This is how works Lil Casey, the radial rail tonearm (zipped MP4 attachments)

Perfectly leveled rail - AT 95 high compliance cartridge - VTF 1.5 gr - 3mm warp! - + -1.5mm eccentricity!

Observe the cantilever: during the insertion the carriage has no tilting, on the eccentricities the behavior is similar to a good gimbal pivoted. On the warps it must still improve. (even if this kind of deformations do not live among my LPs).

Now I'm thinking how to halve the weights (from 37 to 20-25 gr) and the number of bearings: this one has no play at all on the parallelogram, but this can be achieved with much less than I previously thought

carlo

and the sound? much better video

YouTube

Perfectly leveled rail - AT 95 high compliance cartridge - VTF 1.5 gr - 3mm warp! - + -1.5mm eccentricity!

Observe the cantilever: during the insertion the carriage has no tilting, on the eccentricities the behavior is similar to a good gimbal pivoted. On the warps it must still improve. (even if this kind of deformations do not live among my LPs).

Now I'm thinking how to halve the weights (from 37 to 20-25 gr) and the number of bearings: this one has no play at all on the parallelogram, but this can be achieved with much less than I previously thought

carlo

and the sound? much better video

YouTube

Attachments

Hope to be in that hell, when I'll die. (I'm joking).

On eccentricity the carriage moves back and forth + - 1.5 mm (thank goodness, many passives have some difficulties to do so) bur how much is the stylus moving with respect to the cartridge and the carriage?

carlo

On eccentricity the carriage moves back and forth + - 1.5 mm (thank goodness, many passives have some difficulties to do so) bur how much is the stylus moving with respect to the cartridge and the carriage?

carlo

Sorry guys,

The severe sideways flexing of the stylus in the ECC video more than negates any positive benefit of linear tracking that you are trying to achieve.

In the WARP video the arm linkage bottoms out before the warp bottoms out so that the stylus loses contact with the groove. To make the demonstration fair, the arm height needs to be lowered so the cartridge/stylus 'rides' the full height of the warp.

Also, in the WARP video it is evident that the cartridge 'rocks' fore and aft as it makes contact with the groove. Unwanted motion along the groove causes pitch instability, which can be quite audible.

Ray K

The severe sideways flexing of the stylus in the ECC video more than negates any positive benefit of linear tracking that you are trying to achieve.

In the WARP video the arm linkage bottoms out before the warp bottoms out so that the stylus loses contact with the groove. To make the demonstration fair, the arm height needs to be lowered so the cartridge/stylus 'rides' the full height of the warp.

Also, in the WARP video it is evident that the cartridge 'rocks' fore and aft as it makes contact with the groove. Unwanted motion along the groove causes pitch instability, which can be quite audible.

Ray K

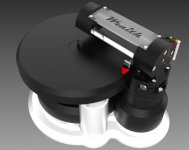

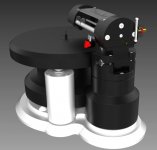

I saw this on Facebook, but don't know the construction of the arm. It seems to me like a clone of Clear Audio linear tracking arm.

Attachments

-

49719576_2485008214843084_7633797760067567616_n.jpg59.3 KB · Views: 456

49719576_2485008214843084_7633797760067567616_n.jpg59.3 KB · Views: 456 -

49829630_2485007821509790_2990593819923185664_n-2.jpg33.4 KB · Views: 462

49829630_2485007821509790_2990593819923185664_n-2.jpg33.4 KB · Views: 462 -

49639336_2485007991509773_1915519031348035584_n-2.jpg35.9 KB · Views: 466

49639336_2485007991509773_1915519031348035584_n-2.jpg35.9 KB · Views: 466 -

49608105_2485008154843090_2928745427572359168_n-2.jpg81.7 KB · Views: 471

49608105_2485008154843090_2928745427572359168_n-2.jpg81.7 KB · Views: 471 -

49467962_2485008091509763_7878341927907622912_n.jpg67 KB · Views: 464

49467962_2485008091509763_7878341927907622912_n.jpg67 KB · Views: 464

I still think, that it needs low compliance cartridge, as it is definitely not an ultra-low mass tonearm. I suspect, it will work very well with Denon DL-103 or EMT TSD-15 kind of cartridges.Hope to be in that hell, when I'll die. (I'm joking).

On eccentricity the carriage moves back and forth + - 1.5 mm (thank goodness, many passives have some difficulties to do so) bur how much is the stylus moving with respect to the cartridge and the carriage?

carlo

Thanks for the deep observations, Ray.

I know I'm trying to follow a difficult (or wrong) road and it's easy not to see the faults of one's own creatures. Not seeing with a 10x macroscope what you see on those low resolution files worried me, so I enlarged and cleared some frames and, damn: I continue to see just a small bending on +-1,5 mm eccentricity (I saw worse on old low compliance pivoted ) and to see the stylus into the groove on warps. (attachments)

When it plays, the cart trace without problems on eccentricities, while on the vertical articulation there are still visible problems, and I have to reach a mass similar at least to an old 12" SME.

But maybe I have bad references, can you link me videos of passive linears without these problems? usually they show everything except the stylus.

ciao carlo

Walter: I agree, it would be better. Now i'm testing with AT 95 that is so prone to skip and so intolerant of heavy VTf and it works. I've just said what to modify. Any advice?

I know I'm trying to follow a difficult (or wrong) road and it's easy not to see the faults of one's own creatures. Not seeing with a 10x macroscope what you see on those low resolution files worried me, so I enlarged and cleared some frames and, damn: I continue to see just a small bending on +-1,5 mm eccentricity (I saw worse on old low compliance pivoted ) and to see the stylus into the groove on warps. (attachments)

When it plays, the cart trace without problems on eccentricities, while on the vertical articulation there are still visible problems, and I have to reach a mass similar at least to an old 12" SME.

But maybe I have bad references, can you link me videos of passive linears without these problems? usually they show everything except the stylus.

ciao carlo

Walter: I agree, it would be better. Now i'm testing with AT 95 that is so prone to skip and so intolerant of heavy VTf and it works. I've just said what to modify. Any advice?

Attachments

Last edited:

Mass issues aside, a low compliance cartridge will show less sideways deflection of the cantilever, but that does not mean the problem went away. Even if you no longer see the effects on the cantilever, the sideways forces are still there and rob effective VTF from one groove wall or the other depending on which direction the eccentricity is going.I still think, that it needs low compliance cartridge, as it is definitely not an ultra-low mass tonearm. I suspect, it will work very well with Denon DL-103 or EMT TSD-15 kind of cartridges.

Ray K

But maybe I have bad references, can you link me videos of passive linears without these problems? usually they show everything except the stylus.

ciao carlo

Sorry, no links. If it's any consolation to you, I'm not aware of a passive linear that doesn't have this problem to some extent. I have not observed all passive linears in action but IMO, as a retired engineer, passive linear designs are inherently plaqued by bearing friction/stick-tion.

Ray K

Have to agree with Diyrayk

Have seen the future, and it’s active

There is no workaround for friction, effective mass and cantilever off set

So without further ado.....

Coolerooney

Have seen the future, and it’s active

There is no workaround for friction, effective mass and cantilever off set

So without further ado.....

Coolerooney

I would install two pulleys with some weight on a string which would help to pull the carriage. Just enough weight so the cantilever still does some of the jobs. I gave this advice several times and got rejected. I see some marvelous engineering, I know the idea would 100% work, hard to understand why no one will try it or test it. It is a simple method. Greetings

Carlo, as to vertical mass, we already discussed possibility to decrease it in half, or close to it. It should work.

string & pulleys

Such as in this video? I can't see the video clearly due to its low resolution. There's a red string, some pulleys, and a hanging nut in there.

I would install two pulleys with some weight on a string which would help to pull the carriage. Just enough weight so the cantilever still does some of the jobs.

Such as in this video? I can't see the video clearly due to its low resolution. There's a red string, some pulleys, and a hanging nut in there.

Yeap! With that, you can adjust the weight until perfection, until almost moves freely. How long you use that idea? Are you satisfied with? When I mentioned several years everybody rejected the idea, they want the cantilever to do the job, I do believe is a good and cheap solution next to air bearing. Happy to see that!

When I mentioned several years everybody rejected the idea

Hello Gabor,

The reason everybody rejected your idea is that, it would only work correctly with a perfectly concentric record. The instant the tone arm encounters an eccentric record, it not only would have to move its own mass in an outward direction but it would also have to lift the weight. That would cause the stylus to skip or at least bend the cantilever.

Sincerely,

Ralf

I would install two pulleys with some weight on a string which would help to pull the carriage. Just enough weight so the cantilever still does some of the jobs. I gave this advice several times and got rejected. I see some marvelous engineering, I know the idea would 100% work, hard to understand why no one will try it or test it. It is a simple method. Greetings

I did it years ago. Go back all the way this thread. But I don't think it is good idea. Why? I can't tell from theoretical aspects . One thing I can tell I can hear the difference with and without the pulleys. Pulleys degrade sound.

The cantilever lateral wriggling of the ECC video reminds me of this video of a Clearaudio TT5 linear tonearm. Watch the 1:16 mark and it appears to have too much friction.

This video shows clearly there are serious problems with the design or the combo of arm and cartridge.

This video shows clearly there are serious problems with the design or the combo of arm and cartridge.

That was the lead out groove and in addition to that, look at the 0:50 mark after the needle drop and it still exhibits wriggling. It only lasts a second but it's enough to see the wavering.

Last edited:

..... IMO, as a retired engineer, passive linear designs are inherently plaqued by bearing friction/stick-tion. Diyrayk

More, Imho the side force, not multiplied by the lever on pivot is instead partly dissipated by the torque on the carriage: the longer the arm and shorter the carriage = greater friction = more bending, to produce increased SF

From this my attempt to bypass this "original sin" with a radial rail, of course not a simple task. Even when successfull (very far from here) remains the problem that the available forces are minimal. I said it clearly in the review and even before, without hiding problems and failures: as always i'm experimenting, and learning from trials&errors.

Frankly the behavior of this arm (a first DIY prototype, built with less tools that needed) surprised me, just comparing the same type of non recirculating balls used on a normal linear done before: there is a lot of work to do, but the beginning seems encouraging, a visible advantage.

At this point I would be curious to know the impressions and thoughts of those who have perfected the passive ones at the highest level with authentic masterpieces, starting from Vynuhl.addict, my friend Niffy and others.

carlo

severe bending: on the frames I measured deviations of a few tenths: on heavy pivoted arms, or with cables too rigid or too heavily damped i'd seen something even worse; more - on youtube there are dozens of cartridge's tests, mounted on notoriously reliable arms: there you can finally see the stylus well, and also the bending on warps and eccentricities milder than in my "crash test".

Walter: as said, the spring was tried too, and it worked very well. But that spring is too short and the fine regulation of the VTF is problematic. I have to find a better spring and, in the meantime, in the scrap bin I found an old avional arrow to make a rail of 8 grams instead of 22...

More, Imho the side force, not multiplied by the lever on pivot is instead partly dissipated by the torque on the carriage: the longer the arm and shorter the carriage = greater friction = more bending, to produce increased SF

From this my attempt to bypass this "original sin" with a radial rail, of course not a simple task. Even when successfull (very far from here) remains the problem that the available forces are minimal. I said it clearly in the review and even before, without hiding problems and failures: as always i'm experimenting, and learning from trials&errors.

Frankly the behavior of this arm (a first DIY prototype, built with less tools that needed) surprised me, just comparing the same type of non recirculating balls used on a normal linear done before: there is a lot of work to do, but the beginning seems encouraging, a visible advantage.

At this point I would be curious to know the impressions and thoughts of those who have perfected the passive ones at the highest level with authentic masterpieces, starting from Vynuhl.addict, my friend Niffy and others.

carlo

severe bending: on the frames I measured deviations of a few tenths: on heavy pivoted arms, or with cables too rigid or too heavily damped i'd seen something even worse; more - on youtube there are dozens of cartridge's tests, mounted on notoriously reliable arms: there you can finally see the stylus well, and also the bending on warps and eccentricities milder than in my "crash test".

Walter: as said, the spring was tried too, and it worked very well. But that spring is too short and the fine regulation of the VTF is problematic. I have to find a better spring and, in the meantime, in the scrap bin I found an old avional arrow to make a rail of 8 grams instead of 22...

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm