I didn't exactly say I was hearing it, just wondering whether hissing noise I'd heard (with a woofer making big excursions while very inadequate for radiating infra bass) could have been Barkhausen.Is Mike's FSAF stuff, now embedded in REW, the only repeatable method to get a hook on this? Bill Waslo & Hornli suggest you can hear it clearly on LF sine.

If so, a small mid driver in open air driven by something like a big 10Hz sinewave could be a way to hear it. No FSAF or Distortion Isolation needed, physics takes care of taking out the applied tone.

I think the idea is to have a well-defined place to control and linearize the eddy currents in the dedicated shorting rings/caps.Were the eddy currents ever a problem though? In voltage drive they just help to flatten the response, complimenting the cone's acoustic gain. They behave the same as a weak shorting ring but to much lower frequencies due to the skin depth in steel. Having no eddy currents would actually make the problem worse because the eddy currents mitigate flux modulation and hysteresis. A laminated pole piece would give a hard inductance, so your cone would also have to have a steeply rising treble response in voltage drive. But then I suppose for a woofer this would just be a convenient HF rolloff.

The main issue I'm aware of with eddy currents is that while there is a current in the voicecoil, they produce a nonlinear drag which increases H3 quickly with level. I haven't seen many signs of this in the usual drivers though so I think if it is an issue it must be at very high powers.

I think I've read about a segmented magnetic circuit somewhere in Purifi papers/patents/blog, maybe @lrisbo might want to comment?

On that topic, it's kind of funny to see crossover inductors with carefully chosen lamination thickness and special steel whereas the speaker they are driving is just a voicecoil surrounding a solid slug of unremarkable steel with some ferrite, no laminations and a hope and a prayer. Maybe crossover inductors should be made the same way?

@lrisboDriver designers would love to use segmented/laminated structures that eliminate/minimize eddy current paths, it's just almost impossible to build them with reasonable effort, as of yet.

Purifi is working on that problem, AFAIK.

JBL is using a unique motor design with copper and steel lamination at the magnet gap in their 1500AL and 1501AL drivers.

https://www.audioheritage.org/html/projectmay/technology/1500al.htm

source: https://adeogroup.it/sites/default/..._synthesis_informazioni_tecniche_k2_s9900.pdfK2.S9900 White Paper

G.T.

The top plate is constructed of alternating copper-steel laminations. The presence of the copper rings linearizes the magnetic properties of the gap to all but eliminate eddy current distortion. The total gap is 41 mm long and provides a completely uniform flux field for the voice coil. Another benefit of this construction method is that the voice coil inductance remains essentially constant over the operating range of the driver. This means that the load presented to the crossover network and ultimately to the driving amplifier is uniform with coil position.

This eliminates yet another source of dynamic distortion (inductance modulation) that is prevalent in many lesser drivers.

The pdf document is also attached herein.

source: https://www.audioheritage.org/vbulletin/showthread.php?33557-1501al-2

Attachments

Last edited:

If high levels are required to generate loadsa Barkhausen, it might be masked by music. Keantoken, you are right that familiarity with a particular distortion in in listening tests makes it easier to hear them later. see eg appendix ofBill Waslo & Hornli suggest you can hear it clearly on LF sine.

Intermodulation Distortion Listening Tests

Are large LF sine waves the best to avoid masking of Barkhausen noise ?I think all that is needed is high excursion, level could be low if your driver is small. Perhaps this doesn't matter as the barkhausen is also quiet then. Perhaps for practical testing it's more comfortable to do with small speaker at 80db than big system blasting 120db 😀

The Barkhausen noise can be plainly audible when sweeping - heard it on underhung woofers (a lot of iron around the coil).

In the past I have found that woofers with foam surrounds would make a "faint swooshing" sound that was clearly audible with large excursions on low sinewaves and woofers with rubber surrounds were much more quiet under the same conditions. I assumed that there was something to do with the light weight of the foam being a better radiator of high frequencies but never knew if the sound came from bending the foam or something else.I didn't exactly say I was hearing it, just wondering whether hissing noise I'd heard (with a woofer making big excursions while very inadequate for radiating infra bass) could have been Barkhausen.

If so, a small mid driver in open air driven by something like a big 10Hz sinewave could be a way to hear it. No FSAF or Distortion Isolation needed, physics takes care of taking out the applied tone.

That is an interesting observation since bending most types of foam will result in a noise. I wonder if age is a large factor since foam surrounds can still be working even when they are very delicate and liable to go at any moment.

Can you link to some sound files? With details please.The Barkhausen noise can be plainly audible when sweeping - heard it on underhung woofers (a lot of iron around the coil).

