Perceval,

That's a great idea about ink! I love the look of the white but I may try it on a smaller fullrange box as a test. Glad to hear about your good kitty.

An idea came to me after all the discussion about lamination with wood. I can get 1mm or 2mm EVA foam here in Japan in rolls very cheap (around $10 for 1m x 1m x 2mm) I'm thinking about using this to repair my cat destroyed speaker. Sand down the speaker to remove most of the damage and then laminate with a thin layer of EVA foam. Laminated EVA will also act as a sacrifice layer so it will be easier to replace when the cat destroys it the next time. He is much better now though most of the damage was in the first few months he was with me. Also the laminated layer will allow me to cover up the seams and make for a very clean look.

I'll add this to my to do list

That's a great idea about ink! I love the look of the white but I may try it on a smaller fullrange box as a test. Glad to hear about your good kitty.

An idea came to me after all the discussion about lamination with wood. I can get 1mm or 2mm EVA foam here in Japan in rolls very cheap (around $10 for 1m x 1m x 2mm) I'm thinking about using this to repair my cat destroyed speaker. Sand down the speaker to remove most of the damage and then laminate with a thin layer of EVA foam. Laminated EVA will also act as a sacrifice layer so it will be easier to replace when the cat destroys it the next time. He is much better now though most of the damage was in the first few months he was with me. Also the laminated layer will allow me to cover up the seams and make for a very clean look.

I'll add this to my to do list

Mattes

The more I look at your black flower speaker the more I'm loving the idea. I'm starting to think about a new version of my cannoli TL using the 10f driver. I'd like to use your flower petal concept for the front baffle. Outside of the 5 petal symmetry is there any other math to the design?

The more I look at your black flower speaker the more I'm loving the idea. I'm starting to think about a new version of my cannoli TL using the 10f driver. I'd like to use your flower petal concept for the front baffle. Outside of the 5 petal symmetry is there any other math to the design?

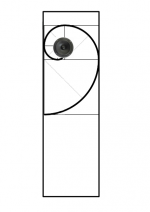

You can also make a Fibonacci spiral baffle but it will be a snail vs a flower. You might like the look of a flower more, but mathematically, the snail has probably less diffraction artifacts due to asymmetry.

That could be cool!

So, the center of the spiral is higher, and gradually gets thinner at the edges, put that on a baffle.

Would the driver be flush with the spiral, or recessed?

So, the center of the spiral is higher, and gradually gets thinner at the edges, put that on a baffle.

Would the driver be flush with the spiral, or recessed?

You can also make a Fibonacci spiral baffle but it will be a snail vs a flower. You might like the look of a flower more, but mathematically, the snail has probably less diffraction artifacts due to asymmetry.

I'm not sure i can imagine what a spiral front baffle would look like, but I can't imagine liking the esthetics of it. I can understand the spiral for a rear loaded TL like the B&W Nautilus or your nautilos. But I'm happy with my previous versions of open baffles and cannoli-TL designs so far for the back side of small fullrange drivers.

I'm actually leaning either to try mattes flower baffle or a zero baffle like linkwitz lxmini for my next attempt.

Attachments

Hi Jeshi,

XRK and Perceval are right insofar as that the Fibonacchi spiral is theoretically the better way to go. Please have a look at Rudolf´s work regarding dipole speakers:

Dipolplus - Alles über offene Schallwände

where you may download a compendium regarding dipole theory in english laguage. Some of that is also applicable to a front baffle design, I for myself name either dipole baffle effects and baffle diffraction effects geometrical resonances; bell modes of cones (for which your F 10 has these little curves on the backside, in order to suppress them) or whizzers (therefore the petal design of the Fertin´s whizzer, which had led me to the idea of the big flowers) fall in the same category.

So, I was aware of the superiority of the spiral, but liked the flowers more, asthethically... but of course, if you curve the spiral perpendicular - smallest radii at shortest distance from speaker, largest radii at longest distance, this should be perfect.

However, I myself felt that making the flowers (literally hundreds of hours of routing circles in steps of 2 mm and sanding those down, and I´m not finished yet) brought me to the limits, attempting the spiral in the same way will not be easier... but of course, more simple solutions for making those baffles might exist.

A comparison might be interesting, but I won´t do the spiral, will be glad once the bass flowers of 932 mm diametre and 160 mm depth are finished...

I´m sorry, I don´t have my design sketches with me in the moment, but they´re just this, sketches by hand, sadly no elaborated 3D CAD files from my side... will share them in the (yet to start...) building thread in maybe 10 days or so from now.

All the best

Mattes

XRK and Perceval are right insofar as that the Fibonacchi spiral is theoretically the better way to go. Please have a look at Rudolf´s work regarding dipole speakers:

Dipolplus - Alles über offene Schallwände

where you may download a compendium regarding dipole theory in english laguage. Some of that is also applicable to a front baffle design, I for myself name either dipole baffle effects and baffle diffraction effects geometrical resonances; bell modes of cones (for which your F 10 has these little curves on the backside, in order to suppress them) or whizzers (therefore the petal design of the Fertin´s whizzer, which had led me to the idea of the big flowers) fall in the same category.

So, I was aware of the superiority of the spiral, but liked the flowers more, asthethically... but of course, if you curve the spiral perpendicular - smallest radii at shortest distance from speaker, largest radii at longest distance, this should be perfect.

However, I myself felt that making the flowers (literally hundreds of hours of routing circles in steps of 2 mm and sanding those down, and I´m not finished yet) brought me to the limits, attempting the spiral in the same way will not be easier... but of course, more simple solutions for making those baffles might exist.

A comparison might be interesting, but I won´t do the spiral, will be glad once the bass flowers of 932 mm diametre and 160 mm depth are finished...

I´m sorry, I don´t have my design sketches with me in the moment, but they´re just this, sketches by hand, sadly no elaborated 3D CAD files from my side... will share them in the (yet to start...) building thread in maybe 10 days or so from now.

All the best

Mattes

However, I myself felt that making the flowers (literally hundreds of hours of routing circles in steps of 2 mm and sanding those down, and I´m not finished yet) brought me to the limits,...

Mattes

Wow... that is dedication.

Love that.

Keep it up, Mattes.

Last edited:

Hi Mattes,

Wow, definitely wow. That is dedication. Now I completely understand your comment about being sad if you had a cat destroy your flower like mine did.

Ok I think I understand the concept now. I'll have a go at copying this mathematically. I want to try a 3 petal version and see how it looks. I do all my EVA construction by hand with tracing patterns and then careful cutting with an exacto knife. I'll work on my design and post my progress in a few days.

I hope you don't mind if I follow your lead on this and make a version of it

Wow, definitely wow. That is dedication. Now I completely understand your comment about being sad if you had a cat destroy your flower like mine did.

Ok I think I understand the concept now. I'll have a go at copying this mathematically. I want to try a 3 petal version and see how it looks. I do all my EVA construction by hand with tracing patterns and then careful cutting with an exacto knife. I'll work on my design and post my progress in a few days.

I hope you don't mind if I follow your lead on this and make a version of it

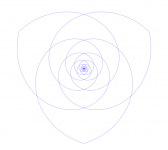

Ok here is a rough version of my understanding of mattes' Fibonacci flower (my version with 3 petals)

This rough version keeps repeating, but for the actual baffle I would only follow the paths once from the outside of the driver until they connect.

So with the flower version, there will be a few points (6 in my case) with the same radial distance from the driver.

I'll play with this a bit more, but I think this is the idea.

- take a golden ratio spiral (counter-clockwise spiral)

- then create radial symmetric copies. In my case to get 3 petals I rotate the spiral 120deg

- create mirrored version spiraling clockwise

- combine

This rough version keeps repeating, but for the actual baffle I would only follow the paths once from the outside of the driver until they connect.

So with the flower version, there will be a few points (6 in my case) with the same radial distance from the driver.

I'll play with this a bit more, but I think this is the idea.

Attachments

Hi Jeshi,

of course I don´t mind, in contrary I´m happy if I could supply some inspiration!

Your 3-petal-version, if I imagine the outer lines forming the border of the baffle, looks good, too.

I don´t think that the number of petals or the exact shape is critical, as long as there´s enough variation in the distance from driver to edge, because in the end this is what counts, and a rectangular baffle could for sure have the same (positive) effect, given everything is well rounded. I think that the roundover of the surface and the edges is equally important.

With my flower design, at the larger distances, there´s a large general roundover and a smaller one (app. 15 mm radius) at the termination. At the smaller distances, the roundover is smaller, also around 15 mm.

I would have loved to enlarge this radius, but wanted to have similar ratios as the bigger bass flower has. The general ratio between the two flowers is nearly 2,6, and even if I ease up this ratio, the practical limit (at least for me and my skills) is a radius of 28,4 mm, with my biggest handheld router and my biggest routing tool. Therefore, the small flowers have 15 mm smallest radius.

The only reason for me to choose 5 petals over anything else were the 5 petals of the whizzer of the driver, I wanted to stay in this pattern.

All the best and good luck with your work!

Mattes

of course I don´t mind, in contrary I´m happy if I could supply some inspiration!

Your 3-petal-version, if I imagine the outer lines forming the border of the baffle, looks good, too.

I don´t think that the number of petals or the exact shape is critical, as long as there´s enough variation in the distance from driver to edge, because in the end this is what counts, and a rectangular baffle could for sure have the same (positive) effect, given everything is well rounded. I think that the roundover of the surface and the edges is equally important.

With my flower design, at the larger distances, there´s a large general roundover and a smaller one (app. 15 mm radius) at the termination. At the smaller distances, the roundover is smaller, also around 15 mm.

I would have loved to enlarge this radius, but wanted to have similar ratios as the bigger bass flower has. The general ratio between the two flowers is nearly 2,6, and even if I ease up this ratio, the practical limit (at least for me and my skills) is a radius of 28,4 mm, with my biggest handheld router and my biggest routing tool. Therefore, the small flowers have 15 mm smallest radius.

The only reason for me to choose 5 petals over anything else were the 5 petals of the whizzer of the driver, I wanted to stay in this pattern.

All the best and good luck with your work!

Mattes

Dear all,

just forgot to say thanks for the nice words...

Please find attached another teaser, showing the bass flowers in raw form and again with a little bit more detail the roundover of the small flowers.

Yes, I know, this belongs to the yet to come building thread, and I will repeat myself there...

All the best

Mattes

just forgot to say thanks for the nice words...

Please find attached another teaser, showing the bass flowers in raw form and again with a little bit more detail the roundover of the small flowers.

Yes, I know, this belongs to the yet to come building thread, and I will repeat myself there...

All the best

Mattes

Attachments

Thanks Mattes, you have definitely inspired me.

I can really see what you mean by your rounding over variations between the closer and farther points of the petals. I think you might be right about the actual curve being less critical and that just keeping lots of variation in the distance to the edges being more critical. Every time I run baffle diffraction sims I always come back to having many distances and off-center driver placement. I will rethink my flower approach less on a golden ratio Fibonacci spiral and more based on creating many distances and large round over.

I can also see that your EVA foam appears denser than the type I get. The finished look is similar, but I don't think mine is strong enough to be routed like you are able to do.

I also agree with you that round over is probably more important (even though I don't do it enough). But I think I will do more round over (almost spherical) on my version of the flower.

Some previous tests that like to go back too when I think about baffle diffraction.

The classic 1950 Olson analysis, where he observed spherical shape (rounding) creates the smoothest response despite having perfect radial symmetry. True Audio TechTopics: Diffraction Loss

And Linkwitz did some interesting experiments too Diffraction from baffle edges

I can really see what you mean by your rounding over variations between the closer and farther points of the petals. I think you might be right about the actual curve being less critical and that just keeping lots of variation in the distance to the edges being more critical. Every time I run baffle diffraction sims I always come back to having many distances and off-center driver placement. I will rethink my flower approach less on a golden ratio Fibonacci spiral and more based on creating many distances and large round over.

I can also see that your EVA foam appears denser than the type I get. The finished look is similar, but I don't think mine is strong enough to be routed like you are able to do.

I also agree with you that round over is probably more important (even though I don't do it enough). But I think I will do more round over (almost spherical) on my version of the flower.

Some previous tests that like to go back too when I think about baffle diffraction.

The classic 1950 Olson analysis, where he observed spherical shape (rounding) creates the smoothest response despite having perfect radial symmetry. True Audio TechTopics: Diffraction Loss

And Linkwitz did some interesting experiments too Diffraction from baffle edges

Last edited:

Hi Jeshi,

of course the Olson analysis is well known and still useful today, exactly. The only issue is that our drivers are bigger. Therefore I started with the angle of the cone, made a smooth curve to the largest part of the flower and voila: the shape of the petals was there. Then I added in the shortcuts for the lesser distances, trying to make them the least obstrusive. Then as well, I formed the backside and whilst trying to be least obstrusive as well, I also tried to maintain a certain thickness of the whole affair, in order not to have anything flabby...

The density of the foam is an important factor. After several trials, I opted for 125 kg/m³. The material must not be floppy (in the end, it´s an open baffle speaker, also in the bass region... and my AE Dipole 18 bass driver can move a little bit of air...) but should have at best a non-resonant behaviour as well.

A not unimportant property of this material was the very smooth and luxurious feel and look of the surface, once finely sanded. It´s like the flowers were made out of a solid block of suede... and maybe this smooth surface rejects some reflections of the baffle as well.

All the best

Mattes

of course the Olson analysis is well known and still useful today, exactly. The only issue is that our drivers are bigger. Therefore I started with the angle of the cone, made a smooth curve to the largest part of the flower and voila: the shape of the petals was there. Then I added in the shortcuts for the lesser distances, trying to make them the least obstrusive. Then as well, I formed the backside and whilst trying to be least obstrusive as well, I also tried to maintain a certain thickness of the whole affair, in order not to have anything flabby...

The density of the foam is an important factor. After several trials, I opted for 125 kg/m³. The material must not be floppy (in the end, it´s an open baffle speaker, also in the bass region... and my AE Dipole 18 bass driver can move a little bit of air...) but should have at best a non-resonant behaviour as well.

