I've made a few speakers with 3" Faital. Some small line arrays that were nice, and some goofy horns, as shown below. All worked well and showed promise. None could go low enough without a woofer, IMO.

A fun driver.

A fun driver.

Attachments

It looks like the 16 ohm version was used in this speaker ($3,000 a pair)

VIVACE mini (Discontinued) — Finale Audio

6moons audioreviews: Finale Vivace Mini

VIVACE mini (Discontinued) — Finale Audio

6moons audioreviews: Finale Vivace Mini

Last edited:

I wonder what the cabinet looks like inside. It seems to be an expanding MLTL with a back chamber as lowpas?

I wonder what the cabinet looks like inside.

Not particualrily interesting. Sort of an ML-TL, but not by design.

dave

My app uses it FR.

That it fits nicely in essentially the same box as FF85wk and A5.2/3 suggests its sensitivity is less than rated.

dave

This looks nice!

Did you make the box design public? Would love to look into it. Planning to do a project with my son and this could very well be it.

Hey XRK. Yes that dollar store foam core is fun and handy for prototyping. I found that it buzzed far too much for final use, but I never moved on to plywood with these. Should have.

Tom Danley turned me on to these little Faital drivers, and I thank him for that.

Tom Danley turned me on to these little Faital drivers, and I thank him for that.

I've made a few speakers with 3" Faital....and some goofy horns, as shown below.

The set in the picture on the right look much like the old AT&T microwave relay horns used at 4 GHz before they were mostly replaced with fiber optic cables. A few are still in use here to bridge across the Ohio River. Those frequencies are being reassigned to 5G cellular now, so the remaining horns will soon go extinct.

I got a couple 3FE22s for use in an electric guitar body to provide some "quiet practice" level sound with the effects and accompaniment built into the guitar. It showed promise, but its partially assembled pieces got shoved into boxes when I had to leave Florida on short notice 7 years ago. Several boxes went missing during the move.

Unfortunately, I still haven't found all of the parts including the wired neck which was the critical piece of the whole design. I have however started making a new neck.

This looks nice! Did you make the box design public? Would love to look into it. Planning to do a project with my son and this could very well be it.

I could be interested in making a pair of speakers like those for my PC, seeing as I have all the parts. I haven't made any speakers since making the FH-3s and EZ-10s about 10 years ago. Those would probably pair well with the Polk Audio 10 inch powered sub that's sitting under the bench unused.

Yes George, those big microwave horns were precisely my inspiration.The set in the picture on the right look much like the old AT&T microwave relay horns...

Those giants fascinated me throughout my childhood, and immediately came to mind for this project. The idea came from a desire to have a horn 150-200cm deep that didn't need that much floor space. So the AT&T reflector horns seemed worth exploring.

Those giants fascinated me throughout my childhood, and immediately came to mind for this project. The idea came from a desire to have a horn 150-200cm deep that didn't need that much floor space. So the AT&T reflector horns seemed worth exploring.I was going to make my reflector tops curved, as they are on the microwave horns, but for a first build just went flat for ease of build. And of course theorizing that a flat reflector would spread the HF better - pure rationalization on my part. 😉

On these Reflect-O-Horns and the flared conical horns I did not notice any efficiency gain over the normal driver. Shouldn't there be?

I might be an expert at blowing up tubes, and have actually melted more solid state stuff than tubes in my lifetime, but I'm a neophyte at speaker building.

I would assume that a horn should show some efficiency gain over a box enclosure, but from what I read, it's mostly in the lower octave or so around or below the driver's resonance.

Back in my teens and early 20's I did make some speakers that were good enough to sell, but those were the pre-disco days in the Latin music capital of the USA, so if it went boom - boom at dance floor volume, it sold. A 15 inch Eminence driver fed with a DIY SS amp making about 100 watts did the trick.

Other than the 6 X 9 car speakers in a 1.5 cu ft sealed box, and some guitar cabinets, everything else I built was from someone else's plans.

In the point to point microwave world where these horns were used the idea was to focus all of the energy at the receiving horn. In this application these horns worked much like a folded megaphone. One sized properly for audio would be large and have a small sweet spot.

I would assume that a horn should show some efficiency gain over a box enclosure, but from what I read, it's mostly in the lower octave or so around or below the driver's resonance.

Back in my teens and early 20's I did make some speakers that were good enough to sell, but those were the pre-disco days in the Latin music capital of the USA, so if it went boom - boom at dance floor volume, it sold. A 15 inch Eminence driver fed with a DIY SS amp making about 100 watts did the trick.

Other than the 6 X 9 car speakers in a 1.5 cu ft sealed box, and some guitar cabinets, everything else I built was from someone else's plans.

In the point to point microwave world where these horns were used the idea was to focus all of the energy at the receiving horn. In this application these horns worked much like a folded megaphone. One sized properly for audio would be large and have a small sweet spot.

Hey XRK. Yes that dollar store foam core is fun and handy for prototyping. I found that it buzzed far too much for final use, but I never moved on to plywood with these. Should have.

Tom Danley turned me on to these little Faital drivers, and I thank him for that.

It is an ancillary sheet on either the FF85wk or the A5.2/3 plansets.

dave

Perhaps if you made a before/after comparison.I would assume that a horn should show some efficiency gain over a box enclosure, but from what I read, it's mostly in the lower octave or so around or below the driver's resonance.

From the outside, you can view the waveguide as a focussing device.. when directivity is constant with frequency, power falls at -6dB/oct.

Hey XRK. Yes that dollar store foam core is fun and handy for prototyping. I found that it buzzed far too much for final use, but I never moved on to plywood with these. Should have.

Tom Danley turned me on to these little Faital drivers, and I thank him for that.

You can reduce the buzzing a lot by glueing on a second (CLD like) layer with latex caulking. The added foam core pieces can be smaller and applied outside. Or auto sound mass loaded butyl works well too.

I managed to really reduce the buzz and distortion with the added CLD on my tractrix horns. Typically would get 10dB gain in the mid to highs.

PRV 5MR450-NDY for FAST/WAW applications

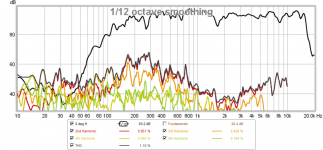

Before CLD, lots of buzzing:

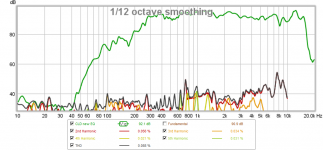

After the latex CLD treatment:

Attachments

Last edited:

Thanks. All that low harsh on the first plot is a good visual representation of what I was hearing.

Thanks. All that low harsh on the first plot is a good visual representation of what I was hearing.My app uses it FR.

That it fits nicely in essentially the same box as FF85wk and A5.2/3 suggests its sensitivity is less than rated.

dave

Did you do an article on this, I am interested, will like to see the measurements and box dimensions?

Another project is hornloading the 3FE22 with a large CD horn. It will need quite a bit of EQ. The adapter is 3D printed, ready for measurements.

Is that a 2" throat horn?

Did you do an article on this, I am interested, will like to see the measurements and box dimensions?

Yes. Email me is interested. Part of a paid planset.

dave

- Home

- Loudspeakers

- Multi-Way

- FaitalPro 3FE22 projects (nice little full range driver!)