This is my first attempt at re-building an electronic component. It was partially inspired by the late Bill Thomas over at audiocircle and his PAS 3 and SCA 35 projects which he very meticulously documented. I've done some minor repairs in the past but not anything of substance.

My goal is to restore this PAS 3X with minimal if any mods. The exception is the replacement of the selenium rectifier with a pair of diodes as recommended by Curcio Audio Engineering, but I'm open to other options if anyone has any suggestions. Again, I'd like to keep this PAS as close to the original design as possible. I have a couple of other PAS preamps that need work and if all goes well here, will attempt to bring them back to life and with the help of this forum, hopefully improve upon the original design.

So, with a little extra time on my hands yesterday and today, I completely stripped the preamp of all of the gloopy solder and spaghetti like wiring from the chassis and got everything cleaned up.

All of the pots and slide switches were cleaned with CRC Contact Cleaner. Once the unit is assembled, wired and soldered, I will give them a shot of Deoxit to make sure everything is lubricated. The two selector switches were cleaned with denatured alcohol and a toothbrush. Again, I will Deoxit the contacts after the soldering is completed. I will then grease the detents as well. I'm doing it in this sequence because the Deoxit tends to drip.

My goal is to restore this PAS 3X with minimal if any mods. The exception is the replacement of the selenium rectifier with a pair of diodes as recommended by Curcio Audio Engineering, but I'm open to other options if anyone has any suggestions. Again, I'd like to keep this PAS as close to the original design as possible. I have a couple of other PAS preamps that need work and if all goes well here, will attempt to bring them back to life and with the help of this forum, hopefully improve upon the original design.

So, with a little extra time on my hands yesterday and today, I completely stripped the preamp of all of the gloopy solder and spaghetti like wiring from the chassis and got everything cleaned up.

All of the pots and slide switches were cleaned with CRC Contact Cleaner. Once the unit is assembled, wired and soldered, I will give them a shot of Deoxit to make sure everything is lubricated. The two selector switches were cleaned with denatured alcohol and a toothbrush. Again, I will Deoxit the contacts after the soldering is completed. I will then grease the detents as well. I'm doing it in this sequence because the Deoxit tends to drip.

Attachments

Last edited:

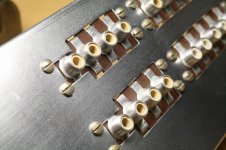

Here is the front panel and components ready for wiring. With the exception of the two 1 mfd capacitors, all of the components tested good.

Attachments

Last edited:

You are in luck your GI paper capacitors are sealed. I had one burned open by the builder, who hid the burn on the bottom. It didn't prevent moisture from getting in and changing the value. I changed the .020 uf capacitors for .022 uf MKT, which made it sound weird. Very trebly. Unfortunately the one with the burn was the last one I changed out. Have collected some .018 uf and .0018 uf Polypro caps for the 2nd attempt but my op amp disco mixer is sounding so good I haven't bothered. 1/100 th the power use.

On the schematic I have, which is not original, there are a couple of 100 nf capacitors and no 1 uf ones that I see. 1 uf was very expensive in 1960. Also huge, about 2.5" long x 1" diameter.

I replaced the selenium rectifier about 1979, after the one in the ST70 needed replacing the second time.

I've been through two B+ caps four 2000 uf caps and two rectifier tubes. I didn't have a way to measure capacitance and ESR until 2017, but I could measure B+ voltage as low easily enough. I don't understand your focus on the wiring versus the electrolytic caps and rectifier tubes.

I would change all resistors 100 kohm and up with metal film. Those made the idle hiss in my ST70 a lot lower. Vishay, Welwyn, Multicomp (farnell) have been quite successful and not made in countries not known for falsifying QA paperwork.

The other carbon comp resistors are the AB or Sprague ones with the good paint that don't change value, if you don't burn the paint off.

Some techs on organforum warn that deoxit contains a chemical that both dissolves oxide, and long term, promotes it. I don't use it. Contact cleaners are flammable these days, use outside and not near any source of sparks or open flame.

I'd beware of long neat parallel runs of wiring. While amateur solder can be a problem, dynaco specified in the build guide where every wire should be placed. This advice can be ignored at some peril. I find messy wiring flying through the air reduces interstage capacitance and reduces the opportunity for oscillation, as compared with nice neat parallel runs on a PCB. One of the special features of the PAS3 is that the noisy 60 hz wiring is in a different steel box from the sensitive 50 mvac signal wiring.

Best of fortune in your endeavor.

On the schematic I have, which is not original, there are a couple of 100 nf capacitors and no 1 uf ones that I see. 1 uf was very expensive in 1960. Also huge, about 2.5" long x 1" diameter.

I replaced the selenium rectifier about 1979, after the one in the ST70 needed replacing the second time.

I've been through two B+ caps four 2000 uf caps and two rectifier tubes. I didn't have a way to measure capacitance and ESR until 2017, but I could measure B+ voltage as low easily enough. I don't understand your focus on the wiring versus the electrolytic caps and rectifier tubes.

I would change all resistors 100 kohm and up with metal film. Those made the idle hiss in my ST70 a lot lower. Vishay, Welwyn, Multicomp (farnell) have been quite successful and not made in countries not known for falsifying QA paperwork.

The other carbon comp resistors are the AB or Sprague ones with the good paint that don't change value, if you don't burn the paint off.

Some techs on organforum warn that deoxit contains a chemical that both dissolves oxide, and long term, promotes it. I don't use it. Contact cleaners are flammable these days, use outside and not near any source of sparks or open flame.

I'd beware of long neat parallel runs of wiring. While amateur solder can be a problem, dynaco specified in the build guide where every wire should be placed. This advice can be ignored at some peril. I find messy wiring flying through the air reduces interstage capacitance and reduces the opportunity for oscillation, as compared with nice neat parallel runs on a PCB. One of the special features of the PAS3 is that the noisy 60 hz wiring is in a different steel box from the sensitive 50 mvac signal wiring.

Best of fortune in your endeavor.

Last edited:

Thanks for the input. I'll try not to obsess too much about the wiring. I'm going to use stranded wire which doesn't stay where you put it so that should keep things from being too uniform.

The power supply will have all new caps. i ordered a pair of 2000 mfd's and a 20/20/20/20 mfd can cap as well as the diodes. I'd like to hear it with the other orginal caps and resistors before swapping them out. This is a learning project for me so there will be some things that I will have to do over.

The power supply will have all new caps. i ordered a pair of 2000 mfd's and a 20/20/20/20 mfd can cap as well as the diodes. I'd like to hear it with the other orginal caps and resistors before swapping them out. This is a learning project for me so there will be some things that I will have to do over.

The paper caps are apparently just the right thing. 1960 paper caps had more inductance than modern film caps. I'd leave them alone if the wax case is not damaged. GI caps were top of the line.

With my solder skills, I do a lot better with teflon insulated wire than PVC. Fewer burns I have to replace. As I have bought the rolls over the years when I found a bargain, it has cost me more like $.30 a foot rather than the $.65 of first line product. Kynar is burn resistant, too, but mostly can't be had in bigger than 26 ga solid core wire wrap wire.

With my solder skills, I do a lot better with teflon insulated wire than PVC. Fewer burns I have to replace. As I have bought the rolls over the years when I found a bargain, it has cost me more like $.30 a foot rather than the $.65 of first line product. Kynar is burn resistant, too, but mostly can't be had in bigger than 26 ga solid core wire wrap wire.

I have 20 & 22 ga stranded PVC wiring that's rated for 300V. The PTFE (teflon?) I saw at Remington is rated for 600V. Is there a need for the higher rating in the PAS circuit? Power supply maybe?

Yes, any B+ wiring needs to be 600 v rated. Plates and screen grids. Also AC mains wire can have 1100 v spikes on it from refrigerator/AC shutoff. Hint, MOV supressor on solder terminal strip is a good addition after the fuse. Cuts the pop from lightning nearby too. I use the 20 mm ones, the 7 mm have minimal energy rating.

You can use the min max tool on the farnell website to set voltage gauge and length, to see what bargains they have on closeout. Don't buy the solid core NTE wire, it breaks pretty easily. Alpha, Belden, some UK supplier I forget who sold 20 m rolls at a decent price. Insisting on 100' rolls limits one unnecessarily. I think teflon is TFE, kynar is EFTE.

I've gotten good teflon wire from electronicsurplus.com and apexsurplus.com of sun valley CA too. One of the few things that is not overpriced. Got some 22 ga black teflon stranded off ebay last month, 25' rolls but when I bought 2 they were continuous length.

Teflon doesn't strip easily, often 1/2 comes off and I have to cut the other half off with dikes. Worth it to not replace the bottom wire in a stack after I burn it installing a later wire.

You can use the min max tool on the farnell website to set voltage gauge and length, to see what bargains they have on closeout. Don't buy the solid core NTE wire, it breaks pretty easily. Alpha, Belden, some UK supplier I forget who sold 20 m rolls at a decent price. Insisting on 100' rolls limits one unnecessarily. I think teflon is TFE, kynar is EFTE.

I've gotten good teflon wire from electronicsurplus.com and apexsurplus.com of sun valley CA too. One of the few things that is not overpriced. Got some 22 ga black teflon stranded off ebay last month, 25' rolls but when I bought 2 they were continuous length.

Teflon doesn't strip easily, often 1/2 comes off and I have to cut the other half off with dikes. Worth it to not replace the bottom wire in a stack after I burn it installing a later wire.

Last edited:

Do you have a possible explanation for this observation? Where are these caps located in the circuitry?I changed the .020 uf capacitors for .022 uf MKT, which made it sound weird. Very trebly.

Best regards!

For signal wire, wire wrap stuff is silver plated copper, with "kynar" fluorocarbon insulation that's way better than PVC, but not as troublesome, when stripping, as PTFE. Look here for brand new. I don't know what the surplus houses have (if any) on hand.

Thanks for the link. I've seen "wire wrap" on a few solid state amps, very nice way to go. I don't know if it will work on my PAS as there are no "posts" to wrap to.

Is there a need for the higher rating in the PAS circuit? Power supply maybe?

The voltage to the line stage is 330VDC, so you really should use 600V wire,

at least for that connection.

The voltage to the line stage is 330VDC, so you really should use 600V wire,

at least for that connection.

Great, thank you.

Last edited:

I solder the stuff. Strips nicely, doesn't burn for a second if you touch it with the iron. 26 ga is okay for most vacuum tube wiring except filaments. My roll of jonard WW wire doesn't have a voltage rating on it, so I wouldn't use it for any high voltage areas like B+ or AC mains wiring.Thanks for the link. I've seen "wire wrap" on a few solid state amps, very nice way to go. I don't know if it will work on my PAS as there are no "posts" to wrap to.

I solder the stuff. Strips nicely, doesn't burn for a second if you touch it with the iron.

Exactly what I mean. The stuff is easier to strip than wire with PTFE insulation, while being reasonably soldering heat tolerant. It's a good compromise.

The RCA jacks on this PAS have always bugged me because of the inward curvature of the phenolic bases.

I considered after-market upgrades but they are out of stock at PAS Modern RCA Jack Kit - Dynakit Parts.

After considering other options, I decided to try to restore the originals, reversing the phenolic so that when installed, the chassis would flatten them out.

I considered after-market upgrades but they are out of stock at PAS Modern RCA Jack Kit - Dynakit Parts.

After considering other options, I decided to try to restore the originals, reversing the phenolic so that when installed, the chassis would flatten them out.

Last edited:

Very tidy, keep up the good work.

Thank you.

Had I bought new components it would have been a cleaner build but I want to keep this as original as possible.

Last edited:

- Home

- Amplifiers

- Tubes / Valves

- Dynaco PAS 3X Re-Build