a before and after mod would be better, just saying.....so "try it"

Last edited:

This is all about speculation and arguing. We'd be lucky to get an actual listening test of FC vs PM just to find a preference.

If you're volunteering a FC, I'll volunteer the time. The cost is a bit prohibitive.

I was hoping to get an insight into why I was impressed by the FCs heard in the past. What's wrong with that?

I have a late 50s Jensen F12N for loan if somebody has an 8 ohm P12N and the relevant scientific apparatus to check them both out.

I am going the conversion route, probably starting with Altec 802-A/Bs, which I have in stock. Will talk to Fabio, Wolf von Langa, and a few other people who do this at the German show next week. There are a few guys doing Altecs and JBL conversions in Korea also.

Requested the data and pricing from the OP on kits but might go it alone using Silbatone's winding equipment if I can't con my old bud Slagle into winding me some coils. My old ham radio crank coil winder should work also.

If I convert the 802-B tangerine version I can switch between Alnico, Ferrite (902B) and electrodynamic which should be an interesting comparison.

I will also meet up with some highly knowledgeable magnetics folks in Munich and I will see if I can get those references on flux modulation behavior of various magnetic materials.

I am going the conversion route, probably starting with Altec 802-A/Bs, which I have in stock. Will talk to Fabio, Wolf von Langa, and a few other people who do this at the German show next week. There are a few guys doing Altecs and JBL conversions in Korea also.

Requested the data and pricing from the OP on kits but might go it alone using Silbatone's winding equipment if I can't con my old bud Slagle into winding me some coils. My old ham radio crank coil winder should work also.

If I convert the 802-B tangerine version I can switch between Alnico, Ferrite (902B) and electrodynamic which should be an interesting comparison.

I will also meet up with some highly knowledgeable magnetics folks in Munich and I will see if I can get those references on flux modulation behavior of various magnetic materials.

Thanks Joe! I have some Altec 1" drivers that I might be willing to put under the knife, depending on the cost of the surgery. Before and after measurements would be fascinating.

Art (Weltersys) has a clever technique for recording that could allow us all to listen to the before and after.

Art (Weltersys) has a clever technique for recording that could allow us all to listen to the before and after.

The day that ANY measurements that one makes can be correlated back to the way it is perceived by the ear, someone should send me a Telegram. Wait a second. There are no more Telegrams, right? So, I have nothing to wait for...

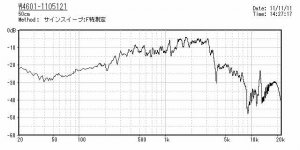

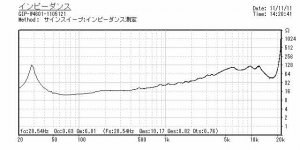

There are already measurements posted that show "a difference" between one and the other - tells me nothing about how it will sound, the differences are pretty small. Maybe within unit to unit variations to begin with.

Pano, I am not sure but Tom Danley uses the "rinse and repeat" recording technique to "amplify" variations between DUTs... same thing as Weltersys' method?

_-_-bear

There are already measurements posted that show "a difference" between one and the other - tells me nothing about how it will sound, the differences are pretty small. Maybe within unit to unit variations to begin with.

Pano, I am not sure but Tom Danley uses the "rinse and repeat" recording technique to "amplify" variations between DUTs... same thing as Weltersys' method?

_-_-bear

A bigger concern with those measurements would be potential overload at some stage in the recording chain. They're suspiciously flat in shape for loudspeakers. I recall another commercial vendor making the same measurement error with their modification of a field coil magnet system and publishing corrections that looked more 'speakerish'.Maybe within unit to unit variations to begin with.

Before and after measurements would be fascinating.

No, before and after measurements would be useful background information on the epiphenomenon of FR.

Before and after listening would be fascinating (hopefully).

I must agree with Bear that minor variations in FR are not that instructive to read about. I'm expecting a large shift in character and presentation, more like a shift from Miller High Life to Stone IPA.

I say this because I have often EQed drivers to very noticeable degrees but they always sound like the same driver.

One measurement that I would like to be able to do is magnetic flux density so I could know if the drivers are running at the same level, but I don't have the capability in-house.

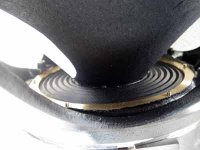

I am interested in making fc compression drivers because I just returned home from visiting a sick relative to find the speakers in the pictures waiting at my door... GIP W-4601A field coil 18"s!! These use a TA-4181 spec cone, which weighs something like 24 grams!

Feast your sighted belief systems on these babies!!

I worked with these speakers before. The performance of the GIP 18" does not require A-B tests to verify whether I am hearing any difference between this and a Dayton or Eminence. I mean come on..get real.

Hope all you fanatic empiricists will join me in some empirical activity.

Attachments

you're on my ignore list

OK, then... I'll PM you.

These are awesome. I'll have to donate some furniture to the War Vets thrift shop to create room for the baffles though.

For those of you going to Munich, I believe Suzuki sent a three way system composed of this series of GIP drivers to the show, so we can check them out together, Franziskaner Weissbier in hand!

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Field Coil conversion for JBL, Altec, and Western