Good eye. Me blind eye =D How are the primaries connected? Are they by any chance in series? Shouldn’t it be possible to wire it on the primary side so as to function just as well on 230v circuit?

Wrt how to connect it correctly or alternatively, I am out of my league here.

Wrt how to connect it correctly or alternatively, I am out of my league here.

Last edited:

Stop transformers hum or buz

Get some electrical varnish, enamel, etc

Poor mans way. Submerge transformers in liquid, remove let dry. Days to evaporate solvents out. A little heat helps.

Better way. Place transformer in vacuum chamber. Pull deep vacuum, open valve containing varnish or enamel, poly, epoxy, etc. to flood chamber above level of transformer.

Now open valve to pressurize with nitrogen or argon.

Now release pressure, remove transformer, let air dry to remove flammable solvents.

Now place transformer in oven

Times and temperature vary on manufacturers of the specific chemical coating being used.

It’s not difficult

Just a lot of reading and research your first time.

I already own all the mechanical equipment because of my work so no money out of pocket just witch ever coatings I purchase.

If you are going to buy a new transformer any way it dose not hurt to try the poor mans way as experiment. It will work or not.

I tried replacing the foam either side of the transformer with thicker and more dense foam. The mechanical hum 'might' be quieter, but I can still hear it from the listening seat 4m away. Not a supprise as the outside and inside of the transformer are still free to flap about, but the right place to start.

Looks like I need to try DC blocker, potting the transformer or adding coils to the primary (which doesn't make sense to me yet. I thought one would want to remove coils to reduce saturation, but I read it on the Internet so it must be true...?) or another solution that doesn't involve buying new transformers.

Get some electrical varnish, enamel, etc

Poor mans way. Submerge transformers in liquid, remove let dry. Days to evaporate solvents out. A little heat helps.

Better way. Place transformer in vacuum chamber. Pull deep vacuum, open valve containing varnish or enamel, poly, epoxy, etc. to flood chamber above level of transformer.

Now open valve to pressurize with nitrogen or argon.

Now release pressure, remove transformer, let air dry to remove flammable solvents.

Now place transformer in oven

Times and temperature vary on manufacturers of the specific chemical coating being used.

It’s not difficult

Just a lot of reading and research your first time.

I already own all the mechanical equipment because of my work so no money out of pocket just witch ever coatings I purchase.

If you are going to buy a new transformer any way it dose not hurt to try the poor mans way as experiment. It will work or not.

Do not use polyester type resins. They support combustion. Epoxy does not support combustion. The varnish/enamel are OK, very little material is left after they have dried.

If you are potting the transformer inside and out, you would have to remove the plastic wrap so the exposed coils can be infiltrated with epoxy.

I use epoxy, and just pot the inside of the transformer, but that doesn’t do the same job as potting the transformer as indicated by ThermalAlchemy.

Rush

If you are potting the transformer inside and out, you would have to remove the plastic wrap so the exposed coils can be infiltrated with epoxy.

I use epoxy, and just pot the inside of the transformer, but that doesn’t do the same job as potting the transformer as indicated by ThermalAlchemy.

Rush

Thanks for the suggestions! Listening through them now and feeling they are worth a bit more effort to get them finished. Thinking I'll try the insulating varnish first. Will let you know how I get on.

Best regards

Steve

Best regards

Steve

Rixsta:

Uhm, if you're building F5 Turbos as monoblocks then I think you may be building (or should consider building) a pair of V3 amps, not a V2. And as a former owner of Pass Labs Aleph 1.2 amps, I'd suggest you consider how you will move the amps you're building. The 1.2s weighed just over 100 pounds apiece and, like all of the Aleph series amps, had a chassis made almost entirely of (sharp-finned) heatsink. Your V3s will very likely weigh far less but moving them may be painful if the heatsinks are sharp.

The rear sink on the 1.2s differed from the other three sides in that a narrow vertical portion lacked fins; that was where Pass Labs located the IEC inlet, fuse holder, single-ended and balanced inputs and binding posts. You might consider a blank (non-finned) panel on the rear of your amps to which you could attach a couple of handles as well. Just a thought.

In any event, good luck with your project!

Regards,

Scott

Thanks Scott

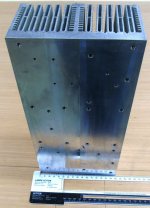

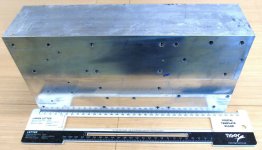

I have another set of heatsinks in mind at the bottom of this post and had a question for people here the heatsinks there have much deeper fins and are a more manageable size for an amplifier compared to stacking my other sinks up.

This is what I was looking at originally, the 4 heatsinks together to make a whole F5 Turbo V2, If that is not enough heatsink then hmmm as I feel that using 8 of those sinks to make two monoblocks would be an insane use of space in my small room! lol

4 Sinks, Stereo F5 turbo

415mm Length

230mm high together

30mm fin depth (not so big)

Possible layout

4 Sinks Upright, Stereo F5

415mm high

230mm wide

30mm fin depth

Possible Layout (Transistors further down sinks as the heat rises)

or a Heat tunnel Turbo, I think personally I would not like this as I hate fan noise! but they are lovely sinks

Here are the heatsinks I have found that I would prefer to use as it would just make the whole process easier, the fins are also deeper so my question is would 2 of those plus one along the back of the amp be better than the ones above ?

fins 80mm

Length 330mm

Width 160mm

My intuition tells me here are the better sinks to use, overall smaller yes but Fins are bigger, the 330mm Length is also much more suitable for an amplifier length on a work surface/living room cabinet compared the very long 415 in the sinks above.

Any thoughts ?

Thanks

Last edited:

with shorter fins - you need to cut them and orient vertically

short but wiiiiide heatsink is much more efficient than long and narrow (tall tower)

so, all in all, it seems you have fan assistance as only choice

fans at 7-8V are very silent, nowadays

even wiithout resorting to expensive ones

short but wiiiiide heatsink is much more efficient than long and narrow (tall tower)

so, all in all, it seems you have fan assistance as only choice

fans at 7-8V are very silent, nowadays

even wiithout resorting to expensive ones

If you look up the specs for those tunnels, you‘ll find that they have incredible good heat-transfer IF the forced airflow is high enough...

with shorter fins - you need to cut them and orient vertically

short but wiiiiide heatsink is much more efficient than long and narrow (tall tower)

so, all in all, it seems you have fan assistance as only choice

fans at 7-8V are very silent, nowadays

even wiithout resorting to expensive ones

Thanks Zen, I hear you this short but wide heatsink ... I should have realised, so I can keep fins upright. I could put those long sinks upright and make a tall amp?

I could get the sinks here cut maybe ... hmmmm

If you look up the specs for those tunnels, you‘ll find that they have incredible good heat-transfer IF the forced airflow is high enough...

Do you think those two sinks are enough for Turbo 2 ? as that's all I have of those heat tunnel ones.

I'm at another crossroads in my F5 build. As previously mentioned I jumped in a bit hastily, so I'm definitely still figuring things out as I go. So far I have basically everything I need to build an F5Tv2 with cascodes in dual mono. This includes a 5U chassis, one set of F5 boards, a soft start board, two sets of UPS boards, and two 600VA transformers (AN-6224s). To build this in dual mono, things are getting a little tight. There are three options I'm considering.

The first seems to be the most common, which is to just "make it work." In my research outside this forum that seems to be what I see the most, people with their 5U chassis stuffed to the brim. This would probably involve having the transformers in a horizontal line somewhere around 3/4 of the way back, so there is just enough room between them and the back panel for the soft start board and a power distribution terminal strip. This brings them pretty close to the amp boards though, and in particular to the signal path. This also puts the soft start and the power distribution quite close to the output jacks. I would also have to separate the diode boards from the filter boards in the power supplies most likely, mounting the filters on the front panel, with the rectifiers and the floating grounds in between them and the transformers.

The second is not one I have seen "in the wild" yet, which is to use the risers sold on the store here. I think if I get two pairs of 150x120 and one pair of 180x150 I could make a tunnel running down the middle of the chassis, starting at the front panel, that is 180 wide, 120 tall, and 300 long. I think I would even have space to leave a 10mm gap in the middle to feed wiring through, if needed. This should let me put the transformers inside the tunnel, and the full/unseparated PSU boards on top of the tunnel. Based on the chassis specs and the estimated height of the built board+standoffs I think I'll have enough vertical space to pull this off, with the top of the PSU caps and the heatsinks on the bridge rectifier having a few cm of vertical clearance. This might be my favorite option. I would have more free space overall since I'm building higher, and the riser panels would hopefully provide some shielding. At a glance it's possible that this configuration may bring the rear transformer closer to the output jacks than it would otherwise be, but it's so much farther away from everything else, I'm hoping it won't be an issue. But maybe there's something I'm missing or have miss-measured or something. Maybe thermal or interference concerns with the PSU boards above the transformers like that? There would be several cm between the transformer and the top and sides of the tunnel, and again hopefully the tunnel will provide some shielding, but I haven't seen anybody else doing this which makes me think there might be some reason not to do it. At the very least I'd like to build my PSU boards or hear from somebody else who has already done something similar before committing to this option so that I can know for sure that it will all fit.

The third choice is by far the most expensive, but also possibly the most "reasonable," which is to go full monoblock. I could make space in my listening room and in my budget, but this is for a nearfield setup so it feels unnecessary. The speakers I'll be driving are 4ohm and around 87db sensitivity, but SPL calculation suggests that even an ACA would be adequately loud for my needs. I'm using an 80w class D right now and I'd never taken it past noon until I put a preamp into my chain. It would make the build a whole lot simpler, but I'm not sure that simplicity is worth the extra ~$600 I'd have to commit for another chassis, another set of F5 boards, and more components. The classic time versus money equation. Until yesterday I had more money than time, but my schedule is starting to open up again. And I'm replacing a working amp in an existing stack, so there's no real hurry.

The fact that I tend to see the first option the most suggests that perhaps I'm just overthinking things, and that these will be non-issues, but I've been following NocturneVid66's progress on youtube and he seems to be running into a lot of these concerns. Super-interested in everybody's thoughts and opinions, advice and admonitions on this. Thanks!!

The first seems to be the most common, which is to just "make it work." In my research outside this forum that seems to be what I see the most, people with their 5U chassis stuffed to the brim. This would probably involve having the transformers in a horizontal line somewhere around 3/4 of the way back, so there is just enough room between them and the back panel for the soft start board and a power distribution terminal strip. This brings them pretty close to the amp boards though, and in particular to the signal path. This also puts the soft start and the power distribution quite close to the output jacks. I would also have to separate the diode boards from the filter boards in the power supplies most likely, mounting the filters on the front panel, with the rectifiers and the floating grounds in between them and the transformers.

The second is not one I have seen "in the wild" yet, which is to use the risers sold on the store here. I think if I get two pairs of 150x120 and one pair of 180x150 I could make a tunnel running down the middle of the chassis, starting at the front panel, that is 180 wide, 120 tall, and 300 long. I think I would even have space to leave a 10mm gap in the middle to feed wiring through, if needed. This should let me put the transformers inside the tunnel, and the full/unseparated PSU boards on top of the tunnel. Based on the chassis specs and the estimated height of the built board+standoffs I think I'll have enough vertical space to pull this off, with the top of the PSU caps and the heatsinks on the bridge rectifier having a few cm of vertical clearance. This might be my favorite option. I would have more free space overall since I'm building higher, and the riser panels would hopefully provide some shielding. At a glance it's possible that this configuration may bring the rear transformer closer to the output jacks than it would otherwise be, but it's so much farther away from everything else, I'm hoping it won't be an issue. But maybe there's something I'm missing or have miss-measured or something. Maybe thermal or interference concerns with the PSU boards above the transformers like that? There would be several cm between the transformer and the top and sides of the tunnel, and again hopefully the tunnel will provide some shielding, but I haven't seen anybody else doing this which makes me think there might be some reason not to do it. At the very least I'd like to build my PSU boards or hear from somebody else who has already done something similar before committing to this option so that I can know for sure that it will all fit.

The third choice is by far the most expensive, but also possibly the most "reasonable," which is to go full monoblock. I could make space in my listening room and in my budget, but this is for a nearfield setup so it feels unnecessary. The speakers I'll be driving are 4ohm and around 87db sensitivity, but SPL calculation suggests that even an ACA would be adequately loud for my needs. I'm using an 80w class D right now and I'd never taken it past noon until I put a preamp into my chain. It would make the build a whole lot simpler, but I'm not sure that simplicity is worth the extra ~$600 I'd have to commit for another chassis, another set of F5 boards, and more components. The classic time versus money equation. Until yesterday I had more money than time, but my schedule is starting to open up again. And I'm replacing a working amp in an existing stack, so there's no real hurry.

