Hey @Halauhula,

looks like I missed the source of the hum in my second paragraph 🙂

1. Yes. Everything disconnected -> Toroidal hum

2. Yes. Only speaker connected without a source or input shorted -> Speaker hum

looks like I missed the source of the hum in my second paragraph 🙂

1. Yes. Everything disconnected -> Toroidal hum

2. Yes. Only speaker connected without a source or input shorted -> Speaker hum

Keep narrowing it down.

1. If it's 300VA or more and if the manufacturer advertises it 'for audio' etc., you could try to get a replacement. If you've checked to ensure no shorted turns and there are no installation errors, it's just a 'hummer'. You never answered (that I saw) if it got warm or hot to the touch over the ambient temp.

2. Both channels have the "same" hum?

You mentioned that you live in a flat with potentially poor mains power. Before you start digging in too deeply, do you have a way to take it to a friend's house. Did you try (and is it practical) seeing if the hum is affected when you turn off all appliances and LED lamps that are on the same circuit (like a small air conditioner etc)?

1. If it's 300VA or more and if the manufacturer advertises it 'for audio' etc., you could try to get a replacement. If you've checked to ensure no shorted turns and there are no installation errors, it's just a 'hummer'. You never answered (that I saw) if it got warm or hot to the touch over the ambient temp.

2. Both channels have the "same" hum?

You mentioned that you live in a flat with potentially poor mains power. Before you start digging in too deeply, do you have a way to take it to a friend's house. Did you try (and is it practical) seeing if the hum is affected when you turn off all appliances and LED lamps that are on the same circuit (like a small air conditioner etc)?

@loadsas: thank you for your clarifying post!

Turning first to transformer hum, did addition of the hum blocker significantly reduce hum after installation? Asking in order to try and verify, as much as I can think of, to eliminate possibilities that hum blocker is defective (mid assembled or bad part(s) or not installed correctly. Am I correct in understanding that although hum is reduced, the transformer still hums? Can you put your hand on the transformer and feel it vibrate? Does the chassis right under the transformer mount also vibrate? If vibration is significant, you may have either a defective transformer or one that is not well-designed. You have your choice of seeking a replacement from the vendor/mfg., replacing it with a known good brand lije Pliton, Toroidy, Antelope or Abel.

As a parallel matter, can you verify that you installed a dampening pad, usually neoprene, under transformer? The mfg of transformer should have provided this to you. If not, and assuming you want to avoid replacing the transformer, then consider adding a pad between transformer and chassis, and optionally adding isolation washers and another isolation pad between transformer and what appears to be a nylon mounting washer on the top of your transformer.

Turning first to transformer hum, did addition of the hum blocker significantly reduce hum after installation? Asking in order to try and verify, as much as I can think of, to eliminate possibilities that hum blocker is defective (mid assembled or bad part(s) or not installed correctly. Am I correct in understanding that although hum is reduced, the transformer still hums? Can you put your hand on the transformer and feel it vibrate? Does the chassis right under the transformer mount also vibrate? If vibration is significant, you may have either a defective transformer or one that is not well-designed. You have your choice of seeking a replacement from the vendor/mfg., replacing it with a known good brand lije Pliton, Toroidy, Antelope or Abel.

As a parallel matter, can you verify that you installed a dampening pad, usually neoprene, under transformer? The mfg of transformer should have provided this to you. If not, and assuming you want to avoid replacing the transformer, then consider adding a pad between transformer and chassis, and optionally adding isolation washers and another isolation pad between transformer and what appears to be a nylon mounting washer on the top of your transformer.

1. It's a 300VA Transformer which is not explixitly for audio and he only gets lukewarm/warm not hot.

2. Both channels have the same hum

3. Same hum in another house (except the DC on the line and the voltage swings)

Maybe I try another transformer or take the way of the SMPS.

Btw whats an acceptable voltage swing on the mains? Because mine is sometimes 10V...

2. Both channels have the same hum

3. Same hum in another house (except the DC on the line and the voltage swings)

Maybe I try another transformer or take the way of the SMPS.

Btw whats an acceptable voltage swing on the mains? Because mine is sometimes 10V...

With respect to your second hum issue, it may be: 1. transformer magnetic field induced hum into the signal circuitry; 2. AC power wire induced hum into the signal circuitry; or 3. a ground loop issue; 4. a combo of one or more of the above; and 5. AC transformer induced hum into the F6 line transformer (this last I would not think is likely as the transformers are very separated, but if you are using a no-name transformer, then it could be a problem).

To address, with loudspeaker connected but no source, unloosen transformer mounting bolt and rotate transformer slowly to see if hum is reduced. If you find a spot where it is, mark a line on transformer and chassis with Sharpie so that you can re-establish the orientation in the future if you need to remove transformer for some reason and then remount that same transformer.

You could consider buying a steel shield for your transformer and mounting it over the transformer. I know Antek sells two different kinds and given you have a F6, I think I would consider purchasing their heavy shield, but only after trying the suggestions below!

Dress the AC wires well away from the signal wires and signal PCBs mounted on heat sinks. This includes leads from power transformer to the rectifier/capacitor filtering boards! The shortest direct path is usually the best. I see you have twisted those wires(as best as I can tell), so good there!

Dress all signal wires as far away from power transformer as you can.

Verify that you have used isolation washers on the RCA inputs. Touch up soldering at the RCAs; visually verify there are no shorts, and clean off all flux either 99% isopropyl alcohol of flux remover snd and a toothbrush or fiberglass PCB cleaning brush.

Did you use a ground lift? my eyes are not the best in pattern recognition and I did not see anything that looks like a ground lift. If you did not use one, then consider using one; a good design is the Nelson Pass one. Abstractly speaking, it should not make a difference w it’s no source connected and a properly wired amp….

Beyond this, we would have to look very carefully how your signal wires are attached to the PCBs: you could touch up soldering at signal inputs to the PCBs.

Go through all these steps methodically and check them off as you complete them, and reporting amp to determine any change in hum; then reattach I put to verify that you did not create a new problem.

To address, with loudspeaker connected but no source, unloosen transformer mounting bolt and rotate transformer slowly to see if hum is reduced. If you find a spot where it is, mark a line on transformer and chassis with Sharpie so that you can re-establish the orientation in the future if you need to remove transformer for some reason and then remount that same transformer.

You could consider buying a steel shield for your transformer and mounting it over the transformer. I know Antek sells two different kinds and given you have a F6, I think I would consider purchasing their heavy shield, but only after trying the suggestions below!

Dress the AC wires well away from the signal wires and signal PCBs mounted on heat sinks. This includes leads from power transformer to the rectifier/capacitor filtering boards! The shortest direct path is usually the best. I see you have twisted those wires(as best as I can tell), so good there!

Dress all signal wires as far away from power transformer as you can.

Verify that you have used isolation washers on the RCA inputs. Touch up soldering at the RCAs; visually verify there are no shorts, and clean off all flux either 99% isopropyl alcohol of flux remover snd and a toothbrush or fiberglass PCB cleaning brush.

Did you use a ground lift? my eyes are not the best in pattern recognition and I did not see anything that looks like a ground lift. If you did not use one, then consider using one; a good design is the Nelson Pass one. Abstractly speaking, it should not make a difference w it’s no source connected and a properly wired amp….

Beyond this, we would have to look very carefully how your signal wires are attached to the PCBs: you could touch up soldering at signal inputs to the PCBs.

Go through all these steps methodically and check them off as you complete them, and reporting amp to determine any change in hum; then reattach I put to verify that you did not create a new problem.

@loadsas: temperature rise is not the only criterion for assessing transformer: if windings are designed poorly it will result in more harmonics of the AC line being transferred to the secondary, which is not a good thing; if wound poorly, as in uneven or loosely, this could result in physical transformer hum.

