Vunce on Prasi’s CRC psu board, what are the components because i want to bouild the same.

Thanks

Prasi’s CRC GB psu board that I used had the following:

MSRF1560G Diodes

CDE 22000uF, 50V capacitors

3x 0R68, 3W Panasonic ERX = 0R23 final resistance

6K8, 3W Pani ERX bleed resistors

4K7, 1W Vishay MBE Rled resistors

This was originally built for a Class A amplifier, not for this amp. I just grabbed it from my psu stash. If I was going to go with a linear power supply for this amplifier I would utilize the LT4320 ideal bridge instead of silicone diodes. Retrofit Prasi’s small THT or SMD LT4320 rectifier boards with this pcb or I believe he has an updated CRC pcb that easily accepts ideal bridge.

63V capacitors would also be required.

I’d go with two paralleled 1R, 5W KOA BPR58’s resistors.

Is this design already copied

Someone is selling board with same topology and almost similar component values

Tenghong Audio Power Amplifier Board 100W Ultimate Fidelity Amplifiers MOS Tube Amplificador IRFP240 IRFP9240 Mono AMP DIY Audio|Amplifier| - AliExpress

Someone is selling board with same topology and almost similar component values

Tenghong Audio Power Amplifier Board 100W Ultimate Fidelity Amplifiers MOS Tube Amplificador IRFP240 IRFP9240 Mono AMP DIY Audio|Amplifier| - AliExpress

In keeping with the budget conscious theme, what if we used a cast iron skillet as a heatsink? Only $10! Not as conductive as aluminum but might be ok for Class AB.

https://www.walmart.com/ip/Ozark-Trail-Small-Cast-Iron-Griddle-Reversible/55208725

Even has “rack mount” handles.

If you ran it Class A, it would also be the first amp to cook breakfast for you. 🙂

https://www.walmart.com/ip/Ozark-Trail-Small-Cast-Iron-Griddle-Reversible/55208725

Even has “rack mount” handles.

If you ran it Class A, it would also be the first amp to cook breakfast for you. 🙂

Hi JPS64,

Are your suggesting that the cast iron skillet heat sink can be used for the Alpha Nirvana? Vunce reminded me that drilling and tapping cast iron is a b!tch. It’s possible, just not butter smooth easy like aluminum.

I am digging through my stash of donuts and found two unused AN-3232’s. Can’t remember what project they are for but should make 45v nicely. +/-45v happens to make 29Vrms exactly and that’s 105w into 8ohms. Looks like all I need are 8x 4700uF 63v caps and I have myself a PSU.

I might dress mine up with a RTR SSR on the output to protect my 10F/RS225 TL speakers.

I just need to find a chassis now. I might have to kick the MoFo to the curb to free up room for a temporary chassis with 7.2in x 5in heatsinks all ready to go.

Are your suggesting that the cast iron skillet heat sink can be used for the Alpha Nirvana? Vunce reminded me that drilling and tapping cast iron is a b!tch. It’s possible, just not butter smooth easy like aluminum.

I am digging through my stash of donuts and found two unused AN-3232’s. Can’t remember what project they are for but should make 45v nicely. +/-45v happens to make 29Vrms exactly and that’s 105w into 8ohms. Looks like all I need are 8x 4700uF 63v caps and I have myself a PSU.

I might dress mine up with a RTR SSR on the output to protect my 10F/RS225 TL speakers.

I just need to find a chassis now. I might have to kick the MoFo to the curb to free up room for a temporary chassis with 7.2in x 5in heatsinks all ready to go.

Last edited:

Hi X,

you‘re thinking about something like modular class A amplifier?

Drilling is not a problem, I see some issues with corrosion!

JP

you‘re thinking about something like modular class A amplifier?

Drilling is not a problem, I see some issues with corrosion!

JP

Cast iron won’t corrode if you season it by wiping with vegetable oil and letting the heat bake it in and seal it just like we do when cooking. My worry is that it doesn’t conduct well enough to spread the heat load outwards. Although a quick FEA analysis will answer that right away. Or an experiment. Two MOSFETs each 45w over 2cm x 1cm patch. As long max temp on MOSFET body is below 100C, I’ll be ok with it.

