I want a loud fanfare here...

And you've just stated the parameters Precisely!

Very good, Friend Cochleus. *VBS* Now we can cut to the chase of How To Get THERE. *L*

To make 'the above' as 'bomb-proof' as possible, or at least, practical to diy.

Make your class A's sing and make my solid state's 'fake it' nicely. 😉

(*L* Settle down, I've nothing but respect for A amps. For that matter, any well designed and assembled amp is still great.... just subject to taste and budget, ultimately. I'm still kicking myself for letting go of a pair of Kenwood L-07 monoblocks that were my level of perfection at the time. Now I just want versatility over sheer quality, as my listening area has more negatives than I can correct on a practical level. That, and the listener has a lot of 'uncorrectable issues' himself. But, since nobody here is a doctor, a shrink, or a bartender, I won't go there. *L*)

So now we can focus on defining the details desired of the individual elements. Since we've been discussing these various items before at various levels of contention, it shouldn't be too difficult to amass the 'shopping list', and their strengths and weaknesses.

In the meanwhile, spouse and self are off to listen to some rooftop jazz for awhile. The local Aloft hotel downtown is doing a series of benefits for local groups on the roof; tonight, for one of the local pet adoption agencies. We've down with that, both of ours are 'pound pups'.

So I'll leave this for the moment in the hands of some bluegrass pickin' old hippie type...😉

CU, C

And you've just stated the parameters Precisely!

Very good, Friend Cochleus. *VBS* Now we can cut to the chase of How To Get THERE. *L*

To make 'the above' as 'bomb-proof' as possible, or at least, practical to diy.

Make your class A's sing and make my solid state's 'fake it' nicely. 😉

(*L* Settle down, I've nothing but respect for A amps. For that matter, any well designed and assembled amp is still great.... just subject to taste and budget, ultimately. I'm still kicking myself for letting go of a pair of Kenwood L-07 monoblocks that were my level of perfection at the time. Now I just want versatility over sheer quality, as my listening area has more negatives than I can correct on a practical level. That, and the listener has a lot of 'uncorrectable issues' himself. But, since nobody here is a doctor, a shrink, or a bartender, I won't go there. *L*)

So now we can focus on defining the details desired of the individual elements. Since we've been discussing these various items before at various levels of contention, it shouldn't be too difficult to amass the 'shopping list', and their strengths and weaknesses.

In the meanwhile, spouse and self are off to listen to some rooftop jazz for awhile. The local Aloft hotel downtown is doing a series of benefits for local groups on the roof; tonight, for one of the local pet adoption agencies. We've down with that, both of ours are 'pound pups'.

So I'll leave this for the moment in the hands of some bluegrass pickin' old hippie type...😉

CU, C

Ohm F Driver

This has been a fascinating thread to follow! Thanks to all. I don't know if any DIY folks would be interested in a rough drawing I made of the original F drivers. I have really seen any detailed descriptions of how the cone is constructed.

This has been a fascinating thread to follow! Thanks to all. I don't know if any DIY folks would be interested in a rough drawing I made of the original F drivers. I have really seen any detailed descriptions of how the cone is constructed.

Attachments

I don't know if any DIY folks would be interested in a rough drawing I made of the original F drivers.

Thanks, I appreciate that. 🙂

Ohm F D, thanks for your supportive comment and the nicely detailed jpg of the F cone details. Any and all constructive commentary and information adds to the pool that is under inspection and consideration. I think I can speak for the regulars that hang out here that we're fascinated by the Walsh concept, and are doing what we can do to recreate that for our personal enjoyment. *G* Please feel free and comfortable to join in....

...and *damn* that cone was complicated! It's no wonder that HHR is pricey for repairing/rejuvenating them.... not a simple object, no....

I knew by photos that there was a lot going on at the cone's interior, but the extent is still surprising...

Hey Ohm, where/how did you come upon this detailed of information, if I might ask? Former fabricator of them? Found this bit of arcana squirrelled away? Did an analysis of a moribund cone while the owner wasn't looking? *G* Curious minds ask curious questions... 😉

...and *damn* that cone was complicated! It's no wonder that HHR is pricey for repairing/rejuvenating them.... not a simple object, no....

I knew by photos that there was a lot going on at the cone's interior, but the extent is still surprising...

Hey Ohm, where/how did you come upon this detailed of information, if I might ask? Former fabricator of them? Found this bit of arcana squirrelled away? Did an analysis of a moribund cone while the owner wasn't looking? *G* Curious minds ask curious questions... 😉

Interesting....taking these dimensions and doing a little bit of extrapolation, I get a 'base diameter' for the titanium cone of 4.625", and 6.875" for the aluminum....

If these dimensions have any significance to material used vs. frequency range...considering the previous line of reasoning of having the material matched to the frequency range to be radiated/created (metal to paper as a 'physical crossover' for the bass frequencies, tangential/pistonic motion)...

Titanium for the high(er) frequencies, alum for the mids to upper base +/-....a physical '3 way' full range radiator...perhaps?

Anybody feel like poking holes in that conjecture? *L*

Hey, Mags...this is starting to edge into your 'summer project' in terms of complexity. 😉 Building one of these cones would make me a little crazy(er) when it came to mating the individual cone segments together....*L* And then there's the linings...

Where can I tap into that 'ant man' tech? *G* Be a lot easier if one could really 'get into it' vs. big fingers in a confined space.....

If these dimensions have any significance to material used vs. frequency range...considering the previous line of reasoning of having the material matched to the frequency range to be radiated/created (metal to paper as a 'physical crossover' for the bass frequencies, tangential/pistonic motion)...

Titanium for the high(er) frequencies, alum for the mids to upper base +/-....a physical '3 way' full range radiator...perhaps?

Anybody feel like poking holes in that conjecture? *L*

Hey, Mags...this is starting to edge into your 'summer project' in terms of complexity. 😉 Building one of these cones would make me a little crazy(er) when it came to mating the individual cone segments together....*L* And then there's the linings...

Where can I tap into that 'ant man' tech? *G* Be a lot easier if one could really 'get into it' vs. big fingers in a confined space.....

Hey, Mags...this is starting to edge into your 'summer project' in terms of complexity. 😉

Not even close 🙄 Would anyone be interested if I made a exact 3d model of German physics speaker and layed out the process for building it? As far as I can tell its within everyone's reach. this may take a bit with my current schedule.

It would just be basic info and plans and such much like on my page. Ill leave the discussing to you guys.

Very niceThis has been a fascinating thread to follow! Thanks to all. I don't know if any DIY folks would be interested in a rough drawing I made of the original F drivers. I have really seen any detailed descriptions of how the cone is constructed.

Ohm drawings

I just pulled mine out and measured it 😉

Seriously, it was time to check the condition of the interior foam (which is in a rather advance state of decay).

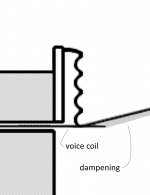

I think what makes the cone interesting is the decreasing mass of the materials - titanium @283 lbs/ft2, aluminum @169 lbs/ft2, and paper @60 lbs/ft2. I haven't really seen details on the GP cone (titanium or carbon fiber) and wonder if the behavior is similar (with one material). From what I've read, the type and positioning of the dampening material is critical. I don't really know what the material used on the titanium is (as described before, it does look like clay but it is hard).

I wish that my smaller wattage tube amps were able to drive them to their comfort zone.

I just pulled mine out and measured it 😉

Seriously, it was time to check the condition of the interior foam (which is in a rather advance state of decay).

I think what makes the cone interesting is the decreasing mass of the materials - titanium @283 lbs/ft2, aluminum @169 lbs/ft2, and paper @60 lbs/ft2. I haven't really seen details on the GP cone (titanium or carbon fiber) and wonder if the behavior is similar (with one material). From what I've read, the type and positioning of the dampening material is critical. I don't really know what the material used on the titanium is (as described before, it does look like clay but it is hard).

I wish that my smaller wattage tube amps were able to drive them to their comfort zone.

Fabricating Ohm cones

Jerryrigged, I have read that these cones were originally constructed on Walsh's kitchen table (along with other prototypes) and a 30 degree angle was agreed to be most effective. All you need is a 30 degree mandrel (wood, ceramic, etc) and you would have the template (similar to the inlow sound horn pattern). One time I saw a 3 foot tall wooden spire at a furniture store that had a 30 degree taper. I think the bottom was around 18". With something like that, your finished cone could be any size you want depending on the section used. Positioning and layering would be much easier, sort of like a seamstress with a mannequin.

Another interesting note is that the dampening material used on the titanium section extends 2/3 the way up (from the 3" VC), at that point the remaining 1/3 is covered by the open-cell foam which continues to the aluminum/paper inner seam.

Those observations on the base diameters look pretty darn close, but now you've got me thinking about a set of calipers I own and don't remember when I used last! Where are those things?

Jerryrigged, I have read that these cones were originally constructed on Walsh's kitchen table (along with other prototypes) and a 30 degree angle was agreed to be most effective. All you need is a 30 degree mandrel (wood, ceramic, etc) and you would have the template (similar to the inlow sound horn pattern). One time I saw a 3 foot tall wooden spire at a furniture store that had a 30 degree taper. I think the bottom was around 18". With something like that, your finished cone could be any size you want depending on the section used. Positioning and layering would be much easier, sort of like a seamstress with a mannequin.

Another interesting note is that the dampening material used on the titanium section extends 2/3 the way up (from the 3" VC), at that point the remaining 1/3 is covered by the open-cell foam which continues to the aluminum/paper inner seam.

Those observations on the base diameters look pretty darn close, but now you've got me thinking about a set of calipers I own and don't remember when I used last! Where are those things?

Last edited:

*LOL*

...when I have to open a second window to catch up on this threads' progress, I'm really grateful and further inspired by y'all. I wanted this forum to develop some form of 'critical mass', that 'rolling stone/moss gathering' in inverse.

Well, way kewl. Thanks...let's continue to conspire. Let's see if together we can do something significant with what we all seem to regard as a special bit of audio technology. That's more or less where I'm coming from and heading towards. And I really appreciate all the support that appears here.

Yeah, I know I've stated this all before. It bears repeating. *S*

...when I have to open a second window to catch up on this threads' progress, I'm really grateful and further inspired by y'all. I wanted this forum to develop some form of 'critical mass', that 'rolling stone/moss gathering' in inverse.

Well, way kewl. Thanks...let's continue to conspire. Let's see if together we can do something significant with what we all seem to regard as a special bit of audio technology. That's more or less where I'm coming from and heading towards. And I really appreciate all the support that appears here.

Yeah, I know I've stated this all before. It bears repeating. *S*

Anyhow...back to 'bizness'...

(I think I'll pick up where I got left behind...*L*)

Mags, re #487~89...

Re complexity, that was a gentle 'tease'. Your midrange is Wonderfully wrought, and a tribute to your patience and skills. I still feel like I'm shooting rubber bands at the moon in contrast. So there. *G* 😉

As for your offer...I'd be the fool of the decade to say no to such a kind offer. I'd be near orgasmic with a 3D drawing, much less a model. Towards that, Yes, Please. You take whatever time you like and can spare. "Basic" for you may approach creating a virtual 'roadmap' for us...

But I will warn you that when you find yourself in Asheville, you will get 'dined' at least. 'Wined' may be subject to tolerance and any other scheduled activities. Anything else I can do to help, well, PM and ask. 😉

Philajoe73, the decreasing mass IMHO makes sense if one was attempting to create a full-range driver of that scale. As Cochleus noted, even a smaller cone has the surface area of a 10" speaker. I haven't 'run the numbers', but I suspect an F cone is approaching an 18~24" typ. driver, which is massive.

That, and as a waveform is descending the surface of the cone, it should be losing energy as it's being 'stretched' by the increasing circumference. It would follow that one would want the mass of the material to decrease to allow that wave to continue to 'flow'...or that's my take on it...

The damping materials were obviously carefully chosen, and the placement ditto. Likely to control 'ringing', harmonics, and the other plethora that cones of any sort are subject to. Since we're considering a rather steep cone profile, and one made even partly made of metal(s), I wouldn't be surprised if 'bell modes' are in there as well, further complicating the thing.

And as for 'kitchen tables', I wouldn't be surprised by that. *L* The patent states that there were prototypes made and displayed as 'proof of concept', typical for the patent process. HHR uses wood mandrels...me? I've got a plaster cone for smaller ones, and a larger foam one from Michael's that is virtually the same angle. It's used for floral displays and the like....and cheap. *L*

As for laying up 'cone on cone', it's just me reacting to the scale. That, and doing it pre- or post application of the damping materials is a question. It's just difficult as 'ell to do what I've doing without sweating damaging damping...

I pull out the calipers on assembly, or checking sizes on the dinky stuff. And I can relate to 'where the F did I leave them' issues.... I sometimes find myself looking for something that I finally remember that I don't own it anymore. The peril of 'too much Stuff'... 😉

The diameters I posted for the cone bases are based on your stated dimensions of the F cone. I imported the jpg into Corel, 'tweaked' the proportions a little to make it fall into line, and just noted what was depicted. Pretty easy, all in all...

I'd advise continued caution on driving your F's. Since things are already showing their age, it'd be better to treat them like granddad...'he ain't as spry as he used to be', much like us to varying degrees. 😉

As for the material used to damp the titanium....I've heard that description before of a hard 'clay-like' substance that really tweaks my curiosity. Can you discern how thick it might be?

It reminds me of old, thick oil paint, applied heavily. As to Why...eons ago, I used to work at a shop that refinished/rejuvenated 'turn of the century' furniture. To color match new oak to old oak, we'd use old paint that had dried up in their cans like crayons, accenting the grain and making it look 'old enough'. It looked like clay, and it was hard. We'd dip it in solvents to soften it up to various degrees.

I'm still wondering why nobody's subjected that coating to a chemical or spectroscopic analysis. That would put an end to that question, once and for all....but I also understand why nobody would want to, as it might require the end of that particular cone.

I wouldn't be surprised if HHR has. If I was doing what he does, I'd opt for that in a heartbeat.

(I think I'll pick up where I got left behind...*L*)

Mags, re #487~89...

Re complexity, that was a gentle 'tease'. Your midrange is Wonderfully wrought, and a tribute to your patience and skills. I still feel like I'm shooting rubber bands at the moon in contrast. So there. *G* 😉

As for your offer...I'd be the fool of the decade to say no to such a kind offer. I'd be near orgasmic with a 3D drawing, much less a model. Towards that, Yes, Please. You take whatever time you like and can spare. "Basic" for you may approach creating a virtual 'roadmap' for us...

But I will warn you that when you find yourself in Asheville, you will get 'dined' at least. 'Wined' may be subject to tolerance and any other scheduled activities. Anything else I can do to help, well, PM and ask. 😉

Philajoe73, the decreasing mass IMHO makes sense if one was attempting to create a full-range driver of that scale. As Cochleus noted, even a smaller cone has the surface area of a 10" speaker. I haven't 'run the numbers', but I suspect an F cone is approaching an 18~24" typ. driver, which is massive.

That, and as a waveform is descending the surface of the cone, it should be losing energy as it's being 'stretched' by the increasing circumference. It would follow that one would want the mass of the material to decrease to allow that wave to continue to 'flow'...or that's my take on it...

The damping materials were obviously carefully chosen, and the placement ditto. Likely to control 'ringing', harmonics, and the other plethora that cones of any sort are subject to. Since we're considering a rather steep cone profile, and one made even partly made of metal(s), I wouldn't be surprised if 'bell modes' are in there as well, further complicating the thing.

And as for 'kitchen tables', I wouldn't be surprised by that. *L* The patent states that there were prototypes made and displayed as 'proof of concept', typical for the patent process. HHR uses wood mandrels...me? I've got a plaster cone for smaller ones, and a larger foam one from Michael's that is virtually the same angle. It's used for floral displays and the like....and cheap. *L*

As for laying up 'cone on cone', it's just me reacting to the scale. That, and doing it pre- or post application of the damping materials is a question. It's just difficult as 'ell to do what I've doing without sweating damaging damping...

I pull out the calipers on assembly, or checking sizes on the dinky stuff. And I can relate to 'where the F did I leave them' issues.... I sometimes find myself looking for something that I finally remember that I don't own it anymore. The peril of 'too much Stuff'... 😉

The diameters I posted for the cone bases are based on your stated dimensions of the F cone. I imported the jpg into Corel, 'tweaked' the proportions a little to make it fall into line, and just noted what was depicted. Pretty easy, all in all...

I'd advise continued caution on driving your F's. Since things are already showing their age, it'd be better to treat them like granddad...'he ain't as spry as he used to be', much like us to varying degrees. 😉

As for the material used to damp the titanium....I've heard that description before of a hard 'clay-like' substance that really tweaks my curiosity. Can you discern how thick it might be?

It reminds me of old, thick oil paint, applied heavily. As to Why...eons ago, I used to work at a shop that refinished/rejuvenated 'turn of the century' furniture. To color match new oak to old oak, we'd use old paint that had dried up in their cans like crayons, accenting the grain and making it look 'old enough'. It looked like clay, and it was hard. We'd dip it in solvents to soften it up to various degrees.

I'm still wondering why nobody's subjected that coating to a chemical or spectroscopic analysis. That would put an end to that question, once and for all....but I also understand why nobody would want to, as it might require the end of that particular cone.

I wouldn't be surprised if HHR has. If I was doing what he does, I'd opt for that in a heartbeat.

If these dimensions have any significance to material used vs. frequency range...considering the previous line of reasoning of having the material matched to the frequency range to be radiated/created (metal to paper as a 'physical crossover' for the bass frequencies, tangential/pistonic motion)...

Titanium for the high(er) frequencies, alum for the mids to upper base +/-....a physical '3 way' full range radiator...perhaps?

Anybody feel like poking holes in that conjecture? *L*

I will add (without poking holes), that the choice of higher modulus materials near the driving circle was [also] to counter the increasing velocity of the wave as it travels along to the larger diameter end of the cone. In other words, he used the increased velocity gained by higher modulus of elasticity (measured radially) to counter the increasing velocity due to cone geometry (hoop compliance).

Keeping the [average] wave velocity constant is needed to maintain sound coherency (with a straight-sided cone geometry).

Last edited:

I am not sure if I should do the info as I find it or a dump.

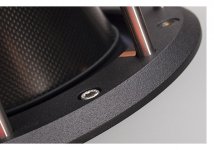

First piece of info. German Physics seems to use This carbon fiber at 0 degrees.

The weave checks out orientation and weight are as far as I can tell exact matches.

2.9 oz Carbon Fiber Woven Fabric: 42 inch Wide

First piece of info. German Physics seems to use This carbon fiber at 0 degrees.

The weave checks out orientation and weight are as far as I can tell exact matches.

2.9 oz Carbon Fiber Woven Fabric: 42 inch Wide

Attachments

Hard Dampening Material

Upon further inspection, I can see a very small piece of this material has flaked off and it is clear that it serves as a filler at the joint of the merging angles of the cone and VC. See attached (quick) drawing. I looked for it and thought I might send it post so you could have it analyzed, but to no avail. BTW, I don't recall if it was mentioned, but the VC looks like titanium as well.

Jerryrigged, I do treat these two with TLC and despite what I mentioned about the listening levels, that was just me pining for the past. They still sound good on my 14w WE monoblocs. 😀

Upon further inspection, I can see a very small piece of this material has flaked off and it is clear that it serves as a filler at the joint of the merging angles of the cone and VC. See attached (quick) drawing. I looked for it and thought I might send it post so you could have it analyzed, but to no avail. BTW, I don't recall if it was mentioned, but the VC looks like titanium as well.

Jerryrigged, I do treat these two with TLC and despite what I mentioned about the listening levels, that was just me pining for the past. They still sound good on my 14w WE monoblocs. 😀

Attachments

Hey guys-

Reminder that there are speaker reconing supply sites that sell all sorts of useful stuff- worth some looking into.

Just got an email regarding a new photo polymer "welder" called Bondic. I haven't tried it- but it looks useful. Pen is complete with UVED. Might be worth $20 to experiment.

OK- back to the laser

Reminder that there are speaker reconing supply sites that sell all sorts of useful stuff- worth some looking into.

Just got an email regarding a new photo polymer "welder" called Bondic. I haven't tried it- but it looks useful. Pen is complete with UVED. Might be worth $20 to experiment.

OK- back to the laser

Mags, you might post just as you come across but keep a file for a dump later. That way we've always got a topic du jour to analyze and argue about. *L*

The surround on the GP unit looks like a 'U' shape, a 'flipped' version of what we see on a conventional surround. I wonder if there's anything beneath it, augmenting it's action(s)...

Good analysis, Coch...the patent claims that the wave is traveling at a supersonic velocity, at which coherency would be maintained on the face of the cone since it's so short. Even on an 'F' or 'A' cone, the distance is essentially nil. It might begin to lose coherency on the proposed 6' tall 'stadium' versions, but I suspect that even then it would take a Very Sharp set of ears to discern that...

And the material's choice(s) make sense.... My alum cones have a 'voice' to them, and I'd not be surprised that they 'speak' slightly differently than your paper/composite ones. *L* Mine 'speak middle F', while yours 'bottom F", perhaps.

Same 'language', different 'accents'. Jersey vs. Bronx. 😉

Phil, that's the problem with flakes...when you want them to stick around, they're nowhere to be found. 😉 Well, just keep 'em under surveillance. If anything else falls off (not that I'm wishing it does), snag it and maybe we can find the answer to the Ohm Mystery Gook. But I swear it sounds like paint....thick, gookey paint. And it would make for a good filler, too.

A titanium vc form would actually make good sense. You'd get heat transfer into the upper cone to some degree, at the risk of adhesive deterioration at the intersection.

And making titanium cones would almost guarantee 'drops' of material; made sense to utilize it, and why not for the vc? Nice quick sketch, too.

And I didn't doubt that you treat your 'grandchildren' nice. I don't 'push' mine too hard, either...but because of vc heat issues, rather than advanced age....

Growing old really sucks, basically. Personally, I bruise and 'tear' too easily of late. One of my dogs is helpful in 'cleaning me up, but I'm watching him to make sure he doesn't develop any vampire tendencies. I don't have a gun nor silver bullets, and I don't have the heart to stake him. He wouldn't like it either. *G* Even if he's a obedience school dropout. 😉

Bondic? Sounds kinky. *L* Glo, I used to make a lot of photopolymer signage, UV 'set' stuff, all that. PM or post where it is, and I'll go check it out. The stuff's durable if cured correctly; as an adhesive, it didn't exist 'back then'. It could be an answer to a question we haven't thought of yet.... 😉

Anyway...Forward to Page 51! Charge! *L*

The surround on the GP unit looks like a 'U' shape, a 'flipped' version of what we see on a conventional surround. I wonder if there's anything beneath it, augmenting it's action(s)...

Good analysis, Coch...the patent claims that the wave is traveling at a supersonic velocity, at which coherency would be maintained on the face of the cone since it's so short. Even on an 'F' or 'A' cone, the distance is essentially nil. It might begin to lose coherency on the proposed 6' tall 'stadium' versions, but I suspect that even then it would take a Very Sharp set of ears to discern that...

And the material's choice(s) make sense.... My alum cones have a 'voice' to them, and I'd not be surprised that they 'speak' slightly differently than your paper/composite ones. *L* Mine 'speak middle F', while yours 'bottom F", perhaps.

Same 'language', different 'accents'. Jersey vs. Bronx. 😉

Phil, that's the problem with flakes...when you want them to stick around, they're nowhere to be found. 😉 Well, just keep 'em under surveillance. If anything else falls off (not that I'm wishing it does), snag it and maybe we can find the answer to the Ohm Mystery Gook. But I swear it sounds like paint....thick, gookey paint. And it would make for a good filler, too.

A titanium vc form would actually make good sense. You'd get heat transfer into the upper cone to some degree, at the risk of adhesive deterioration at the intersection.

And making titanium cones would almost guarantee 'drops' of material; made sense to utilize it, and why not for the vc? Nice quick sketch, too.

And I didn't doubt that you treat your 'grandchildren' nice. I don't 'push' mine too hard, either...but because of vc heat issues, rather than advanced age....

Growing old really sucks, basically. Personally, I bruise and 'tear' too easily of late. One of my dogs is helpful in 'cleaning me up, but I'm watching him to make sure he doesn't develop any vampire tendencies. I don't have a gun nor silver bullets, and I don't have the heart to stake him. He wouldn't like it either. *G* Even if he's a obedience school dropout. 😉

Bondic? Sounds kinky. *L* Glo, I used to make a lot of photopolymer signage, UV 'set' stuff, all that. PM or post where it is, and I'll go check it out. The stuff's durable if cured correctly; as an adhesive, it didn't exist 'back then'. It could be an answer to a question we haven't thought of yet.... 😉

Anyway...Forward to Page 51! Charge! *L*

Physics brush up

Boy reading this thread had made me remember how much I've forgotten about wave theory! Had to brush up to follow along with some posts. For other challenged folks enjoying the discussion, I ran across this:

https://www.youtube.com/watch?v=DovunOxlY1k

Nothing better than visualization to explain/entertain. (Brought to you by the same folks who brought you anti-ballistic missile systems, who knew)

https://www.youtube.com/watch?v=ARx2-wRn9-Y

Boy reading this thread had made me remember how much I've forgotten about wave theory! Had to brush up to follow along with some posts. For other challenged folks enjoying the discussion, I ran across this:

https://www.youtube.com/watch?v=DovunOxlY1k

Nothing better than visualization to explain/entertain. (Brought to you by the same folks who brought you anti-ballistic missile systems, who knew)

https://www.youtube.com/watch?v=ARx2-wRn9-Y

- Home

- Loudspeakers

- Planars & Exotics

- DIY Walsh driver revisited