The fact that I tend to see the first option the most suggests that perhaps I'm just overthinking things, and that these will be non-issues, but I've been following NocturneVid66's progress on youtube and he seems to be running into a lot of these concerns. Super-interested in everybody's thoughts and opinions, advice and admonitions on this. Thanks!!

Last edited:

Do you think those two sinks are enough for Turbo 2 ? as that's all I have of those heat tunnel ones.

Sorry, I can’t tell wether they‘re good or not. It depends on the airflow you‘ll get with the fan(s) you would use.

I was tempted for ma f4, but stepped back and stayed with the conventional passive massive chassis...

Compare the heatsink‘s heat absorption capacity.

I did not read the entire thread, can anyone report how this amp sounds with speakers that are recommended for 50-350W amps? I have Focal Aria 848 and more often than not I feel like they are underpowered.

to AiGO

Hello AiGO,

my experience with my F5T-Monoblocks are, that they can drive also

'difficult' speakers. Depends on how powerful you build them? You know

that the F5T is an upscalable amp-project from Nelson Pass.

My F5T run on +-42,5V railvoltage (1000 VA toroid per channel, PSU

with 120000µF per channel, biased at around 330mV).

You need a very big case to get rid of the heat! - it is ClassA.

I can't tell you how it will sound with the FOCAL Aria848? Could be a bit

of too much in the highs? I would expect that this combo will sound super detailed in the highs - but?😕

I owned a pair of FOCAL speakers in the 1990ies. They had the inverted

dome tweeter (I think it was the T90 or T120). I remember they were very

unforgiving in the highs - cristalclear.

But the power of a F5T should be more than enough to drive your FOCAL

Aria 848. My Focals haven't been so hungry for watts. It is about the efficiency of a speaker. If I remember right, my ones were around 91-92dB/

1 W/1m. I drove my Focals with DENON POA-4400 Monoblocks those days.

The Aria 948 has a sensitivity of 92,5dB/W/m.

That is all I can say.

Greets

Dirk

Hello AiGO,

my experience with my F5T-Monoblocks are, that they can drive also

'difficult' speakers. Depends on how powerful you build them? You know

that the F5T is an upscalable amp-project from Nelson Pass.

My F5T run on +-42,5V railvoltage (1000 VA toroid per channel, PSU

with 120000µF per channel, biased at around 330mV).

You need a very big case to get rid of the heat! - it is ClassA.

I can't tell you how it will sound with the FOCAL Aria848? Could be a bit

of too much in the highs? I would expect that this combo will sound super detailed in the highs - but?😕

I owned a pair of FOCAL speakers in the 1990ies. They had the inverted

dome tweeter (I think it was the T90 or T120). I remember they were very

unforgiving in the highs - cristalclear.

But the power of a F5T should be more than enough to drive your FOCAL

Aria 848. My Focals haven't been so hungry for watts. It is about the efficiency of a speaker. If I remember right, my ones were around 91-92dB/

1 W/1m. I drove my Focals with DENON POA-4400 Monoblocks those days.

The Aria 948 has a sensitivity of 92,5dB/W/m.

That is all I can say.

Greets

Dirk

Thanks Dirk,

The belief is that the power amplifier does not need many watts to deliver top quality sound, as the name 'First Watt' (first that matters) suggests. Maybe it is so, but then why do I hear bass reminiscent to the soft hands clap rather than the strong fist hit? There is definitely something of a mismatch somewhere in that chain. And it does come stronger when connected to the large AVR (Marantz SR in my case). Strange.

The belief is that the power amplifier does not need many watts to deliver top quality sound, as the name 'First Watt' (first that matters) suggests. Maybe it is so, but then why do I hear bass reminiscent to the soft hands clap rather than the strong fist hit? There is definitely something of a mismatch somewhere in that chain. And it does come stronger when connected to the large AVR (Marantz SR in my case). Strange.

to AiGo

Good Morning AiGo,

we are HiFi-freaks and searching for the best sound....

In my opinion an amp and a speaker should 'fit' together. It is like looking

for a good partner for a marriage ( a little metapher 🙄).

If you have an uncontrolled bass, I would say the amp has not enough 'control'

over the speaker. Could be not enough power (delivers not enough current and/or voltage) or not enough damping factor. There can be different reasons? Also other problems in the chain.

I would assume that a F5T V3 could be a good 'candidate'.

For good bass I prefer the BA-3 poweramp ( BA-3 FE + complementary outputstage) from Nelson Pass. But that is my experience.... 😀

Greets

Dirk

Good Morning AiGo,

we are HiFi-freaks and searching for the best sound....

In my opinion an amp and a speaker should 'fit' together. It is like looking

for a good partner for a marriage ( a little metapher 🙄).

If you have an uncontrolled bass, I would say the amp has not enough 'control'

over the speaker. Could be not enough power (delivers not enough current and/or voltage) or not enough damping factor. There can be different reasons? Also other problems in the chain.

I would assume that a F5T V3 could be a good 'candidate'.

For good bass I prefer the BA-3 poweramp ( BA-3 FE + complementary outputstage) from Nelson Pass. But that is my experience.... 😀

Greets

Dirk

Hello Dirk,

BA-3 is rated as 40W @8Ohm whereas F5T 50W. Don't know if and how anyone ever measure it, but that's what they say at least. So I would imagine F5T would do a notch better as far as the punch goes, would not you agree?

BW, did you build BA-3 or did someone else put it together for you? Just asking.

BA-3 is rated as 40W @8Ohm whereas F5T 50W. Don't know if and how anyone ever measure it, but that's what they say at least. So I would imagine F5T would do a notch better as far as the punch goes, would not you agree?

BW, did you build BA-3 or did someone else put it together for you? Just asking.

to AiGo

Hello AiGo,

I have built two BA-3 (sure on my own 😀). One is running at +-26 Volt rails the

other one at +-34,5 Volt rails (which gives you also a bit more power). It is also

important how much current an amp can deliver. The BA-3 amp is also upscalable (more outputdevices). And we are talking about ClassA-amps.

You will have to built really big, heavy cases!

I drive a JBL subwoofer (38cm / 15 inch chassis, 94dB/W/m) with my BA-3.

But we are getting off-topic here in the F5-T builders thread!

You can ask me directly by private message over this forum.

And give me time to answer - My life is busy...

Greets

Dirk

Hello AiGo,

I have built two BA-3 (sure on my own 😀). One is running at +-26 Volt rails the

other one at +-34,5 Volt rails (which gives you also a bit more power). It is also

important how much current an amp can deliver. The BA-3 amp is also upscalable (more outputdevices). And we are talking about ClassA-amps.

You will have to built really big, heavy cases!

I drive a JBL subwoofer (38cm / 15 inch chassis, 94dB/W/m) with my BA-3.

But we are getting off-topic here in the F5-T builders thread!

You can ask me directly by private message over this forum.

And give me time to answer - My life is busy...

Greets

Dirk

The BA-3 is never out of topic, dear Dirk!

AiGo: You are wise to take advise from Dirk. Knows his stuff. Take a look at post #367 in the BA-3 build guide thread.

Wrt F5T vs BA-3, they have similarities but are different beasts. Dependant on speaker and other equip of course, the F5T would deliver more punch in many instances, as the output current is 38 amps (v2). This is achieved by the use of diodes in parallell with the transistors, ref the manual by Papa. Would a BA-3 work better on your speakers? Difficult to say, probably must try first. But with 6 deep config like Dirk mentions, possibly so. 3 deep? Probably not, if they are really current hungry and have impedance dips of notable swing in the bass region.

It would help if you posted your PSU capacitance and R, and rail voltage, as well as speakers specs and also impedance curves from 0-20khz. If this is allready posted, disregard. I am on the move and haven’t read it all.

Cheers,

Andy

AiGo: You are wise to take advise from Dirk. Knows his stuff. Take a look at post #367 in the BA-3 build guide thread.

Wrt F5T vs BA-3, they have similarities but are different beasts. Dependant on speaker and other equip of course, the F5T would deliver more punch in many instances, as the output current is 38 amps (v2). This is achieved by the use of diodes in parallell with the transistors, ref the manual by Papa. Would a BA-3 work better on your speakers? Difficult to say, probably must try first. But with 6 deep config like Dirk mentions, possibly so. 3 deep? Probably not, if they are really current hungry and have impedance dips of notable swing in the bass region.

It would help if you posted your PSU capacitance and R, and rail voltage, as well as speakers specs and also impedance curves from 0-20khz. If this is allready posted, disregard. I am on the move and haven’t read it all.

Cheers,

Andy

The stuffed Front End Board, couple questions and differences?

I have a few differences between my stuffed board, and 6L6 illustrated build guide. Some of those changes might be personality, and some of those differences might make a fire - and I don't know what's what! So, here's my semi-long post.

=====================================

=== QUESTIONS =====================

=====================================

1. I bought the "transistor kit" from diyaudiostore, it came with 2 - TIP32 (replaces obsolete 2SA1837), and 2 - TIP31 (replaces obsolete 2SC4793). Should these have a heatsink on them? 6L6 puts a small clip on version. Also in his post, he mentioned the other transistors in the PSU will make the heatsinks "live." Seems like putting an insulator between the transistor and heatsink is a good idea. How about this amazon special? I also noticed that diyaudio store sells "keratherm" pads $19. Should I insulate the PSU transistors as well as Q8 and Q7 on my Front End Boards?

2. Bourns Multiturn Pot (potentiometer). The ones I found are smaller than the ones in 6L6 post. There are three pins on the bottom, and they can go in either way: are the pin direction <up> vs <down>, <left> vs <right> important? I couldn't tell from the specs guide on mouser. Here are the two parts that I bought:

5k ohm https://www.mouser.com/ProductDetail/652-3266Y-1-502LF/

200 ohm https://www.mouser.com/ProductDetail/652-3266Y-1-201LF/

There are a couple flavors of each of those, I made sure to get the ones with the pins in a straight row. They fit perfectly, but are a little small.

3. A couple of my resistors are different looking: like smaller wattage, fireproof or not, whatever, than 6L6's selections. I didn't stray from the BOM for my selections - but a 1/4watt resistor is really small! Is that going to be a problem?

R5, R6, R25, R26, R27, R28, R29, and R30.

R5, R6: "1Kohm 0.6W"

R25, R26: "4.75Kohm-10Kohm (may be different value, see formula) only use when cascoding"

R27, R28: "4.75Kohm (may be different value, see formula) only use when cascoding"

=====================================

=== COMMENTS ========================

=====================================

Took me a while to find where these parts actually went. On the BOM (pdf) linked from the F5T diyaudiostore PCB page, refers to a couple depreciated parts:

Q7 = 2SC4793 only use when cascoding. Otherwise short C-E

Q8 = 2SA1837 only use when cascoding. Otherwise short C-E

Then, on the "transistor kit" it mentions the above parts 2SC4793 and 2SA1837 are both old, replaced by new parts:

TIP32 (replaces obsolete 2SA1837)

TIP31 (replaces obsolete 2SC4793)

And, they aren't identical.

Q1 and Q2 are these little guys, that I also received in the Transistor Kit. Ovals with one flat side. They are also different from one to the other. I didn't get a close up of the code on them - but I think they are correct to the BOM for DIYaudio F5 Turbo. You can see the four little guys (transistors?) in the bottom right here:

R7, R8, R9, and R10: 6L6 mentioned that he was using "high voltage caddock resistors" and that most people would use regular resistors. That was my route.

I have a few differences between my stuffed board, and 6L6 illustrated build guide. Some of those changes might be personality, and some of those differences might make a fire - and I don't know what's what! So, here's my semi-long post.

=====================================

=== QUESTIONS =====================

=====================================

1. I bought the "transistor kit" from diyaudiostore, it came with 2 - TIP32 (replaces obsolete 2SA1837), and 2 - TIP31 (replaces obsolete 2SC4793). Should these have a heatsink on them? 6L6 puts a small clip on version. Also in his post, he mentioned the other transistors in the PSU will make the heatsinks "live." Seems like putting an insulator between the transistor and heatsink is a good idea. How about this amazon special? I also noticed that diyaudio store sells "keratherm" pads $19. Should I insulate the PSU transistors as well as Q8 and Q7 on my Front End Boards?

2. Bourns Multiturn Pot (potentiometer). The ones I found are smaller than the ones in 6L6 post. There are three pins on the bottom, and they can go in either way: are the pin direction <up> vs <down>, <left> vs <right> important? I couldn't tell from the specs guide on mouser. Here are the two parts that I bought:

5k ohm https://www.mouser.com/ProductDetail/652-3266Y-1-502LF/

200 ohm https://www.mouser.com/ProductDetail/652-3266Y-1-201LF/

There are a couple flavors of each of those, I made sure to get the ones with the pins in a straight row. They fit perfectly, but are a little small.

3. A couple of my resistors are different looking: like smaller wattage, fireproof or not, whatever, than 6L6's selections. I didn't stray from the BOM for my selections - but a 1/4watt resistor is really small! Is that going to be a problem?

R5, R6, R25, R26, R27, R28, R29, and R30.

R5, R6: "1Kohm 0.6W"

R25, R26: "4.75Kohm-10Kohm (may be different value, see formula) only use when cascoding"

R27, R28: "4.75Kohm (may be different value, see formula) only use when cascoding"

=====================================

=== COMMENTS ========================

=====================================

Took me a while to find where these parts actually went. On the BOM (pdf) linked from the F5T diyaudiostore PCB page, refers to a couple depreciated parts:

Q7 = 2SC4793 only use when cascoding. Otherwise short C-E

Q8 = 2SA1837 only use when cascoding. Otherwise short C-E

Then, on the "transistor kit" it mentions the above parts 2SC4793 and 2SA1837 are both old, replaced by new parts:

TIP32 (replaces obsolete 2SA1837)

TIP31 (replaces obsolete 2SC4793)

And, they aren't identical.

Q1 and Q2 are these little guys, that I also received in the Transistor Kit. Ovals with one flat side. They are also different from one to the other. I didn't get a close up of the code on them - but I think they are correct to the BOM for DIYaudio F5 Turbo. You can see the four little guys (transistors?) in the bottom right here:

R7, R8, R9, and R10: 6L6 mentioned that he was using "high voltage caddock resistors" and that most people would use regular resistors. That was my route.

I would isolate the heatsinks. Keratherm is probably overkill, temperature-transferwise (that is, they‘re relatively expensive)

Don‘t underrate resistor‘s wattage. They may overheat or even fry (not probable but still)

Take great care to use the correct fets and little guys. They look almost similar but are different. Correct position matters.

Get accustomed to the led‘s orientation, they only work when correct.

Trimpots are fine either way, as long as they fit in size and value.

Hth, have fun and success!

Don‘t underrate resistor‘s wattage. They may overheat or even fry (not probable but still)

Take great care to use the correct fets and little guys. They look almost similar but are different. Correct position matters.

Get accustomed to the led‘s orientation, they only work when correct.

Trimpots are fine either way, as long as they fit in size and value.

Hth, have fun and success!

thank you very much @myleftear! It has been exciting to pull these pieces together.

On the P1 and P2 trimpots, 6L6 has arrows on them that he drew on with a pen. What's that for? Something I should measure before stuffing and soldering them down?

Stuffing the N and P channel boards. On the "BOM for DIYaudio F5 Turbo"

mentions TH1 = 4.7Kohm NTC for BOTH N channel and P channel boards. The "F-5t N Channel O/P" board only has a TH2. That's a typo right? There's a thermistor (?) on both P channel and both N channel boards: four in total.?

Also, only R11, and TH1, on P channel boards say

"use only on 1 P ch board pr channel"

R12 and TH1 (TH2?), on N channel boards say

"use only on 1 N ch board pr channel"

Each channel, Left and Right, have one P and one N channel boards. So, that's only one P channel board and one N channel board per Left and Right channel. So all boards get all of them?

Let me know if you see any other glaring mistakes on these boards - thank you very much!

P-channel board

N-channel board

On the P1 and P2 trimpots, 6L6 has arrows on them that he drew on with a pen. What's that for? Something I should measure before stuffing and soldering them down?

Stuffing the N and P channel boards. On the "BOM for DIYaudio F5 Turbo"

mentions TH1 = 4.7Kohm NTC for BOTH N channel and P channel boards. The "F-5t N Channel O/P" board only has a TH2. That's a typo right? There's a thermistor (?) on both P channel and both N channel boards: four in total.?

Also, only R11, and TH1, on P channel boards say

"use only on 1 P ch board pr channel"

R12 and TH1 (TH2?), on N channel boards say

"use only on 1 N ch board pr channel"

Each channel, Left and Right, have one P and one N channel boards. So, that's only one P channel board and one N channel board per Left and Right channel. So all boards get all of them?

Let me know if you see any other glaring mistakes on these boards - thank you very much!

P-channel board

N-channel board

- Home

- Amplifiers

- Pass Labs

- F5 Turbo Builders Thread