A not unimportant property of this material was the very smooth and luxurious feel and look of the surface, once finely sanded. It´s like the flowers were made out of a solid block of suede... and maybe this smooth surface rejects some reflections of the baffle as well.

All the best

Mattes

the white koyo-soft-board EVA that I get doesn't specify a density, but I just did a quick measurement. I can't remember if I did this before, but it looks like koyo-EVA is around 110 kg/m³ so that is not that different to what you get. So maybe I could use a router on mine. I may have to try that at some point.

I also measured a few EVA yoga blocks and one was about 50kg/m³ and the other was about 70kg/m³. I was thinking about using a yoga block at some point but I keep going back to using laminated sheet of that koyo-EVA.

Mattes, I think you found a really nice source of EVA foam.

My EVA foam is not really cheap. 450mmx450mmx10mm sheets are now about $7 and a 1m x 1m x 10mm is about $35. But now I can more easily find 20mm and 30mm thick pieces (450mmx450mm x 30mm is about $20). I used to be able to get 600x900sheets but they are impossible to find now.

cheers jeshi

I also measured a few EVA yoga blocks and one was about 50kg/m³ and the other was about 70kg/m³. I was thinking about using a yoga block at some point but I keep going back to using laminated sheet of that koyo-EVA.

Mattes, I think you found a really nice source of EVA foam.

My EVA foam is not really cheap. 450mmx450mmx10mm sheets are now about $7 and a 1m x 1m x 10mm is about $35. But now I can more easily find 20mm and 30mm thick pieces (450mmx450mm x 30mm is about $20). I used to be able to get 600x900sheets but they are impossible to find now.

cheers jeshi

Hi Jeshi,

I think your prices are OK, not so far off from what I´ve paid. I was offered EVA from China, 600 $ per m³, but only if I buy a whole container and pay the freight as well...

I had to search for a while, but couldn´t get any better offer than nearly 1000 € for 8 pieces of 1000 x 1000 x 40 mm, until they arrived at my door.

But so far I´m happy with the results, and if the bass flowers turn out as well as the small ones, I will not regret my decision. Well, the manufacturer sent me a sample before final order, so it was easy to evaluate the properties of the material.

All the best

Mattes

I think your prices are OK, not so far off from what I´ve paid. I was offered EVA from China, 600 $ per m³, but only if I buy a whole container and pay the freight as well...

I had to search for a while, but couldn´t get any better offer than nearly 1000 € for 8 pieces of 1000 x 1000 x 40 mm, until they arrived at my door.

But so far I´m happy with the results, and if the bass flowers turn out as well as the small ones, I will not regret my decision. Well, the manufacturer sent me a sample before final order, so it was easy to evaluate the properties of the material.

All the best

Mattes

yeah this is one of the problems with the EVA. It is still a bit industrial. So we either get low density stuff in floor mats (with terrible bumps that are impossible to sand off), or we have to get it from industrial sources. I am lucky here in Japan that the cosplay people discovered EVA and have created a small market for it and I can buy from yahoo or amazon.

This is the closest I found to Mattes' 40mm EVA.

[法人宛ノミ]コーヨーソフトボード (旧ライオンボード) 黒 40mm厚 925mmx1835mm 3枚 :k-board-channel-softboard-40t36-b:NSDpaint資材 ヤフー店 - 通販 - Yahoo!ショッピング

but still this is like 330euro for only 3 sheets of 900mm x 1800mm. But the 40mm EVA, even in Japan is only sold in large quantity like this (not popular with the cosplay group)

Here is a youtube video where a guy talks about where he finds EVA (for costume making) YouTube

Mattes, maybe you can encourage others in Europe to try EVA for speakers and be able to sell some of your extra material. But honestly once I got it in the house, I was finding all sorts of uses for it (made and arm board for a turntable which is working amazingly!) so you might feel the same and just keep it as "magic" building material for future projects.

cheers

jeshi

This is the closest I found to Mattes' 40mm EVA.

[法人宛ノミ]コーヨーソフトボード (旧ライオンボード) 黒 40mm厚 925mmx1835mm 3枚 :k-board-channel-softboard-40t36-b:NSDpaint資材 ヤフー店 - 通販 - Yahoo!ショッピング

but still this is like 330euro for only 3 sheets of 900mm x 1800mm. But the 40mm EVA, even in Japan is only sold in large quantity like this (not popular with the cosplay group)

Here is a youtube video where a guy talks about where he finds EVA (for costume making) YouTube

Mattes, maybe you can encourage others in Europe to try EVA for speakers and be able to sell some of your extra material. But honestly once I got it in the house, I was finding all sorts of uses for it (made and arm board for a turntable which is working amazingly!) so you might feel the same and just keep it as "magic" building material for future projects.

cheers

jeshi

Last edited:

- Home

- Loudspeakers

- Full Range

- EVA foam for performance speaker enclosures