The cone would indeed be very very light. But, it would also be robust, a perfect material for cones IMO, especially for tweets.

I am referring to "graphene oxide paper", a different animal from straight graphene sheets.

I am referring to "graphene oxide paper", a different animal from straight graphene sheets.

...and I followed up on that 'GOP' (unfortunate initials, there *G*)...still too small, too expensive to be considered viable, But I thought you'd like to see that the 'tech' is being inevitably 'pushed'. The Next Big Thing, eventually....

But it still is an interesting 'thought experiment', as Albert used to say. How does one handle next to nothing? I used to periodically have to handle gold leaf. You can't use your fingers; we used rabbit's hair brushes (I'm not kidding, and NO, I've no clue as to how 'they' figured That out...all those naked rabbits...*L*) You'd maneuver it into place, these 85mm square sheets, and literally blow it into place gently. It'd stick to your fingers...disappear into nothing if you tried to handle it...

Hopefully it'll be a little easier to handle...😉 And, agreed, it'd be the superlative tweet in terms of a near massless cone, nearly the weight of the air about it...

But it still is an interesting 'thought experiment', as Albert used to say. How does one handle next to nothing? I used to periodically have to handle gold leaf. You can't use your fingers; we used rabbit's hair brushes (I'm not kidding, and NO, I've no clue as to how 'they' figured That out...all those naked rabbits...*L*) You'd maneuver it into place, these 85mm square sheets, and literally blow it into place gently. It'd stick to your fingers...disappear into nothing if you tried to handle it...

Hopefully it'll be a little easier to handle...😉 And, agreed, it'd be the superlative tweet in terms of a near massless cone, nearly the weight of the air about it...

In betwixt 'n meanwhile...

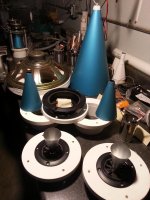

Structural parts for V3.5 (or V.4, I've been calling it both) have finally been completed...on to cutting hardware to size, cutting and applying surrounds, and assembly.

Hopefully sooner than later should get to see if my 2nd take on a Walsh tweet based on the Infinity 'ice cream cone' works properly, and a large scale driver using a 'previously' 10" woofer driving a 9" dia. cone. The latter ought to be interesting; since the original Ohm A physically 'crossed over' to a paper cone from aluminum @ a 7 1/2" +/- dia., I'm wondering if it'll exhibit pistonic motion despite the rather stiff surrounds I apply...or will it manage to create some upper bass response in a dml fashion typical for the rest of the cone. I do expect the voice coil to warm up from this adventure, we'll see how long it can handle the strain, even though the unit has a higher wattage rating.

This might be a 'test to destruct' affair, depending on how it sounds, anyway. Fortunately, the balance of the array is physically independent from it, not 'hard attached' to the larger structure below it.

Anyway...parts pic attached, hope it displays properly upside right...

Structural parts for V3.5 (or V.4, I've been calling it both) have finally been completed...on to cutting hardware to size, cutting and applying surrounds, and assembly.

Hopefully sooner than later should get to see if my 2nd take on a Walsh tweet based on the Infinity 'ice cream cone' works properly, and a large scale driver using a 'previously' 10" woofer driving a 9" dia. cone. The latter ought to be interesting; since the original Ohm A physically 'crossed over' to a paper cone from aluminum @ a 7 1/2" +/- dia., I'm wondering if it'll exhibit pistonic motion despite the rather stiff surrounds I apply...or will it manage to create some upper bass response in a dml fashion typical for the rest of the cone. I do expect the voice coil to warm up from this adventure, we'll see how long it can handle the strain, even though the unit has a higher wattage rating.

This might be a 'test to destruct' affair, depending on how it sounds, anyway. Fortunately, the balance of the array is physically independent from it, not 'hard attached' to the larger structure below it.

Anyway...parts pic attached, hope it displays properly upside right...

Attachments

Looking good

I love and dread the building process. I know I will end up with a superior product and thus sound, but boy is it tedious and frustrating. I am looking forward to measurements, listening impressions and maybe a recording that I know will not do it justice.

I love and dread the building process. I know I will end up with a superior product and thus sound, but boy is it tedious and frustrating. I am looking forward to measurements, listening impressions and maybe a recording that I know will not do it justice.

Attachments

To flip the image

To flip the image simply flip it in a photo viewing app like windows photo viewer and click save or just click exit-out and it will automatically save.

To flip the image simply flip it in a photo viewing app like windows photo viewer and click save or just click exit-out and it will automatically save.

Jer- your stuff looks phenomenal! I notice you may be dabbling with Walsh tweeters. If I may I'd like to offer a few suggestions if you haven't already thought about it.

A Donut of felt applied to the front of the driver body will help discourage diffraction near the base of the "cone".

There needs to be some sort of termination at the large end of the cone. This will help stabilize the cone, help control weird radial contortions around the periphery, and finally terminate the line to prevent reflections back the the voice coil.

We (and Infinity) used a NON magnetic dowel adhered to the center pole piece that was about as long as the cone. The old Seas mid tweeter we used had a hole in the center of the pole piece that we tapped, then used threaded aluminum rod to couple the dowel and secured it with epoxy.

We protected the gap from filings and glue with masking tape. When we removed the tape, we used a bit of cardboard with masking tape folded over it sticky side out to clear any bits of shavings.

Earlier versions used Dacron to fill the void inside the cone to absorb radiation from the back of the "cone" and thus prevent interference with the opposite side. It was simply gently stuffed inside.

Infinity later used urethane foam, possibly cut to fit, and possibly glued to the cone to fill the void. This was also the termination. Problem is, urethane oxidizes over time and turns into a powdery crud.

My suggestion is to stack increasingly larger felt "donuts" up the center rod that don't actually touch the cone. This would absorb the inside energy reflections and cavity resonances.

Lastly, top it off with a disk of relatively dense packing foam, maybe 1'4" thick cut at the angle of the cone along it's edge and gently pressed into place. That black stuff- This would be the termination.

A Donut of felt applied to the front of the driver body will help discourage diffraction near the base of the "cone".

There needs to be some sort of termination at the large end of the cone. This will help stabilize the cone, help control weird radial contortions around the periphery, and finally terminate the line to prevent reflections back the the voice coil.

We (and Infinity) used a NON magnetic dowel adhered to the center pole piece that was about as long as the cone. The old Seas mid tweeter we used had a hole in the center of the pole piece that we tapped, then used threaded aluminum rod to couple the dowel and secured it with epoxy.

We protected the gap from filings and glue with masking tape. When we removed the tape, we used a bit of cardboard with masking tape folded over it sticky side out to clear any bits of shavings.

Earlier versions used Dacron to fill the void inside the cone to absorb radiation from the back of the "cone" and thus prevent interference with the opposite side. It was simply gently stuffed inside.

Infinity later used urethane foam, possibly cut to fit, and possibly glued to the cone to fill the void. This was also the termination. Problem is, urethane oxidizes over time and turns into a powdery crud.

My suggestion is to stack increasingly larger felt "donuts" up the center rod that don't actually touch the cone. This would absorb the inside energy reflections and cavity resonances.

Lastly, top it off with a disk of relatively dense packing foam, maybe 1'4" thick cut at the angle of the cone along it's edge and gently pressed into place. That black stuff- This would be the termination.

Up, up, and oy vay....

Mags, the pic displays properly 'here' on my desktop 'puter. I think it's due to the pic being taken with my phone, which I've turned 90 to take it originally. I've tried 'flipping' previous pics to compensate, but they revert like obstinate children. I will give it another go in the future, but I'd just rather blame it on the 'Windows Annoyance Subroutine Protocol' (WASP) that someone in Redmond thought would be a cute addition to have pop up at random Somewhere to Someone...and I'm just paranoid enough to believe in such.

It beats believing in fairies and statistics...😉

Glo, thanks and thanks for the suggestions. Initially, I'm going to go with, quote "Lastly, top it off with a disk of relatively dense packing foam, maybe 1'4" thick cut at the angle of the cone along it's edge and gently pressed into place. That black stuff- This would be the termination." The mounting of the tweets will allow me to add/subtract various 'routines', such as you've suggested, to see what might occur. The previous attempt had a 'core' of an ordinary plastic straw. A dab of glue within the tip allowed it to be placed on the center pole without hazarding the vc gap...and the price was right at the time. *G* More sophisticated refinements will follow with more sophisticated observations of what hath been wrought by this ham-handler. 😉

BTB. here's a drawing of the concept...half section views, half WYSIWYG, typical for my drawing style for things of this and most natures. Allows me to work out details, resolve kinks, etc. Height just under 43". Upper tweet and mid mid-range sit atop the woof, base of mid surrounds the magnet of the woof but is separate. If the woof don't woof nice, I still have the remaining to run tweet tests with....

Mags, the pic displays properly 'here' on my desktop 'puter. I think it's due to the pic being taken with my phone, which I've turned 90 to take it originally. I've tried 'flipping' previous pics to compensate, but they revert like obstinate children. I will give it another go in the future, but I'd just rather blame it on the 'Windows Annoyance Subroutine Protocol' (WASP) that someone in Redmond thought would be a cute addition to have pop up at random Somewhere to Someone...and I'm just paranoid enough to believe in such.

It beats believing in fairies and statistics...😉

Glo, thanks and thanks for the suggestions. Initially, I'm going to go with, quote "Lastly, top it off with a disk of relatively dense packing foam, maybe 1'4" thick cut at the angle of the cone along it's edge and gently pressed into place. That black stuff- This would be the termination." The mounting of the tweets will allow me to add/subtract various 'routines', such as you've suggested, to see what might occur. The previous attempt had a 'core' of an ordinary plastic straw. A dab of glue within the tip allowed it to be placed on the center pole without hazarding the vc gap...and the price was right at the time. *G* More sophisticated refinements will follow with more sophisticated observations of what hath been wrought by this ham-handler. 😉

BTB. here's a drawing of the concept...half section views, half WYSIWYG, typical for my drawing style for things of this and most natures. Allows me to work out details, resolve kinks, etc. Height just under 43". Upper tweet and mid mid-range sit atop the woof, base of mid surrounds the magnet of the woof but is separate. If the woof don't woof nice, I still have the remaining to run tweet tests with....

Attachments

It's just the usual noises in here....

Ambitious, perhaps. It's certainly has had a long 'gestation period'... And actually more of a test bed for the tweeter and some construction detailing on individual segments.

The tweeter @ top will be able to be removed by just removing 4 nuts. In this way I can apply/try different 'routines', such as suggested by Glo, to see what effects occur. Hopefully this can be done in a non-destructive/'swappable' fashion, as it's made from the 2 mil alum that you graciously donated. 😉 That's the idea, anyway...

The 'midrange' at the center is similar to what I've done previously, just adapted to the physical details of the co-opted driver (plastic basket vs. metal). It'll just sit on the woofer's frame with some foam applied to damp any vibrations, as the magnet fits within the mids base. A lucky occurrence...

The lower 'woofer' is an excursion into finding out 'where' the cone transits from a dml to pistonic excitation as frequency descends. The base is made purposely to allow reducing the diameter of the cone by inserting 'shim rings' beneath the cone, which can be reduced in diameter and receive a smaller diameter surround. This obviously will reduce it's height; the posts can be cut down to accommodate this.

The cones will all align vertically, so that more or less addresses 'time alignment'. The cone's profiles are all the same (small up, big down), which hopefully will allow the radiation patterns to more or less 'blend/overlap'. I can't get them any closer together vertically, so I'll see if this works. A 'sonic layer cake', if you will... My earlier test of 'flipping' the top unit (much like the Ikonoklast units) didn't work IMHO, so here's my 'go' at it.

One thing I'm trying to simplify the surround construction is the use of 3M's 77 spray adhesive to apply the EVA foam to the base structure in lieu of the VHB film adhesive I have been using. A test with scraps went well, so I'm reasonably confident it'll hold up. I'll continue to use the 4475 adhesive to bond the EVA to the cones, as it's doing well with all 6 of the units I have now...

...and masking tape is cheap, and the spray is easy to apply. Applying the foam accurately is still a 'hold the breath/focus/steady hands process...*G*

I'm starting to sound like an advert for 3m products. *L* Maybe I can get some corporate support...*L* Yeah, right...

Actually, I've noticed that the 4 units that I've been running consistently are 'breaking in', flaws and all. Certain cuts that I play and the instruments played within them are 'smoothing out', and the occasional 'innocent bystander' that hears them are starting to ask when they could have a pair. They still need a lot of development before I'd consider that. I prefer to keep those around me pleased with what I do and/or subject them to. And it's just good karmic relations. *L*

It is exciting to have 6 speakers underway at once, but it's also 6 speakers in progress at once. I can only dedicate 'snippets' of time, and nibble away at what needs to happen when and what order for what... An obscure bit of multitasking...*G*

Ambitious, perhaps. It's certainly has had a long 'gestation period'... And actually more of a test bed for the tweeter and some construction detailing on individual segments.

The tweeter @ top will be able to be removed by just removing 4 nuts. In this way I can apply/try different 'routines', such as suggested by Glo, to see what effects occur. Hopefully this can be done in a non-destructive/'swappable' fashion, as it's made from the 2 mil alum that you graciously donated. 😉 That's the idea, anyway...

The 'midrange' at the center is similar to what I've done previously, just adapted to the physical details of the co-opted driver (plastic basket vs. metal). It'll just sit on the woofer's frame with some foam applied to damp any vibrations, as the magnet fits within the mids base. A lucky occurrence...

The lower 'woofer' is an excursion into finding out 'where' the cone transits from a dml to pistonic excitation as frequency descends. The base is made purposely to allow reducing the diameter of the cone by inserting 'shim rings' beneath the cone, which can be reduced in diameter and receive a smaller diameter surround. This obviously will reduce it's height; the posts can be cut down to accommodate this.

The cones will all align vertically, so that more or less addresses 'time alignment'. The cone's profiles are all the same (small up, big down), which hopefully will allow the radiation patterns to more or less 'blend/overlap'. I can't get them any closer together vertically, so I'll see if this works. A 'sonic layer cake', if you will... My earlier test of 'flipping' the top unit (much like the Ikonoklast units) didn't work IMHO, so here's my 'go' at it.

One thing I'm trying to simplify the surround construction is the use of 3M's 77 spray adhesive to apply the EVA foam to the base structure in lieu of the VHB film adhesive I have been using. A test with scraps went well, so I'm reasonably confident it'll hold up. I'll continue to use the 4475 adhesive to bond the EVA to the cones, as it's doing well with all 6 of the units I have now...

...and masking tape is cheap, and the spray is easy to apply. Applying the foam accurately is still a 'hold the breath/focus/steady hands process...*G*

I'm starting to sound like an advert for 3m products. *L* Maybe I can get some corporate support...*L* Yeah, right...

Actually, I've noticed that the 4 units that I've been running consistently are 'breaking in', flaws and all. Certain cuts that I play and the instruments played within them are 'smoothing out', and the occasional 'innocent bystander' that hears them are starting to ask when they could have a pair. They still need a lot of development before I'd consider that. I prefer to keep those around me pleased with what I do and/or subject them to. And it's just good karmic relations. *L*

It is exciting to have 6 speakers underway at once, but it's also 6 speakers in progress at once. I can only dedicate 'snippets' of time, and nibble away at what needs to happen when and what order for what... An obscure bit of multitasking...*G*

Two loudspeaker terms that I hate..."pistonic" (even being part of the Detroit community), and "cone breakup", sounds depressing...

*L* 'Pistonic' always sounds like something you'd take for a urinary issue...or a non-issue, if you'll pardon the very obvious pun, likely painful at that. *LOL*

I'll leave any Detroit commentary unsaid...I've heard and read enough, and talking about someone else stomping grounds seems trollish if one's never been there to form a proper opinion. There's good and bad about anywhere one finds oneself these days. One loves it or leaves it...

Cone breakup...sounds like an SNL skit that never got explored. 😉 There's a YouTube vid of a guy trashing a Huge woofer that's got it's voyeuristic moments...not that yours truly would do such a sacrilege...*smirk*

I'll leave any Detroit commentary unsaid...I've heard and read enough, and talking about someone else stomping grounds seems trollish if one's never been there to form a proper opinion. There's good and bad about anywhere one finds oneself these days. One loves it or leaves it...

Cone breakup...sounds like an SNL skit that never got explored. 😉 There's a YouTube vid of a guy trashing a Huge woofer that's got it's voyeuristic moments...not that yours truly would do such a sacrilege...*smirk*

Cone breakup...sounds like an SNL skit that never got explored. 😉

What to do on a 6/4 weekend.

Assemble the V3.5 bass units, that's what...

Due to the size, they (there's 2) were actually easier to put together than a smaller unit. There's room for fingers to fit without bumping into something else...*G* You can see the foot ruler in the pic.

At this point, they're being glued at the surrounds and the voice coils. The 4475 needs 24 hours to cure completely, so patience becomes a necessity as well as a virtue. The tweets are essentially done; the mids' posts need a bit of shaping at their top ends before they can be assembled and enter into the 'adhesion cycle' (i.e., application of more patience).

The goal is to complete assembly prior to leaving Tuesday 7/7 for a business 'overnight speed tour' to Fayetteville and the Raleigh area for some deliveries and minor installs. By my return (Thursday-ish), everything should be cured and ready for hook-up and 'first voice'.

...and then we'll see what hath been wrought...

Assemble the V3.5 bass units, that's what...

Due to the size, they (there's 2) were actually easier to put together than a smaller unit. There's room for fingers to fit without bumping into something else...*G* You can see the foot ruler in the pic.

At this point, they're being glued at the surrounds and the voice coils. The 4475 needs 24 hours to cure completely, so patience becomes a necessity as well as a virtue. The tweets are essentially done; the mids' posts need a bit of shaping at their top ends before they can be assembled and enter into the 'adhesion cycle' (i.e., application of more patience).

The goal is to complete assembly prior to leaving Tuesday 7/7 for a business 'overnight speed tour' to Fayetteville and the Raleigh area for some deliveries and minor installs. By my return (Thursday-ish), everything should be cured and ready for hook-up and 'first voice'.

...and then we'll see what hath been wrought...

Attachments

Might be a good idea to glue some felt or something inside the basket ribs (spokes) to discourage reflections back the the cone.

Too bad you can't get your hands on some old Altec 412 B or C models. They ran from 40 to 18K, and used a "BiFlex" come as sort of a mechanical crossover. When they were in production, you could get re-cone kits for them. Even more too bad they don't make 'em any more. Great platform for your LF drivers.

Both Altec and JBL used a shorted turn in their voice coils to extend the HF limit of their "full range" drivers. I also seem to remember the JBL LE-8T having a copper cap on the pole piece.

When I was playing with these back in the '70's, these two drivers seemed like the holy grail for such builds, but they were expensive.

I mention this because that motor is your next challenge. If you can extend the bandwidth of the "LF" section, you can start getting rid of those awful, pesky crossover networks and get closer to audio Nirvana.

Too bad you can't get your hands on some old Altec 412 B or C models. They ran from 40 to 18K, and used a "BiFlex" come as sort of a mechanical crossover. When they were in production, you could get re-cone kits for them. Even more too bad they don't make 'em any more. Great platform for your LF drivers.

Both Altec and JBL used a shorted turn in their voice coils to extend the HF limit of their "full range" drivers. I also seem to remember the JBL LE-8T having a copper cap on the pole piece.

When I was playing with these back in the '70's, these two drivers seemed like the holy grail for such builds, but they were expensive.

I mention this because that motor is your next challenge. If you can extend the bandwidth of the "LF" section, you can start getting rid of those awful, pesky crossover networks and get closer to audio Nirvana.

Well, hi Jay...*G* Started to think you'd fallen off the planet or alien abduction. More likely the daily grind and garden subduction...😉 Yeah, me too. I'd rather listen than work, but gotta do one to do the other...

BTB, watched "Mr. Robot" on the USA network or online. Finally something not aimed at ones' knees re subject or presentation. You might check it out... more cybernoia, but intelligent for a change...😉

I'll try the felt, it might even work on the V3's as well. As for things I can't get my hands on, there's way too much of that about. *L* Some aren't audio related...I'm allowed to look, as long as I don't get grabby or drool. It's summer, after all. 😉

Actually, I have a pair of the LE-8's in hand. Had them reconed by pros awhile ago. But even I have some scruples at the end of the day...plan to mount then into enclosures, but not something typical...

BTB, watched "Mr. Robot" on the USA network or online. Finally something not aimed at ones' knees re subject or presentation. You might check it out... more cybernoia, but intelligent for a change...😉

I'll try the felt, it might even work on the V3's as well. As for things I can't get my hands on, there's way too much of that about. *L* Some aren't audio related...I'm allowed to look, as long as I don't get grabby or drool. It's summer, after all. 😉

Actually, I have a pair of the LE-8's in hand. Had them reconed by pros awhile ago. But even I have some scruples at the end of the day...plan to mount then into enclosures, but not something typical...

Still here. Had to replace water pump on my car, at at my age, I really don't like working on cars anymore.... Finally getting the first of the Ceanothus planted yesterday, and oh, yes, record heat in our area, too....

My fingers barely work after digging, soil amending, and water pumping.. I look forward to finding that you can do what Ohm and Infinity couldn't.

My fingers barely work after digging, soil amending, and water pumping.. I look forward to finding that you can do what Ohm and Infinity couldn't.

That makes two of us, Mags...*G*

Jay, cars of this era, it's a feat to Get To a water pump, with all the mechanicals that exist under the modern hood. Seems to require joints not found on humans....

...maybe that's where the aliens are hanging out....the modern car assembly plant...*L*

..and IF I can 'give the tech a push' enough to rival the original Ohms...(I should be able to surpass the old Inf and the current Ohms)...and approach what GP is up to, I'll be pleased. Physically the 3.5's are going together with a minimum of drama. This could be simply experience with the routine, or I've managed to 'tighten up' the tolerances and have reduced the surprize factors.

I have my hopes...we'll see what reality offers soon enough. It'll be fun to play about with, since that's what it's essentially designed to be, an 'audio playground'/test bed.

What else would you expect from someone who builds playgrounds for a living? *L*😉

Jay, cars of this era, it's a feat to Get To a water pump, with all the mechanicals that exist under the modern hood. Seems to require joints not found on humans....

...maybe that's where the aliens are hanging out....the modern car assembly plant...*L*

..and IF I can 'give the tech a push' enough to rival the original Ohms...(I should be able to surpass the old Inf and the current Ohms)...and approach what GP is up to, I'll be pleased. Physically the 3.5's are going together with a minimum of drama. This could be simply experience with the routine, or I've managed to 'tighten up' the tolerances and have reduced the surprize factors.

I have my hopes...we'll see what reality offers soon enough. It'll be fun to play about with, since that's what it's essentially designed to be, an 'audio playground'/test bed.

What else would you expect from someone who builds playgrounds for a living? *L*😉

Well, my car isn't really "of this era", it's 20 years old, and the water pump wasn't all that difficult to get to. I do resent the plastic impeller, that typically lasts 60k miles. I have double that, and, turns out, the pump was fine, was the belt that was shredded.

I had a pair of "Walsh 2" left over from when I closed the stereo store. Included a rather standard looking 8" cone on top of a big box, with a dome tweeter. Sounded pretty good, but I never actually had a good place to set them up, so never really listened to 'em. Goodwill got them a few years ago, in my last move.

I expect better from your effort!

I had a pair of "Walsh 2" left over from when I closed the stereo store. Included a rather standard looking 8" cone on top of a big box, with a dome tweeter. Sounded pretty good, but I never actually had a good place to set them up, so never really listened to 'em. Goodwill got them a few years ago, in my last move.

I expect better from your effort!

- Home

- Loudspeakers

- Planars & Exotics

- DIY Walsh driver revisited