Such a mirror finish, and this was done by polishing only? It looks like it was chrome plated.

Sanding first, then different grits polishing compound.

Metal is not what it was and is difficult to remove the blue color tinting. It's 6061 T6.

I need to try more compounds but is $ and no one cares.

Needs one more polish/glaze then wax and assemble the Pass parts.

Just trying to show if you have done this work enough you can drill/tap w/o the best equipment.

All it takes is decades of drill breakage and you're good to go.

Metal is not what it was and is difficult to remove the blue color tinting. It's 6061 T6.

I need to try more compounds but is $ and no one cares.

Needs one more polish/glaze then wax and assemble the Pass parts.

Just trying to show if you have done this work enough you can drill/tap w/o the best equipment.

All it takes is decades of drill breakage and you're good to go.

You must have hydraulic punches. So many good rotary drills now that I can't afford. But, I'm supposed to be in bed and not making stuff anymore.use chassis punches for the rest.

There was a class at Uni where one of the things we had to make using hand tools (files and saws only) was a two piece fitting with a complex mating surface/pattern. It had to be such that light could not be seen through the mating and blue dye when spread, only a thin blue line was visible, i.e. all the cut sanded surfaces were perfectly orthogonal to the face of the peices. Took me 5 or 6 tries to pass that class. Hated it.

You must have hydraulic punches. So many good rotary drills now that I can't afford. But, I'm supposed to be in bed and not making stuff anymore.

Just Greenlee punches and a wrench. I've managed to punch 1" diameter holes in 1/4" aluminum.

There was a time when tools were limited to what you could use in your hand. IIRC the motor on the wright brothers first powered flight was made entirely with hand tools.

The Milwaukee Holeshooter was born 100 years ago when Henry Ford requested that a 1/4" drill be designed and produced. We've come a long way...

I use hand drill and eye ball it. Works for me. I would like a drill press, but I am trying to empty my garage! Now have this drill guide on the way!Yup, I use a Big Gator drill guide too for drilling and tapping. I don't have room to store a drill press so I use an electric hand drill and the drill guide for vertical alignment. The drill guide is used to align the tap vertically before starting the tap.

https://biggatortools.com/shop/ols/...warranty-it-s-like-a-portable-drill-press-vlf

Right? If I'm drilling through holes, a nice low profile cap screw between the fins is the best alternative to tapping. Don't leave a visible screw/nut there...

I'm in the threaded blind hole camp though whenever possible

I'm in the threaded blind hole camp though whenever possible

for securing outut devices to heatsinks wonder if double sided kapton would work?

I will check for electrical insulation capabilites.

I will check for electrical insulation capabilites.

Last edited:

Dial "M" for monoblocks

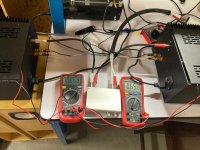

This was mostly done out of expediency. Two monoblock chassis each with an Antek AS-2218 and Randy Thatcher's "V8 CRCRC" dual rail PSUs with all the trimmins were within specs and ready for a quick amp swap. Would the F5m boards hold bias? would they thump or run away without their thermistors? I didn't know.

Turns out they bias up just fine and gentle and seem to hold that bias at a smidge under 1.4A for quite a while. The heat sinks are warm but not evenly so, there is sinking to spare. No turn-on or turn off thumps, neither.

I don't recall hearing quite so much bass or detail or bass detail out of the garage speakers before. These will be fun to hear in the main system for sure.

This was mostly done out of expediency. Two monoblock chassis each with an Antek AS-2218 and Randy Thatcher's "V8 CRCRC" dual rail PSUs with all the trimmins were within specs and ready for a quick amp swap. Would the F5m boards hold bias? would they thump or run away without their thermistors? I didn't know.

Turns out they bias up just fine and gentle and seem to hold that bias at a smidge under 1.4A for quite a while. The heat sinks are warm but not evenly so, there is sinking to spare. No turn-on or turn off thumps, neither.

I don't recall hearing quite so much bass or detail or bass detail out of the garage speakers before. These will be fun to hear in the main system for sure.

Attachments

I have drilled and tapped lots and lots of holes in heatsinks. Here are some things I have encountered and learned:

- Most of my experience has been with hole drilling and tapping for #4-40 and #6-32 screws. #4-32 is a pain in the *** because the taps easily break, particularly when drilling through the baseplate at the edge of a fin.

- There is no need to drill through holes in a 3/8" baseplate. Stop drilling and tapping before going all of the way through. The screws do not need more than 6-8 screw threads to anchor the FET.

- Recently I have stopped using #4-32 screws and use M3 screws instead. The M3 thread taps are much less prone to breaking.

One nice thing about drilling for M3 instead of #6-32 is that M3 will work for both TO-3P and TO-247 parts while #6-32 is too large for TO-3P. I ran into this trying to use some Fairchild power mosfets (in TO-3P) on headshinks previously drilled for #6-32 and ended up having to enlarge the holes on the mosfets.

- Home

- Amplifiers

- Pass Labs

- F5m kit