bjorno said:You’re becoming to vague, new requirements?

I’ve already shown some of the ported enclosure consequences for the bargain Vifa BC18SG49-08 in post # 62 and its up to you to make further decisions or simply post your new requirements and hope that somebody will help you.

thanks for the reply.

I will definitely go with the 3.3L for the mid.

When it comes to the woofers, I didn't mean to have new requirements. Just thought I could make better application of the woofers with a ported design - I thought these were generally a way to provide extended bass response, but at the cost of tightness and flatness and quality of response?

With the diagram in #62.. Unfortunately I am new to this, and it's technicality goes beyond my understanding.

however that speaks to me 🙂 and 89L definitely too large.In my examples shown, the net volumes for two drivers will be around 45 L (closed) to 89 L (small ported aperiodic box) and I think this is large enough for a center speaker recommendation.

but i am confused.. i thought 42L so ~84L for a closed box, and 20Lx2 for the aperiodic, not 89L? im talking about this :

Normal closed box for this driver is a rather large size and one driver requires for a Qtc of 0.7 about a volume of 42 L but in a Aperiodic box the volume can be reduced to a minimum of 20 L if there is sufficient headroom dimension for a 4” x dia 7” port.

With the diagram in #62.. Unfortunately I am new to this, and it's technicality goes beyond my understanding.

The first red colored plot is the FR curve of the ported 20 L aperiodic box; the blue dotted is if the driver is in an IB (infinite baffle).

The second plot shows the driver response separated from the port. The very low amplitude, wide and flattish port response is an indication of a damped port and a damped enclosure.

The third plot shows the proposed relative box layout dimensioning, with the blue ports positions marked and so the drivers relative positions.

The forth plot is the characteristic cone excursion in RMS (mm) = x-max/sqrt (2) (red curve), the blue dotted is for the IB example.

Here you also can tell this is an aperiodic alignment as the curve deviates from an ordinary ported designs excursion slopes starting from about 30 Hz, i.e. the increase of the excursion for lower frequencies.

The last plot shows the acting acoustical impedance on the rear of the driver. The wide and lowest peak centered at about 30 Hz indicates where the port control definition of the driver is chosen.

….Just thought I could make better application of the woofers with a ported design…

Then you have to tell me how? But …what… are… your… requirements…what’s wrong with the suggestions I already posted?

I provided an example of what I think is a minimum application for this woofer in a minimum reflex box to start with.

By choosing this bargain driver based on the price at most, you’ve put yourself in a corner because of the high Qts value this driver is restricted to use a closed box of minimum 42 L or ported aperiodic enclosures only that also is usable with less volumes than for the former type, (other types of enclosures not specified and not known is irrelevant for this case as they will be larger).

I.e. there is no possibility for a normal ported design with those W drivers and no free simulating program in the world can ever show you a standard ported speaker design without severe peaking response and other non-preferable data.

…I thought these were generally a way to provide extended bass response, but at the cost of tightness and flatness and quality of response?…

Of course, increasing the volume could add a slight extension, but with what volume to be used and what are you willing to trade with and what quality compared with what?

There are endless volumes to chose from, what is the internal volume limit for your W drivers? You must submit this clue, no one else knows but you.

What’s wrong with the first FR curve in picture in post # 62?

It represents the FR curve for a ported aperiodic box of 20 L from which I think you cannot get any lower cutoff frequency from, I believe for this W driver this volume is quite appealing.

You will obviously make 2 compartments and this together with the M –T volume is an extra volume about 5 liters that totally adds up to be at least 20+20+5 = 45 L.

Increase this volume and you might gain very little extension but the culprit here is that you still have to give any numbers or requirements like volumes to work with.

...but i am confused.. i thought 42L so ~84L for a closed box, and 20Lx2 for the aperiodic, not 89L?…

Sorry, this is an obvious simple typo, it should of course be the other way around, thus net 45 L (added 5L for the gross M (T) compartment) for 2 small ported aperiodic boxes and the minimum 89 L (2x42 + added 5L for the gross M (T) compartment) is for the 2 closed boxes.

You have to figure out the total volumes yourself, as I don’t know what wood thickness you will use, maybe 16 mm?

If you want to extend beyond and lower the cutoff further you have to make a decision how large this W enclosure part is allowed to be and supply a response including a drawing. It is simple as that.

...however that speaks to me and 89L definitely too large…

89 L is only for the sum of the internal volumes of the closed compartments that in the end will result in a volume as large as 120 L, the wood included.

I repeat:

If otherwise, there is something wrong with the net 20 L ported aperiodic box or if the net volume of 89 L for the closed suggestion is too large, you have to provide the unknown dimensions.

You have to estimate the total volumes and dimensioning, I wont, and if you want any further help or response from me, or new FR predictions using other volumes, you have to supply valid numbers from the drawings of your center.

b

Thanks for the reply. Nothing is wrong with the frequency responses you provided, I was simply wondering what my options were. I'll definitely go with the aperiodic box, I'm guessing the between 50 and 60L is gonna be the biggest I'll want to go for, but I'll do some measurements tonight and work it out 🙂 and start designing the box since I think I have what I need now

only other things on my mind are, I'm going to want to have all the drivers as close to each other as possible right?

only other things on my mind are, I'm going to want to have all the drivers as close to each other as possible right?

have finally started to design

thinking at the moment, using 3/4" wood for the box... 1/2" for the inner box the midrange - if want to have the midrange and tweeter close together, 3/4" too big...

also thinking of using some 2" wood for rear bracing, and 3/4" for the rest of the bracing

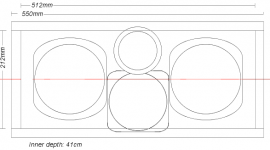

lots of stuff sketched on paper, but here's one mostly to scale done on computah of part of front view (the inner circles of the drivers arent to scale, the outers are, and everything else should be... hopefully 🙂 )

thinking at the moment, using 3/4" wood for the box... 1/2" for the inner box the midrange - if want to have the midrange and tweeter close together, 3/4" too big...

also thinking of using some 2" wood for rear bracing, and 3/4" for the rest of the bracing

lots of stuff sketched on paper, but here's one mostly to scale done on computah of part of front view (the inner circles of the drivers arent to scale, the outers are, and everything else should be... hopefully 🙂 )

Attachments

Hi,

Use 19 mm wood throughout, the W drivers will be close enough.

Your sketch suggests a volume less than 14 L if 3/4 “ wood is used?

The volume for the W drivers should at least be 21 L if ported, the port and bracing not taken into account.

Post a drawing with all drawing dimensioning visible.

b

1(1)

Use 19 mm wood throughout, the W drivers will be close enough.

Your sketch suggests a volume less than 14 L if 3/4 “ wood is used?

The volume for the W drivers should at least be 21 L if ported, the port and bracing not taken into account.

Post a drawing with all drawing dimensioning visible.

b

1(1)

Attachments

I think we see my diagram differently.. 🙂bjorno said:Your sketch suggests a volume less than 14 L if 3/4 “ wood is used?

I was thinking of just doing a 3.3L box for the mid, so really it's 45L(the whole box dimension) - ~5L =40L for the 2 woofers...

Ahoy there!

I'm back 🙂

Box is (I suppose) around 2/3 complete. Got the holes routed, and the main parts of the box together.

In terms of wooden construction, just need to add bracing, and add the front/rear panels.

Anyways, had some qustions (related to doing an aperiod box)..

1) Is it just a matter of cutting holes in the back and then covering them with insulation? Or do I buy special ports for this?

2) With insulation, do I need to say fill half the box with insulation, or do I just use insulation for lining? I've heard someone say between half and 2/3's of insulation for an aperiodic? Just wanted to double check..

3) (Not aperiodic related..) with the inner sealed box, should I line that with insulation or just leave the wood bare?

Thanks!

I'm back 🙂

Box is (I suppose) around 2/3 complete. Got the holes routed, and the main parts of the box together.

In terms of wooden construction, just need to add bracing, and add the front/rear panels.

Anyways, had some qustions (related to doing an aperiod box)..

1) Is it just a matter of cutting holes in the back and then covering them with insulation? Or do I buy special ports for this?

2) With insulation, do I need to say fill half the box with insulation, or do I just use insulation for lining? I've heard someone say between half and 2/3's of insulation for an aperiodic? Just wanted to double check..

3) (Not aperiodic related..) with the inner sealed box, should I line that with insulation or just leave the wood bare?

Thanks!

Hi Sunrise,

1) You have to design your own ports, see picture 1(2).

2) I always first line with ¼” – (1”) wool felt, spray glued on all internal surfaces but is optional if the driver is operating in the mid bass area or lower.

How to fill the enclosure with damping material see picture 1(2)

3) Fill the entire volume with stuffing 8 kg/m^3 = 0.5 lb/ft^3

b

1(2)-2(2) =updated simulation (post # 61).

1(1)

1) You have to design your own ports, see picture 1(2).

2) I always first line with ¼” – (1”) wool felt, spray glued on all internal surfaces but is optional if the driver is operating in the mid bass area or lower.

How to fill the enclosure with damping material see picture 1(2)

3) Fill the entire volume with stuffing 8 kg/m^3 = 0.5 lb/ft^3

b

1(2)-2(2) =updated simulation (post # 61).

1(1)

Attachments

bjorno said:Hi Sunrise,

1) You have to design your own ports, see picture 1(2).

Hi thanks for the reply!!

I take it, its like I said, a matter of cutting the holes to the dimensions said, and then covering over with stuffing?

Thank you so much

and with the ports, by the diagram.. I'm guessing that's 4" diameter, 7" length.. I'm thinking of getting basically ports used for ported boxes, and then just filling that up with polyfill...

Closest matching at an electronics store 30mins away is with diamater of 110mm (4.4"). Would that be close enough if I keep the volume the same by keeping the length to ~6.36" ?

Also wondering, if you recommend priming inside of the enclosure.. I'm thinking it might help reduce moisture getting in the MDF? and is priming necessary for outside if veneering

Thanks!

Closest matching at an electronics store 30mins away is with diamater of 110mm (4.4"). Would that be close enough if I keep the volume the same by keeping the length to ~6.36" ?

Also wondering, if you recommend priming inside of the enclosure.. I'm thinking it might help reduce moisture getting in the MDF? and is priming necessary for outside if veneering

Thanks!

and going back to the topic of ports..

I'm just wondering why is it necessary (ie the technical side of things) to have the aperiod port in an actual port...

I've heard of people basically just cutting a hole, and then using either dense polyfill over it or coffee filters.

There's also companies that sell aperiodic vents which are just like this..... just a flat/disc insert kinda thing

I'm just wondering why is it necessary (ie the technical side of things) to have the aperiod port in an actual port...

I've heard of people basically just cutting a hole, and then using either dense polyfill over it or coffee filters.

There's also companies that sell aperiodic vents which are just like this..... just a flat/disc insert kinda thing

as promised, more..

late in construction.. the box, with some bracing (which I think will be adequate).. also the sides/bottom/top have some bits inside the wood joining them too

when it came to attaching the front panel to the box,

my clamps were an inch too short, so I improvised with bricks.. a lot of bricks... sealed perfectly on about 2/3 that many bricks, but extras just to make sure 😉

spent a day sanding the wood from 200 to 2000 grit paper

then an evening priming the inside, and in 1 day, primed, sanded, primed, sanded, spray painted (2 coats on visible surfaces) the outside in 10 hours 🙂

some lining...

my approach to making it aperiodic.. basically done some reading on what other people have done (both on diyaudio and other sites), and came up with my own... concensus seems to be, ignore what port readings, and just cut out the diameter....

I saw in one thread someone suggesting use of coffee filters, and setting it up so it can easily be modified

what i've done is used fly screen and bolts, so can easily remove the outer fly screen and take out / add more stuffing into the small gap without removing the rear panel...

think that's effective enough??

it's new, and final (for now..) resting place

overall, first serious wood work project i've done..

first time using a router and they're AWESOME! (and surprisingly easy to use! just required patience and care)

and i'm happy with the result 🙂

just need to do the REAL crossover now

late in construction.. the box, with some bracing (which I think will be adequate).. also the sides/bottom/top have some bits inside the wood joining them too

An externally hosted image should be here but it was not working when we last tested it.

when it came to attaching the front panel to the box,

my clamps were an inch too short, so I improvised with bricks.. a lot of bricks... sealed perfectly on about 2/3 that many bricks, but extras just to make sure 😉

An externally hosted image should be here but it was not working when we last tested it.

spent a day sanding the wood from 200 to 2000 grit paper

then an evening priming the inside, and in 1 day, primed, sanded, primed, sanded, spray painted (2 coats on visible surfaces) the outside in 10 hours 🙂

An externally hosted image should be here but it was not working when we last tested it.

some lining...

An externally hosted image should be here but it was not working when we last tested it.

my approach to making it aperiodic.. basically done some reading on what other people have done (both on diyaudio and other sites), and came up with my own... concensus seems to be, ignore what port readings, and just cut out the diameter....

I saw in one thread someone suggesting use of coffee filters, and setting it up so it can easily be modified

what i've done is used fly screen and bolts, so can easily remove the outer fly screen and take out / add more stuffing into the small gap without removing the rear panel...

think that's effective enough??

An externally hosted image should be here but it was not working when we last tested it.

it's new, and final (for now..) resting place

An externally hosted image should be here but it was not working when we last tested it.

overall, first serious wood work project i've done..

first time using a router and they're AWESOME! (and surprisingly easy to use! just required patience and care)

and i'm happy with the result 🙂

just need to do the REAL crossover now

hi, sorry to disappoint, but unfortunately don't have anything to update.Excalibur said:bump for update

I'm still yet to do the proper crossover for it (and I'm busy the next few weekends too argh), but with what I've got at the moment, I am still impressed by it. (Maybe I'm just easily impressed? 🙂 ).

Also, my ears say the tweeter is VERY nice!

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- DIY Centre Speaker advice