With respect to your second Q, how many volts above the standard mains voltage does it go, and what type of voltmeter are you using (ie, true RMS meter?). You will have to look at the capacitor voltage ratings on your board and calculate the absolute maximum DC that could be produced by your transformer and PS to see if you have a problem. You will have to find the “no load” voltage ratings for your transformer, add a safety margin, calculate the increased voltage output of the transformer at the maximum mains voltage you have measured (a ratio or percentage), and then calculate voltage after rectifiers - 1.41 x max transformer voltage no load, high mains plus safety factor.

With respect to your second Q, how many volts above the standard mains voltage does it go, and what type of voltmeter are you using (ie, true RMS meter?). You will have to look at the capacitor voltage ratings on your board and calculate the absolute maximum DC that could be produced by your transformer and PS to see if you have a problem. You will have to find the “no load” voltage ratings for your transformer, add a safety margin, calculate the increased voltage output of the transformer at the maximum mains voltage you have measured (a ratio or percentage), and then calculate voltage after rectifiers - 1.41 x max transformer voltage no load, high mains plus safety factor.

Talema is well established brand. Potting may reduce physical hum assuming the cause is not DC on the AC mains line, but will do nothing to reduce magnetic field induced hum, unless potted in a steel case. Not clear that this Takema is potted in such a case.

Hallo loadsas,

with regard to mains voltage variation: I don't know what area you are located in, but at our house (suburbs of Düsseldorf) we have mains voltage variations over the course of a full day of between less than 220V and 235V+, though most of the time the voltage remains between 225V and 235V.

(I have a logger running continuously as part of my home automation system 😉)

Regards, Claas

with regard to mains voltage variation: I don't know what area you are located in, but at our house (suburbs of Düsseldorf) we have mains voltage variations over the course of a full day of between less than 220V and 235V+, though most of the time the voltage remains between 225V and 235V.

(I have a logger running continuously as part of my home automation system 😉)

Regards, Claas

Thanks for the many replies.

Beforehand: I bought this transformer https://www.sedlbauer.de/wp-content/uploads/2022/02/Ringkerntrafo-Datenblatt-825052.pdf

And I have to correct my statement about the transformer temperature. The transformer get's not warm. Only lukewarm.

@Halauhula The Hum Blocker works because without it the transformer produces a really annoying hum every minute or so.

I can feel a vibration during the "bad phase" without the hum blocker. I can't feel a vibration from the "silent hum" with the hum blocker.

I don't have a dampening pad but I already moved the transformer outside the case which changed nothing.

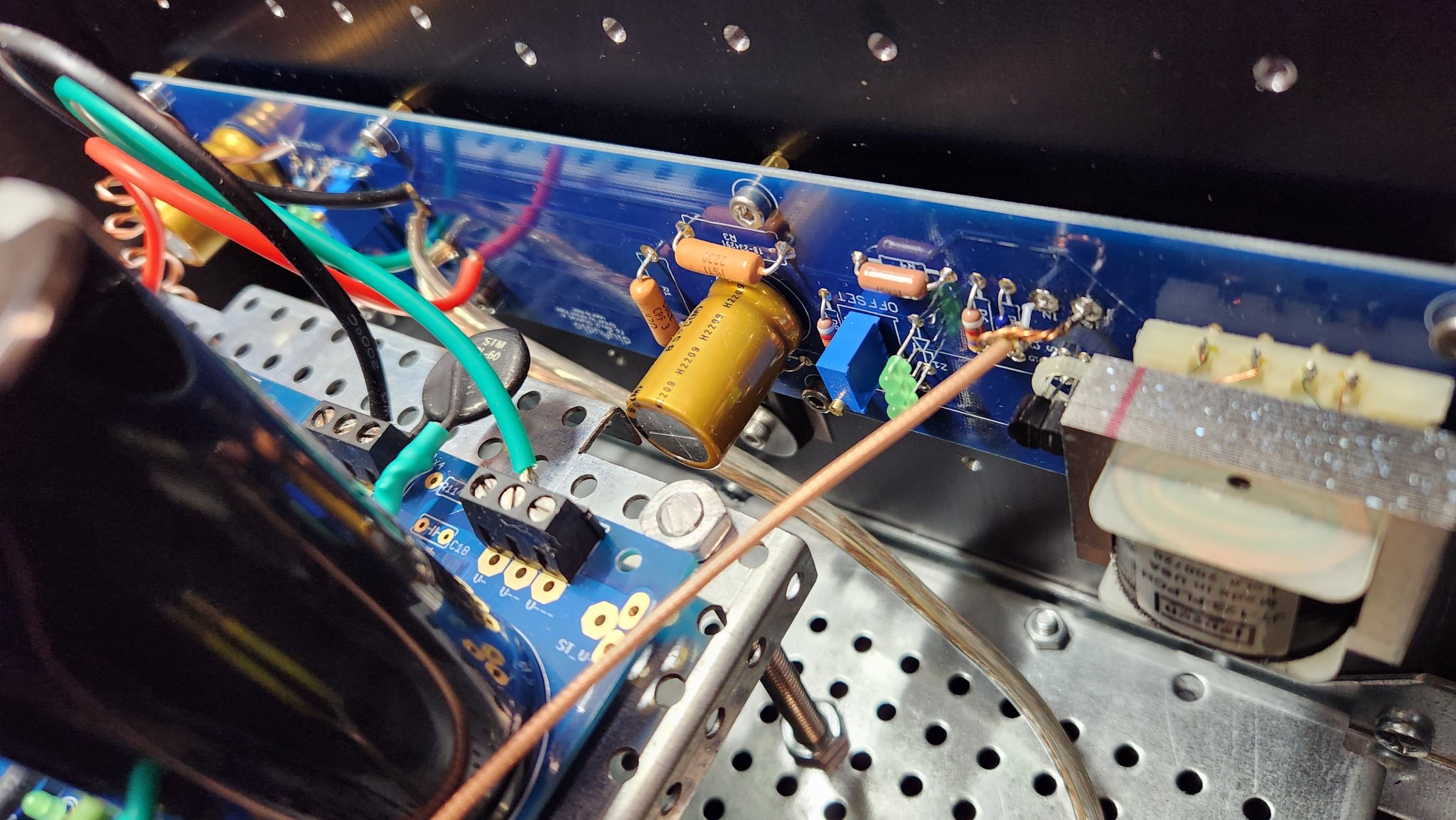

I have a CL-60 between the mains ground and the audio ground.

I don't think it's because of bad solder connections (checked them a lot) because with the SMPS there is no hum.

I dressed the output signal wires. The wires from the RCA input are shielded.

@barossi maybe. Or one from TOROIDY.

@Halauhula @chede The voltage swings are in the (don't find the word right now) standard values. Between 225V and 236V. The capacitors are safe. I ask because of the amplifier boards and the bias.

Beforehand: I bought this transformer https://www.sedlbauer.de/wp-content/uploads/2022/02/Ringkerntrafo-Datenblatt-825052.pdf

And I have to correct my statement about the transformer temperature. The transformer get's not warm. Only lukewarm.

@Halauhula The Hum Blocker works because without it the transformer produces a really annoying hum every minute or so.

I can feel a vibration during the "bad phase" without the hum blocker. I can't feel a vibration from the "silent hum" with the hum blocker.

I don't have a dampening pad but I already moved the transformer outside the case which changed nothing.

I have a CL-60 between the mains ground and the audio ground.

I don't think it's because of bad solder connections (checked them a lot) because with the SMPS there is no hum.

I dressed the output signal wires. The wires from the RCA input are shielded.

@barossi maybe. Or one from TOROIDY.

@Halauhula @chede The voltage swings are in the (don't find the word right now) standard values. Between 225V and 236V. The capacitors are safe. I ask because of the amplifier boards and the bias.

@loadsas: you can use the same approach I mentioned to calculate voltage after rectifiers, to also determine how much bias could increase at the highest voltage. After calculating voltage drop due to CRC, and adding the voltage drop if two diodes in series assuming you are using a bridge configuration, you can then determine your rail voltage. Then use source resistor resistance value to calculate bias current.

However, IMO heat sink temperature is the best indicator of over bias: if at high mains voltage, you cannot keep your hands in the heat sink, then I would consider using a thermometer of your choice to evaluate HS temps. If over 65 degrees centigrade, I would consider that too hot and reduce bias. But that is a personal choice.

However, IMO heat sink temperature is the best indicator of over bias: if at high mains voltage, you cannot keep your hands in the heat sink, then I would consider using a thermometer of your choice to evaluate HS temps. If over 65 degrees centigrade, I would consider that too hot and reduce bias. But that is a personal choice.

And you checked that the RCAs are isolated from chassis with isolation washers? Note: shields on signal wires are not effective against low frequency electromagnetic fields. Only steel, mu metal shielding or physical separation will reduce the impact of AC fields from wiring and transformers, chokes, etc. I would definitely redressing signal leads away from AC lines and the transformer.

Yes, the RCAs are isolated from the chassis. I measure ~15 Ohm on the RCA ground to mains ground through the CL-60 and no connection (very high resistance) on the signal line.

If the temp of the heatsinks is the prime indicator that's fine. I can monitor that and turn the amp off if it gets too hot.

If the temp of the heatsinks is the prime indicator that's fine. I can monitor that and turn the amp off if it gets too hot.

I ordered two different transformers from toroidy to test the setup. I'll let you know the result.

I was nearly finished with my "stock" diyaudiostore F6 build, then I wanted to do a last bias check..

The result is, that R1 (0R56) is burnt now. One of my cables going to the multimeter had touched the enclosure, while the other end was connected to R2 (the 0R47).

I do not think anything else was harmed. Not sure. Starting the F6 again, resulted in R1 smoking again. I do not think that anything else got hot too.

Touched Q1, Q2, Q3 and Q4, they appeared to be Okay concerning their temperature.

I removed R1 with my knippex and tested it with a multimeter: it looks okay. I assume that it is damaged, even though it measures okay. Is that possible?

Does anyone have a mouser or digikey code for R1? I hope that replacing it will help. I cannot find the correct part.. any help appreciated.

The result is, that R1 (0R56) is burnt now. One of my cables going to the multimeter had touched the enclosure, while the other end was connected to R2 (the 0R47).

I do not think anything else was harmed. Not sure. Starting the F6 again, resulted in R1 smoking again. I do not think that anything else got hot too.

Touched Q1, Q2, Q3 and Q4, they appeared to be Okay concerning their temperature.

I removed R1 with my knippex and tested it with a multimeter: it looks okay. I assume that it is damaged, even though it measures okay. Is that possible?

Does anyone have a mouser or digikey code for R1? I hope that replacing it will help. I cannot find the correct part.. any help appreciated.

Sorry to come back to this. Any recommendations for resistors?I was nearly finished with my "stock" diyaudiostore F6 build, then I wanted to do a last bias check..

The result is, that R1 (0R56) is burnt now. One of my cables going to the multimeter had touched the enclosure, while the other end was connected to R2 (the 0R47).

I do not think anything else was harmed. Not sure. Starting the F6 again, resulted in R1 smoking again. I do not think that anything else got hot too.

Touched Q1, Q2, Q3 and Q4, they appeared to be Okay concerning their temperature.

I removed R1 with my knippex and tested it with a multimeter: it looks okay. I assume that it is damaged, even though it measures okay. Is that possible?

Does anyone have a mouser or digikey code for R1? I hope that replacing it will help. I cannot find the correct part.. any help appreciated.

Meanwhile if replaced the IFPR240ies. Checked the diode Z2. Replaced resistors R1, R2 and P2. R2 is still getting very hot starts smelling after a while. Everything else looks good. I can adjust bias and offset, both rails have the same current draw.

What would be the symptoms of the capacitors being damaged?

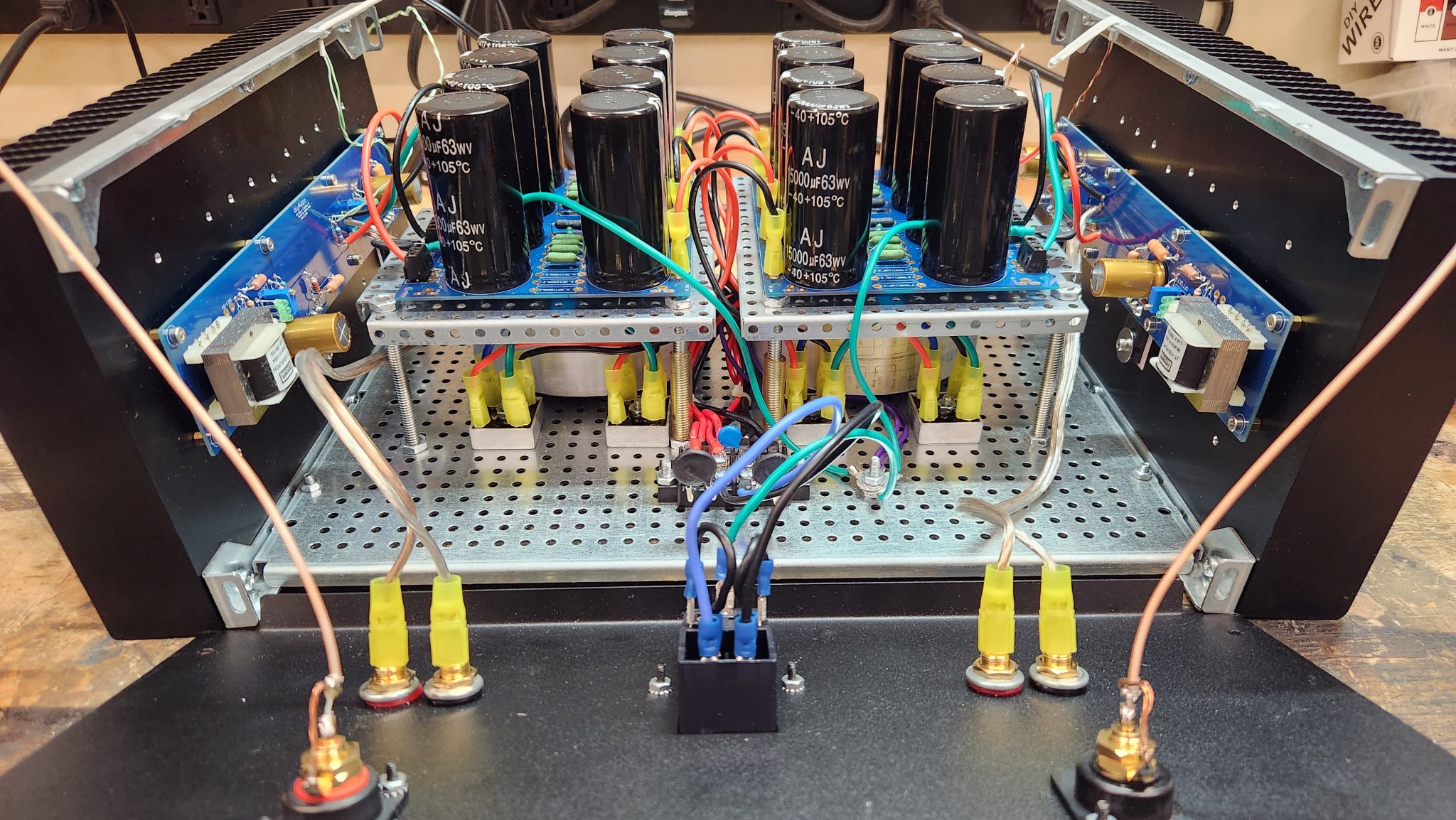

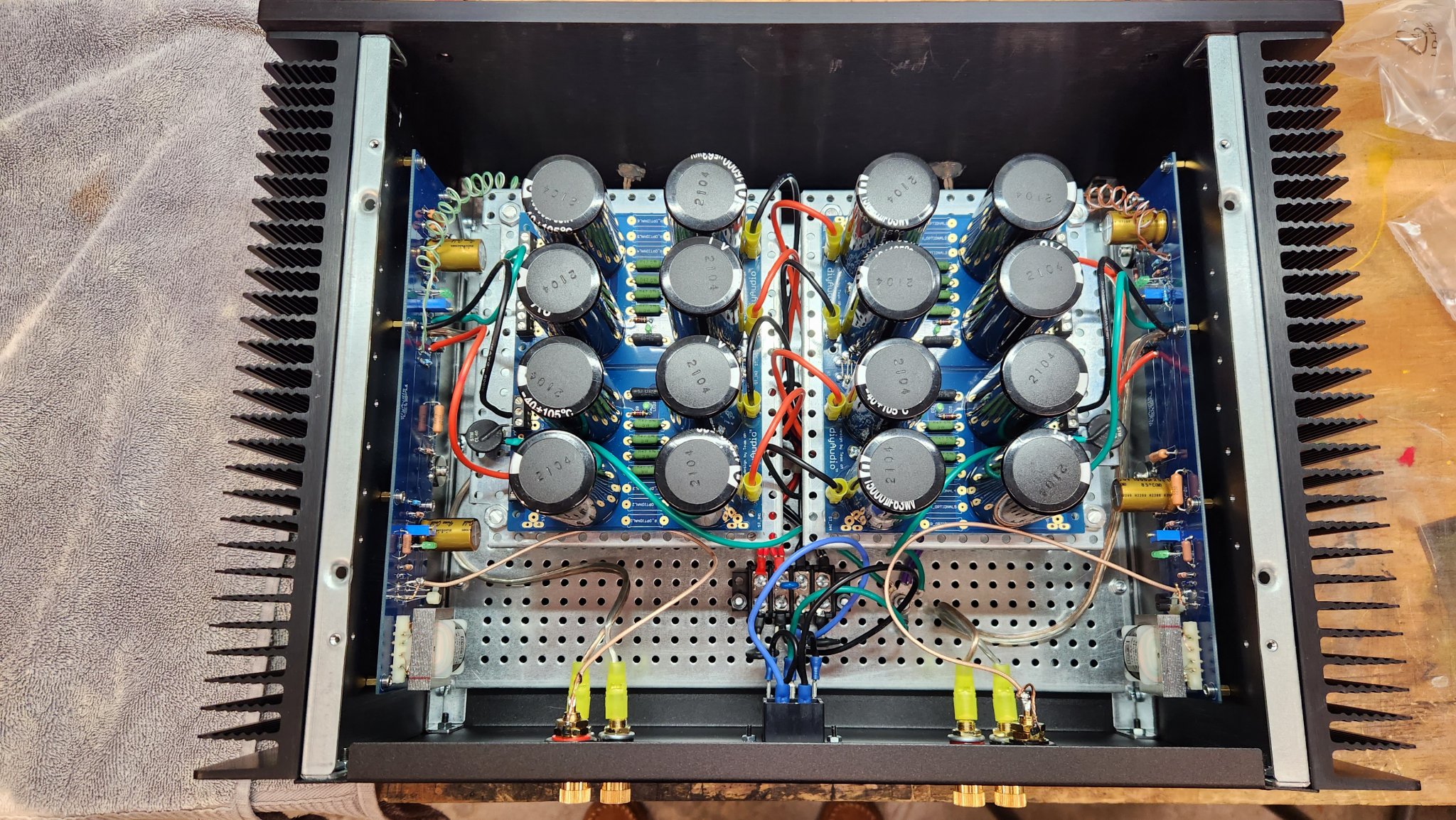

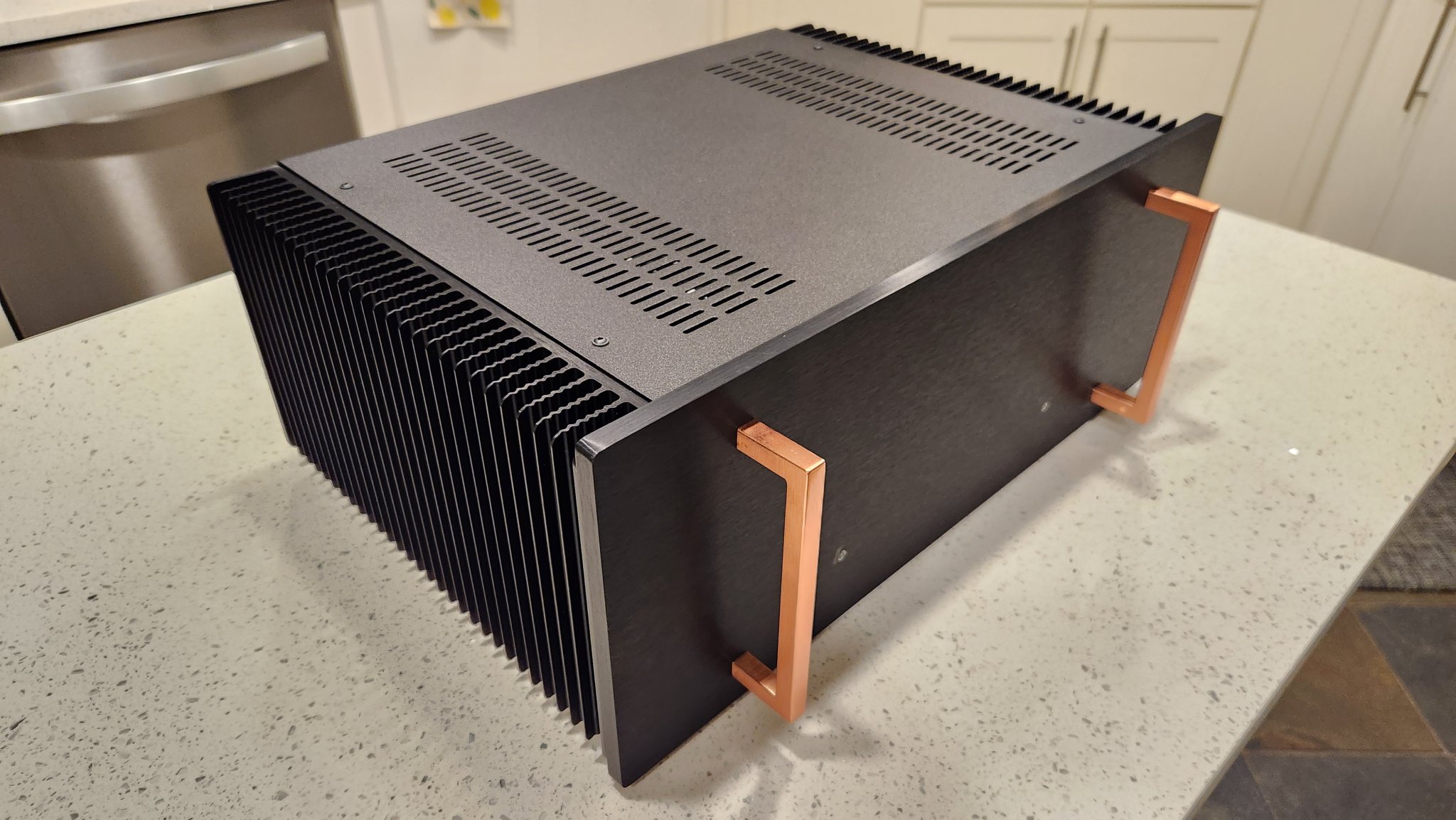

Rather cramped in that enclosure! Kudos to you for fitting it in so neatly!Well I got bored and converted my F6 to dual mono. My blueprint to finishing the F5m.

Are you going to add a spacer, washer ir partial gasket to space the top panel from the rail, thereby clearing the zip ties in the new holes you drilled?

Another way to fit a dual mono F6 into a 4U case.

Dual mono F6 in Deluxe 4U case. Thank you Papa and diyAudio store!

- Home

- Amplifiers

- Pass Labs

- F6 Illustrated Build Guide