Funny you should say that- my surname is 'Green'

The rod is 12mm and (so far) appears to work very well

The rod is 12mm and (so far) appears to work very well

For dimensions,

The 12mm tube will require a 5-6mm bearing spacing, a 10mm tube is 4-5mm. Bearings should be loose enough to slide easily across the shim when not riding the tube.

Colin

Thank You !! very clear answer .. now I feel confident to proceed with the carriage works tomorrow .. as for now

Thanks again ,

Paul

Funny you should say that- my surname is 'Green'

The rod is 12mm and (so far) appears to work very well

Were you using a 10mm rod previously? If so, then wouldn't you have changed your VTA unless you changed the height of the rod, thus the change in sound? Does it give the same results on different vinyl thickness? Kind of curious about this as I am trying to come up with a mechanism that would be easy to build and not overly expensive to change the vertical tracking angle.

one more Q :

I'm realy wondering how tide , or loose the bearing should slide across the bras rod

Paul

Paul,

It`s a Round Brass Tube 3/16" x 0.014" a perfect slide, inner and outer!!!

I ordered it in the UK K & S 129 Round Brass Tube (1 piece) 3/16" x 0.014" x 12" New | eBay

I d`nt know where to buy in Holland, so...................

Hans.

Last edited:

Were you using a 10mm rod previously? If so, then wouldn't you have changed your VTA unless you changed the height of the rod, thus the change in sound? Does it give the same results on different vinyl thickness? Kind of curious about this as I am trying to come up with a mechanism that would be easy to build and not overly expensive to change the vertical tracking angle.

you can also buy them, search " concave Yo Yo bearings "

Many thanks !

What I can do myself I don't buy.

But is there any benefit to do that ?

Hi

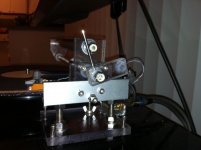

Look at my pictures. The whole assembly is mounted on a single 3/16" threaded rod. Very simple:

Simple to mount and align as only one hole needed

Very rigid

Makes adjusting VTA a very simple process of screwing the nuts up and down the thread

Genius.........

Look at my pictures. The whole assembly is mounted on a single 3/16" threaded rod. Very simple:

Simple to mount and align as only one hole needed

Very rigid

Makes adjusting VTA a very simple process of screwing the nuts up and down the thread

Genius.........

My technique for Vta and arm levelling. For Vta a double barrelled rigid dual bolt and nuts to raise or lower and lock Vta. The Allen key bolts at side top two lock arm level, the bottom hex bolt raises or lowers the bar level. I liked the idea of the somewhat substantial lexan base, this gives a secure footing on which to mount the arm and also aids in decoupling it from the rest of the turntable, though it will have partial coupling through the small Allen key base levelling bolts and the arm mounting bolt.

Colin

Colin

Attachments

this may provide soem inspiration

Vertical Tracking Angle on the Fly (VTAF)

Best regards Moray James.

Were you using a 10mm rod previously? If so, then wouldn't you have changed your VTA unless you changed the height of the rod, thus the change in sound? Does it give the same results on different vinyl thickness? Kind of curious about this as I am trying to come up with a mechanism that would be easy to build and not overly expensive to change the vertical tracking angle.

Vertical Tracking Angle on the Fly (VTAF)

Best regards Moray James.

Paul,

It`s a Round Brass Tube 3/16" x 0.014" a perfect slide, inner and outer!!!

I ordered it in the UK K & S 129 Round Brass Tube (1 piece) 3/16" x 0.014" x 12" New | eBay

I d`nt know where to buy in Holland, so...................

Hans.

Hi Hans ,

I can make the rod out of any available material myself on my lathe , so no need to order .

I'm thinking of a solid 6MM brass or bronze rod to serve as slider for the carriage bearings . got some neat unshielded roller bearings .

( 6MM I.D. / 10MM O.D. )

The reason to opt for a solid rod is for better precision and perpendicular mounting onto the carriage . not sure however if it will work out as for the

total weight of the carriage . will have to figure that too .

THX ,

Paul

it became brass 🙂 and of course the idea of a solid rod would'nt work in reality given the minute dimensions 😱

all together ... took me an hour with the lathe to fabricate . P.O.C. 😀

Now up to work the other stuff .

Paul

all together ... took me an hour with the lathe to fabricate . P.O.C. 😀

Now up to work the other stuff .

Paul

Attachments

Last edited:

Paul,Hi Hans ,

I can make the rod out of any available material myself on my lathe , so no need to order .

I'm thinking of a solid 6MM brass or bronze rod to serve as slider for the carriage bearings . got some neat unshielded roller bearings .

( 6MM I.D. / 10MM O.D. )

The reason to opt for a solid rod is for better precision and perpendicular mounting onto the carriage . not sure however if it will work out as for the

total weight of the carriage . will have to figure that too .

THX ,

Paul

Have no fear your solid rod will work just fine. Check back in my posts for a description of my bearing mounts from turned down aluminum stock and simple interference fit positioning rings. Glad to see someone else doing it this way. You can save a bit of weight by drilling them out as well.

BillG

SS Rod & VTAF

Lurking and collecting parts for some time now, I'm much enthused by ChrisG's steel rod experiment (#650). Last week I ordered from Amazon "17-4 Stainless Steel Round Rod, Annealed/Ground, ASTM 5643, 0.375" Diameter, 12" Length" at a cost of $11.30 (photo attached). I've also got some 10mm diameter borosilicate tubing coming with that order.

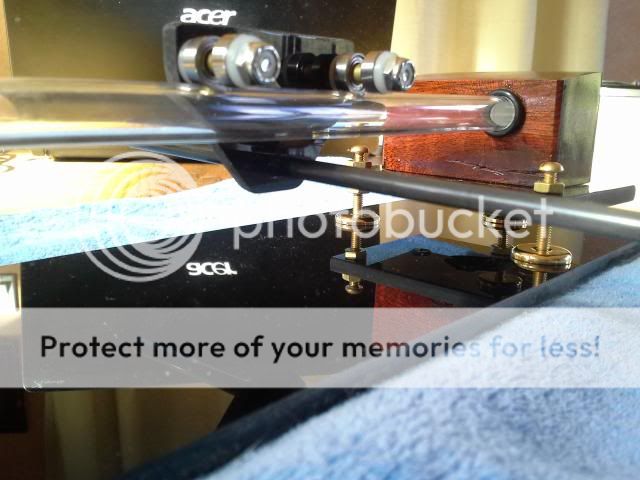

Moray James (#669) referenced the "VTAF" device for use in VTA adjustment. I'm just completing a complete redo of my Teres Kit turntable and venerable Black Widow tonearm (photo attached). Please note my custom VTAF modifications to get it to work with the Black Widow. It is NOT cheap either. Please note that there is NO complaint by me against Pete Riggle here. The VTAF requires a separate 'vertical' section to keep the tonearm from twisting horizontally when adjusting - and, the tonearm is essentially loose in the VTAF threaded section. You can see the gap between the BW and the copper fittings in the photo.

BTW, Honduras Rosewood is the hardess and most dense wood I've ever come into contact with - it smells sweet when being worked.

John Whittaker

Lurking and collecting parts for some time now, I'm much enthused by ChrisG's steel rod experiment (#650). Last week I ordered from Amazon "17-4 Stainless Steel Round Rod, Annealed/Ground, ASTM 5643, 0.375" Diameter, 12" Length" at a cost of $11.30 (photo attached). I've also got some 10mm diameter borosilicate tubing coming with that order.

Moray James (#669) referenced the "VTAF" device for use in VTA adjustment. I'm just completing a complete redo of my Teres Kit turntable and venerable Black Widow tonearm (photo attached). Please note my custom VTAF modifications to get it to work with the Black Widow. It is NOT cheap either. Please note that there is NO complaint by me against Pete Riggle here. The VTAF requires a separate 'vertical' section to keep the tonearm from twisting horizontally when adjusting - and, the tonearm is essentially loose in the VTAF threaded section. You can see the gap between the BW and the copper fittings in the photo.

BTW, Honduras Rosewood is the hardess and most dense wood I've ever come into contact with - it smells sweet when being worked.

John Whittaker

Attachments

Has anyone found out what the coefficient of friction should be for the carriage assembly.

I do not think my bearings are the right ones as I am getting a coefficient of friction of 0.1.

I am tilting the rod when the carriage just starts moving. I get a tilt angle of 6 degrees.

Regds

I do not think my bearings are the right ones as I am getting a coefficient of friction of 0.1.

I am tilting the rod when the carriage just starts moving. I get a tilt angle of 6 degrees.

Regds

How are you making the connection between the glass tube and wood/plastic that is holding it?

Is it just a tight hole or is it glued in or something else?

Is it just a tight hole or is it glued in or something else?

The glass tube is tightly fitted to a MDF stand. I have not glued it yet.

I am using a 12.5mm dia CFL tube, which I know may not be the right material. Till I get a proper glass tube or printer rod, I wanted to experiment with the CFL tube because it is readily available.

I am using a 12.5mm dia CFL tube, which I know may not be the right material. Till I get a proper glass tube or printer rod, I wanted to experiment with the CFL tube because it is readily available.

PDRCanada,

Judging by the pics it looks like a rather long arm?, with mechanical bearings I have tried this to clear the platter with little success but rather a displaced stylus 🙁. The arm wand is best kept to 2-2.5", for best results.

On another note its great to see all of the builds happening, And the evolution of the concept whether for better or worse, once again the great part of the DIY audio is that we can take a few backwards and some forwards steps in the name of learning and palpable sonic results 🙂.

Colin

Judging by the pics it looks like a rather long arm?, with mechanical bearings I have tried this to clear the platter with little success but rather a displaced stylus 🙁. The arm wand is best kept to 2-2.5", for best results.

On another note its great to see all of the builds happening, And the evolution of the concept whether for better or worse, once again the great part of the DIY audio is that we can take a few backwards and some forwards steps in the name of learning and palpable sonic results 🙂.

Colin

Colin, the arm isnt to size, just a dry fit piece about 8" long.

I wanted to see the carriage roll. have found that my nylon

washers are a bit large and interfere with the bearings action.

Will need to source smaller or modify the ones I have.

What are you guys coming up for measurements from needle

to center of the tube? roughly. If the wand is 2.5" the needle is

another inch or so?

Is there an advantage to having the front and back of the arm

on one plane, or is it better to break it and raise the back?

Thanks for any light you guys can shed.

Perry

I wanted to see the carriage roll. have found that my nylon

washers are a bit large and interfere with the bearings action.

Will need to source smaller or modify the ones I have.

What are you guys coming up for measurements from needle

to center of the tube? roughly. If the wand is 2.5" the needle is

another inch or so?

Is there an advantage to having the front and back of the arm

on one plane, or is it better to break it and raise the back?

Thanks for any light you guys can shed.

Perry

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm