Colin are the tubes bent or the holes drilled at an angle?

My bearings arrived from Acer racing so should have a working arm in a couple of weeks.I have to take swmbo on holiday first😉

My bearings arrived from Acer racing so should have a working arm in a couple of weeks.I have to take swmbo on holiday first😉

Marra,

The holes are drilled at an angle for .125" carbon fiber tubes and drilled into the back of the cartridge mount too.

Colin

The holes are drilled at an angle for .125" carbon fiber tubes and drilled into the back of the cartridge mount too.

Colin

So,

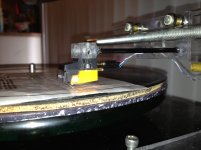

After extensive listening the triangle/cantus style of carriage sounds better across the board, lower noise, and just absolutely solid and best dynamics and imaging by far, why?, hell if I know, anyone feel free to interject. Bass is most solid reaching deep, I mean deep down while maintains brilliant layering and seperation, yes, I imagine I know understand why Bo Hansen said that it could potentially be hard to differentiate between the master tape and a linear arm. This is good stuff, and well worth the journey of diy.

Colin

After extensive listening the triangle/cantus style of carriage sounds better across the board, lower noise, and just absolutely solid and best dynamics and imaging by far, why?, hell if I know, anyone feel free to interject. Bass is most solid reaching deep, I mean deep down while maintains brilliant layering and seperation, yes, I imagine I know understand why Bo Hansen said that it could potentially be hard to differentiate between the master tape and a linear arm. This is good stuff, and well worth the journey of diy.

Colin

Attachments

The new wand looks more rigid, perhaps this is taming low frequency dispersion.

Is your assembly not bolted to the table? Seems that this would be another advantage for quick arm changes as I'd imagine precise distance to the spindle is not as critical as for a pivot arm?

Is your assembly not bolted to the table? Seems that this would be another advantage for quick arm changes as I'd imagine precise distance to the spindle is not as critical as for a pivot arm?

Last edited:

Hi batsong,

Yes the bar assembly is bolted to the table and the alignment of the hole is set for a 210 mm spindle to pivot mounting, so it would be a drop in for most tables. It also uses four adjustable hex bolts to adjust for primary leveli g of the base but also semi decouples the armbase from the turntable yet provides very rigid mounting. This newest arm has the benefit of being as rigid as the glass arm but almost as light as the second carbon fiber arm but wih no play whatsoever at the cartridge mount. This has been turning into one killer arm, and still remaining simple.

Colin

Yes the bar assembly is bolted to the table and the alignment of the hole is set for a 210 mm spindle to pivot mounting, so it would be a drop in for most tables. It also uses four adjustable hex bolts to adjust for primary leveli g of the base but also semi decouples the armbase from the turntable yet provides very rigid mounting. This newest arm has the benefit of being as rigid as the glass arm but almost as light as the second carbon fiber arm but wih no play whatsoever at the cartridge mount. This has been turning into one killer arm, and still remaining simple.

Colin

Hey vynuhl.addict

Nice arm!

How much tracking force are you using for flawless tracking?

Sincerely,

Ralf

Nice arm!

How much tracking force are you using for flawless tracking?

Sincerely,

Ralf

Thanks Straight Tracker,

I'm using about 1.6g for the at120e for flawless tracking and good bass retrieval, the linear seems to favor the upper end from middle of the range but even so there is very little stylus displacement.

Colin

I'm using about 1.6g for the at120e for flawless tracking and good bass retrieval, the linear seems to favor the upper end from middle of the range but even so there is very little stylus displacement.

Colin

vynuhl.addict: May i ask how much the total weight is for your carriage? I always think that many carriages look quite heavy, and that wouldn't be optimal for a high compliance cart? I may be wrong but, i'm just thinking out loud.

I am planning on giving this ago....

BUT

how do you align the whole tone arm assembly so you know stylus runs dead straight to the groove...

sorry if its a stupid question...

BUT

how do you align the whole tone arm assembly so you know stylus runs dead straight to the groove...

sorry if its a stupid question...

use a ruler and draw a straight line from the edge of the platter to the centre. That line is the line that that the tip must track. Best regards Moray James.

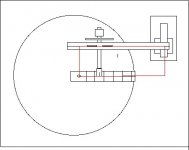

yes of course....but in the attached picture the copper and aluminium rods represent two of ,any of hundreds of possible stylus tracks.Your saying any line will do? I could have the stylus running along any track as in this example the copper track or alumium? As long as the track from the center and not slightly off like the aluminium bar.

Attachments

Last edited:

Aluminium assuming you mount the Linear tracker where your existing arm is.Study some of the earlier pics on both this thread and the Opus Cantus thread.

For alignment I use the enjoythemusic protractor since it has a straight line the spindle AND lines to align cartridge body for paralell setup. Start by lining up the stylus before arm is bolted firmly to plinth, then slide the assembly towards the spindle, the needle should follow the line then adjust as necessary to get it to follow this line. Also remember to make sure the glass rod is level first as this will also affect alignment!. Make sure you set this with a standard thickness record on the platter for precise measurement.

Colin

Colin

Attachments

Thanks Colin, that's a better answer.

Can't see the point of going to all this trouble to find out its running along the wrong path...

Can't see the point of going to all this trouble to find out its running along the wrong path...

No problem chokesrule!,

With linear arms setup is as important as the build, tracking is dependant on proper setup Much more so than a pivoted arm, once this is nailed prepare yourself for a vinyl experience like you've never heard!.

Colin

With linear arms setup is as important as the build, tracking is dependant on proper setup Much more so than a pivoted arm, once this is nailed prepare yourself for a vinyl experience like you've never heard!.

Colin

there are 360 perfect tracks you can choose

Yes you are right so long as the line intersects with the centre of the platter and your cartridge runs at right angle to the line it is a perfect track. Best regards Moray James.

yes of course....but in the attached picture the copper and aluminium rods represent two of ,any of hundreds of possible stylus tracks.Your saying any line will do? I could have the stylus running along any track as in this example the copper track or alumium? As long as the track from the center and not slightly off like the aluminium bar.

Yes you are right so long as the line intersects with the centre of the platter and your cartridge runs at right angle to the line it is a perfect track. Best regards Moray James.

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm