oh well time to take apart one of my crt projector and find out what lenses inside are of any use to me, if any.

some one give me the perfect dimmintions to a parobolic relfector and ill try to make the out of alum. and sell them to you guys through ebay for cheap that of cource if they work out.where i work has alot of tools etc. that i can work with. but if this dose work out im only making a limited amount just for u guys. nonprofit work sucks after a while. we see how it gose.

😀 😀 😀 😀

😀 😀 😀 😀

Hey, thanks guys. You just saved me about $40.00.

As far as the Lights of America goes, they are 8,000 lumens and they are color corrected (I don`t know if color corrected is better or not). But I think 8000 lumens is bright enough...isn`t it?

Mitch

As far as the Lights of America goes, they are 8,000 lumens and they are color corrected (I don`t know if color corrected is better or not). But I think 8000 lumens is bright enough...isn`t it?

Mitch

8000 lumens is not enough I think. You would defiently have to have a good reflector even then it would be dim. Use a metal halide although they are a bit more expensive they have good color tempature and are very bright. Most people are using 400 watt metal halide which seems to be good size. They output 40,000 lumens. ROTFLMAO on icculus comment that his pictures look like a video bagel.

Hi Guys,

Where (and whose) was the post a few days back about using a cardboard cutout to create a solid elliptical dome out of plaster/clay that could be used as a mold to build an elliptical reflector around using aluminium foil/sheet?

I remember reading it a week or so ago, but it seems to have been lost in the weeds...

Having seen the commercial reflectors from stage lights, I am sure that this is the answer to the reflector problem.

A suitably cut (like petals on a flower) aluminium disc could be wrapped around this dome, fastened in place, and its inside surfaces polished. It would be cool!

I THINK a suitably set-up elliptical arrangement would also eliminate the center hotspot situation that affects many who have used a parabolic reflector, or cylindrical + fresnel combination. But, then again, I might be wrong...

Bill.

Where (and whose) was the post a few days back about using a cardboard cutout to create a solid elliptical dome out of plaster/clay that could be used as a mold to build an elliptical reflector around using aluminium foil/sheet?

I remember reading it a week or so ago, but it seems to have been lost in the weeds...

Having seen the commercial reflectors from stage lights, I am sure that this is the answer to the reflector problem.

A suitably cut (like petals on a flower) aluminium disc could be wrapped around this dome, fastened in place, and its inside surfaces polished. It would be cool!

I THINK a suitably set-up elliptical arrangement would also eliminate the center hotspot situation that affects many who have used a parabolic reflector, or cylindrical + fresnel combination. But, then again, I might be wrong...

Bill.

woneill said:A suitably cut (like petals on a flower) aluminium disc could be wrapped around this dome, fastened in place, and its inside surfaces polished. It would be cool!

Bill,

The plaster mold idea is here on this page.

I liked your idea of the thin - petal approach, but wonder how easily it would conform to the shape required. The better the specular surface, the worse any imperfections will affect the light reflected off of it.

I still think it would be easier to use thinner, easily formed metal like foil, built up in many layers to obtain the wall strength needed. Sort of like paper mache, but using foil instead of paper. The sticking point (bad pun alert!) I think would be glue.

Biteon had suggested melting the aluminum together, but I don't think that would work unless you formed a complete mold and did a pour like a foundry. Otherwise you'd be essentially trying to weld it, and as far as I know, aluminum doesn't cooperate around oxygen.

Any adhesive experts among us? What sort of heat does super-glue handle? Would it start producing toxic fumes after we'd been watching our TV a while? Are there any epoxies made for automotive repair that could handle the heat?

Maybe something like that black gasket goo they use for auto engines. Gasket cement. Gasket replacemnt. May need highish pressure to work properly.

cowanrg said:possibly. i have the site done, and hosting done, it just got pulled because of some disputes with my hosting over traffic...

this site pulls a LOT of people when its up. i think i was doing like 4K page visits a day near the end. i forgot how much bandwidth was used, but its more than a cable/dsl can handle for sure. it was in the multiple GB/month range.

ill get it back up and see if i need a mirror. where you located?

I wouldn't be to sure cowan.

I host a very popular forum on my DSL line (512k/256k) I have ~13000 members and usually around 30 connected at any one time. Traffic wise this costs me around 700MB a day, on busy days though its usually around 1GB, recently it came up to 2.5GB in one day.

Beleive me, a well configured server on a dsl line can handle a hell of a load (this was my problem). I had to upgrade the server for a performance boost, the line was not the bottleneck. In my 2 years experience of home-hosting 🙂 the hardest thing is keeping the server running.

Anyway, back to projection 🙂

Im all setup, sorry I havent posted pics yet, im still trying to get hold of a camera. I have an Elite Vision 4000 OHP that takes EVD Lamps, and my panel is a Spectra Pro (different to Spectra C)

I never thought i would get such a good projection on such a budget. It's amazing, the best thing i have ever purchased for home cinema is this panel and ohp. I had it setup yesterday on my outside wall, the picture was about 14ft diagonal. Amazingly it was still crisp and bright (this was about 11pm 🙂 )

I am aiming to fit my ohp with a new MH setup though because i have a few problems::

1. The panel gets EXTREMELY HOT (REALLY REALLY HOT 🙂 )

2. There is a small spot in the middle of the picture (the tungsten filament.

3. It would be nice to have a brighter image for ambient lighting

4. Im worried that in this state it would be a fire hazard to roof mount.

Also, I would like to upgrade the panel to an XGA QA-2500 and have emailed ISI to ask them to keep one reserved if they get a few in. If anyone is selling a Sharp QA-2500 please send me a private message.

Thanks ppl

cya,

Hi Mycamel,

Awesome original idea!!! 😎 😎 😎

I was thinking that something like 1mm aluminium sheeting would be robust enough to hold its shape once formed, but ductile enough that it could be "forced" using blunt implements (and a small hammer - hammers are always fun) 🙂 to conform to the curve of the dome.

The petals would overlap each other to some extent, and a solution as crazy as pot-riveting near the exit apeture might be good enough to hold them together in place without disrupting the output beam too much (the rivets would probably need to be applied from inside the reflector). The holes could be drilled through the reflector petals while they are still on the mold.

Even a crude and simple arrangement such as this would be better than most of the existing reflectors out there, and once polished, would probably be equal to many of the stage-lighting ones.

If nothing else, it would dramatically increase the amount of usable light from the big 400W MH bulbs.

Bill.

Awesome original idea!!! 😎 😎 😎

I was thinking that something like 1mm aluminium sheeting would be robust enough to hold its shape once formed, but ductile enough that it could be "forced" using blunt implements (and a small hammer - hammers are always fun) 🙂 to conform to the curve of the dome.

The petals would overlap each other to some extent, and a solution as crazy as pot-riveting near the exit apeture might be good enough to hold them together in place without disrupting the output beam too much (the rivets would probably need to be applied from inside the reflector). The holes could be drilled through the reflector petals while they are still on the mold.

Even a crude and simple arrangement such as this would be better than most of the existing reflectors out there, and once polished, would probably be equal to many of the stage-lighting ones.

If nothing else, it would dramatically increase the amount of usable light from the big 400W MH bulbs.

Bill.

Mycamel,

Your foil idea is definitely a good alternative, though! High-temperature epoxy would be your best bet - it is what is used by the Xenon car headlamp manufacturers to glue the base to the bulb.

I don't know what the heat characteristics of normal epoxy are, but I too would be wary of superglue - it contains cyanide compounds. Not good!!!

Bill.

Your foil idea is definitely a good alternative, though! High-temperature epoxy would be your best bet - it is what is used by the Xenon car headlamp manufacturers to glue the base to the bulb.

I don't know what the heat characteristics of normal epoxy are, but I too would be wary of superglue - it contains cyanide compounds. Not good!!!

Bill.

sure this has been thought of before

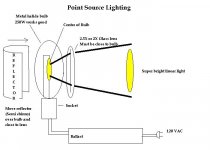

For those of you who would like to use multiple lamps to get more light: Couldn't we setup the lamps behind a fresnel that would catch almost all their light, and focus it, and then at the focal point, we could put a diffusing lense (I am sure this isn't the right word, but I don't know the name of it), like the ones in the Elmos HP A305's, and 3M 9550 OHP's. For those of you who haven't seen these diffuser lenses, these lenses are real thick and go right in front of the bulbs in these projectors. This technique would conentrate relatively diffuse light, and then diffuse it out onto another fresnel, and the LCD panel.

Lamps Fresnel Diffuser Fresnel LCD Objective

} |

} | ) | LCD ()(

} |

This should allow you to use multiple light sources without hotspotting, I think.....

An update on my work: I got a fresnel, a diffuser lens and an objective lens from Inventory Solutions on Friday. I now have everything I need to build the projector. The objective I got has a variable focal length, you just rotate the mount to change the focus. This means I woun't have to have a moving part to the front of my box, which is a key!

Current parts:

Nview MediaPro LCD panel

4 1/2 in elliposidal downlight reflector

diffuser lens from Elmo HP A305

triplet objective lens from Elmo HP A305

fresnel from Elmo HP A305

400 Watt MH BT 28 bulb with MultiTap M59 ballast

My setup will be very similar to Marlakar's, but hopefully smaller!

J

For those of you who would like to use multiple lamps to get more light: Couldn't we setup the lamps behind a fresnel that would catch almost all their light, and focus it, and then at the focal point, we could put a diffusing lense (I am sure this isn't the right word, but I don't know the name of it), like the ones in the Elmos HP A305's, and 3M 9550 OHP's. For those of you who haven't seen these diffuser lenses, these lenses are real thick and go right in front of the bulbs in these projectors. This technique would conentrate relatively diffuse light, and then diffuse it out onto another fresnel, and the LCD panel.

Lamps Fresnel Diffuser Fresnel LCD Objective

} |

} | ) | LCD ()(

} |

This should allow you to use multiple light sources without hotspotting, I think.....

An update on my work: I got a fresnel, a diffuser lens and an objective lens from Inventory Solutions on Friday. I now have everything I need to build the projector. The objective I got has a variable focal length, you just rotate the mount to change the focus. This means I woun't have to have a moving part to the front of my box, which is a key!

Current parts:

Nview MediaPro LCD panel

4 1/2 in elliposidal downlight reflector

diffuser lens from Elmo HP A305

triplet objective lens from Elmo HP A305

fresnel from Elmo HP A305

400 Watt MH BT 28 bulb with MultiTap M59 ballast

My setup will be very similar to Marlakar's, but hopefully smaller!

J

forgot to add this

I was at Advance autoparts the other day, and noticed that they have chrome tape. It is very shiny tape, that could be used as part of a reflector, I think.

they also had aluminum tape, but not as shiny.

If you get a good mold, you could just use this tape? Not sure how well it would stand up to heat, though.

J

I was at Advance autoparts the other day, and noticed that they have chrome tape. It is very shiny tape, that could be used as part of a reflector, I think.

they also had aluminum tape, but not as shiny.

If you get a good mold, you could just use this tape? Not sure how well it would stand up to heat, though.

J

Where did Redevil Go? I`d like to find out more about his projector. If he`s getting a really good image, then ignoring his ideas would be really dumb...

Concerning new ideas of reflectors: You guys should do a google search for 'solar cooker'. There are a lot of reflectors out there...!

Well, if they are good enough for optical instruments is another question, but it's worth a look!

xblocker

Well, if they are good enough for optical instruments is another question, but it's worth a look!

xblocker

woneill said:Even a crude and simple arrangement such as this would be better than most of the existing reflectors out there

I guess the only real reason for pursuing our own reflector is to allow us to try optimizing the light from the 'cheap' 400w MH bulbs.

Got another question, but being that its reflector oriented, I'll take it over to the reflector thread.

My latest creation. $8 and 3 hours.

I havent mounted the bulb permanently in it yet. But, its going to be easy. Plastic planter and a plastic bowl, purchased at Walmart for $1.97 and $.50, respectively. I also havent done any testing with it yet (havent even hooked up the bulb.

But, it looks very promising.

An externally hosted image should be here but it was not working when we last tested it.

I havent mounted the bulb permanently in it yet. But, its going to be easy. Plastic planter and a plastic bowl, purchased at Walmart for $1.97 and $.50, respectively. I also havent done any testing with it yet (havent even hooked up the bulb.

But, it looks very promising.

couple more pics.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Redevil,

I have some questions about your particular design.

How long is the entire structure? What is the distance between the two fresnal lenses you use for light dispersion?

Also, what size is your LCD? I want to use a 14", but I have a 3 7/8" plano convexlens that was made for a Mitsubishi projection tv. Do you think that`ll be big enough to "suck in" the entire image of the 14", or will I need a bigger one?

Mitch

I have some questions about your particular design.

How long is the entire structure? What is the distance between the two fresnal lenses you use for light dispersion?

Also, what size is your LCD? I want to use a 14", but I have a 3 7/8" plano convexlens that was made for a Mitsubishi projection tv. Do you think that`ll be big enough to "suck in" the entire image of the 14", or will I need a bigger one?

Mitch

Adhesive solutions

A good heat resistent epoxy solution would be JBweld, it has been used in many automotive applications including use on the egine block. How much heat it can stand exactly I'm not sure.

I'm almost certain superglue would break down past 120 degrees fahrenheit . Also doesn't seem like it would bond well to foil. JBweld will bond to most anything.

I work for a tool store and have access to a huge resorce of knowlege, coming from experts in all aspects of hardware related fields. Feel free ask any questions such as the "quote" above, and I'll do my absolute best to get the answers you need.

You guys have been a great help in my own project (still on paper), and would like to contribute as much as possible.

mycamel said:

Any adhesive experts among us? What sort of heat does super-glue handle? Would it start producing toxic fumes after we'd been watching our TV a while? Are there any epoxies made for automotive repair that could handle the heat?

A good heat resistent epoxy solution would be JBweld, it has been used in many automotive applications including use on the egine block. How much heat it can stand exactly I'm not sure.

I'm almost certain superglue would break down past 120 degrees fahrenheit . Also doesn't seem like it would bond well to foil. JBweld will bond to most anything.

I work for a tool store and have access to a huge resorce of knowlege, coming from experts in all aspects of hardware related fields. Feel free ask any questions such as the "quote" above, and I'll do my absolute best to get the answers you need.

You guys have been a great help in my own project (still on paper), and would like to contribute as much as possible.

- Home

- General Interest

- Everything Else

- The Moving Image

- DIY Projectors

- DIY Video Projector Part II