Cork can be finished with anything that you would finish wood with. If you want a gloss finish like in the picture you posted, probably the easiest thing would be to spray on a decent brand of polyurethane varnish. It might take 3 or 4 coats.

There are two kinds of stains: pigment based and dye based. The most common hardware store types are pigment based, and are essentially diluted paint. For maximum lightfastness, use pigment based. The newer types of dye staines (ie, transtint) are fairly lightfast however, and should be fine for interior use.

One thing you shouldn't do is glue the cork with contact cement, and then finish with shellac. It will dissolve the glue and the cork will fall off. Guess how I know... 😉😱

Here are my 10.3 with a very light coat of linseed oil. They have since gotten a couple shades darker. Any linseed based finish darkens with age. The bookshelf they are sitting on was blond when I made it 20 years ago.

There are two kinds of stains: pigment based and dye based. The most common hardware store types are pigment based, and are essentially diluted paint. For maximum lightfastness, use pigment based. The newer types of dye staines (ie, transtint) are fairly lightfast however, and should be fine for interior use.

One thing you shouldn't do is glue the cork with contact cement, and then finish with shellac. It will dissolve the glue and the cork will fall off. Guess how I know... 😉😱

Here are my 10.3 with a very light coat of linseed oil. They have since gotten a couple shades darker. Any linseed based finish darkens with age. The bookshelf they are sitting on was blond when I made it 20 years ago.

Hmm, why do you need any BSC when up against the wall unless there's no room gain in the speaker's pass band, which is unlikely in most rooms and especially in a small one, so curious what room conditions, bass alignments you've found the need?

GM

I've run into this a couple times, but most recently with the CHR70 in basic reflex boxes. They sat on shelves in a relatively small 12'x13' room (timber frame/lathe/plaster). Apparently against the wall isn't as good as flush with the wall. 😕 The old boxes are gone now but I suppose the drivers/baffles were about 9-10 inches from the wall.

They didn't need full BSC by any means, but IIRC they needed about 2-3db, vs about 4db when out away from the wall. I don't recall the exact alignment. It was a bit lower/bigger than QB3, but not EBS by any means.

Anyhow, since the intended woofer for this project is just slightly more efficient than the TC9FD, everything should work out just right.

Cork can be finished with anything that you would finish wood with.

OK, I don't know what the binder is, so assumed it was some sort of spirits based.

BTW, the cork I've used is the thicker decorator patterns: https://www.google.com/search?q=dec...rk.net%2Fdesigner-cork-walltiles.html;250;161

GM

Apparently against the wall isn't as good as flush with the wall. 😕 The old boxes are gone now but I suppose the drivers/baffles were about 9-10 inches from the wall.

According to Henney's 'Handbook of Engineering' [and IME], if a speaker is flush mounted in a wall, half its power [3 dB] goes into another space whereas if up against the wall it's reflected back into the space, so mutual coupling is identical where the WLs are > the speaker's radiating area [including baffle area], just the directivity Q [DI] changes, so not sure why there wasn't good LF coupling since I've only verified with larger cabs up against and also angled to, a wall.

Regardless, I agree that it's probably a moot point in this app.

GM

After a quick round of asking around hardware stores, it seems that cork is either impossible to get or expensive enough to push over the budget. I'll instead make the front baffle of wood and surface mount the drivers, I doubt it will be too detrimental to the sound quality.

Try small DIY stores, instead of big hardware stores. The kind of place that has small balsa wood planks and sticks, foamcore or coroplast sheets for making scaled down models.

Or maybe a school supplies store, they have cork for using with thumb tacks. They sell whole boards, but also just the cork sheet.

I have a bunch of stores here that sell cork in a roll, in different thickness.

Or maybe a school supplies store, they have cork for using with thumb tacks. They sell whole boards, but also just the cork sheet.

I have a bunch of stores here that sell cork in a roll, in different thickness.

Last edited:

it seems that cork is either impossible to get or expensive enough to push over the budget.

Hmm, I still have the receipts for the decorative cork I bought in the late '60s as well as the cork tool drawer liner and doing a bit of shopping I was shocked to find that the decorative sheets are >1000% higher!!!

The drawer liner that at least looks like what GB used tracks inflation, so cheap by even my 'cheapskate' standards, though it's 38% higher in the UK, which still seems pretty cheap, all things considered, though doesn't have nearly the impact on acoustics as the thick decorator panels, what with its 'cratered' surface: Amazon.co.uk: Con-Tact Specialty Coverings Cork Liner

Regardless, if still too expensive, consider open cell foam or felt that's ~1.5x 'taller' [thicker] than the driver/baffle height to somewhat damp the baffle's eigenmodes.

All these types of tweaks are subtle, but improves clarity in the critical telephone BW and even well into the sibilance BW of small speakers.

GM

I have a bunch of stores here that sell cork in a roll, in different thickness.

Yeah, last time I noticed, Home Depot, Lowe's was still selling 1/8" [~3 mm] by the linear foot x either 3 or 4 ft wide IIRC, though don't recall the price, but out of curiosity will check.

GM

After a quick round of asking around hardware stores, it seems that cork is either impossible to get or expensive enough to push over the budget. I'll instead make the front baffle of wood and surface mount the drivers, I doubt it will be too detrimental to the sound quality.

Actually it can be pretty detrimental with some drivers. The edges diffract and the frequency response will be much rougher than it needs to be.

However, in this case the woofer doesn't really need it, but the TC9FD should be flush somehow.

Last edited:

At all the various measurements xrk971 has published for TC9FD it don't seems a problem for that driver to be front mounted to have nice response, but okay don't know if a front mounted bass drivers frame with close spacing to TC9FD could disturb the performance.

Last edited:

Hmm, I still have the receipts for the decorative cork I bought in the late '60s as well as the cork tool drawer liner and doing a bit of shopping I was shocked to find that the decorative sheets are >1000% higher!!!

I find that prices can vary greatly. IIRC I bought the last stuff off the roll at Home Depot, and it wasn't terribly expensive. I think it was sold as cork bulletin board material.

Anyhow, if it isn't relatively cheap in Finland, use something else that is.

I could buy a sheet of rubber cork gasket quite cheap, but not sure how aesthetic it is and how well it would work in this kind of setup. Probably need to go to store personally tomorrow to check it out. Something like this:

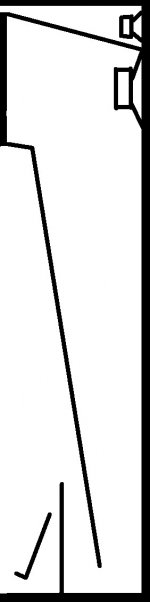

Anyhow, I sketched up the enclosure on paper, and as I don't own a scanner I drew a crude MSpaint mockup of the detailed drawing. Measures are 282mm deep, 1130mm tall and 306mm wide. Front baffle is 24mm ply, everything else 18mm ply. The small floaty bit is the amplifier cover, 8mm ply. Line lenght is approximately 130cm on woofer, 26cm on full range. Both have 1:10 taper.

Anyhow, I sketched up the enclosure on paper, and as I don't own a scanner I drew a crude MSpaint mockup of the detailed drawing. Measures are 282mm deep, 1130mm tall and 306mm wide. Front baffle is 24mm ply, everything else 18mm ply. The small floaty bit is the amplifier cover, 8mm ply. Line lenght is approximately 130cm on woofer, 26cm on full range. Both have 1:10 taper.

Attachments

Last edited:

At all the various measurements xrk971 has published for TC9FD it don't seems a problem for that driver to be front mounted to have nice response, but okay don't know if a front mounted bass drivers frame with close spacing to TC9FD could disturb the performance.

It's not usually the end of the world with full range drivers, as they are somewhat directional. However, I'd guess there will be about 1-2db more wiggle in the frequency response if not flush mounted, and a subjective reduction in image clarity. DIY audio is all about hot rodding and tweaks for best performance, and it all adds up. 🙂

BTW, for those of you who live in the US, I remember now where I got the cork for those MA 10.3 cabinets: cork sheet

.....DIY audio is all about hot rodding and tweaks for best performance, and it all adds up. 🙂.....

Very right, and thanks the tips 🙂.

I am making some careful measurements of response of TC9FD and other drivers in a short tapered TL and will try adding a flush mount rebate and felt to see if the 1-2dB wiggle can be reduced. The TL definitely flattens the impedance peak - but that is at fs near 130Hz, more than an octave below where I would XO as a FAST. However, the midrange does seem very open.

Cool. It will be interesting to see your results. 1-2db is only a guesstimate, based on past experience.

Where flush mounting really makes a huge difference is dome tweeters, and I haven't goofed with them for many years.

As the OP intends to use PLLXO, it doesn't matter that much, but any sort of Z peak one octave below a passive crossover high pass will entirely screw it up.

Where flush mounting really makes a huge difference is dome tweeters, and I haven't goofed with them for many years.

As the OP intends to use PLLXO, it doesn't matter that much, but any sort of Z peak one octave below a passive crossover high pass will entirely screw it up.

I will post more info later but the short story with the TC9FD: do not rebate and flush mount. The way it is designed it is flatter and smoother when surface mounted. A real time saver for DIY builds with this driver. Kind of silly but I will have to un-rebate the bezel and go back to surface mount.

That info could be a real time saver. If I don't achieve any real benefits with flush mounting the TC9FD, I might as well leave the cork since I'm having such a damned time acquiring it. There is also the problem with the woofer having the surface-mountable frame with only 1mm depth at the edge, whilst the TC9 has 3mm frame depth. Also my friend would prefer the natural wood finish instead of the cork as it "looks too much like an office notice board" 😀

I think this time looks might come over acoustical performance.

I think this time looks might come over acoustical performance.

Last edited:

I could buy a sheet of rubber cork gasket.......

Line lenght is approximately 130cm on woofer, 26cm on full range. Both have 1:10 taper.

The cork gasket I buy shows a ~uniform fleck pattern due to its black rubber content, lending a dark tint to it. Very utilitarian look to it, but could be totally different if European gasket material specs are different.

That said, one obvious, inexpensive material that I didn't have as an option way back when is the current style tool drawer/shelf liner I noticed at Target today. Its open weave pattern and soft rubber-like 'feel', not to mention a decent color selection, seems a near ideal baffle cover if a gloss finish isn't required: Shelf liners : see more closet organization : Target

Surely this has got to be popular, cheap most everywhere in the free world.

FYI, these are 10:1 taper ratio TQWTs; 1:10 would be a conic [horn] expansion.

GM

Last edited:

Should be. Loads of craft cork to have a crack at, and prices don't seem unreasonable, even here in the UK. Here's one I found: Pure Tree Cork - Product Range : Pure Tree Natural Compressed Cork Sheets

Plenty to go at on Ebay & even amazon too. Model railway / kit shops seem a good source too. Not the fanciest, but I've seen worse & should be workable into something attractive. Then again, I do like natural cork anyway -always been drawn that way.

Plenty to go at on Ebay & even amazon too. Model railway / kit shops seem a good source too. Not the fanciest, but I've seen worse & should be workable into something attractive. Then again, I do like natural cork anyway -always been drawn that way.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- FAST with TL?