Pattern is applied first. Zig glue is applied next and Gloss is the final step. Before any of this you must first develop patterns that will work for your specific cone design.

The flat paint can be any color flat acrylic sold by either Poly S or Tamiya. The paint used on the AN8 in the pics was a light tan and it turned golden in hue against the black cone. The paint is applied full strength right from the bottle.

You MUST practice on some cheap drivers just to get the hang of using the pen tips upside down and to get to an agreement with the uncut paint about how much flow you get for how much pressure you apply. Doesn't take long to acquire the needed skills, but you must practice.

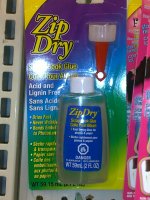

The zig glue is only used to stop ringing. The most likely places for it are at the outer 1/4 of the main cone, on the back side and also up the first pleat of the surround and at the base 1/4 of the whizzer cone, on both sides of the whizzer and out at the last 1/4 or so, again on both sides. You will likely apply a 10% to 90% gloss to water mix on top of the zig glue and you may have to apply a couple of coats of each to build constrained layers. You will not be able to determine where or how much is needed until after all of the patterns have been applied.

If you are going to learn the tap test method and disperse the problems where they arise on the cones you may need no more than a 10% to 90% gloss to water mix for the rest of both cones, on the face surfaces and under the lip of the whizzer "hat brim". Again, you must have the patterns on, dried and listened to carefully before taking this step.

Bud

The flat paint can be any color flat acrylic sold by either Poly S or Tamiya. The paint used on the AN8 in the pics was a light tan and it turned golden in hue against the black cone. The paint is applied full strength right from the bottle.

You MUST practice on some cheap drivers just to get the hang of using the pen tips upside down and to get to an agreement with the uncut paint about how much flow you get for how much pressure you apply. Doesn't take long to acquire the needed skills, but you must practice.

The zig glue is only used to stop ringing. The most likely places for it are at the outer 1/4 of the main cone, on the back side and also up the first pleat of the surround and at the base 1/4 of the whizzer cone, on both sides of the whizzer and out at the last 1/4 or so, again on both sides. You will likely apply a 10% to 90% gloss to water mix on top of the zig glue and you may have to apply a couple of coats of each to build constrained layers. You will not be able to determine where or how much is needed until after all of the patterns have been applied.

If you are going to learn the tap test method and disperse the problems where they arise on the cones you may need no more than a 10% to 90% gloss to water mix for the rest of both cones, on the face surfaces and under the lip of the whizzer "hat brim". Again, you must have the patterns on, dried and listened to carefully before taking this step.

Bud

You MUST practice on some cheap drivers just to get the hang of using the pen tips upside down and to get to an agreement with the uncut paint about how much flow you get for how much pressure you apply. Doesn't take long to acquire the needed skills, but you must practice.

Likely not as much problem with a single driver, but yours is big, as the paint sits there open the top layet starts dry and the flow will change consistency as it does, so when the spots start to misbehave stir the paint pot again.

Don't try to carry too many spots with one dip of the paint... with the size you will be doing on the outer ring, you will likely need to refresh the paint every spot.

dave

Pattern is applied first. Zig glue is applied next and Gloss is the final step. Before any of this you must first develop patterns that will work for your specific cone design.

The flat paint can be any color flat acrylic sold by either Poly S or Tamiya. The paint used on the AN8 in the pics was a light tan and it turned golden in hue against the black cone. The paint is applied full strength right from the bottle.

You MUST practice on some cheap drivers just to get the hang of using the pen tips upside down and to get to an agreement with the uncut paint about how much flow you get for how much pressure you apply. Doesn't take long to acquire the needed skills, but you must practice.

The zig glue is only used to stop ringing. The most likely places for it are at the outer 1/4 of the main cone, on the back side and also up the first pleat of the surround and at the base 1/4 of the whizzer cone, on both sides of the whizzer and out at the last 1/4 or so, again on both sides. You will likely apply a 10% to 90% gloss to water mix on top of the zig glue and you may have to apply a couple of coats of each to build constrained layers. You will not be able to determine where or how much is needed until after all of the patterns have been applied.

