Because of the wide baffle I doubt there would be any diffraction benefits, plus it would make construction that much more difficult if you intended to keep the proper horn path lengths.

Because of the wide baffle I doubt there would be any diffraction benefits, plus it would make construction that much more difficult if you intended to keep the proper horn path lengths.

OK, got it. Does 6 different horn lengths "cover" the lower frequencies differently than having 4, all of the same length? Just curious... Thanks!

Yes. And perhaps with all the different lengths with different all-offs and phase responses it would be a real crap-shoot. The recent threads on MDD composite TLs might give some insight.

dave

dave

The Cornu has two different horn lengths. IIRC there's about a 25% difference but I can't find my measurements just now.

different lengths with different all-offs and phase responses it would be a real crap-shoot

I too think it would tend to 'muddy the waters'

Hi Fi Hangar

Got the micro cornys hung up at the hangar today. Amazing how 2 inch drivers can fill up a 60x60x20 ft box. The sound really changes as you move around the space, but there are some sweet spots near the plane.

Neighbor stopped in an could not believe the sound they made. Thanks to everyone here for the ideas and help on the way. Very cool, inexpensive, and satisfying project!

Got the micro cornys hung up at the hangar today. Amazing how 2 inch drivers can fill up a 60x60x20 ft box. The sound really changes as you move around the space, but there are some sweet spots near the plane.

Neighbor stopped in an could not believe the sound they made. Thanks to everyone here for the ideas and help on the way. Very cool, inexpensive, and satisfying project!

My BIL built a pair of 20" units with some small Aura drivers and his wife said from the kitchen...

...well you know the story. 🙂

What are we looking at in the foreground of the second pic? Can we see a pic of just it?

...well you know the story. 🙂

What are we looking at in the foreground of the second pic? Can we see a pic of just it?

What are we looking at in the foreground of the second pic? Can we see a pic of just it?

Hi Cal,

My other hobby is building and flying planes. This is my Experimental RV-9A. We do k-9 rescues and beer runs (among other things) with it.

It took about 3 years to build and I have been flying it for almost 14 years now.

1st time build.. good 'ol pandemic leaving me too much time at home

I had a couple of 3.5 inch full range drivers and someone close to me who needed some audio on their wall so I thought I'd give these a try while I wait for the drivers in my other speaker cabinet obsession to show up.

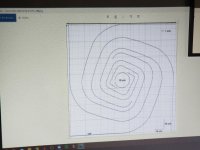

I ended up making a 20x20 base, taping it onto my wall, and using a projector to trace the pattern I'd be gluing with.

Hoping to get the front panel glued on tonight.

I had a couple of 3.5 inch full range drivers and someone close to me who needed some audio on their wall so I thought I'd give these a try while I wait for the drivers in my other speaker cabinet obsession to show up.

I ended up making a 20x20 base, taping it onto my wall, and using a projector to trace the pattern I'd be gluing with.

Hoping to get the front panel glued on tonight.

Attachments

Good work. I see you did it by compressing the foam rather than slicing it? When I tried that, the facer delaminated.

I ended up making a 20x20 base, taping it onto my wall, and using a projector to trace the pattern I'd be gluing with.

I have a projector - and know how it feels to want.

Is it even possible to make one of these that can be dis-assembled / re-assembled a few times after finishing? Glue one side, screws into the edge along the horn length on the other? Small embedded plastic drywall fasteners along the horn length? Just to end up with a flappy, buzzing mess?

I'm trying to imagine the skill it takes to apply glue along all that edge length, then "wing it" putting the back side in place, w/o smearing the glue all over. What glue has that long a work time while staying put? Obviously folks here and elsewhere do it successfully -

I'll be right back with a post that shows you how to glue the second piece.

EDIT: Here you go Joe. Simple but extremely effective especially since that is a 48" Cornu that entails 46 feet of foam edge to glue.

https://www.diyaudio.com/forums/full-range/225622-building-cornu-spiral-horn-62.html#post5339219

Also you make a jig to align the pieces. A wall works for one direction and you can use a carpenters square taped to a block of wood for the other direction.

EDIT: Here you go Joe. Simple but extremely effective especially since that is a 48" Cornu that entails 46 feet of foam edge to glue.

https://www.diyaudio.com/forums/full-range/225622-building-cornu-spiral-horn-62.html#post5339219

Also you make a jig to align the pieces. A wall works for one direction and you can use a carpenters square taped to a block of wood for the other direction.

Attachments

Micro - Mini???

Any reason why a 10x10 inch units with 1.5" drivers would not work? I was given a broken Soundcore BT speaker that could be parted out.

I found some thin corrugated cardboard that can be easily curved into shape and scaled the spirals to the 10" size. The foamcore would be too tight for the inner spirals.

Might make interesting sounds behind desk........

Any reason why a 10x10 inch units with 1.5" drivers would not work? I was given a broken Soundcore BT speaker that could be parted out.

I found some thin corrugated cardboard that can be easily curved into shape and scaled the spirals to the 10" size. The foamcore would be too tight for the inner spirals.

Might make interesting sounds behind desk........

I see no reason why not. If you keep in mind that a 1.5" speaker is only going to go so low anyways, then making the horn much larger might be a waste. Besides, they're inexpensive and not very time consuming.

Not sure how easy to incorporate the cardboard into the mix is going to be. The way I see it, the cardboard is going to be easiest to bend in line with the corrugations but that means the edges you are attempting to glue the baffles to are the open parts of the corrugation. ie: nothing to hold the glue. The first piece will be fine as you can spot glue and then caulk but not the second piece.

Not sure how easy to incorporate the cardboard into the mix is going to be. The way I see it, the cardboard is going to be easiest to bend in line with the corrugations but that means the edges you are attempting to glue the baffles to are the open parts of the corrugation. ie: nothing to hold the glue. The first piece will be fine as you can spot glue and then caulk but not the second piece.

- Home

- Loudspeakers

- Full Range

- Ever think of building a Cornu Spiral horn? Now you can!