The Igusses are for a linear one!, so skating will not be an issue, right?

Certainly, but this is not an advantage to move the carriage. In pivoted TA the offset angle converts part of the stylus drag into side force, here none.

Resonance frequency is surely a concern for working tonearms and less for static ornaments, so there are priorities for diyers. More, in linear TA the hor. eff. mass may be very different from vert. one, and this makes calcs problematic. What would be the resulting resonance and, as says Walter, the effect on sound?. Lot of opinions around.

Meanwhile search something like - Calculator-effective-tonearm-mass -

carlo

ok Walter, but there are great ideas and small, small ones, like mine

Certainly, but this is not an advantage to move the carriage. In pivoted TA the offset angle converts part of the stylus drag into side force, here none.

Resonance frequency is surely a concern for working tonearms and less for static ornaments, so there are priorities for diyers. More, in linear TA the hor. eff. mass may be very different from vert. one, and this makes calcs problematic. What would be the resulting resonance and, as says Walter, the effect on sound?. Lot of opinions around.

Meanwhile search something like - Calculator-effective-tonearm-mass -

carlo

ok Walter, but there are great ideas and small, small ones, like mine

Hi all

Mr Pierce has graciously replied that it is complicated to capture the effective mass calculation in an Excel sheet due to the many different configurations of arms

Carlo:

Did the search, yielded only 3 pages of results! There is a calculator that calculates total eff mas, but wants the eff mass of the TA first- bummer!

Different approach:

An Ortofon 2 Red specifies an out put of 5,5 mV @ 1000 Hz

If this is measured in flagrante, then achieving this 5,5 mV would mean that all (coil) cylinders are firing as they should?

And therefore, the optimal combination of compliance and eff mass is achieved?

Let me know

Rgds

Coolerooney

Mr Pierce has graciously replied that it is complicated to capture the effective mass calculation in an Excel sheet due to the many different configurations of arms

Carlo:

Did the search, yielded only 3 pages of results! There is a calculator that calculates total eff mas, but wants the eff mass of the TA first- bummer!

Different approach:

An Ortofon 2 Red specifies an out put of 5,5 mV @ 1000 Hz

If this is measured in flagrante, then achieving this 5,5 mV would mean that all (coil) cylinders are firing as they should?

And therefore, the optimal combination of compliance and eff mass is achieved?

Let me know

Rgds

Coolerooney

It may be easy to just measure resonance frequency. However, I am still not sure why the need for low limit of resonance frequency. On my arms, the resonance frequencies are 4 and 5 Hz respectively. I don't have any problems though. I can understand the need for up limit.

ok Walter, but there are great ideas and small, small ones, like mine[/QUOTE]

That's true. However, lets not forget, that small and simple idea sometimes makes a huge difference. With some very simple and small ideas, a stick and a piece of rope makes a bow, and it revolutionized hunting and war, changing course of history😀

That's true. However, lets not forget, that small and simple idea sometimes makes a huge difference. With some very simple and small ideas, a stick and a piece of rope makes a bow, and it revolutionized hunting and war, changing course of history😀

It may be easy to just measure resonance frequency.

Hi Super, let me know how 😀

Ok,

Spoken to my Igus guy and he says the friction is about 0,15x weight

So for a 20 gr arm this would take a “force”of 3 grams to overcome- sounds like a lot, but lets work with this (will be less as there are 2 support points)

Hmmm

So assuming this friction is constant or near constant, what if a wire and 3 gram weight is hung in such a way that it pulls the bearing/arm in the direction of the center of the record, thereby canceling the friction and make it “free floating”. 😉))

Thx

Coolerooney

Spoken to my Igus guy and he says the friction is about 0,15x weight

So for a 20 gr arm this would take a “force”of 3 grams to overcome- sounds like a lot, but lets work with this (will be less as there are 2 support points)

Hmmm

So assuming this friction is constant or near constant, what if a wire and 3 gram weight is hung in such a way that it pulls the bearing/arm in the direction of the center of the record, thereby canceling the friction and make it “free floating”. 😉))

Thx

Coolerooney

That’s what I thought they did !!

Don’t you balance it to where the part of the rod holding the arm is not level , the long part of the rod the is near the center of the LP is lower then where it’s mount is?

That’s how I thought these things worked, riding the LP grove and using gravity to move the needle , because the arm is naturally going to slide down the rod

Don’t you balance it to where the part of the rod holding the arm is not level , the long part of the rod the is near the center of the LP is lower then where it’s mount is?

That’s how I thought these things worked, riding the LP grove and using gravity to move the needle , because the arm is naturally going to slide down the rod

Hello Coolerooney and carlthess40,

If you bias a linear tone arm toward the label with either a weight or by inclining its track, it will skip grooves when you play an eccentric record because the tone arm will not back up.

Sincerely,

Ralf

If you bias a linear tone arm toward the label with either a weight or by inclining its track, it will skip grooves when you play an eccentric record because the tone arm will not back up.

Sincerely,

Ralf

The idea is to balance to neutral, then the cantilever of the cartridge has the least force to deal with(the €@€&@@“!?!) Effective mass....

If truly neutral, theb an excentric hole would be no problem

I know, keep dreaming

If truly neutral, theb an excentric hole would be no problem

I know, keep dreaming

Then your saying that the groves do all the pulling on the needle ?

Hello carlthess40,

Yes, and by the way it is a pushing force. There is no such force as a pulling force! I know that I'll get FLAK over that last sentence. 🙂

Sincerely,

Ralf

The idea is to balance to neutral, then the cantilever of the cartridge has the least force to deal with(the €@€&@@“!?!) Effective mass....

If truly neutral, theb an excentric hole would be no problem

I know, keep dreaming

Hello Coolerooney,

The neutral condition only exists while the tone arm is moving toward the label. During the outward excursion of an eccentric record, the inside groove flank would have to overcome the frictional resistance of the tone arm plus it would have to LIFT the weight.

Sincerely,

Ralf

Hi Carl, Ralf

The push or pull issue runs up against the convention of drawing arrows (vectors) to show the result of a force. This has surreptitiously altered the language used. The action is a push, but diagrams show a pull. It matters in printed diagrams.

It is easy to draw the groove frictional force as being exerted as a push (one arrow, behind the stylus) that makes the stylus go in the forward direction. When the push must be resolved into two directions (part going forward; part going inward, toward the label), the convention is to show two arrows with their tails "dragging" a share of the stylus. It would be less clear to draw two arrowheads converging on a stylus point trying to push differently.

It doesn't help that every published math explanation refers to the result as one or more drag forces, but like all conventions, you have to think through it to get the analogy.

Happy New Year!

Andy

The push or pull issue runs up against the convention of drawing arrows (vectors) to show the result of a force. This has surreptitiously altered the language used. The action is a push, but diagrams show a pull. It matters in printed diagrams.

It is easy to draw the groove frictional force as being exerted as a push (one arrow, behind the stylus) that makes the stylus go in the forward direction. When the push must be resolved into two directions (part going forward; part going inward, toward the label), the convention is to show two arrows with their tails "dragging" a share of the stylus. It would be less clear to draw two arrowheads converging on a stylus point trying to push differently.

It doesn't help that every published math explanation refers to the result as one or more drag forces, but like all conventions, you have to think through it to get the analogy.

Happy New Year!

Andy

Last edited:

Hi to all. Forces, acting on the stylus are pushing, however, the same forces, acting on cantilever are pulling. Maybe, that is the reason, why all of them, applied on tonearm, are usually considered, as pulling.

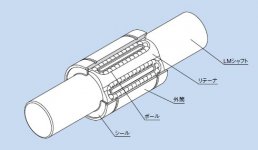

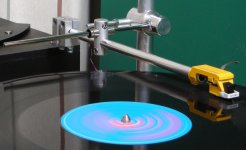

Any opinions on using linear ball bearings, like that? I wonder, what are friction numbers there? On video it looks, like they are extremely small, and arm tracking on warped and eccentric records is excellent.

幸せの黄色いホーン資料室

Any opinions on using linear ball bearings, like that? I wonder, what are friction numbers there? On video it looks, like they are extremely small, and arm tracking on warped and eccentric records is excellent.

幸せの黄色いホーン資料室

Attachments

Linear bearing have way too much friction. You can play records, but I bet the cantilever will not last very long. I know a guy who made one and admitted he had to give a slight tilt downward of the arm toward the label. This guys Denon 103D was ruined in a few weeks.

Walter: recirculating balls may be good for CNC or 3D not here, cause all the balls have to recirculate along a small radius, and this brings frictions and chattering. Imho only jewels and non recirculating balls are really viable, with precision radial bearings just at limit.

The problem is that we have a "skipping force" of 6,5 mN with VTF 2gr and only 3,5 mN with 1,5gr (remember my measures on the other thread?) and just a tenth of this bends intolerably the stylus during tracing. Ralf explained very well why tricks like rail slanting or wheights are harmful.

Then consider that due the torque on carriage (#2406), of that small force we can use only a fraction for carriage movement (F sin alfa - that's why those super short arms) or, since with zero friction the point of application of forces becomes irrelevant, trying to reduce at most the friction with air bearing.

My effort with LilCasey's* radial rail starts from these naive thoughts.

carlo

* washing oils away from the 8 bearings halved the friction of the vert. movement: wow

The problem is that we have a "skipping force" of 6,5 mN with VTF 2gr and only 3,5 mN with 1,5gr (remember my measures on the other thread?) and just a tenth of this bends intolerably the stylus during tracing. Ralf explained very well why tricks like rail slanting or wheights are harmful.

Then consider that due the torque on carriage (#2406), of that small force we can use only a fraction for carriage movement (F sin alfa - that's why those super short arms) or, since with zero friction the point of application of forces becomes irrelevant, trying to reduce at most the friction with air bearing.

My effort with LilCasey's* radial rail starts from these naive thoughts.

carlo

* washing oils away from the 8 bearings halved the friction of the vert. movement: wow

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm