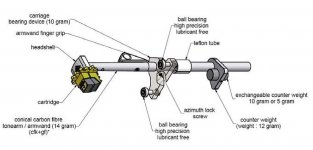

carbon tube / polycarbonate carriage

This is going to work out far better 😛 14 Gramm w/o cart and CW .

Paul

This is going to work out far better 😛 14 Gramm w/o cart and CW .

Paul

How about something like that for the carriage T part?

Real Carbon Fibre/Fiber Flat Sheet in 3mm A4 (Rigid Panel Not Vinyl Wrap) | eBay

Real Carbon Fibre/Fiber Flat Sheet in 3mm A4 (Rigid Panel Not Vinyl Wrap) | eBay

Golana,

Exactly as it states, platter top to bottom of glass tube.

Polycarbonate is great stuff, easy to work with, easy to cut and holds its shape well. It's also light, and stiff enough for this use.

Colin

Exactly as it states, platter top to bottom of glass tube.

Polycarbonate is great stuff, easy to work with, easy to cut and holds its shape well. It's also light, and stiff enough for this use.

Colin

Last edited:

Yesterday I spent almost the entire evening looking for bearings on various RC shops... It seems that 9mm outer diameter is pretty uncommon for RC cars. I think only Kyosho has something close to 10mm. Not to mention that non-Chinese ones are OMG expensive...

Add to that the crisis that makes everyone here reduce their stock...

So I came home empty handed...

At least one of the shop owners was kind enough to point me to a local SKF dealer. SKF seems to be the supplier for the cantus bearings as well, so this sounds nice. Unfortunately those industry oriented shops are open only on office hours, so I have to wait till Monday to check it out.

But a look at their range is very interesting.

What almost immediately caught my eye are linear bearings which sound very promising, and industrial hardened axles which are designed to be harder than the bearings.

The axle stuff is pretty self-explanatory and might add to the total rigidity of the thing without the need for inner thread or additional rigidity rods.

The linear bearings also sound nice. Some research showed that they tend to be a bit on the stiff side, but I think this can be overcome by using an oversized one and let it hang on the rod.

Anyway. Even if you do not feel adventurous enough to experiment, the SKF rods and bearings are definitely worth a look. I just hope that their pricing will be reasonable 🙂

Add to that the crisis that makes everyone here reduce their stock...

So I came home empty handed...

At least one of the shop owners was kind enough to point me to a local SKF dealer. SKF seems to be the supplier for the cantus bearings as well, so this sounds nice. Unfortunately those industry oriented shops are open only on office hours, so I have to wait till Monday to check it out.

But a look at their range is very interesting.

What almost immediately caught my eye are linear bearings which sound very promising, and industrial hardened axles which are designed to be harder than the bearings.

The axle stuff is pretty self-explanatory and might add to the total rigidity of the thing without the need for inner thread or additional rigidity rods.

The linear bearings also sound nice. Some research showed that they tend to be a bit on the stiff side, but I think this can be overcome by using an oversized one and let it hang on the rod.

Anyway. Even if you do not feel adventurous enough to experiment, the SKF rods and bearings are definitely worth a look. I just hope that their pricing will be reasonable 🙂

Hi,

dimkkasta:

If you put "diy linear bearing tonearm" in You Tube you will find someone who has done this a while ago and seems to work.

I think the linear bearing is too heavy when you add the carriage, arm and cartridge.

Joe

dimkkasta:

If you put "diy linear bearing tonearm" in You Tube you will find someone who has done this a while ago and seems to work.

I think the linear bearing is too heavy when you add the carriage, arm and cartridge.

Joe

Thanks for that post Calvin, if, and only if those specs are accurate this places the horizontal mass at 30g plus before cartridge, I'm willing to bet this arm wasn't designed around high compliance cartridges since essentially they are a thing of the past in many regards. The majority of existing carts are mid to low compliance anyways now, with perhaps the exception of the Shure m97 since the v15 is no more.

Colin

Colin

Clearaudio TT1

Another interesting document from Clearaudio is their patent on the TT1. Worthwhile reading:

https://depatisnet.dpma.de/DepatisNet/depatisnet?action=pdf&docid=DE102006052913B3

Wilfried

Another interesting document from Clearaudio is their patent on the TT1. Worthwhile reading:

https://depatisnet.dpma.de/DepatisNet/depatisnet?action=pdf&docid=DE102006052913B3

Wilfried

I think the linear bearing is too heavy when you add the carriage, arm and cartridge.

Joe the LBBR3 bearing from SKF is 0.7gr according to the pdf, while the 3x10x4 simple bearing is 1.5gr... and we need 2 or 4 🙂

OK the shaft for LBB3 has to be 3mm, but only the screws and the nuts on Cantus design should weigh more than that. In fact, 2x m3 screws 20mm long and 2 nuts weigh for me 1,8gr. Add to that 6 grams for the bearings ( from the skf pdf) and we go to 7,8grams, still with no washers or brass tubing.

So not counting some stuff, we could use the LBBR 8 for an 8mm rod and still be on slightly less weight. Not to mention that the T polycarbonate part does not have to be that big any more.

Anyway. I do not mean to hijack the thread. I am just exploring different and maybe simpler approaches since I am having trouble finding the bearings locally. Since I am going to the industrial parts store, I might as well check the options there 🙂

I will probably build both eventually 🙂

What troubles me is that linear bearings usually run tightly on the rod, and that they have a breaking in period. Perhaps a 8mm bearing on a 7mm rod?

Dimkasta;

There is no doubt that this type of bearing will work in linear tonearm. There are 4 videos on You Tube showing that it tracks well--even large warps in the record.

These bearings were designed to be used as a match between the bearing and the rod. If you use an 8mm bearing on a 7mm rod you will open up a another can of worms I believe.

I think you will have bearing noise/chatter to contend with as a result.

I say give it a shot. Those bearing/rods are not expensive and have very good tolerances. If you can " cherry pick " among a couple of samples you may find a magic combination that yields a tight fit and very low friction. Best of luck.

Joe

There is no doubt that this type of bearing will work in linear tonearm. There are 4 videos on You Tube showing that it tracks well--even large warps in the record.

These bearings were designed to be used as a match between the bearing and the rod. If you use an 8mm bearing on a 7mm rod you will open up a another can of worms I believe.

I think you will have bearing noise/chatter to contend with as a result.

I say give it a shot. Those bearing/rods are not expensive and have very good tolerances. If you can " cherry pick " among a couple of samples you may find a magic combination that yields a tight fit and very low friction. Best of luck.

Joe

carbon / polycarbonate

Hi there ,

I have attached two shots of the current brew . still some work to do but this is my first attempt . it weighs a very little over 28 Gram incl. a Stanton XV15 body .

There's space on the T-bar to drill a couple 6MM holes .. just in case I'd be in need for further loss of weight . 😀

As for now ... I'm lurking to try the 6MM carbon tube to serve as bearing shims . that would again save weight .. though I'm not sure if it works out .. will see 😀

Also .. I'm at the point where I should start thinking about the right wiring ..

i.e. minimal friction , souplesse , quality etc.

THX for looking and any inputs will be appreciated of course !!

Hi there ,

I have attached two shots of the current brew . still some work to do but this is my first attempt . it weighs a very little over 28 Gram incl. a Stanton XV15 body .

There's space on the T-bar to drill a couple 6MM holes .. just in case I'd be in need for further loss of weight . 😀

As for now ... I'm lurking to try the 6MM carbon tube to serve as bearing shims . that would again save weight .. though I'm not sure if it works out .. will see 😀

Also .. I'm at the point where I should start thinking about the right wiring ..

i.e. minimal friction , souplesse , quality etc.

THX for looking and any inputs will be appreciated of course !!

Attachments

Nice one 🙂

For wiring I can vouch for cardas litz shielded. You would have to run it unshielded for the most length though to allow the arm to move freely.

I also liked some 33AWG medical grade silver wire I found on a local shop.

For wiring I can vouch for cardas litz shielded. You would have to run it unshielded for the most length though to allow the arm to move freely.

I also liked some 33AWG medical grade silver wire I found on a local shop.

spinning wheel:

You have done a nice job on the arm. The carbon fiber tube shim will work and save weight at the same time so long as it lets the bearings roll freely. You should shorten the rear part of the arm and use a brass or bronze counter weight and get it as close to the pivot point as possible. When you are happy with the performance/weight of the carriage you can always reconstruct it out of solid carbon fiber to make the whole assembly as light as possible if you wanted.

Joe

You have done a nice job on the arm. The carbon fiber tube shim will work and save weight at the same time so long as it lets the bearings roll freely. You should shorten the rear part of the arm and use a brass or bronze counter weight and get it as close to the pivot point as possible. When you are happy with the performance/weight of the carriage you can always reconstruct it out of solid carbon fiber to make the whole assembly as light as possible if you wanted.

Joe

Joe,

This is not a regular pivoted arm,the same rules don't apply. You don't want a heavier weight nearer the pivot here, not only because of lateral mass but because a heavier weight nearer the pivot lowers the vertical effective mass, since its small and already much lower than the horizontal mass we want to increase it. This means smaller, lighter weight further back in the wand 🙂.

Colin

This is not a regular pivoted arm,the same rules don't apply. You don't want a heavier weight nearer the pivot here, not only because of lateral mass but because a heavier weight nearer the pivot lowers the vertical effective mass, since its small and already much lower than the horizontal mass we want to increase it. This means smaller, lighter weight further back in the wand 🙂.

Colin

Thanks for the inputs guys !

Meanwhile the postman brought 5 pcs of Duran glass tubes , very well cutted in lenghts of 25CM . extra thick 2.2MM wall btw ( feels very solid and less ringing if you ask me ) .

I'll take all advices and options into consideration during this project !

For now .. time to cut a couple of different wand lenghts .. some CW inserts

to balance and apply VTF etc. Have some ideas how to do this and will share with you as soon as it works out OK .

THX again guys !!

Paul

Meanwhile the postman brought 5 pcs of Duran glass tubes , very well cutted in lenghts of 25CM . extra thick 2.2MM wall btw ( feels very solid and less ringing if you ask me ) .

I'll take all advices and options into consideration during this project !

For now .. time to cut a couple of different wand lenghts .. some CW inserts

to balance and apply VTF etc. Have some ideas how to do this and will share with you as soon as it works out OK .

THX again guys !!

Paul

Joe,

This is not a regular pivoted arm,the same rules don't apply. You don't want a heavier weight nearer the pivot here, not only because of lateral mass but because a heavier weight nearer the pivot lowers the vertical effective mass, since its small and already much lower than the horizontal mass we want to increase it. This means smaller, lighter weight further back in the wand 🙂.

Colin

I think I have just seen ( and realized ) the reason for a light weight CW .. positioned at the end of the tail 😉 .. there's no need for anything heavy on the tail end ... and have the cart + gravity do most of the job regarding VTF .

Than after I have used my scale and set up things for approx. 1.7 Gram VTF .. only than the up and down movement of the wand + bearings is getting as smooth as it gets

time for a beer I guess 😉

Paul

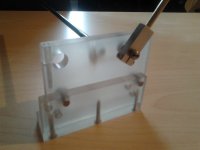

Hi Guys ,

Made some progress in the arm construction . it took me some time to figure

a smooth movement of the armlift and adjusting points etc. , but here some shots of how one and other is looking at the moment .

Have a nice weekend !

Paul

Made some progress in the arm construction . it took me some time to figure

a smooth movement of the armlift and adjusting points etc. , but here some shots of how one and other is looking at the moment .

Have a nice weekend !

Paul

Attachments

-

linear tonearm diy.com (7).jpg889.6 KB · Views: 364

linear tonearm diy.com (7).jpg889.6 KB · Views: 364 -

linear tonearm diy.com (6).jpg968.3 KB · Views: 449

linear tonearm diy.com (6).jpg968.3 KB · Views: 449 -

linear tonearm diy.com (5).jpg932 KB · Views: 467

linear tonearm diy.com (5).jpg932 KB · Views: 467 -

linear tonearm diy.com (4).jpg195.2 KB · Views: 420

linear tonearm diy.com (4).jpg195.2 KB · Views: 420 -

linear tonearm diy.com (3).jpg939.7 KB · Views: 689

linear tonearm diy.com (3).jpg939.7 KB · Views: 689 -

linear tonearm diy.com (2).jpg947.6 KB · Views: 706

linear tonearm diy.com (2).jpg947.6 KB · Views: 706 -

linear tonearm diy.com (1).jpg195.9 KB · Views: 731

linear tonearm diy.com (1).jpg195.9 KB · Views: 731 -

linear tonearm diy.com (8).jpg182.9 KB · Views: 361

linear tonearm diy.com (8).jpg182.9 KB · Views: 361

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm