Thanks for your feedback. Think I'll start of with a 4 to 5inch seas or fostex driver instead.

How does the single layer 4 horns design compare to the dual layer 8 horns?

Can I just reconfirm that the depth of the spiral is 4.5-5 inches wide for a 4-5 inch driver and I can use the pdf spiral template of 74cm x 74cm as attached in previous posts?

How does the single layer 4 horns design compare to the dual layer 8 horns?

Can I just reconfirm that the depth of the spiral is 4.5-5 inches wide for a 4-5 inch driver and I can use the pdf spiral template of 74cm x 74cm as attached in previous posts?

Thanks for your feedback. Think I'll start of with a 4 to 5inch seas or fostex driver instead.

How does the single layer 4 horns design compare to the dual layer 8 horns?

Can I just reconfirm that the depth of the spiral is 4.5-5 inches wide for a 4-5 inch driver and I can use the pdf spiral template of 74cm x 74cm as attached in previous posts?

Yes the 75cm wide x 5in deep should work. The 2 layer was made mainly because of the construction technique used by the original requires a middle template to hold the small wood slats. With curved wall foam core channels no need to make half depth horns. Larger horn mouth actually enables deeper wavelengths to be supported.

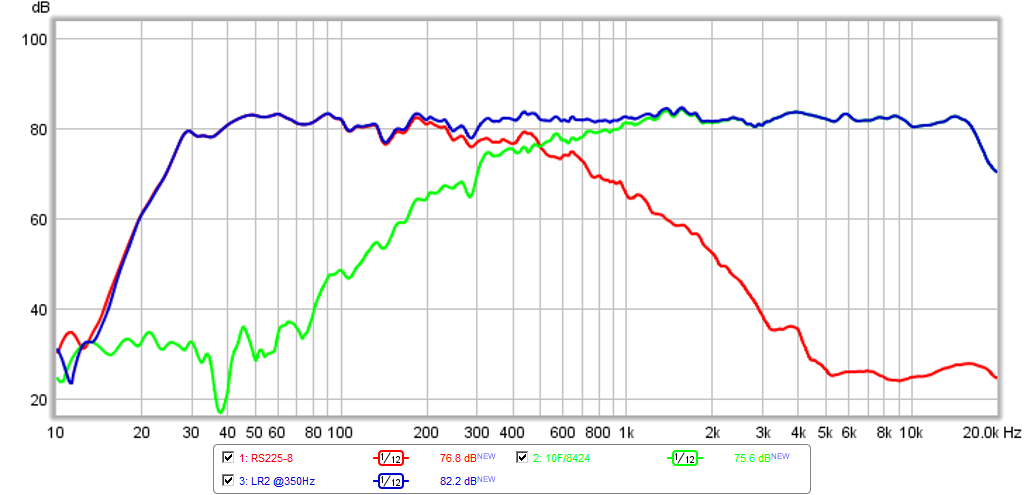

You may want to try a ScanSpeak 10F/8424 or 10F/8414 drive unit.

The scanspeak 8424 is a mid range driver.. Any reason in particular to use a mid range instead of a full range?

The scanspeak 8424 is a mid range driver.. Any reason in particular to use a mid range instead of a full range?

It may be called mid range but is truly full range - sounds fantastic. See measurement here in this thread. I am using it as a reference studio monitor:

http://www.diyaudio.com/forums/full-range/273524-10f-8424-rs225-8-fast-ref-monitor.html

Change .asc extension to .mp3 to listen:

http://www.diyaudio.com/forums/attachments/full-range/480537d1430447820-10f-8424-rs225-8-fast-ref-monitor-10f-8424-rs225-8-fast-bw1-350hz-clip-b.asc

It is used in a 2-way FAST here but the top extends to 16kHz, there is no EQ at all on the 10F - it is naturally flat response +/- 2dB:

Last edited:

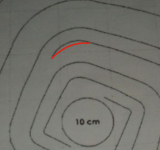

Yes but pay attention to the secondary horns where they start. The curve on that template seems out of whack as you can see in post 1 and in gmonno's second pic in post 2074. Compare that with the 'corrected' spirals in post 1573 where I evened that out. Not sure how much of a difference it makes but in my mind it was the right thing to do.74cm x 74cm as attached in previous posts?

Hi,

The template is wrong. The curve seems strange where the second horns start. I 'fixed' it when transferring the drawing to the baffles.

The template is wrong. The curve seems strange where the second horns start. I 'fixed' it when transferring the drawing to the baffles.

After you transfer the template just take a little of the 'hook' out of those two small locations. It won't take but one minute before you start gluing.

Ok just a slight variation to trim off the driver end off the 1st 2 horns..

Also how do you run the speaker hook up wires through the spirals.. Just make a tiny incision through the spirals?

Also how do you run the speaker hook up wires through the spirals.. Just make a tiny incision through the spirals?

Damping depends on the driver, room and taste. Start with the driver chamber and add more into the throats as is needed to reduce the boominess.

Green glue might be helpful but here's what I do:

In post 1583 you see what I do for the second baffle. I run glue along the foam core edge and cover it with paper. The paper holds the glue by way of surface tension. I then cut out the excess paper leaving a small amount either side of the foam core so what's left is about a 1" strip. I then add glue to the top of the paper. It acts as a ledge to hold the glue while I set the baffle in place. I do this because you only get one chance to make that seal leak free. I then con it with something solid that covers the whole piece and weight it down overnight. This is not a perfect joint so it takes quite a while for the glue to dry as it is acting partly as a sealant as well.

http://www.diyaudio.com/forums/full...u-spiral-horn-now-you-can-40.html#post3897058

Green glue might be helpful but here's what I do:

In post 1583 you see what I do for the second baffle. I run glue along the foam core edge and cover it with paper. The paper holds the glue by way of surface tension. I then cut out the excess paper leaving a small amount either side of the foam core so what's left is about a 1" strip. I then add glue to the top of the paper. It acts as a ledge to hold the glue while I set the baffle in place. I do this because you only get one chance to make that seal leak free. I then con it with something solid that covers the whole piece and weight it down overnight. This is not a perfect joint so it takes quite a while for the glue to dry as it is acting partly as a sealant as well.

http://www.diyaudio.com/forums/full...u-spiral-horn-now-you-can-40.html#post3897058

The boards are 20"x30". Measure the length of the black lines on the template to get your total length and figure out how many strips you can get from each board.

If your strips are 4", you can squeeze out 5 per board, so you now have 150" from each board. Take it from there.

If your strips are 4", you can squeeze out 5 per board, so you now have 150" from each board. Take it from there.

- Home

- Loudspeakers

- Full Range

- Ever think of building a Cornu Spiral horn? Now you can!