If you are going to learn the tap test method and disperse the problems where they arise on the cones you may need no more than a 10% to 90% gloss to water mix for the rest of both cones, on the face surfaces and under the lip of the whizzer "hat brim". Again, you must have the patterns on, dried and listened to carefully before taking this step.

Bud

Bud,

Many thanks to you. Ah..now I know I turn everything up side down. I have to admit that I'm stupid. Yes, I'm learning tapping the cone with other smaller driver, but found it's hard to hear the different. Put a little more time on and I'm sure I'll get it. I'm still waiting for the kit to come anyway no rush..

You quoted :The zig glue is only used to stop ringing. The most likely places for it are at the outer 1/4 of the main cone, ( do you mean 1/4 from the surround ) on the back side and also up the first pleat ( where is the first pleat ) of the surround and at the base 1/4 of the whizzer cone, on both sides of the whizzer and out at the last 1/4 or so, again on both sides. ( To apply Zig glue to 1/4 area on both side from the cone, 1/4 area on both side from the edge of whizzer ) You will likely apply a 10% to 90% gloss to water mix on top of the zig glue and you may have to apply a couple of coats of each to build constrained layers. You will not be able to determine where or how much is needed until after all of the patterns have been applied.

Regards

Albert

Likely not as much problem with a single driver, but yours is big, as the paint sits there open the top layet starts dry and the flow will change consistency as it does, so when the spots start to misbehave stir the paint pot again.

Don't try to carry too many spots with one dip of the paint... with the size you will be doing on the outer ring, you will likely need to refresh the paint every spot.

dave

Dave,

Thanks. It's very good hint. I thought I better off have my pen washed after finished every different ring.

Albert

Dave,

Thanks. It's very good hint. I thought I better off have my pen washed after finished every different ring.

Albert

To avoid smearing the existing spots, it is a good idea to have an intermission between ring sets. I store my working tips in a jar of isoproponol.

During application of a ringset you will likely need to wipe down the tip with paper towel. And it is useful to have a long fingernail to clean between the tip layers.

dave

To avoid smearing the existing spots, it is a good idea to have an intermission between ring sets. I store my working tips in a jar of isoproponol.

During application of a ringset you will likely need to wipe down the tip with paper towel. And it is useful to have a long fingernail to clean between the tip layers.

dave

Ah..... my old honey has a finger with long fingernail. This would be nice if she promise. I wish....

Still patiently waiting for the kit to come, but I have some improvement on tapping the cone. I use a rather big ball pen handle to tap on the AN12 cone and found some locations which I thought are the locations that I should aim at. I slightly marked that spots with a pencil right on the cone. I'll take a photo to show if they are the spots I should put the patterns on.

I also will take a photo with dimension and see if Bud can kindly provide/ design the patterns.

Albert

I also will take a photo with dimension and see if Bud can kindly provide/ design the patterns.

Albert

2 way ZIG glue

Dave, BUD,

I found hard time to locate the ZIG glue at Michael's. The manager there said they don't carry that glue any more. Will there be any other store I can try.

Ed,

Will I be forgotten ?? I'm still patiently waiting for your kit.

Albert

Dave, BUD,

I found hard time to locate the ZIG glue at Michael's. The manager there said they don't carry that glue any more. Will there be any other store I can try.

Ed,

Will I be forgotten ?? I'm still patiently waiting for your kit.

Albert

Cone tapping result

Bud,

After couple weeks tapping, I have the attached photo shows with white dots of where I found the tone different from other area, and dimension are as below.

Main cone dia. 9.25"

first white dot is about 12-13 mm from the first pleat of surround.

second white dot is about 25 mm from the first dot.

Whizzer cone dia. 3"

I can clearly hear the tone different at the cone right under the outer edge of the whizzer.

Can I just simple make the pattern to size that you have for super 8 for my application ??

Albert

Bud,

After couple weeks tapping, I have the attached photo shows with white dots of where I found the tone different from other area, and dimension are as below.

Main cone dia. 9.25"

first white dot is about 12-13 mm from the first pleat of surround.

second white dot is about 25 mm from the first dot.

Whizzer cone dia. 3"

I can clearly hear the tone different at the cone right under the outer edge of the whizzer.

Can I just simple make the pattern to size that you have for super 8 for my application ??

Albert

Attachments

Mod Podge the Enabl

I got my kit from Ed last week and I purchased a small bottle of Mod-Podge Matte to pre-treat my speakers. I subsequently saw the photos of the Mod-Podge in this thread and it was for "gloss." I purchased a bottle of Gloss, yesterday. My thinking was to experiment with the two finishes.

Is gloss the preferred product?

What might I expect if I use the matte over the gloss?

I got my kit from Ed last week and I purchased a small bottle of Mod-Podge Matte to pre-treat my speakers. I subsequently saw the photos of the Mod-Podge in this thread and it was for "gloss." I purchased a bottle of Gloss, yesterday. My thinking was to experiment with the two finishes.

Is gloss the preferred product?

What might I expect if I use the matte over the gloss?

I use Mod Podge to pre-treat paper cones, some paper cones come with a surfqce treatment, they often do not require any.

Gloss goes over everything afterwards.

dave

Gloss goes over everything afterwards.

dave

planet827081 said:Gloss goes overything afterwards.

You mean micro gloss or do you finish with a coat of Modge Podge?

Cheers,

Alex

Hi Guys,

Not sure if this is the correct place to put this, but I'm seeking a little advice on potentially EnABL'ing a set of Tangband w832se's that I'm currently using in my vehicle.

I'm not sure whether the round over I have on the faceplate of the driver will affect the EnABL results.

Does anyone have any advice? I suspect many will say just try it, which I often do, but don't want to potentially hurt something that sounds pretty reasonable currently.

Thanks in advance.

Ben

Not sure if this is the correct place to put this, but I'm seeking a little advice on potentially EnABL'ing a set of Tangband w832se's that I'm currently using in my vehicle.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

I'm not sure whether the round over I have on the faceplate of the driver will affect the EnABL results.

Does anyone have any advice? I suspect many will say just try it, which I often do, but don't want to potentially hurt something that sounds pretty reasonable currently.

Thanks in advance.

Ben

RE: Mod Podge the Enabl

I did not clearly ask my second question. I plan to pre-treat my drivers. Does it make a difference whether I use the Mod-Podge gloss or the matte finish Mod-Podge for the pre-treatment?

Can I expect different results using one finish (matte) over the other (gloss) for this pre-treatment?

I did not clearly ask my second question. I plan to pre-treat my drivers. Does it make a difference whether I use the Mod-Podge gloss or the matte finish Mod-Podge for the pre-treatment?

Can I expect different results using one finish (matte) over the other (gloss) for this pre-treatment?

BMW, this is the place. Your drivers can either be dealt with by utilizing the EnABL 1.0 generic pattern sets or with a more complex gen 2.0 set. I can Photoshop the correct placement for gen1 on your pics. If you provide a scale for driver dimensions I can even provide a pattern guide set for you.

Gen 2 requires you to not only make your own pattern placement decisions but make them precise enough that I can generate PDF pattern sets to suit your dimensions. This will require you to read deeply into this thread and teach yourself how to find these unique and very non generic pattern location needs. We can help with arm waving and grand eloquence, but you are the only person who can do the needed work. The improvement in performance is worth the effort.

Gen 1.0 does not preclude gen 2.0 at a latter date, even if you have gloss coated the drivers.

Bud

Gen 2 requires you to not only make your own pattern placement decisions but make them precise enough that I can generate PDF pattern sets to suit your dimensions. This will require you to read deeply into this thread and teach yourself how to find these unique and very non generic pattern location needs. We can help with arm waving and grand eloquence, but you are the only person who can do the needed work. The improvement in performance is worth the effort.