Looks like I’ll be picking up a pair of cast iron griddles shortly 🙂

Looks like I’ll be picking up a pair of cast iron griddles shortly 🙂

X,

Isn't heat retention one of the qualities that cast iron skillets are known for? 🙂

On the other hand materials like aluminum are renowned for their ability to dissipate heat.

Isn't heat retention one of the qualities that cast iron skillets are known for? 🙂

On the other hand materials like aluminum are renowned for their ability to dissipate heat.

Heat retention is just specific heat of the material x density.

For cast iron specific heat is 460J/kg-K and density is 7900kg/m^3

Aluminum specific heat is 921J/kg-K and density is 2700kg/m^3

Aluminum actually has a higher heat capacity than cast iron per unit mass but not volume. So Aluminum pans of the same mass will retain more heat than cast iron. But for same volume the cast iron will retain more heat because it is more dense.

Aluminum conducts heat at a higher rate so heat transfer is more rapid.

For cast iron specific heat is 460J/kg-K and density is 7900kg/m^3

Aluminum specific heat is 921J/kg-K and density is 2700kg/m^3

Aluminum actually has a higher heat capacity than cast iron per unit mass but not volume. So Aluminum pans of the same mass will retain more heat than cast iron. But for same volume the cast iron will retain more heat because it is more dense.

Aluminum conducts heat at a higher rate so heat transfer is more rapid.

Last edited:

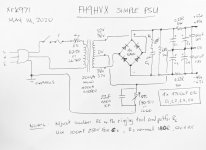

I think Prasi CRC is great if you have it already. It’s overkill for the FH9HVX.

I was thinking more along the lines of something lower cost and simple like four 10A10 diodes with windings set up as common center tap. Four 4700uF 63v caps and 0.22R 5W resistors. A 6k8 2W bleeder resistor. 100nF 250v MKP output bypass cap. An RC snubber setup and tuned to your particular trafo (optional). Use 100nF film and 180R as baseline for snubber.

Do all of this as P2P.

Schematic for a single channel monoblock:

For a stereo supply use 9600uF caps and 0.1R resistors.

Edit: for single 6k8 bleed red between +/- rails, use 3w. Or two 2W connected between +ve and -ve rails and ground.

I was thinking more along the lines of something lower cost and simple like four 10A10 diodes with windings set up as common center tap. Four 4700uF 63v caps and 0.22R 5W resistors. A 6k8 2W bleeder resistor. 100nF 250v MKP output bypass cap. An RC snubber setup and tuned to your particular trafo (optional). Use 100nF film and 180R as baseline for snubber.

Do all of this as P2P.

Schematic for a single channel monoblock:

For a stereo supply use 9600uF caps and 0.1R resistors.

Edit: for single 6k8 bleed red between +/- rails, use 3w. Or two 2W connected between +ve and -ve rails and ground.

Attachments

Last edited:

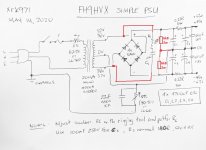

Hi Folks,

I have a couple of errors on the above schematic. The snubber needs to be on the secondaries AC side. The 6k8 2w bleeder needs to be from each rail to 0v in order to keep the dissipation low enough. Also, if using one PSU for stereo, make the bulk caps 9600uF ea and use 0.1R 5W resistors. Here is the corrected schematic.

I have a couple of errors on the above schematic. The snubber needs to be on the secondaries AC side. The 6k8 2w bleeder needs to be from each rail to 0v in order to keep the dissipation low enough. Also, if using one PSU for stereo, make the bulk caps 9600uF ea and use 0.1R 5W resistors. Here is the corrected schematic.

Attachments

Looks good, 10,000uF is great but not necessary to be that big. The ground should have NTC to isolate clean vs dirty chassis/earth ground.

- Home

- Group Buys

- FH9HVX - Budget Conscious 100w Class AB for Lean Times