I might suggest you re-examine the 'coupling' between the driver and the chamber, particularly if using car repair 'bog' - not exactly the best material for sound vibration performance.

I tried a number of materials and ended up using a wood 'mounting board' with the driver mounted from the inside so the edge of the driver frame was flush with the curve of the front 'half sphere' - a lot of sanding and finishing required when gluing front baffle board to the chamber spherical wall - and different timbers do effect the sound, just like guitars.

I tried a number of materials and ended up using a wood 'mounting board' with the driver mounted from the inside so the edge of the driver frame was flush with the curve of the front 'half sphere' - a lot of sanding and finishing required when gluing front baffle board to the chamber spherical wall - and different timbers do effect the sound, just like guitars.

Hi James,

the enclosure, the first ring i have cut, has a cutout for the driver. It will be attached as usual by other speakers. I will use some sort of vibration absorbing material between the driver and the ply. Yes I constructed it out of ply wood. Not the best quality thought, as I had to use what was available in the shops.

The body filler and paint is only surface finish. inside i will use Dynamat damping on whole surface, + wool if necessary.

Danny

the enclosure, the first ring i have cut, has a cutout for the driver. It will be attached as usual by other speakers. I will use some sort of vibration absorbing material between the driver and the ply. Yes I constructed it out of ply wood. Not the best quality thought, as I had to use what was available in the shops.

The body filler and paint is only surface finish. inside i will use Dynamat damping on whole surface, + wool if necessary.

Danny

You might be right with the cushion under the driver frame - I remember needing something like this with the 8" driver to tame down the resonance a bit - made of leaded vinyl or something, I think.

Nothing wrong with plywood construction - it's that customwood and chipbrd that produces the biggest problems.

Also, you'll need a circular internal diffuser - like a tube to reduce radial interference - a good material for this is that 3mm thick clear polycarb sheet with some round holes drilled in it - will probably need higher damping than the B&W model as very different driver behaviour for the tapered resistance down the long 'tail' - you might go easy on the Dynamat coating at the start until you try the driver fully assembled as there's a tendency using this stuff to 'over-damp' and you lose a lot of small signal response in exchange for a smoother response

Oh yeah, you might have a look at the Rethym speakers for some ideas about adding some 'covers' and things on the back of the driver, magnet, etc - makes quite a difference to upper mids/treble surprisingly enough.

... all the best.

Nothing wrong with plywood construction - it's that customwood and chipbrd that produces the biggest problems.

Also, you'll need a circular internal diffuser - like a tube to reduce radial interference - a good material for this is that 3mm thick clear polycarb sheet with some round holes drilled in it - will probably need higher damping than the B&W model as very different driver behaviour for the tapered resistance down the long 'tail' - you might go easy on the Dynamat coating at the start until you try the driver fully assembled as there's a tendency using this stuff to 'over-damp' and you lose a lot of small signal response in exchange for a smoother response

Oh yeah, you might have a look at the Rethym speakers for some ideas about adding some 'covers' and things on the back of the driver, magnet, etc - makes quite a difference to upper mids/treble surprisingly enough.

... all the best.

jim, my internal shape is a copy of B&W's shape, a sphere with a funnel at the end.

What I need to do is smooth it out and direct the back waves out of the enclosure through the back opening (port).

Thanks for advice on the Dynamat, will go slow on it.

Danny

What I need to do is smooth it out and direct the back waves out of the enclosure through the back opening (port).

Thanks for advice on the Dynamat, will go slow on it.

Danny

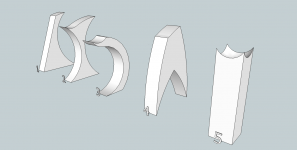

Hello guys.... I am really struggling with the aesthetics of the stand....

I will appreciate any suggestions you might have.... sketches, hand drawn or links to pics...

I am at the end with this, have tried many variants.... and I am not satisfied....

Anybody?

Danny

I will appreciate any suggestions you might have.... sketches, hand drawn or links to pics...

I am at the end with this, have tried many variants.... and I am not satisfied....

Anybody?

Danny

Im working on a small mtm on sub/stand. Im using 8 inch sonotube with a concrete flare to add weight to the base. I used a planter the flares to 12 inches from the 8 inch tube. I will be installed a down firing 8 inch sub in each for stereo sub sound. I will be wrapping the whole column in black grill fabric

Attachments

Last edited:

Im still really like my oak railway sleeper and brass spike combination, gives an airy ness and lightens the mass of each object.

I toyed with the idea of using ikea parts like this to make it look a little Sputnik'y. But the cost seemed a litte high having to buy x6 of those legs

...but flipped around with a big base tapering to the thin point.

...but flipped around with a big base tapering to the thin point.

An externally hosted image should be here but it was not working when we last tested it.

I toyed with the idea of using ikea parts like this to make it look a little Sputnik'y. But the cost seemed a litte high having to buy x6 of those legs

Hi, thanks for the suggestions.

Well I would like to incorporate one or two 6,5" or one 8" woofer in each stand, just to take away some bass duty from the full-range driver.

I had a look at some Scan Speak and Peerless drivers. I would like to avoid big speakers (apartment house).

Later I post some sketches, what you people think. There is one stand which would be about 14 liters, and also looks good, construction might be a trick 🙂

Danny

edit: stand shapes suggestions....

Well I would like to incorporate one or two 6,5" or one 8" woofer in each stand, just to take away some bass duty from the full-range driver.

I had a look at some Scan Speak and Peerless drivers. I would like to avoid big speakers (apartment house).

Later I post some sketches, what you people think. There is one stand which would be about 14 liters, and also looks good, construction might be a trick 🙂

Danny

edit: stand shapes suggestions....

Attachments

Last edited:

Number 4 looks familiar...

An externally hosted image should be here but it was not working when we last tested it.

hahah right, that was actually an attempt to merge enclosures with Star trek commbadge shape (big fan) 🙂)))

Danny

Danny

Update

OK small update. Progress is slow, work permitting. Been to holiday and still have 10 days left at home, so I hope to make some progress. Enclosures sanded and smooth. But I have one big problem, aesthetic problem that is, well I hope its only aesthetic.

The mounting of the driver it self. There is a (how to call this) a bezel?

The area for mounting is bigger by 14 mm on diameter then the driver. I had an idea of letting it covered by some nice aluminium ring or finish it off to merge with the driver by using two part putty (body filler for cars).

Any ideas?

Danny

OK small update. Progress is slow, work permitting. Been to holiday and still have 10 days left at home, so I hope to make some progress. Enclosures sanded and smooth. But I have one big problem, aesthetic problem that is, well I hope its only aesthetic.

The mounting of the driver it self. There is a (how to call this) a bezel?

The area for mounting is bigger by 14 mm on diameter then the driver. I had an idea of letting it covered by some nice aluminium ring or finish it off to merge with the driver by using two part putty (body filler for cars).

Any ideas?

Danny

Attachments

OK small update. Progress is slow, work permitting. Been to holiday and still have 10 days left at home, so I hope to make some progress. Enclosures sanded and smooth. But I have one big problem, aesthetic problem that is, well I hope its only aesthetic.

The mounting of the driver it self. There is a (how to call this) a bezel?

The area for mounting is bigger by 14 mm on diameter then the driver. I had an idea of letting it covered by some nice aluminium ring or finish it off to merge with the driver by using two part putty (body filler for cars).

Any ideas?

Danny

I'd opt for the aluminium ring covering it up. Anodise it clear or black, depending if you cover the entire mounting area of the speaker or a trim ring around it. Have you thought about a finish yet? If you go the putty way you'd have to paint the enclosure. And the wood is too lovely to cover 😀.

Last edited:

wesayso:

Yes I am leaning towards the alu ring, but have problem to find somebody who can make it for me. So I welcome any suggestions for a shop or private person who can make it. I travel a lot to Netherlands, but any country will do 🙂

The finish will be high gloss white...to match furniture

Danny

Yes I am leaning towards the alu ring, but have problem to find somebody who can make it for me. So I welcome any suggestions for a shop or private person who can make it. I travel a lot to Netherlands, but any country will do 🙂

The finish will be high gloss white...to match furniture

Danny

Sadly I can't help you with that, I don't have access to a lathe. I'm already glad I can outsource my aluminium baffles to a friend. Another option would be 3D printing? Not cheap though, but almost unlimited possibilities and a variety of materials available.

You could also have it turned in wood, have a small streak of walnut or something, but if its gloss white you want maybe an aluminium ring is the way to go.

Shapeways to 3D printing based on volume. It would cost the earth to have it printed in stainless steel, can use sketchup and it tell you how much the model costs almost instantly.

Shapeways to 3D printing based on volume. It would cost the earth to have it printed in stainless steel, can use sketchup and it tell you how much the model costs almost instantly.

How about Home- Schaeffer AG - Frontplatten, Front Panels, Faces Avant , I worked with them a lot and (outside of what their software tells you) they can do all kinds of shapes...

Have you tested the sound qualities of that white BMW paint? I bet it sounds sharp and fast 😀

Great design, very interested in your progress!!

Have you tested the sound qualities of that white BMW paint? I bet it sounds sharp and fast 😀

Great design, very interested in your progress!!

Hello Hesener

hope to get some work done after this business trip. Work life is killing all my hobbies. I made up my mind on the transit from driver to the enclosure. I made up 6mm high ring, and will make a 45 degree chamfer on it. And if I am not happy, I can always put the Alu ring on it, as it will be a chamfer.

hehe BMW paint...sharp and fast...I like that.

Danny

hope to get some work done after this business trip. Work life is killing all my hobbies. I made up my mind on the transit from driver to the enclosure. I made up 6mm high ring, and will make a 45 degree chamfer on it. And if I am not happy, I can always put the Alu ring on it, as it will be a chamfer.

hehe BMW paint...sharp and fast...I like that.

Danny

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- FE168E Sigma teardrop enclosure