Gen 1.0 does not preclude gen 2.0 at a latter date, even if you have gloss coated the drivers.

Bud

DaveT,

I have only seen gloss modge podge used. I wouldn't experiment with the flat finish on anything you care about, as it is a permanent addition. Plus, you must use very thin mixes of this material, but only Dave knows just how thin.

Bud

I have only seen gloss modge podge used. I wouldn't experiment with the flat finish on anything you care about, as it is a permanent addition. Plus, you must use very thin mixes of this material, but only Dave knows just how thin.

Bud

Hi Alberti,

Sorry to not respond, I am not receiving notifications about posts to this thread and am unusually busy at this time with audio transformers. Please give me a couple of days to perform the processes I have to and I will provide you with pattern sets for the cone dimensions you have provided. I am faintly suspicious of these dimensions as they do correspond to possible changes in timbre of the resultant tap, but might not be the locations for change of direction in the decay.

Right at or just under the whizzer is a typical placement for one set of rings by the way.

In any event you will not harm the driver by adding these ring sets where you have indicated, just pointing to the possibility that you will uncover further needs once these have done their work.

Bud

Sorry to not respond, I am not receiving notifications about posts to this thread and am unusually busy at this time with audio transformers. Please give me a couple of days to perform the processes I have to and I will provide you with pattern sets for the cone dimensions you have provided. I am faintly suspicious of these dimensions as they do correspond to possible changes in timbre of the resultant tap, but might not be the locations for change of direction in the decay.

Right at or just under the whizzer is a typical placement for one set of rings by the way.

In any event you will not harm the driver by adding these ring sets where you have indicated, just pointing to the possibility that you will uncover further needs once these have done their work.

Bud

BMW, this is the place. Your drivers can either be dealt with by utilizing the EnABL 1.0 generic pattern sets or with a more complex gen 2.0 set. I can Photoshop the correct placement for gen1 on your pics. If you provide a scale for driver dimensions I can even provide a pattern guide set for you.

Gen 2 requires you to not only make your own pattern placement decisions but make them precise enough that I can generate PDF pattern sets to suit your dimensions. This will require you to read deeply into this thread and teach yourself how to find these unique and very non generic pattern location needs. We can help with arm waving and grand eloquence, but you are the only person who can do the needed work. The improvement in performance is worth the effort.

Gen 1.0 does not preclude gen 2.0 at a latter date, even if you have gloss coated the drivers.

Bud

Thanks for the reply Bud.

I was reading about Gen 2 and the tapping of the cone to identify the change in sound. I'm not confident to perform that as yet and i also know that I have only moderate patience at best, so probably not the ideal solution for me in this case.

Gen 1 if I understanding correct, is an inner and outer ring, with the 2-3 coen treatments after this. I'm still trying to get my head fully around what is implied with the 1/4 cone comments and am sure I'll have many more questions when I get started.

I'll no doubt need to order a kit from Ed also which will take a little while over the Christmas period to arrive.

I have attached a couple of images of the driver dimensions that I figured you'd need.

Thanks in advance...

Ben

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Hi Alberti,

Sorry to not respond, I am not receiving notifications about posts to this thread and am unusually busy at this time with audio transformers. Please give me a couple of days to perform the processes I have to and I will provide you with pattern sets for the cone dimensions you have provided. I am faintly suspicious of these dimensions as they do correspond to possible changes in timbre of the resultant tap, but might not be the locations for change of direction in the decay.

Right at or just under the whizzer is a typical placement for one set of rings by the way.

In any event you will not harm the driver by adding these ring sets where you have indicated, just pointing to the possibility that you will uncover further needs once these have done their work.

Bud

BUd,

Thanks and I know it's Christmas time and we're all busy for the season. Do take your time, no worry.

BTW Wish everybody a Merry Christmas and a Happy 2012

Albert

- Home

- Loudspeakers

- Multi-Way

- EnABL - Listening impressions & techniques