Are you saying Barkhausen in mainly in the steel (iron)? From this discussion, the impression I got was that it was in the permanent magnet materials.

Also a short voice coil would probably cause the least 'change' to the magnetic system especially at 'zero crossings'.

Same here, I am a bit puzzled...the impression I got was that it was in the permanent magnet materials.

Furthermore, in my experience these puffing, hissing or whatever weird sounds with overly large excursions are more due to high air pressures in small cavities with small air paths than anything else.

This is my take on all this:

It is all about iron noise, both Barkhausen and Hysteresis. It is all about flip flopping of magnetic domains as the Voice Coil field passes past through the B-Field.

To a degree shorting rings help reduce mid-range Iron noise. Shorting rings do little to help long excursion low frequency iron noise.

Real time, to the ear and microphone iron noise sounds like crackling and popping noise.

On a single tone FFT it looks like periodic bursts of noise.

On a Frequency Response done with a tone sweep it looks like “Noise Floor”

On a Level and Distortion Plot the software looks at a particular frequency “F” at a point in time and takes the level of “2F” noise or whatever it is, a single blade of grass is all it takes and uses that number to calculate H2. It is not necessarily a real harmonic but whatever the level of noise that happens to be at frequency F2. The same is true for H3, H4 and the rest.

So if the noise is reduced by 15dB’s so is the "Distortion".

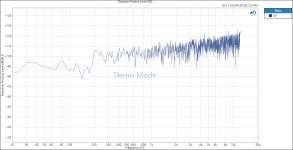

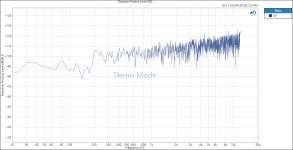

See the attached H2 demo plot as an example.

It says Distortion but looks like noise to me.

Thanks DT

It is all about iron noise, both Barkhausen and Hysteresis. It is all about flip flopping of magnetic domains as the Voice Coil field passes past through the B-Field.

To a degree shorting rings help reduce mid-range Iron noise. Shorting rings do little to help long excursion low frequency iron noise.

Real time, to the ear and microphone iron noise sounds like crackling and popping noise.

On a single tone FFT it looks like periodic bursts of noise.

On a Frequency Response done with a tone sweep it looks like “Noise Floor”

On a Level and Distortion Plot the software looks at a particular frequency “F” at a point in time and takes the level of “2F” noise or whatever it is, a single blade of grass is all it takes and uses that number to calculate H2. It is not necessarily a real harmonic but whatever the level of noise that happens to be at frequency F2. The same is true for H3, H4 and the rest.

So if the noise is reduced by 15dB’s so is the "Distortion".

See the attached H2 demo plot as an example.

It says Distortion but looks like noise to me.

Thanks DT

Last edited:

Got links to sound bytes? The examples posted so far suggest 'swishy wooshy' so difficult to distinguish from noise.Real time, to the ear and microphone iron noise sounds like crackling and popping noise.

The comparison is sorta similar to Quantisation Noise (or Q. Distortion if you prefer)

Badly dithered : crackly noise BAD

Properly dithered : swishy or wooshy (depending on the dithering algorithm) INNOCUOUS

From this discussion, the impression I got was that it was in the permanent magnet materials.

The steel in the polepiece causes distortion of the same kind as is in steel crossover inductors. In measurements I haven't seen this differentiated in any way from any kind of distortion coming from the magnet itself. Maybe they are just very similar?

Isn't all signals a varying DC? 🙂

So is what we hear an induced added signal to the drive signal that flows through the "motor" or is it the physical thing itself that vibrates and emits noise?

//

So is what we hear an induced added signal to the drive signal that flows through the "motor" or is it the physical thing itself that vibrates and emits noise?

//

Last edited:

The magnet flux contains Barkhausen events and adds to the force caused by the voicecoil current (with modification depending on drive impedance). Magnetostriction is unlikely because the measurements show wideband noise whereas noise originating from the motor would be mainly coming out through various box and construction resonances.

Focal have introduced a pair of large 3 and 3½ way speakers with "current drive" amplification-

https://www.focal.com/technologies/remote-amplification-in-current-mode

https://www.focal.com/technologies/remote-amplification-in-current-mode

Now you can.Current drive is a novelty less new than obscure. We are not going to see “current amplifiers” on the shelf at the hifi shop any time soon.

Not likely to find place in sight

Moreover, you need to pick up the two cabinets with the 13" woofer

- Home

- Loudspeakers

- Multi-Way

- Experiments with the current drive