My presentation was bad but I stick with the basic question: if one could manage to have a vacuum enclosed by the arm tube said tube would be compressed by atmospheric pressure (~ 1kg per square cm) which might have a non negligible impact on damping. Opinions?

Last edited:

I am not technically knowledgeable person. As a graphic designer, looks are important to me. I participate in different forums as I like learning about designs and its workings. For the wood I don't know the proportions. As it will depend on wood. But what ever material be it carbon fibre or wood; logic tells that the one which has more damping properties should be near the cartridge. Presuming wood has more damping so a roughly 4" of wood at the cartridge side and rest 12.5" carbon fibre to give stiffness would be all right. Isn't it ?

nigel, if we could see at least one arm you made.

In time. This will be a first as up to now I have always bought or swapped something. Usually I go to someone and say " make this ". As you say this time I must try no matter how poor it might be to do it myself. Yesterday I didn't give a dam what it looks like. Today I am questioning that. I think as I don't want this to get out of control I must stick with plan A, it will not look fantastic. I think I will use the one point cartridge fixing although not beautiful to look at. Plan A is the sound. My first engineering problem is the cartridge rotation ( ring, clamp. rotate, fix ? A ring collar perhaps ? ). I also want it to be very simple to build. The thing that changed my mind was being very disssapointed by the Jelco arms. They look wonderful and are a good price. I exspected better sound. One thing my arm might have is originality, that won't shame me. I am also rebuilding my house so time will be short. I was going to pay someone. Like this I must do it myself. I also work for two compaines, one full time in general engineering. In theory I retired two years ago.

In time. This will be a first as up to now I have always bought or swapped something.....................

I made two arms, one with my friend and one for me. Both work perfectly.

To me it is the simplest DIY and at the same time the best sounding arm.

Make at least one and show. You're wasting your time writing.

Perhaps you were looking to be admired for this arm? To a point yes. Maybe you are angry because someone wants to broaden the subject so it becomes a genuine project. If you copied the Mona Lisa would you be proud ? Yes, I guess you would be. Would you think the world would be proud for you also ? It's a fake, a copy, a knock off, a wax work. If you painted your wife in the style of the Mona Lisa, then already it's your own thing.

Would it have been so hard with your skills to produce something original ? You could say with your admiration of the Schroeder arm you have choosen to make something similar. Your's is an exact copy where possible. I am surprised something inside you isn't a little ashamed ? If the arm wasn't made these days, then I could understand.

Frank as I have said is a complete gentleman so will not tell you this. Not make and show. Design and show. Hiten seems to want to do this. I suspect all will choose the Schroeder route and nothing I have said will change that. It's called conversation. Conversation is often created by broadening the subject. If not we would have stopped this thread long ago. Hiten showed new ideas, he calls me sir. Call me Nige, most do. Hiten unlike me can show as he has the tools to show it as if real. Hiten please finish your ideas. If nothing else we got that from saying what if? Bigger sorry to Frank as I am sure he would say to me don't bother to say anything except about his protected design.

No real hard feelings towards you. You can do better and you should know it. When will we see your first design? If it is wonderful I will be the first to say, I don't hold grudges.

Would it have been so hard with your skills to produce something original ? You could say with your admiration of the Schroeder arm you have choosen to make something similar. Your's is an exact copy where possible. I am surprised something inside you isn't a little ashamed ? If the arm wasn't made these days, then I could understand.

Frank as I have said is a complete gentleman so will not tell you this. Not make and show. Design and show. Hiten seems to want to do this. I suspect all will choose the Schroeder route and nothing I have said will change that. It's called conversation. Conversation is often created by broadening the subject. If not we would have stopped this thread long ago. Hiten showed new ideas, he calls me sir. Call me Nige, most do. Hiten unlike me can show as he has the tools to show it as if real. Hiten please finish your ideas. If nothing else we got that from saying what if? Bigger sorry to Frank as I am sure he would say to me don't bother to say anything except about his protected design.

No real hard feelings towards you. You can do better and you should know it. When will we see your first design? If it is wonderful I will be the first to say, I don't hold grudges.

My presentation was bad but I stick with the basic question: if one could manage to have a vacuum enclosed by the arm tube said tube would be compressed by atmospheric pressure (~ 1kg per square cm) which might have a non negligible impact on damping. Opinions?

Hi again,

Apart from the problem of having to route the wiring differently(than through the wand), the outward increase in (air)pressure would change/raise the fundamental structural resonance frequency, so it would likely be audible. It would not increase damping per se(could be better or worse), but make damping easier. Either put a layer of heavy-ish and/or compliant material around the outside(which would lower the fundamental fres again, - dang...) or use a movable mass/collar, compliantly coupled, to find the most effective damping "spot".

Armwands with considerable inherent/self-generated pressure/tension have been used commercially, either made from glass or ceramic. They do exhibit a significantly smaller tendency to ring(compared to regular, tempered glass/ceramic tubes).

Best,

Frank

Hope no one minds a little explanation. Knowledge should be respected so I address as sir. An old Indian tradition. As for designs trust me as a creative person I want to add something of my own. Thats why such posts and queries. In another forum I posted a magnetically floating Aerogel cone speaker design. Which was doubtful to work. Couple of linear tonearm designs are posted here. which may or may not work. Not sure unless built. I also have in my mind a damped unipivot tonearm; where liquid would work as antiskating and stabizer of tonearm. Will try to post it.

Regards.

Regards.

Hiten, I did know that and I was very touched that you did. Thank you Sir . Would love to see your ideas. The " not sure unless built" is a voice I know from inside myself. Don't share too much as some ideas you have seem rather special. An improved uni-pivot will always be interesting.

Oops, that:

"compared to regular, tempered glass/ceramic tubes"...

was supposed to read: compared to regular, non-tempered ....."

Still jet-lagged...

Frank

"compared to regular, tempered glass/ceramic tubes"...

was supposed to read: compared to regular, non-tempered ....."

Still jet-lagged...

Frank

Good day folks...

...thought I'd stick my neck out (again).

First of all I have never made, nor plan to make a clone of a tonearm, except my own 219, which is really just an Altmann "joke" tonearm as seen here, just scroll down the page. I wanted a "refined" version, using better materials that were (relatively) easy to get.

I view Frank's input as a great value, but more so for illustrative purposes and for the stimulus to myself to ask myself questions. Is the Schroeder arm good (or even great)? I can't say, because I've never heard one nor seen one in the flesh. In the (small-ish) city where I live (southern Alberta, Canada), it's pretty rare to see anything "special". I own an old Oracle Alexandria MkII with an SME309. I know a fellow who owns a Kuzma Stabi/Stogi combination and a Transcriptors Skeleton turntable and tonearm (from 1973 or so IIRC). A few folks I know own LP12s, or Aristons, or Regas, etc. Fewer still with Roksan, Heybrook and Systemdek, etc.

So rather than look to Frank to provide a line by line instruction set to build one of his arms, perhaps we ought to look at the process that he uses. Again I must restate that unless you have a known quantity (in my case the 309), it is very difficult to do comparisons. And we need those comparisons! I know my arms (both the 309 and 219) are not perfect, but the 309 is good enough and well known that I can make comparisons to it and know that they are valid.

So guys, until you have extended personal knowledge of a well known and well reviewed or thought of tonearm, all comments are really moot.

BTW: I do have a Garrard "Zero" tonearm on a Garrard SB100 turntable that is just begging to be re-made using similar materials to the 219. That could be pretty interesting, but would be better posted elsewhere .

...thought I'd stick my neck out (again).

First of all I have never made, nor plan to make a clone of a tonearm, except my own 219, which is really just an Altmann "joke" tonearm as seen here, just scroll down the page. I wanted a "refined" version, using better materials that were (relatively) easy to get.

I view Frank's input as a great value, but more so for illustrative purposes and for the stimulus to myself to ask myself questions. Is the Schroeder arm good (or even great)? I can't say, because I've never heard one nor seen one in the flesh. In the (small-ish) city where I live (southern Alberta, Canada), it's pretty rare to see anything "special". I own an old Oracle Alexandria MkII with an SME309. I know a fellow who owns a Kuzma Stabi/Stogi combination and a Transcriptors Skeleton turntable and tonearm (from 1973 or so IIRC). A few folks I know own LP12s, or Aristons, or Regas, etc. Fewer still with Roksan, Heybrook and Systemdek, etc.

So rather than look to Frank to provide a line by line instruction set to build one of his arms, perhaps we ought to look at the process that he uses. Again I must restate that unless you have a known quantity (in my case the 309), it is very difficult to do comparisons. And we need those comparisons! I know my arms (both the 309 and 219) are not perfect, but the 309 is good enough and well known that I can make comparisons to it and know that they are valid.

So guys, until you have extended personal knowledge of a well known and well reviewed or thought of tonearm, all comments are really moot.

BTW: I do have a Garrard "Zero" tonearm on a Garrard SB100 turntable that is just begging to be re-made using similar materials to the 219. That could be pretty interesting, but would be better posted elsewhere .

I understand what you are saying. Whatever I learned is from forums and articles. I would be happy and honoured if designs has some kind of inspiration. No problem at all. I will think of some other design. If I let go I am free. 🙂Would love to see your ideas. The " not sure unless built" is a voice I know from inside myself. Don't share too much as some ideas you have seem rather special. An improved uni-pivot will always be interesting.

Regards.

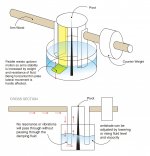

I guessed it wrong that drawing of new tonearm would be easy. It turned out little lengthy. An hours and half's work. Hope the drawing explains the idea. Three basic highlights are any vibrations or resonance will not get through unless it passes through the fluid. And horizontal paddle makes tonearm tortionally stable if we think about changing azimuth point of view. But will not affect the lateral movement. Antiskate can be adjusted by fluid level and viscocity. Hope this is worth exploring.

Regards.

Regards.

Attachments

I guessed it wrong that drawing of new tonearm would be easy. It turned out little lengthy. An hours and half's work. Hope the drawing explains the idea. Three basic highlights are any vibrations or resonance will not get through unless it passes through the fluid. And horizontal paddle makes tonearm tortionally stable if we think about changing azimuth point of view. But will not affect the lateral movement. Antiskate can be adjusted by fluid level and viscocity. Hope this is worth exploring.

Regards.

Why can we just do 4 points as Kuzma's? It is simple and effect.

I myself like carbon fiber. To my ear, it is the most natural sounding material. Wood may colorize the sound. The expensive and wonderful sounding AT arm is another proof. If you really want to use wood, African blackwood may be your best choice. Anyway, the material you chose depends on the construction of your arm, too.

https://www.gyroscope.com/d.asp?product=INVERTERMAGNET

Considering how to use magnets in a unipivot arm similar to schroeder. Wondering if there's anyway to take advantage of this small 'tractor beam gap' created by this magnet arrangement. Perhaps one mounted above the arm pivot and the other in the arm itself to act as a downward force. Or perhaps capture the pivot point in between some magnetic force?

Considering how to use magnets in a unipivot arm similar to schroeder. Wondering if there's anyway to take advantage of this small 'tractor beam gap' created by this magnet arrangement. Perhaps one mounted above the arm pivot and the other in the arm itself to act as a downward force. Or perhaps capture the pivot point in between some magnetic force?

i would think one could scale down the strength/size since it seems it's the arrangement and proportion that is key. But maybe it could be used even 'sideways' to give the unipivot some lateral stability using that approx 1/8" 'tractor force'...........or maybe some other use......I know this is not what shoreder is using magnets for but just an idea......I'm still trying to figure out exactly what shroeder is doing with magnets and what purpose they serve. This is a looooong thread that I only just stumbled on. I've got a carbon fiber golf club and am ready to try and fashion a nice simple light and delicate unipivot that betters the basic rega rb300 or acos lustre. I think it's possible but still trying to figure out how to utilize magnets and also need to source the bearing and 'point'. would a 16 penny nail suffice I wonder what people are using for their points and bearings....

https://www.youtube.com/watch?v=IkXrxR2HssY

https://www.youtube.com/watch?v=IkXrxR2HssY

Last edited:

- Home

- Source & Line

- Analogue Source

- DIY Schroeder Tonearm?