Hi Hiten. That's exactly what I thought.

I have always thought good sound quality starts with maths that look right. Yesterday I stopped at the UK's larger DIY store Wicks. I bought a piece of wood I hadn't considered. 15 x 900 mm pine dowel. The 12mm was hopeless, the 15mm much stiffer. Mass is 2.315g / inch. That is 23.15g if 10 inch. That would be 17g if a 4 mm hole drilled. The cost about $1. The idea is to make this work without the pain of trying to be high end. For a start I have a broken Linn LVV arm and counterweight. Also a Rega R200 counterweight ( not RB ). The intention is to beat the Linn Ekos arm. I have a hunch it will. It will be a slightly unscientific test as it will be LP12 Ekos verses Garrard 401 and this arm. I am going out of my way to do a bad job on the bearings so as to truely know more. It would be easier to use a unipivot from day one. I own a Naim Aro arm which for now lives in Germany. I love the Aro. The test is to allow the Garrard to be heard, it's sound is like a LP12 with more solidity. The LVV always sounded detatched but OK. The modern Jelco also, although worse in a way. The conjecture is that the wood arm will help the modest bearings. I have a Lenco, TD124 and SP10. The Lenco will show a LP12 how to do the job and an SP 10 if I am honest. I don't have a Garrard 301, I could borrow one. And guess what, the 301 is my favourite. SNo 60 000 ( 50 000 to 90 000 ) and not the silly money Hammerite ones. I did make a Garrard clone in the past.

Most people who would copy the Schroeder arm will focus on the cord bearing. The wood seems to be of little interest or so it seems to me. Having heard very primitive wood arms they always seem to sound good. Garrard Lab 80 as used by one of the surviving Beatles is one. He isn't a drummer.

4/root Phi = Pi ( < 0.1% ).

I have always thought good sound quality starts with maths that look right. Yesterday I stopped at the UK's larger DIY store Wicks. I bought a piece of wood I hadn't considered. 15 x 900 mm pine dowel. The 12mm was hopeless, the 15mm much stiffer. Mass is 2.315g / inch. That is 23.15g if 10 inch. That would be 17g if a 4 mm hole drilled. The cost about $1. The idea is to make this work without the pain of trying to be high end. For a start I have a broken Linn LVV arm and counterweight. Also a Rega R200 counterweight ( not RB ). The intention is to beat the Linn Ekos arm. I have a hunch it will. It will be a slightly unscientific test as it will be LP12 Ekos verses Garrard 401 and this arm. I am going out of my way to do a bad job on the bearings so as to truely know more. It would be easier to use a unipivot from day one. I own a Naim Aro arm which for now lives in Germany. I love the Aro. The test is to allow the Garrard to be heard, it's sound is like a LP12 with more solidity. The LVV always sounded detatched but OK. The modern Jelco also, although worse in a way. The conjecture is that the wood arm will help the modest bearings. I have a Lenco, TD124 and SP10. The Lenco will show a LP12 how to do the job and an SP 10 if I am honest. I don't have a Garrard 301, I could borrow one. And guess what, the 301 is my favourite. SNo 60 000 ( 50 000 to 90 000 ) and not the silly money Hammerite ones. I did make a Garrard clone in the past.

Most people who would copy the Schroeder arm will focus on the cord bearing. The wood seems to be of little interest or so it seems to me. Having heard very primitive wood arms they always seem to sound good. Garrard Lab 80 as used by one of the surviving Beatles is one. He isn't a drummer.

4/root Phi = Pi ( < 0.1% ).

Hi guys,

Just had a look at this (for recreational purposes...🙂 after a long trip to the US.

Some comments:

Longer versions of arms like the SME 2012(vs. 3009) are usually perceived as sounding better for the reduced chance for bearing chatter(heavier counterweight = higher load on the knife edge and ball bearings). On some arms the additional friction will yield detrimentral results. More important is the reduced skating force required. Try using an SME 3009 with the counterweight of the 3012, lower the suggested skating compensation(or use none), then listen to a track near the Null points of the record. Now use a SME 3012, same cart, same counterweight, same skating compensation, same track. Hear a difference? 🙂

Tracing error related distorsion is predominantly second order harmonics. As Nigel pointed out, mere humans have a very hard time getting the overhang and offset angle consistently spot on. A mere 0,3mm difference in overhang and only 0,3° deviation from targeted offset will yield the geometric/distorsion difference between a 9 and a 12"er identical (vs. figures for perfect alignment)

Skating compensation offsets the cantilever, often by far more than what I quoted above. In addition, the pre-load on the cantilever results in a reduction of the rendering of micro and macro-dynamic contrast/shading.

Moving an arm across the radius of a record with a small motor based upon the speed of the platter would assume that the record was cut with constant pitch to assure maintanace of tangency(and you have to get it right from the start!).

All records produced after about 1955 are cut with variable pitch, so a constand feed would cause deviations from tangency likely larger than those stemming from well chosen "conventional" tonearmgeometries.

See here:

https://books.google.de/books?id=54...iable pitch record cutting introduced&f=false

Trying to make an extra long tonearm to reduce tracing error significantly, I can only say that one will compare apples with oranges. The fundamental resonance frequency of such a structure would be considerably lower, its energy storage higher and likewise the required damping. No scientific comparison possible unless the armwand/counterweight assembly exhibits a similar resonance spectrum... kinda impossible.

This should not discourage anyone, but please do not come to a generalized conclusion because you end up liking the looooong arm you just made better 🙂

@ Hiten: There a lots of free tonearm geometry calculators on the net. But when it comes to mounting a cartridge, you may have to deviate from what the arm's marking implies due to the cantilever being slightly offset within the cartidge body/generator or *the stylus contact zones not being at 90° with the cantilever(a quality microscope is needed for this assessment!). Obviously that* would be no problem if your cartridge features a spherical stylus...

Cheers,

Frank

Just had a look at this (for recreational purposes...🙂 after a long trip to the US.

Some comments:

Longer versions of arms like the SME 2012(vs. 3009) are usually perceived as sounding better for the reduced chance for bearing chatter(heavier counterweight = higher load on the knife edge and ball bearings). On some arms the additional friction will yield detrimentral results. More important is the reduced skating force required. Try using an SME 3009 with the counterweight of the 3012, lower the suggested skating compensation(or use none), then listen to a track near the Null points of the record. Now use a SME 3012, same cart, same counterweight, same skating compensation, same track. Hear a difference? 🙂

Tracing error related distorsion is predominantly second order harmonics. As Nigel pointed out, mere humans have a very hard time getting the overhang and offset angle consistently spot on. A mere 0,3mm difference in overhang and only 0,3° deviation from targeted offset will yield the geometric/distorsion difference between a 9 and a 12"er identical (vs. figures for perfect alignment)

Skating compensation offsets the cantilever, often by far more than what I quoted above. In addition, the pre-load on the cantilever results in a reduction of the rendering of micro and macro-dynamic contrast/shading.

Moving an arm across the radius of a record with a small motor based upon the speed of the platter would assume that the record was cut with constant pitch to assure maintanace of tangency(and you have to get it right from the start!).

All records produced after about 1955 are cut with variable pitch, so a constand feed would cause deviations from tangency likely larger than those stemming from well chosen "conventional" tonearmgeometries.

See here:

https://books.google.de/books?id=54...iable pitch record cutting introduced&f=false

Trying to make an extra long tonearm to reduce tracing error significantly, I can only say that one will compare apples with oranges. The fundamental resonance frequency of such a structure would be considerably lower, its energy storage higher and likewise the required damping. No scientific comparison possible unless the armwand/counterweight assembly exhibits a similar resonance spectrum... kinda impossible.

This should not discourage anyone, but please do not come to a generalized conclusion because you end up liking the looooong arm you just made better 🙂

@ Hiten: There a lots of free tonearm geometry calculators on the net. But when it comes to mounting a cartridge, you may have to deviate from what the arm's marking implies due to the cantilever being slightly offset within the cartidge body/generator or *the stylus contact zones not being at 90° with the cantilever(a quality microscope is needed for this assessment!). Obviously that* would be no problem if your cartridge features a spherical stylus...

Cheers,

Frank

Last edited:

Hi Berlinta. The point I really like is use a sperical ( forgive point and point ). It is incredibly hard to see a 0.25 mm error when involving a rake angle and yet all assumptions are based on that we can. Drawing the A4 paper triangle for the possible 16.5 inch arm is practical. I think we can see that? I forget the diviation that a human can see when given as paralell lines? I seem to remember it was a very small amount.

One assumption I made was when 16.5 inches the error due to no offset would be small. No, it is massive. The other assumption I made was 9 inch is useless. It is not. The 10 inch arm is an excellent compromise as it will fit on most decks. The mass should not be too high.

The 1 mm wall carbon fibre with foam inner looks good. Price is excellent. 500 mm looks very OK on mass. Hiten has put the idea into my head that a carbon fibre with wood arm could be made to work. I would love to have a 500 mm arm. I wouldn't have to say a word when people visit. Some said to me too large. Get a CD player if so or a JVC L3-E. The owner of the JVC came to Berlin in the summer. She was taking her boys to see the traffic light's and Olympic Stadium. I suspect the ice cream was overlooked as Colleen isn't an ice cream person. I have just won a bid on a JVC L5-E for my old boss for $70. Hope he uses it. If an LP12 he wouldn't bother. It is said to have the TT71/81 motor.

One assumption I made was when 16.5 inches the error due to no offset would be small. No, it is massive. The other assumption I made was 9 inch is useless. It is not. The 10 inch arm is an excellent compromise as it will fit on most decks. The mass should not be too high.

The 1 mm wall carbon fibre with foam inner looks good. Price is excellent. 500 mm looks very OK on mass. Hiten has put the idea into my head that a carbon fibre with wood arm could be made to work. I would love to have a 500 mm arm. I wouldn't have to say a word when people visit. Some said to me too large. Get a CD player if so or a JVC L3-E. The owner of the JVC came to Berlin in the summer. She was taking her boys to see the traffic light's and Olympic Stadium. I suspect the ice cream was overlooked as Colleen isn't an ice cream person. I have just won a bid on a JVC L5-E for my old boss for $70. Hope he uses it. If an LP12 he wouldn't bother. It is said to have the TT71/81 motor.

Thanks for the reply gentlemen.

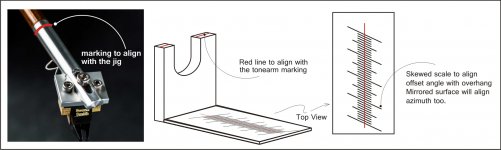

I was also thinking about a very very simple jig like attached drawing for the schroeder tonearm. This would be a 'L' shape jig on which tonearm rests. (Stylus not touching the base) The red line aligns with the marking on the tonearm. The scale is skewed to align the stylus with tonearm specific Offset. Overhang and azimuth can be aligned too.

If we are thinking about 16.5" tonearm I wonder why would it not be easy to move across regardless of gimble bearing or unipivot. Think about long archimedes lever. I guess this would be advantageous. Only condition being total weight, stability and resonance. Other thing I am curious is to deliberately adding some resistance to the thread twisting using different material thread to compensate for the bias. Which could work as antiskating.

Regards

I was also thinking about a very very simple jig like attached drawing for the schroeder tonearm. This would be a 'L' shape jig on which tonearm rests. (Stylus not touching the base) The red line aligns with the marking on the tonearm. The scale is skewed to align the stylus with tonearm specific Offset. Overhang and azimuth can be aligned too.

If we are thinking about 16.5" tonearm I wonder why would it not be easy to move across regardless of gimble bearing or unipivot. Think about long archimedes lever. I guess this would be advantageous. Only condition being total weight, stability and resonance. Other thing I am curious is to deliberately adding some resistance to the thread twisting using different material thread to compensate for the bias. Which could work as antiskating.

Regards

Attachments

...by resistance not like well tempered tonearm but a single thread which minutely resists the rotation.

That's a wonderful drawing and makes something difficult look easy. I will be very ashamed to show my version when made as it will look dreadful. If the sound is good that's 90% of the job done. It is very hard to make the cartridge fixing simpler. I have thought of one bolt only to fix and rotate. It might be better than people would imagine.

Nigel,

Are you talking about the Cosworth in a Vega??? 1970 somthing Automobile? Man, that takes me back! If only the seals held up better. Fantastic design, round n round.

Are you talking about the Cosworth in a Vega??? 1970 somthing Automobile? Man, that takes me back! If only the seals held up better. Fantastic design, round n round.

JVC DD tables (again)

Still not a fan of working with carbon fibre, please use proper safety precautions.

If you can believe the vintage knob , apparently the servo is attached on one side (not bi-directional), but otherwise the same as the TT81/TT101, so no slouch. Your boss should be very happy. Of course, I would encourage (perhaps) an arm rewire, and at least a new stylus if it comes with a cartridge. Is it a "P" mount? Sometimes folks need less finicky.

Hi Berlinta. The point I really like is use a sperical ( forgive point and point ). It is incredibly hard to see a 0.25 mm error when involving a rake angle and yet all assumptions are based on that we can. Drawing the A4 paper triangle for the possible 16.5 inch arm is practical. I think we can see that? I forget the diviation that a human can see when given as paralell lines? I seem to remember it was a very small amount.

One assumption I made was when 16.5 inches the error due to no offset would be small. No, it is massive. The other assumption I made was 9 inch is useless. It is not. The 10 inch arm is an excellent compromise as it will fit on most decks. The mass should not be too high.

The 1 mm wall carbon fibre with foam inner looks good. Price is excellent. 500 mm looks very OK on mass. Hiten has put the idea into my head that a carbon fibre with wood arm could be made to work. I would love to have a 500 mm arm. I wouldn't have to say a word when people visit. Some said to me too large. Get a CD player if so or a JVC L3-E. The owner of the JVC came to Berlin in the summer. She was taking her boys to see the traffic light's and Olympic Stadium. I suspect the ice cream was overlooked as Colleen isn't an ice cream person.

Still not a fan of working with carbon fibre, please use proper safety precautions.

I have just won a bid on a JVC L5-E for my old boss for $70. Hope he uses it. If an LP12 he wouldn't bother. It is said to have the TT71/81 motor.

If you can believe the vintage knob , apparently the servo is attached on one side (not bi-directional), but otherwise the same as the TT81/TT101, so no slouch. Your boss should be very happy. Of course, I would encourage (perhaps) an arm rewire, and at least a new stylus if it comes with a cartridge. Is it a "P" mount? Sometimes folks need less finicky.

Nigel,

Are you talking about the Cosworth in a Vega??? 1970 somthing Automobile? Man, that takes me back! If only the seals held up better. Fantastic design, round n round.

It was an analogy. Hesketh ran a Cosworth V8 at le Mans. Even though detuned it failed. My girl friend of old mother had a claim to fame. She was village police lady in Towcester. She was so fed up with the young Hesketh she smacked his bottom. Lady Hesketh thanked her. Those were the days. The Garrard 501 has parts made by Brian Garman who also worked at the same time for Keith Duckworth on microlights. I never met him, I guess I could have if I asked.

To save F1 I would insist on a generic Cosworth style short engine. Cylinder heads and fuel systems completely the choice of the team. Gearbox and runinig gear standard. Brakes and wheels team choice. Upper body and wings team choice. 70 % of the car could be of standard design from an elected supplier. No hybrid systems. No steering wheel remapping, just a reboot button. The engine power is unimportant as long as it is mostly the same. I would guess 30 BHP would be the maximum difference between teams. Even so 30 BHP is worth having. No turbo's, local fuel only supplied to all teams. Super unleaded would be fine. If the idea had a commercial side the short engine could be sold to anyone at a sensible price. There might be a choice of super light or road version. I have held the old Renault V10 in my hands and looked inside the valve gear. It was lovely, yet less well finished compared with my VW diesel.

About Schroeder arms. It is a protected design, so selling the results of this thread is totally impossible. That's why I have tried to say to people look at a wooden arms with lets say a unipivot bearing. Someone somewhere will be tempted to think it is no big deal to copy. Don't even start to think of it.

Stew. Warning taken on carbon fibre. If I am to make the party piece I suspect I have no choice. Having heard at home a mass loaded Schroeder carbon fibre is sounded wonderful, Tracy Chapman using Lyra Helikon comes to mind. This completely told me my total dislike of the material was not the sound of the carbon fibre. Now a big leap and one people should take serriously. It is what is wrong with the Schroeder design that might make carbon fibre possible. The wrong is that without all of Franks understanding it is actually a very very bad place to start from. To find the exact point between elasticity, plasticity and deformation doesn't look easy. To maintain it year in, year out is nearly impossible. The compromise is to work in the elastic range ( ??? ). I suspect that would allow carbon fibre to work well and all other choices. The elastic range is also able to cope with the energy. The Schroeder design is notable for how it shows the trailing edge of notes. It would be if you think about it. As I said before. You might copy a violin, did you copy the sound? The UK Open University measured a good violin. To their surprise it measured like a solid violin except with a considerable sound output. One could say the people had the maths inside them with no need on a computer. The maths being listen and adjust over generations.

Hiten. If you were building my 16.5 inch version how much wood and how much carbon fibre ? Perhaps 4 inches wood etiher end to make life easier ? Looks come into it.

Hiten. If you were building my 16.5 inch version how much wood and how much carbon fibre ? Perhaps 4 inches wood etiher end to make life easier ? Looks come into it.

.....Having heard at home a mass loaded Schroeder carbon fibre is sounded wonderful, Tracy Chapman using Lyra Helikon comes to mind.

Dear Nigel, I can remember this listening session as well🙂

And we learnt a lot back then. One lesson is, to cross check sonically

what really contributed to the "perfect" or at least perfected tracking

and what was just fiction. The discipline to alter one parameter at a time

and to go from there plus some inspiration do help.

I also strongly support health safety issues when cutting and milling materials

Thanks to the previous posts that keep making us aware of that.

This Thread is a joy to read!

Martina

Hi Nigel,

Three remarks:

An arm that has the ability to how the trailing egde of a note would have to be equally apt at accurately rendering the leading edge. My arms are, if I may say so, extremely good at "keeping things apart" when the signal gets very complex, - and that is the usual condition as i.e orchestral music has both(leading and trailing edge) present at all times.

The difficulty of building a perfectly functioning version of my arms has nothing to do with elasticity, plastictiy or deformation. The thread I have been using for years now is not elastic. It shouldn't be as the attractive force between two magnets is proportional to the square of the distance between them.

The real challenge is to find the right proportions(magnet height/diameter plus attachment point of thread) to allow for neutral balance operation. Almost all diy versions I have seen end of with a strongly stable balance arrangement(not good!), as this results in gross VTF changes when altering VTA.

Whenever I used CF, I did combine it with at least two other materials(CLD...) to counteract its negative traits. Most foams are not that well suited to "stuff" a CF armwand/tube. Though much better than nothing.....

Cheers,

Frank

Three remarks:

An arm that has the ability to how the trailing egde of a note would have to be equally apt at accurately rendering the leading edge. My arms are, if I may say so, extremely good at "keeping things apart" when the signal gets very complex, - and that is the usual condition as i.e orchestral music has both(leading and trailing edge) present at all times.

The difficulty of building a perfectly functioning version of my arms has nothing to do with elasticity, plastictiy or deformation. The thread I have been using for years now is not elastic. It shouldn't be as the attractive force between two magnets is proportional to the square of the distance between them.

The real challenge is to find the right proportions(magnet height/diameter plus attachment point of thread) to allow for neutral balance operation. Almost all diy versions I have seen end of with a strongly stable balance arrangement(not good!), as this results in gross VTF changes when altering VTA.

Whenever I used CF, I did combine it with at least two other materials(CLD...) to counteract its negative traits. Most foams are not that well suited to "stuff" a CF armwand/tube. Though much better than nothing.....

Cheers,

Frank

We truely loved that arm. I think it was the Helikon? If you remember Martina we had no sleep using it? I'm trying to get to Austria for the show. Must look at air tickets.

If you remember Julian my old boss, the JVC L5-E is for him. If it is workable you must listen to it. The L3-E is slightly nicer in some ways ( You know Colleen but probalbly don't remember her , She has the L3-E ). It is not unlike a Garrard and to me better than the 1210. The L3-E seems to play any warp.

Martina is a Jaguar expert, she won't tell you so I will. Engine in pieces photo's came my way to prove it.

Roy Gandy told me when I was 22 ( 59 now ) never change more than one thing at a time because you can never say you really know. He spent 6 weeks listening to nylon bolts on the Rega motor. People were doing up the metal ones for reasons best known to themselves and damaging the suspension. The nylon stopped that. The staff knew on day one it was OK, Roy wanted more time. Whilst I don't agree he should take that time it is better than guessing. Roy told me even then he had a 1 micron finish bearing when 6 was OK. He said " for some unknown reason people look at bearings and 1 micron costs only a tiny bit more ".

If you remember Julian my old boss, the JVC L5-E is for him. If it is workable you must listen to it. The L3-E is slightly nicer in some ways ( You know Colleen but probalbly don't remember her , She has the L3-E ). It is not unlike a Garrard and to me better than the 1210. The L3-E seems to play any warp.

Martina is a Jaguar expert, she won't tell you so I will. Engine in pieces photo's came my way to prove it.

Roy Gandy told me when I was 22 ( 59 now ) never change more than one thing at a time because you can never say you really know. He spent 6 weeks listening to nylon bolts on the Rega motor. People were doing up the metal ones for reasons best known to themselves and damaging the suspension. The nylon stopped that. The staff knew on day one it was OK, Roy wanted more time. Whilst I don't agree he should take that time it is better than guessing. Roy told me even then he had a 1 micron finish bearing when 6 was OK. He said " for some unknown reason people look at bearings and 1 micron costs only a tiny bit more ".

"Hi Frank,

can't you just put in a vacuum? Where there is nothing, there is nothing to vibrate, no?

Also maybe the outside air pressure stabilises and damps the arm?

Merry christmas,

Daniel"

Really? This is your contribution after telling me about stupid postings on diyaudio yesterday? What's the use of the above other than appearing like a troll yourself?

I'm outta here...

F.

can't you just put in a vacuum? Where there is nothing, there is nothing to vibrate, no?

Also maybe the outside air pressure stabilises and damps the arm?

Merry christmas,

Daniel"

Really? This is your contribution after telling me about stupid postings on diyaudio yesterday? What's the use of the above other than appearing like a troll yourself?

I'm outta here...

F.

Frank. I was trying to send people a curved ball ( Cricket, Baseball ) as they are questions that should be asked. Reality will send that ball.

There is a saying. " Amateurs Practice Until They Get It Right; Professionals Practice Until They Can’t Get It Wrong " Frank forgets a little that he has gone the full journey. There is one thing to add. Amateur implies someone who loves. Now can that be bad ?

( e power Pi ) - Pi = 20 to <0.05% e = 2722/1001 approx.

Number pattens are conspiricies theories I can proove. As in the above it is not 20. ( 4/ root Phi )= Pi in the ancient world could only seem true. And yet I don't think any fell into the trap. They had faith in their basic principles.

There is a saying. " Amateurs Practice Until They Get It Right; Professionals Practice Until They Can’t Get It Wrong " Frank forgets a little that he has gone the full journey. There is one thing to add. Amateur implies someone who loves. Now can that be bad ?

( e power Pi ) - Pi = 20 to <0.05% e = 2722/1001 approx.

Number pattens are conspiricies theories I can proove. As in the above it is not 20. ( 4/ root Phi )= Pi in the ancient world could only seem true. And yet I don't think any fell into the trap. They had faith in their basic principles.

Hi Nigel and Frank!

Quote:

"An arm that has the ability to how the trailing egde of a note would have to be equally apt at accurately rendering the leading edge. My arms are, if I may say so, extremely good at "keeping things apart" when the signal gets very complex, - and that is the usual condition as i.e orchestral music has both(leading and trailing edge) present at all times."

I totally aggree - to me Franks Arms are the very best arms I know of.

His Arms are above anything I can name.

I have rarely heard better "music" than with those -

Back then ( 2001 or 2002?) I had an Ortofon Rohman cartridge and the Lyra Helikon came later - I personally remember very well the listening tests.

Frank came back then for a visit and to replaced the carbon tube with a palisander tube and I enjoy this Schroeder till today - this particular arm is still one of my all time love affairs!

Martina

Quote:

"An arm that has the ability to how the trailing egde of a note would have to be equally apt at accurately rendering the leading edge. My arms are, if I may say so, extremely good at "keeping things apart" when the signal gets very complex, - and that is the usual condition as i.e orchestral music has both(leading and trailing edge) present at all times."

I totally aggree - to me Franks Arms are the very best arms I know of.

His Arms are above anything I can name.

I have rarely heard better "music" than with those -

Back then ( 2001 or 2002?) I had an Ortofon Rohman cartridge and the Lyra Helikon came later - I personally remember very well the listening tests.

Frank came back then for a visit and to replaced the carbon tube with a palisander tube and I enjoy this Schroeder till today - this particular arm is still one of my all time love affairs!

Martina

Frank. I remember a gentleman giving me a tour of vacuum enclosed clocks with temperature compenstaion and airpumps. You should have seen the delight on his face and mine. He knew my passion for accuracy in maths. The Harrison timepieces in Greenwich. If they get to be stolen search my house first.

Hi Nigel,

Please go back and read my last posting again. I was not referring to any of what you wrote. And I do consider myself an amateur in the original sense of the word 🙂

Check H4 closely when in Greenwich the next time. You'd be stealing what I exchanged a long time ago .... JUST KIDDING!!!

Now, unless there is a technical question that is actually referring to the title of this thread, I prefer to stay offline...

All the best,

Frank

Please go back and read my last posting again. I was not referring to any of what you wrote. And I do consider myself an amateur in the original sense of the word 🙂

Check H4 closely when in Greenwich the next time. You'd be stealing what I exchanged a long time ago .... JUST KIDDING!!!

Now, unless there is a technical question that is actually referring to the title of this thread, I prefer to stay offline...

All the best,

Frank

I know you Frank. With your skills and contacts I suspect the crime of the century has just been reported.

I don't envy you on this thread. You truely are a gentleman.

I don't envy you on this thread. You truely are a gentleman.

- Home

- Source & Line

- Analogue Source

- DIY Schroeder Tonearm?