Regarding swivel type linear tracking arms. I think that if you are going to have a swivel it is better to have it aligned with the vertical pivot as in Frank's arm rather than at the headshell.

If the ONLY consideration as to wether to have a swivel or not is lateral tracking error then the choice will be dependent upon bearing friction.

If bearing friction is very low then you will probably have less tracking error with a single peace arm without a swivel

If bearing friction is high then you will probably have less tracking error with the swivel.

However lateral tracking error is not the only consideration. Taking the performance of the arm as a whole it will almost certainly be better to have NO swivel regardless of bearing friction.

Having low bearing friction is the best method of reducing lateral tracking error in linear tracking arms.

Niffy

If the ONLY consideration as to wether to have a swivel or not is lateral tracking error then the choice will be dependent upon bearing friction.

If bearing friction is very low then you will probably have less tracking error with a single peace arm without a swivel

If bearing friction is high then you will probably have less tracking error with the swivel.

However lateral tracking error is not the only consideration. Taking the performance of the arm as a whole it will almost certainly be better to have NO swivel regardless of bearing friction.

Having low bearing friction is the best method of reducing lateral tracking error in linear tracking arms.

Niffy

Having low bearing friction is the best method of reducing lateral tracking error in linear tracking arms.

I can’t agree more.

Sorry, Frank, I don’t like the idea at all. Adding 2nd pivot on the carriage can’t keep the cantilever tangent to the groove. It may even make things worse. 2nd pivot adds more mass on the carriage, so the friction will increase too. High friction will even add more stress on cantilever. A pointy pivot can’t keep the cantilever tangent to groove at all.

In Frank’s previous post, he stated:

Try an air bearing arm and that problem disappears, well, kind of, as the high eff. lateral mass will cause low frequency oscillation.

I disagree. From my experience, I started 1/2” bearing, then 3/4”, finally 1”. The bass is getting better as the size of bearing increases. Due to the almost frictionless of air bearing, lateral mass is almost irrelevant. My arm is about 200 grams.

Why does high mass have better bass?

Here is my best guess. For ideal playing condition of a cartridge, the body of cartridge, in other words, the arm, should be kept as stable as possible. For an air bearing arm, if the mass is heavy, it is relatively more stable than light mass arm. So, the cantilever tracks lateral groove better than light mass arm does.

Again, if the best method to reduce lateral tracking error is to reduce friction, why do we even bother to have 2nd pivot? If a linear tracking arm's lateral friction can't be reduced, is 2nd pivot helpful? My answer is no. So, in any cases, it doesn't make sense to add 2nd pivot.

Having massively different vertical and horizontal effective masses could create a problem in crosstalk between the channels. However as long as the ratio of the masses is kept below about 4 this isn't a problem as by the time that there is significant vertical modulation, about 120hz, the amount of crosstalk would be down to about -30dB, greater than the channel separation of your cartridge. The amount of crosstalk decreases from this point by about 12dB/octave so by the time you get to frequencies where there is significant stereo information the amount of crosstalk would be utterly insignificant.

Correction.

The amount of crosstalk would decrease by 6dB/octave with a cartridge with low internal damping. And by about 4.5dB/octave with a cartridge with a typical level of damping. Sorry for the error I was quoting from memory. The amount of crosstalk would still be insignificant.

Niffy

@niffy,

You are 100% right about linear/tangential. Stupid that I never have controlled the right meanings of the words. I read it years ago and thought it was right. Now I have to correct some titles...

You are 100% right about linear/tangential. Stupid that I never have controlled the right meanings of the words. I read it years ago and thought it was right. Now I have to correct some titles...

Hi,

In Jim's recent post he quoted Frank:

In Frank’s previous post, he stated:

"Try an air bearing arm and that problem disappears, well, kind of, as the high eff. lateral mass will cause low frequency oscillation."

This phenomenon is often called "the tail wagging the dog"

Does high effective lateral mass cause low frequency oscillation? Does the tail wag the dog?

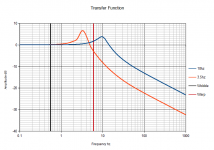

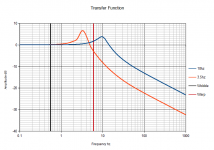

A while back I made a rather lengthy set of posts talking about effective mass and how it helps to control the cartridge. It the second post I included a graph that showed how much the cartridge body moves relative to groove modulation at different frequencies. I have reposted this graph below.

The vertical axis is in decibels. This means that at -10dB the cartridge body moves 1/10 the amount of groove modulation and at -20dB the cartridge moves 1/100 the groove modulation.

Eg if you have a 500hz groove modulation with an amplitude of 50um at - 20dB the cartridge body will vibrate also at 500hz with an amplitude of 0.5um. (but out of phase with the groove)

A pretty typical cartridge was used as a model for the creation of the graph. It has a compliance of 15um/mN and the suspension has a coefficient of 0.5. No additional damping of the arm is included.

The blue plot shows this cartridge attached to an arm with a total effective mass is 16.9grams. This results in a compliance resonance of 10hz which is normally recommended as an ideal.

The Orange plot shows the same cartridge attached to an arm with a total effective mass of 138grams. This results in a compliance resonance of 3.5hz.

The most obvious feature is that the Orange plot is over 9dB below the blue plot within the audio band, above 20hz. This indicates that, with the Orange plot, the cartridge body is moving only 1/8.3 times as much as with the blue plot. Having the cartridge held much more solidly like this is why the higher lateral mass linear arms can have such superior bass reproduction.

The vertical black line on the graph is at 0.55hz which corresponds with the lateral frequency due to eccentricity at 33 1/3rpm. The plots for both the 16.9g(blue) and 138g(Orange) arms are both very close to zero at this frequency. The blue is lower at +0.011dB than the Orange at +0.090dB. Neither are anywhere near to being resonant or capable of exciting oscillations.

The red vertical line at 6hz represents the upper frequency limit at which significant record warps occur with a 33 1/3rpm record. Warps occur at frequencies between the black and red lines. Higher amplitude warps tend to occur at lower frequencies and lower amplitude warps at higher frequencies. Due to the way records warp there also tend to be higher amplitude warps at 1.1hz and 2.2hz (multiples of the rotational speed)

At 2.2hz the blue 16.9g plot is at about +0.2dB rising to about +1.65dB at 6hz. This suggests that you are more likely to excite resonance in the vertical plane of either a pivoted or linear tracking arm than in the lateral plane of a linear tracking arm. If you were to make the arm very heavy, in the kilogram range, then lateral resonance would become a real problem with eccentric records. I don't know of anyone ever making a passive linear tracking tonearm in this mass range so the problem probably hasn't ever really occurred.

The tale of the tail wagging the dog is a MYTH. One of several that surround linear tracking arms.

I think I know how the myth may have arose. An early pioneer of linear air bearing tonearms thinks that the tail wagging the dog might be a problem so adds a damping trough to his prototype arm. Upon hearing an improvement he concludes that this confirms that the tail wagging the dog was the problem. In fact the problem was that the arm needs to be mechanical grounded to some extent and the damping mechanism actually achieved this instead. The assumed problem is seized on by linear opponents as a reason why this type of arm is flawed and it spreads, even though the problem appears to have been eradicated anyway. Just a thought.

Niffy

In Jim's recent post he quoted Frank:

In Frank’s previous post, he stated:

"Try an air bearing arm and that problem disappears, well, kind of, as the high eff. lateral mass will cause low frequency oscillation."

This phenomenon is often called "the tail wagging the dog"

Does high effective lateral mass cause low frequency oscillation? Does the tail wag the dog?

A while back I made a rather lengthy set of posts talking about effective mass and how it helps to control the cartridge. It the second post I included a graph that showed how much the cartridge body moves relative to groove modulation at different frequencies. I have reposted this graph below.

The vertical axis is in decibels. This means that at -10dB the cartridge body moves 1/10 the amount of groove modulation and at -20dB the cartridge moves 1/100 the groove modulation.

Eg if you have a 500hz groove modulation with an amplitude of 50um at - 20dB the cartridge body will vibrate also at 500hz with an amplitude of 0.5um. (but out of phase with the groove)

A pretty typical cartridge was used as a model for the creation of the graph. It has a compliance of 15um/mN and the suspension has a coefficient of 0.5. No additional damping of the arm is included.

The blue plot shows this cartridge attached to an arm with a total effective mass is 16.9grams. This results in a compliance resonance of 10hz which is normally recommended as an ideal.

The Orange plot shows the same cartridge attached to an arm with a total effective mass of 138grams. This results in a compliance resonance of 3.5hz.

The most obvious feature is that the Orange plot is over 9dB below the blue plot within the audio band, above 20hz. This indicates that, with the Orange plot, the cartridge body is moving only 1/8.3 times as much as with the blue plot. Having the cartridge held much more solidly like this is why the higher lateral mass linear arms can have such superior bass reproduction.

The vertical black line on the graph is at 0.55hz which corresponds with the lateral frequency due to eccentricity at 33 1/3rpm. The plots for both the 16.9g(blue) and 138g(Orange) arms are both very close to zero at this frequency. The blue is lower at +0.011dB than the Orange at +0.090dB. Neither are anywhere near to being resonant or capable of exciting oscillations.

The red vertical line at 6hz represents the upper frequency limit at which significant record warps occur with a 33 1/3rpm record. Warps occur at frequencies between the black and red lines. Higher amplitude warps tend to occur at lower frequencies and lower amplitude warps at higher frequencies. Due to the way records warp there also tend to be higher amplitude warps at 1.1hz and 2.2hz (multiples of the rotational speed)

At 2.2hz the blue 16.9g plot is at about +0.2dB rising to about +1.65dB at 6hz. This suggests that you are more likely to excite resonance in the vertical plane of either a pivoted or linear tracking arm than in the lateral plane of a linear tracking arm. If you were to make the arm very heavy, in the kilogram range, then lateral resonance would become a real problem with eccentric records. I don't know of anyone ever making a passive linear tracking tonearm in this mass range so the problem probably hasn't ever really occurred.

The tale of the tail wagging the dog is a MYTH. One of several that surround linear tracking arms.

I think I know how the myth may have arose. An early pioneer of linear air bearing tonearms thinks that the tail wagging the dog might be a problem so adds a damping trough to his prototype arm. Upon hearing an improvement he concludes that this confirms that the tail wagging the dog was the problem. In fact the problem was that the arm needs to be mechanical grounded to some extent and the damping mechanism actually achieved this instead. The assumed problem is seized on by linear opponents as a reason why this type of arm is flawed and it spreads, even though the problem appears to have been eradicated anyway. Just a thought.

Niffy

Niffy,

It is an excellent test! It seems to me my guess has its legitimate base.

Here is my own thought. For arm designs, the consensus is optimum arm resonance should be around 10 hz. What puzzles me is on the air bearing arms, it may not be necessarily correct. The masses of my arms started from 150 g, 175 g to 200 g now. The sound is getting improved but the arm resonance was getting low. It is about 3 hz as I estimated. Perhaps, the common rule doesn’t apply to air bearing arms. I don’t know.

It is an excellent test! It seems to me my guess has its legitimate base.

Here is my own thought. For arm designs, the consensus is optimum arm resonance should be around 10 hz. What puzzles me is on the air bearing arms, it may not be necessarily correct. The masses of my arms started from 150 g, 175 g to 200 g now. The sound is getting improved but the arm resonance was getting low. It is about 3 hz as I estimated. Perhaps, the common rule doesn’t apply to air bearing arms. I don’t know.

Hi Jim,

The reason why 10hz is recommended as the ideal compliance resonance is due to warps. Significant warps occur up to about 6hz. 10hz is safely above this and safely below 20hz. Personally I think that 10hz is a bit high. If you have a good warp flattening clamping system, as you do, the compliance resonance can be safely reduced. I aim for 8.5hz. Of course warps are only vertical and have no effect on lateral effective mass. The only significant lateral input is due to record eccentricity and that occurs at 0.55hz so much higher lateral effective mass is possible. 3hz should not give any problems for tracking, as your arm proves. The only possible problem with having vastly different vertical and horizontal effective masses is the possibility of crosstalk between channels. I have never had any problems with this. In fact one of the greatest strengths of linear tracking tonearms is the supreme stereo imaging so no worries for me there.

Niffy

The reason why 10hz is recommended as the ideal compliance resonance is due to warps. Significant warps occur up to about 6hz. 10hz is safely above this and safely below 20hz. Personally I think that 10hz is a bit high. If you have a good warp flattening clamping system, as you do, the compliance resonance can be safely reduced. I aim for 8.5hz. Of course warps are only vertical and have no effect on lateral effective mass. The only significant lateral input is due to record eccentricity and that occurs at 0.55hz so much higher lateral effective mass is possible. 3hz should not give any problems for tracking, as your arm proves. The only possible problem with having vastly different vertical and horizontal effective masses is the possibility of crosstalk between channels. I have never had any problems with this. In fact one of the greatest strengths of linear tracking tonearms is the supreme stereo imaging so no worries for me there.

Niffy

When calculating effective mass why is counterweight not included ? Suppose we have a unipivot. We calculate even cartridge fastner screws etc. in total effective mass but not counter weight. If a pivoted tonearm is moving and we take inertia of tonearm in to account the counterweight also moves. So counterweight must have effect on tonearm resonance and tracking. Isn't it ?

How about a arm without counter weight. The stylus pressure would be adjusted by supple spring (like in vintage turntables) and to adjust/add the 'proper' mass to the tonearm we add fluid damping in arm tube or some other place. Good Idea ?

How about a arm without counter weight. The stylus pressure would be adjusted by supple spring (like in vintage turntables) and to adjust/add the 'proper' mass to the tonearm we add fluid damping in arm tube or some other place. Good Idea ?

Hi Hiten,

The counterweight definitely has to be included in effective mass calculations. The simple rule is : if it moves include it.

Calculating effective mass for an arm with a spring counterweight would be slightly different. The moving components are calculated in the same way but the effect of the spring needs to added. As I have not experimented with spring counterweights I have not worked out how to do this yet. You have the compliance of the cartridge and the compliance of the spring both acting on the mass of the arm. Might get complicated.

Niffy

The counterweight definitely has to be included in effective mass calculations. The simple rule is : if it moves include it.

Calculating effective mass for an arm with a spring counterweight would be slightly different. The moving components are calculated in the same way but the effect of the spring needs to added. As I have not experimented with spring counterweights I have not worked out how to do this yet. You have the compliance of the cartridge and the compliance of the spring both acting on the mass of the arm. Might get complicated.

Niffy

Thanks niffy.

Actually I was thinking about getting rid of counterweight all together. Like one rigid single body arm tube which is some how filled with damping fluid. The stylus pressure would be adjusted by a spring below the arm tube. (In old record changers you might have seen. But putting a spring on single unipivot tonearm will be little difficult). For example Dual tonearm (Though with counterweight) had coil spring on sideways to the pivot. Basic thinking was to have a cartridge tightly attached to a one body (No linkeages etc.) damped tonearm tube.

Regards.

Actually I was thinking about getting rid of counterweight all together. Like one rigid single body arm tube which is some how filled with damping fluid. The stylus pressure would be adjusted by a spring below the arm tube. (In old record changers you might have seen. But putting a spring on single unipivot tonearm will be little difficult). For example Dual tonearm (Though with counterweight) had coil spring on sideways to the pivot. Basic thinking was to have a cartridge tightly attached to a one body (No linkeages etc.) damped tonearm tube.

Regards.

Pardon me. On second thought the idea is not worth pursuing. We can very well balance a single body tonearm on one unipivot by extending the same material beyond pivot point and bend downwards. I think it will also help stabilizing on unipivot.

Why do you want to get rid of counter weight? To reduce total mass? Using spring doesn't sound too attractive to me. Spring will cause problem. In addition, it is not easy to get fine resolution of adjusting VTF. When I was making moving shaft style air bearing arm, I thought of using silicone fluid to fill the shaft. But I gave up the idea because it was not worth to do it. Fluid damping may give you more trouble than you gain. I used Great Stuff to fill the shaft.

Attachments

I don't think fluid damping would work very well. I would recommend a solid, preferably low density. Balsawood can work well. My carriage is woven carbon fibre built up around a balsa wood core. I also used a balsa dowell press fitted inside a carbon fibre tube for a lightweight test carriage I was experimenting with. The expanding polyurethane foam as recommended by Jim looks like an excellent choice.

I haven't heard a high quality arm that uses a spring counterbalance so cannot comment on sound quality. I know a lot of people swear by them so there may be something to them. However some people swear by snake oil so who knows. I think that the addition of a spring is inevitably going to add a resonance and I can't see how that is a good thing unless there is a benefit that outweighs it.

Niffy

I haven't heard a high quality arm that uses a spring counterbalance so cannot comment on sound quality. I know a lot of people swear by them so there may be something to them. However some people swear by snake oil so who knows. I think that the addition of a spring is inevitably going to add a resonance and I can't see how that is a good thing unless there is a benefit that outweighs it.

Niffy

super10018 and niffy. Yes that's what I wanted to know. Thanks. 🙂

I was thinking about a uniform single body of stiff material tonearm with some sort of cavity where damping fluid will be kept. Which means only cartridge attached. But it seems to have no advantage. And about spring/coil I was talking about dual turntables where the horizontal side pivots had coiled spring so virtually it plays almost at any any angle.

Dual turntable

Regards.

I was thinking about a uniform single body of stiff material tonearm with some sort of cavity where damping fluid will be kept. Which means only cartridge attached. But it seems to have no advantage. And about spring/coil I was talking about dual turntables where the horizontal side pivots had coiled spring so virtually it plays almost at any any angle.

Dual turntable

Regards.

Problems

Hi there

I have been making one of these Glass tube arms. But i am having problems playing my old records. All the new albums plays very good. But the old ones, even tough i had no trouble with them on my old SME arm, keeps skippin. I have been making all kinds of adjustments, But nothing helps.

Maybe you guys have an idea?

I want to be able to play all my records. New and old

Hi there

I have been making one of these Glass tube arms. But i am having problems playing my old records. All the new albums plays very good. But the old ones, even tough i had no trouble with them on my old SME arm, keeps skippin. I have been making all kinds of adjustments, But nothing helps.

Maybe you guys have an idea?

I want to be able to play all my records. New and old

First, I am not sure what you meant by old records. 2nd, can you post a picture so I can see the construction of your arm?

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm