Man, you've got PATIENCE!

One quick question tho...what about just using the resin to FILL plexi or glass forms?

That way you don't need to worry about the surface texture, just removing the bubbles, which you've already solved. Sort of like the water filled you previously did. Just thought it might be an easier route to go before you start pulling your hair out, or go BROKE (let's hope not).

Just trying to help out any way I can.

Bud

One quick question tho...what about just using the resin to FILL plexi or glass forms?

That way you don't need to worry about the surface texture, just removing the bubbles, which you've already solved. Sort of like the water filled you previously did. Just thought it might be an easier route to go before you start pulling your hair out, or go BROKE (let's hope not).

Just trying to help out any way I can.

Bud

If at first you don't suceed, try, try again (just go broke in the process 🙂)

Hi Bud,

I idea with both Perspex and Glass was exactly that - fill them with resin to replace the liquid (water, glyersol, oil and what ever else had been used) with a solid.

As it turns out, this is not as simple as that for a couple of reasons -

1. Different resins behave differently - ie where the latest product pours virtually bubble free and has in most cases set that way.

2. Contraction rates and setting times vary with ambient air temp and the product itself.

The thickness of the prisms also play a part here as you have two very different temps from end to end, where the knife edge (apex) is much cooler than the opposite end (thick end), which gets very hot due to the amount of product, and that fact that it is an exothermic reaction, the heat can not escape.

Building a "hot box" will help level the playing field as it will keep the temp constant for the entire prism.

3. Adhesion to the inside surface will vary as well. I have not had very good results with Perspex of late. All of the latest batches of prisms have crazy cracks on their insides. It might be a reaction between the resin and the Perspex, or as has been suggested, caused by the resin "tearing itself away" as it contracts.

With the glass, the resin simply let go, and whilst it did shrink, the surfaces came out pretty clean. What might work, and is now what I want to try next is to pour the body first, then laminate the glass faces after the main body has set. There is no shrinkage in thin pours, and if the air can be pushed out, the resin "fills" any imperfections on the sufaces. This effect is similar to how water fills and hides scatches on the inside of a fish tank...

This seems to work with left over product that I keep adding to a previous messy job. I had a fualty batch of another product and it went off in the mixing pot before I could degas. What I ended up with is a pot of resin with a rough surface. I have since added small amounts to the rough area, and it seems to strick quite well, but best of all, levels the imperfections...

Mark

Hi Bud,

I idea with both Perspex and Glass was exactly that - fill them with resin to replace the liquid (water, glyersol, oil and what ever else had been used) with a solid.

As it turns out, this is not as simple as that for a couple of reasons -

1. Different resins behave differently - ie where the latest product pours virtually bubble free and has in most cases set that way.

2. Contraction rates and setting times vary with ambient air temp and the product itself.

The thickness of the prisms also play a part here as you have two very different temps from end to end, where the knife edge (apex) is much cooler than the opposite end (thick end), which gets very hot due to the amount of product, and that fact that it is an exothermic reaction, the heat can not escape.

Building a "hot box" will help level the playing field as it will keep the temp constant for the entire prism.

3. Adhesion to the inside surface will vary as well. I have not had very good results with Perspex of late. All of the latest batches of prisms have crazy cracks on their insides. It might be a reaction between the resin and the Perspex, or as has been suggested, caused by the resin "tearing itself away" as it contracts.

With the glass, the resin simply let go, and whilst it did shrink, the surfaces came out pretty clean. What might work, and is now what I want to try next is to pour the body first, then laminate the glass faces after the main body has set. There is no shrinkage in thin pours, and if the air can be pushed out, the resin "fills" any imperfections on the sufaces. This effect is similar to how water fills and hides scatches on the inside of a fish tank...

This seems to work with left over product that I keep adding to a previous messy job. I had a fualty batch of another product and it went off in the mixing pot before I could degas. What I ended up with is a pot of resin with a rough surface. I have since added small amounts to the rough area, and it seems to strick quite well, but best of all, levels the imperfections...

Mark

Hi Mark,

I have been interested in 2.35:1 projection since first reading the thread in the AVS forum and even more so since finding this thread a couple of weeks ago.

I am very impressed with your work over the past year - great perseverance!

I am experimenting with glass faced moulds and 'standard' casting resin (if it works, I will try to source some really clear casting resin like this http://www.smooth-on.com/PDF/Crystal Clear 200 Series - TB.pdf or possibly one of the optical resins that are as clear as, or clearer than, glass - like CR39).

So far I have made one prism. It has no bubbles and released nicely from the glass with no shrinkage. I am letting it harden for a few days before polishing.

My question to you is: Why do you want to make prisms with glass (or perspex) faces? Am I missing something or wouldn't it be better if they were just solid resin?

Greg

I have been interested in 2.35:1 projection since first reading the thread in the AVS forum and even more so since finding this thread a couple of weeks ago.

I am very impressed with your work over the past year - great perseverance!

I am experimenting with glass faced moulds and 'standard' casting resin (if it works, I will try to source some really clear casting resin like this http://www.smooth-on.com/PDF/Crystal Clear 200 Series - TB.pdf or possibly one of the optical resins that are as clear as, or clearer than, glass - like CR39).

So far I have made one prism. It has no bubbles and released nicely from the glass with no shrinkage. I am letting it harden for a few days before polishing.

My question to you is: Why do you want to make prisms with glass (or perspex) faces? Am I missing something or wouldn't it be better if they were just solid resin?

Greg

Hi Fisher,

Good to see some one else having a go at this to 🙂

Basically my thinking is of not having to pollish the faces. The most successful pour to date (whilst I used the wrong resin) came away cleanly from the 6mm glass that I used as a mold. The faces looked smooth, but I feel that they would still need some work to make them "optical" grade. Pollishing takes time and skill...

Are you making a HE or VC?

Thank you. I was only discussing it today whilst re-setting my water prisms - WOW, it really has been a year...

Now I have several questions for you...

I couldn't get your link to work - so is the resin you used epoxy or poly?

I want to hear about the molds. Glass at the front and back - what about the sides? Did you use a release agent, or did the resin you used simply not stick to the glass?

You said no shrinkage - did you mix the full amount of hardener?

Did you build a hot box?

How clear is the one prism you have made? Is it like water?

Are there any striations?

Did you find that the resin takes about 36 hours to fully harden?

I found that the acid from my finger prints can affect the surface if not fully set...

Looking forward to a reply soon...

Mark

Good to see some one else having a go at this to 🙂

My question to you is: Why do you want to make prisms with glass (or perspex) faces? Am I missing something or wouldn't it be better if they were just solid resin?

Basically my thinking is of not having to pollish the faces. The most successful pour to date (whilst I used the wrong resin) came away cleanly from the 6mm glass that I used as a mold. The faces looked smooth, but I feel that they would still need some work to make them "optical" grade. Pollishing takes time and skill...

I have been interested in 2.35:1 projection since first reading the thread in the AVS forum and even more so since finding this thread a couple of weeks ago.

Are you making a HE or VC?

I am very impressed with your work over the past year - great perseverance!

Thank you. I was only discussing it today whilst re-setting my water prisms - WOW, it really has been a year...

I am experimenting with glass faced moulds and 'standard' casting resin (if it works, I will try to source some really clear casting resin like this http://www.smooth-on.com/PDF/Crystal Clear 200 Series - TB.pdf or possibly one of the optical resins that are as clear as, or clearer than, glass - like CR39).

So far I have made one prism. It has no bubbles and released nicely from the glass with no shrinkage. I am letting it harden for a few days before polishing.

Now I have several questions for you...

I couldn't get your link to work - so is the resin you used epoxy or poly?

I want to hear about the molds. Glass at the front and back - what about the sides? Did you use a release agent, or did the resin you used simply not stick to the glass?

You said no shrinkage - did you mix the full amount of hardener?

Did you build a hot box?

How clear is the one prism you have made? Is it like water?

Are there any striations?

Did you find that the resin takes about 36 hours to fully harden?

I found that the acid from my finger prints can affect the surface if not fully set...

Looking forward to a reply soon...

Mark

Hi Mark,

Thanks for the reply, it helps with motivation to have the feedback (translation: gets me off my ****!)

For perspective, I am new to all of this. I haven't made moulds or cast anything before. I have read this thread and struggled through google translations of the project at http://www.homecinema-fr.com/forum/ (see skhattane post 448 this thread). I have also discussed what I wanted to do with the local resin supply companies and they gave me some advice.

My initial aim is to create a 4 prism set. This has two advantages of achromatising and easier-to-make thinner prisms. I will make 4 at 10deg with the 'standard' casting resin. If that is encouraging, I will think about better angles vs refractive index and clearer casting resins.

I'm planning on trialing with VC, but they should be big enough to have a play with HE (fortunately I have a projector with reasonable zoom).

I can't get the link to display correctly (I think the spaces are confusing it). Put www. in front of:

smooth-on.com/PDF/Crystal Clear 200 Series - TB.pdf

However, this wasn't what I used. The product I used was a general purpose (poly I believe) casting resin.

The sides are made from perspex. I used a release agent called Frekote which is chemical (not PVA or wax based). I am going to try a cast without the release agent on the glass. It did come out smooth but left a film which I am having trouble polishing off (you can only see it if you look along the surface into a light source and probably won't affect the optical properties).

I used less catalyst (0.7%) than the 'standard' 1%. The resin people suggested slowing down the cure time to reduce exothermic effects.

No. In fact the reverse. I kept the mould cold during the initial cure phase. This was done to slow the cure process. This wasn't hard - I poured at 6:00pm and left it in the garage. Night temp in Auckland is 6-8degC at the moment. I post cured it (in front of a heater at around 30degC for a few hours) after removing from the mould 2 days after the pour.

It is pretty clear - looks like glass. The manufacturer can't give me a clarity (or refractive index) for it. However, I used this as it was easliy available and cheap to prove (hopefully) the concept. As above, if it works I will try to find some really clear product

As a sidebar, I'm not too worried about light loss. I have used a ND filter to reduce black level in my current setup. My projection priorities in order are contrast, black level, colour then resolution. However, what I don't know is if a less than clear prism will blur or distort the image somehow.

I can't see any optical distortion when looking through the prism (apart from the compression and colour fringing), i.e. no visible swirls or striation.

I released from the mould after 2 days and it was sticky on the sides (I didn't touch the faces but assume they were the same).

It was fine straight after the post cure.

Greg

Thanks for the reply, it helps with motivation to have the feedback (translation: gets me off my ****!)

For perspective, I am new to all of this. I haven't made moulds or cast anything before. I have read this thread and struggled through google translations of the project at http://www.homecinema-fr.com/forum/ (see skhattane post 448 this thread). I have also discussed what I wanted to do with the local resin supply companies and they gave me some advice.

My initial aim is to create a 4 prism set. This has two advantages of achromatising and easier-to-make thinner prisms. I will make 4 at 10deg with the 'standard' casting resin. If that is encouraging, I will think about better angles vs refractive index and clearer casting resins.

I'm planning on trialing with VC, but they should be big enough to have a play with HE (fortunately I have a projector with reasonable zoom).

I couldn't get your link to work - so is the resin you used epoxy or poly?

I can't get the link to display correctly (I think the spaces are confusing it). Put www. in front of:

smooth-on.com/PDF/Crystal Clear 200 Series - TB.pdf

However, this wasn't what I used. The product I used was a general purpose (poly I believe) casting resin.

I want to hear about the molds. Glass at the front and back - what about the sides? Did you use a release agent, or did the resin you used simply not stick to the glass?

The sides are made from perspex. I used a release agent called Frekote which is chemical (not PVA or wax based). I am going to try a cast without the release agent on the glass. It did come out smooth but left a film which I am having trouble polishing off (you can only see it if you look along the surface into a light source and probably won't affect the optical properties).

You said no shrinkage - did you mix the full amount of hardener?

I used less catalyst (0.7%) than the 'standard' 1%. The resin people suggested slowing down the cure time to reduce exothermic effects.

Did you build a hot box?

No. In fact the reverse. I kept the mould cold during the initial cure phase. This was done to slow the cure process. This wasn't hard - I poured at 6:00pm and left it in the garage. Night temp in Auckland is 6-8degC at the moment. I post cured it (in front of a heater at around 30degC for a few hours) after removing from the mould 2 days after the pour.

How clear is the one prism you have made? Is it like water?

It is pretty clear - looks like glass. The manufacturer can't give me a clarity (or refractive index) for it. However, I used this as it was easliy available and cheap to prove (hopefully) the concept. As above, if it works I will try to find some really clear product

As a sidebar, I'm not too worried about light loss. I have used a ND filter to reduce black level in my current setup. My projection priorities in order are contrast, black level, colour then resolution. However, what I don't know is if a less than clear prism will blur or distort the image somehow.

Are there any striations?

I can't see any optical distortion when looking through the prism (apart from the compression and colour fringing), i.e. no visible swirls or striation.

Did you find that the resin takes about 36 hours to fully harden?

I released from the mould after 2 days and it was sticky on the sides (I didn't touch the faces but assume they were the same).

It was fine straight after the post cure.

Greg

Hello Greg,

Totally agreed. I wish I had joined this thread back in 2002 when it was really active...

I too am working with 10 degrees. I honestly don't think that any specific angle must be followed. My water prisms are two 30 degree prisms, but having seen actual Prismasonic product, I choose to make my resin casts 10degrees which turn out to be much thinner.

Out of all that one I have made so far, I have a few that work, but most are not clear enough to use for front projection due to either striations (worked out that slow curing times reduced this), bubbles (mixing and pouring technique affect this and I even bought a vacuum chamber), or crazycrack (why I have turned to glass for molds)...

Well that is interesting becuase the surfboard finish resin I used lats time also (contains wax🙁) left the same result you describe...

The night temps here are 10 to 12 now, so might give this another go...

I'll be interested to hear the results. The local suppliers here seem to only have one "clear casting and embedding" resin, which I have already trialed and think works well...

That is really good news. Sound like you have had success with this project...

I like the idea of the "post cure" and will try that next time. Can you post a photo? How long before you can cast your next prism?

You have just given me a boost of confidence, so I'm off to make another mold 🙂

Mark

Thanks for the reply, it helps with motivation to have the feedback (translation: gets me off my ****!)

Totally agreed. I wish I had joined this thread back in 2002 when it was really active...

My initial aim is to create a 4 prism set. This has two advantages of achromatising and easier-to-make thinner prisms. I will make 4 at 10deg with the 'standard' casting resin. If that is encouraging, I will think about better angles vs refractive index and clearer casting resins.

I too am working with 10 degrees. I honestly don't think that any specific angle must be followed. My water prisms are two 30 degree prisms, but having seen actual Prismasonic product, I choose to make my resin casts 10degrees which turn out to be much thinner.

Out of all that one I have made so far, I have a few that work, but most are not clear enough to use for front projection due to either striations (worked out that slow curing times reduced this), bubbles (mixing and pouring technique affect this and I even bought a vacuum chamber), or crazycrack (why I have turned to glass for molds)...

The sides are made from perspex. I used a release agent called Frekote which is chemical (not PVA or wax based). I am going to try a cast without the release agent on the glass. It did come out smooth but left a film which I am having trouble polishing off (you can only see it if you look along the surface into a light source and probably won't affect the optical properties).

Well that is interesting becuase the surfboard finish resin I used lats time also (contains wax🙁) left the same result you describe...

No. In fact the reverse. I kept the mould cold during the initial cure phase. This was done to slow the cure process. This wasn't hard - I poured at 6:00pm and left it in the garage. Night temp in Auckland is 6-8degC at the moment. I post cured it (in front of a heater at around 30degC for a few hours) after removing from the mould 2 days after the pour.

The night temps here are 10 to 12 now, so might give this another go...

It is pretty clear - looks like glass. The manufacturer can't give me a clarity (or refractive index) for it. However, I used this as it was easliy available and cheap to prove (hopefully) the concept. As above, if it works I will try to find some really clear product

I'll be interested to hear the results. The local suppliers here seem to only have one "clear casting and embedding" resin, which I have already trialed and think works well...

I can't see any optical distortion when looking through the prism (apart from the compression and colour fringing), i.e. no visible swirls or striation.

That is really good news. Sound like you have had success with this project...

I released from the mould after 2 days and it was sticky on the sides (I didn't touch the faces but assume they were the same).

I like the idea of the "post cure" and will try that next time. Can you post a photo? How long before you can cast your next prism?

You have just given me a boost of confidence, so I'm off to make another mold 🙂

Mark

Hi Mark,

I prepped the mould last night and will pour in the weekend (could be sooner but that is the next time slot )🙁

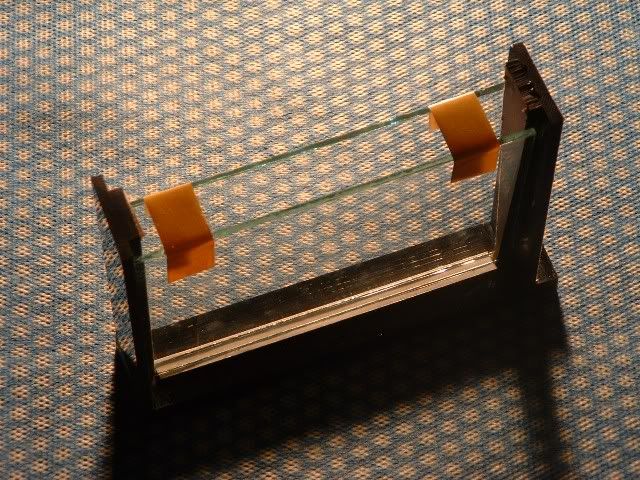

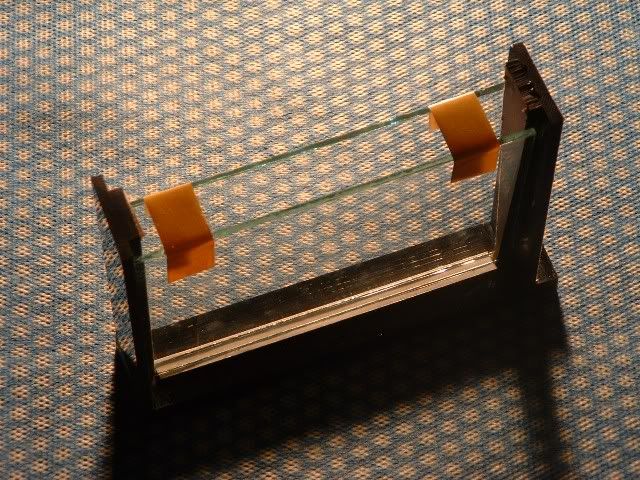

The mould is made from 5mm and 10mm perspex (or acrylic?). just some strips I had available. I made a pair of triangles from the 5mm and CA (superglue) it to another 5mm rectangular piece. These were then CA'd to the 10mm base. I took some care with positioning the triangles and ensuring everything else was square. Set squares were used for assembly to minimise building in a warp.

I then place double sided foam tape on the base to seat the glass, install the glass sides, tape the top to hold in place and silicon around the edges.

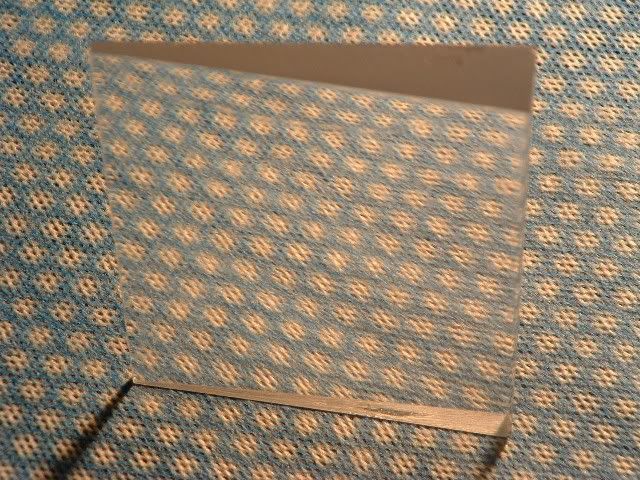

This is the first prism.

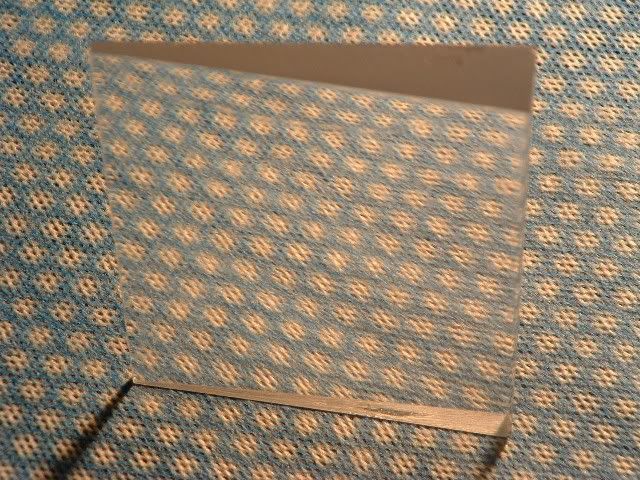

And a closeup

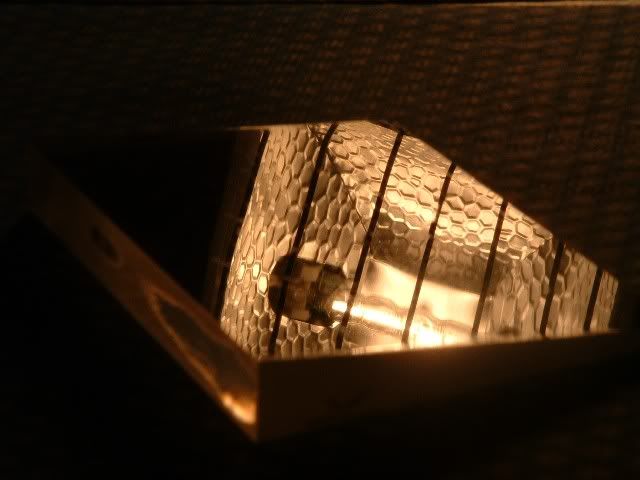

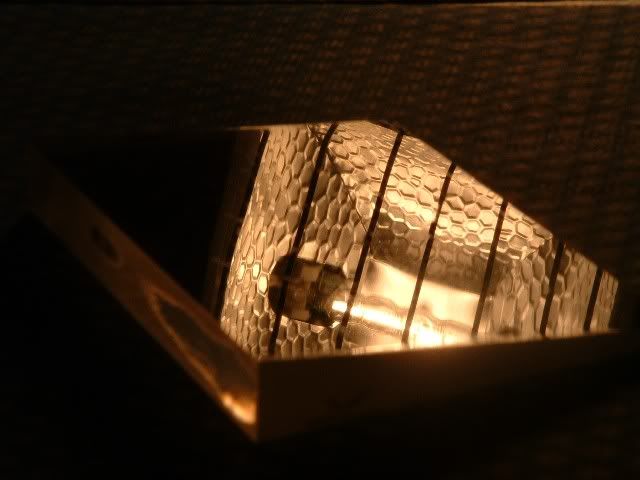

and a view along a face into the light (a 500W builders worklight)

Cheers,

Greg

I prepped the mould last night and will pour in the weekend (could be sooner but that is the next time slot )🙁

The mould is made from 5mm and 10mm perspex (or acrylic?). just some strips I had available. I made a pair of triangles from the 5mm and CA (superglue) it to another 5mm rectangular piece. These were then CA'd to the 10mm base. I took some care with positioning the triangles and ensuring everything else was square. Set squares were used for assembly to minimise building in a warp.

I then place double sided foam tape on the base to seat the glass, install the glass sides, tape the top to hold in place and silicon around the edges.

This is the first prism.

And a closeup

and a view along a face into the light (a 500W builders worklight)

Cheers,

Greg

WOW! That prism looks very good. I can see what your saying about the wax coating on the surface, but that could be simply product related because the prism looks great.

I have made my new mold, and hopefully will buy the resin today and pour either today or tomorrow.

Good work 🙂

Mark

I have made my new mold, and hopefully will buy the resin today and pour either today or tomorrow.

Good work 🙂

Mark

Here is some shots of the last resin cast. Note - This is why surfboard resin is no good for this project...

The smaller prism. The corners cracked off due to thermal differences (I guess), and the glass on one side cracked, but not as bad as this...

The glass was OK but the resin cracked on the larger prism. I'm not sure a hot box will prevent this from happening, but I have made another mold (horizontal this time)...

The sides are glass, the base and back are perspex. I have used the hot glue gun to hold the parts in place (using a set square to check the vertical sides) and then used the modeling clay to form a seal...

I will use the "clear casting and embedding resin" and see how it turns out...

Mark

The smaller prism. The corners cracked off due to thermal differences (I guess), and the glass on one side cracked, but not as bad as this...

The glass was OK but the resin cracked on the larger prism. I'm not sure a hot box will prevent this from happening, but I have made another mold (horizontal this time)...

The sides are glass, the base and back are perspex. I have used the hot glue gun to hold the parts in place (using a set square to check the vertical sides) and then used the modeling clay to form a seal...

I will use the "clear casting and embedding resin" and see how it turns out...

Mark

I see what you mean about the surfboard resin! Good luck with the casting resin.

In your post 515 you discuss an optics specialist (from OPSM) who makes prisms out of CR39. Did you, or are you able to, get CR39 from him?

What are the prism angles that Prismasonic use and what are they made of?

Greg

In your post 515 you discuss an optics specialist (from OPSM) who makes prisms out of CR39. Did you, or are you able to, get CR39 from him?

water prisms are two 30 degree prisms, but having seen actual Prismasonic product, I choose to make my resin casts 10degrees which turn out to be much thinner.

What are the prism angles that Prismasonic use and what are they made of?

Greg

try try again...

Thanks 🙂 I bought another Kg tin today and filled the mold that I prepared yesterday. I think I had too much hardener(again 🙁), as the resin itself cracked. I used the hot box and kept the prism at over 25degC, but I think because the "thick" end heats right up, I need to back down the cat below half a percent/volume...

These photos look a bit yellow due to poor light. I used the "landscape" setting on the camera tonight and the GF then informs me that it will blur the back ground (not the best thing to show clarity of the resin 🙄 but as you can see, this resin is clear. These peices look like glass, and are as brittle as glass...

I'm annoyed that the prism cracked. This might just have been the best pour to date - 100% bubble free - no vacuum chamber required...Oh well, at least I recovered my glass so I can make another mold 🙂

Mark

I see what you mean about the surfboard resin! Good luck with the casting resin.

Thanks 🙂 I bought another Kg tin today and filled the mold that I prepared yesterday. I think I had too much hardener(again 🙁), as the resin itself cracked. I used the hot box and kept the prism at over 25degC, but I think because the "thick" end heats right up, I need to back down the cat below half a percent/volume...

These photos look a bit yellow due to poor light. I used the "landscape" setting on the camera tonight and the GF then informs me that it will blur the back ground (not the best thing to show clarity of the resin 🙄 but as you can see, this resin is clear. These peices look like glass, and are as brittle as glass...

I'm annoyed that the prism cracked. This might just have been the best pour to date - 100% bubble free - no vacuum chamber required...Oh well, at least I recovered my glass so I can make another mold 🙂

No I never got back on to that guy. He went on holidays for five weeks, and when I tried to call, I could not seem to get back in touch...In your post 515 you discuss an optics specialist (from OPSM) who makes prisms out of CR39. Did you, or are you able to, get CR39 from him?

I have never had the oppertunity to actually measure the angles, but they look thinner than 10degree, more closer to 5 or 7 degree...They are made from Optic Glass (probably BK7)...What are the prism angles that Prismasonic use and what are they made of?

Mark

Mark--as you have commented that the material is very "glass" like, it got me thinking--why not use glass? A secretary at my work has a couple of these glass blocks on her desk that are crystal clear, and they have embedded inside an image that has been lasered into the block to form a 3-d pattern.

The one has a flower inside, and is about 4 inches tall by 2 inches wide. I turn it over, and the price tag on the bottom indicates that it was purchased from an "everything under $1" store (we have these here in the States, where everything in the store is $1 or less.

This astounded me--considering how crystal clear the glass was, and how smooth the edges were. And she couldn't have paid more than $1 for this! So how hard would it be to obtain a couple of glass wedges? Granted, they would have to be bigger, but they can't be too expensive, right?

I did some searching, and found this from a store, where you can have words etched into glass forms:

http://www.thingsremembered.com/webapp/wcs/stores/servlet/product_10001_0_564481_-1_537

And while this is expensive, I have to think that there has got to be a way to get these things made, and pretty cheaply, without the resin problems you are trying to solve (although that's a pretty cool solution, as well).

Here's another link:

http://www.crystalgiftsengraved.com/standupawards.html

and an image from that page:

The largest wedge has dimensions: 6in. x 7.5in. x 1.5in.

Just thought I'd pass these thoughts along...

The one has a flower inside, and is about 4 inches tall by 2 inches wide. I turn it over, and the price tag on the bottom indicates that it was purchased from an "everything under $1" store (we have these here in the States, where everything in the store is $1 or less.

This astounded me--considering how crystal clear the glass was, and how smooth the edges were. And she couldn't have paid more than $1 for this! So how hard would it be to obtain a couple of glass wedges? Granted, they would have to be bigger, but they can't be too expensive, right?

I did some searching, and found this from a store, where you can have words etched into glass forms:

http://www.thingsremembered.com/webapp/wcs/stores/servlet/product_10001_0_564481_-1_537

And while this is expensive, I have to think that there has got to be a way to get these things made, and pretty cheaply, without the resin problems you are trying to solve (although that's a pretty cool solution, as well).

Here's another link:

http://www.crystalgiftsengraved.com/standupawards.html

and an image from that page:

The largest wedge has dimensions: 6in. x 7.5in. x 1.5in.

Just thought I'd pass these thoughts along...

Hi Mark,

Those look great (if they had stayed in one peice!).

Did you use a release agent with the glass?

What brand of casting resin are you using? I didn't notice any heating at all during curing. It may be that the hot box is causing the cure to happen too quickly and creating stress as the thickness changes along the prism.

That's interesting. Glass has a lower refractive index than casting resin (BK7 is around 1.5 vs 1.5 to 1.7 for casting resins). I haven't researched this but I assumed that the higher the refractive index, the thinner the prism.

How many prisms in the Prismasonic (were they achromatic pairs), and did the angles look about the same as you have used before (by this I mean the positions of the prisms relative to each other)?

Hello Steve, this would be a great idea if we could find an existing product line. From what I have read, one-off is very expensive.

Greg

Those look great (if they had stayed in one peice!).

Did you use a release agent with the glass?

What brand of casting resin are you using? I didn't notice any heating at all during curing. It may be that the hot box is causing the cure to happen too quickly and creating stress as the thickness changes along the prism.

have never had the oppertunity to actually measure the angles, but they look thinner than 10degree, more closer to 5 or 7 degree...They are made from Optic Glass (probably BK7)...

That's interesting. Glass has a lower refractive index than casting resin (BK7 is around 1.5 vs 1.5 to 1.7 for casting resins). I haven't researched this but I assumed that the higher the refractive index, the thinner the prism.

How many prisms in the Prismasonic (were they achromatic pairs), and did the angles look about the same as you have used before (by this I mean the positions of the prisms relative to each other)?

Hello Steve, this would be a great idea if we could find an existing product line. From what I have read, one-off is very expensive.

Greg

Steve,

If you can find those prisms with NO marking inside or out, your set. The clarity of that product is about as good as you can get. I have tried a few manufactures, and they want huge $$$ for "one offs".

I also need the large prism to be 8 x 6" (7.5" is close enough 🙂) and most of that stuff is 4" max, so both your attachment and the first link looks promising. Good luck with that and keep us updated...

Fisher,

No release agent was used. The resin contracted about 3mm, so came away from the glass without incident. The sides are (where there no cracks) smooth as the glass they were cast from.

Fibre Glass Internation is the brand I have been using. Their "Clear Casting and Embedding" resin is affordable ($A22/Ltr) and works really (as soon as I fix the thermal issues) well.

Last pour (without the hot box), the air temp on the out side was too low compared to the heat from with in. The results were not positive and as a result, both the resin and glass cracked.

I simply used two "flood lamps" and monitored the temp with a thermometer shutting them off when the temp got too high.

I really just think it was a case of TOO MUCH hardender...

They make two types - 2 and 4 prism lenes. The 4 prism lens (cost twice as much) has the two sets of achromatic pairs virtually eliminating CA...

As for the angles, what I have noticed between my 30 degree water prisms and the few 10 degree resin casts (that did work) is that the front angle (the part of the prism that faces the screen) seems to remain close, hence why I don't believe that 20;26 and or 30 degrees were even necessary. Whilst I don't think they are exactly the same, they are close. That same goes for the rear prism (facing the projector)...

Mark

If you can find those prisms with NO marking inside or out, your set. The clarity of that product is about as good as you can get. I have tried a few manufactures, and they want huge $$$ for "one offs".

The largest wedge has dimensions: 6in. x 7.5in. x 1.5in.

I also need the large prism to be 8 x 6" (7.5" is close enough 🙂) and most of that stuff is 4" max, so both your attachment and the first link looks promising. Good luck with that and keep us updated...

Fisher,

No release agent was used. The resin contracted about 3mm, so came away from the glass without incident. The sides are (where there no cracks) smooth as the glass they were cast from.

Fibre Glass Internation is the brand I have been using. Their "Clear Casting and Embedding" resin is affordable ($A22/Ltr) and works really (as soon as I fix the thermal issues) well.

Last pour (without the hot box), the air temp on the out side was too low compared to the heat from with in. The results were not positive and as a result, both the resin and glass cracked.

I simply used two "flood lamps" and monitored the temp with a thermometer shutting them off when the temp got too high.

I really just think it was a case of TOO MUCH hardender...

How many prisms in the Prismasonic (were they achromatic pairs), and did the angles look about the same as you have used before (by this I mean the positions of the prisms relative to each other)?

They make two types - 2 and 4 prism lenes. The 4 prism lens (cost twice as much) has the two sets of achromatic pairs virtually eliminating CA...

As for the angles, what I have noticed between my 30 degree water prisms and the few 10 degree resin casts (that did work) is that the front angle (the part of the prism that faces the screen) seems to remain close, hence why I don't believe that 20;26 and or 30 degrees were even necessary. Whilst I don't think they are exactly the same, they are close. That same goes for the rear prism (facing the projector)...

Mark

For the optical wedges that I found--just curious, how much money is too much? The cheapest I found them is US$36 for the smallest (4x6), $50 for the medium (5x7) and $66 for the large (6x7.5).

I called the one company, and although they are out of stock, can provide these with no markings whatsoever. I asked how clear they were, and the woman I spoke to said they had no visible markings, striations, colors, or any impurities in the crystal.

I think I will order a couple, and see how they come out. If they are no good, well I'll have wasted a bit of money--but if they work, I could get my horizontal expansion lens I have been itching for...

I was thinking of ordering the small one and the medium one. They seem pretty thin, and if they are pretty close to the projector, they wouldn't need to be that big, would they?

I called the one company, and although they are out of stock, can provide these with no markings whatsoever. I asked how clear they were, and the woman I spoke to said they had no visible markings, striations, colors, or any impurities in the crystal.

I think I will order a couple, and see how they come out. If they are no good, well I'll have wasted a bit of money--but if they work, I could get my horizontal expansion lens I have been itching for...

I was thinking of ordering the small one and the medium one. They seem pretty thin, and if they are pretty close to the projector, they wouldn't need to be that big, would they?

WOW - HOW MUCH!?!

Steve,

If they have no markings, etching or engraving, buy them! Buy them NOW for those prices!!! You need at least one 4" x 6" (rear prism) and one 6" x 7.5" (front prism). Or you could use 2 of the same size and build a reversable lens - HE one way and VC when turned and rotated, but at a minium you would need the sizes I have listed above or maybe replace the 4 x 6 with the 5 x 7...

It will cost you $102 with a max of $204 (+P&H and some MDF) and you will have your HE lens for a fraction of the price of a commercial equivalent...I've spent well over 5 times that just getting this far...

Do a "paper test" outlined in the beginning few pages of this thread to confirm your sizes. Remember, shorter throws need larger prisms and you want (need) so room to move so don't just go for the smaller prism if it look OK on paper, as the front prism has to be set at quite a steep angle, so the light will be wide there...

You need two of each if you want to build a 4 prism lens.

Also can you PLEASE find out how much P&H would be to Australia, becuase I want a set, and I sure that I can find few others that want them too...

I used the links and didn't even get a response to email inquiries, so if you can source them, then NO they are not too much...

Remeber I got a quote for optic prisms and it came back at $10.5K for 4 prisms...

Mark

Steve,

If they have no markings, etching or engraving, buy them! Buy them NOW for those prices!!! You need at least one 4" x 6" (rear prism) and one 6" x 7.5" (front prism). Or you could use 2 of the same size and build a reversable lens - HE one way and VC when turned and rotated, but at a minium you would need the sizes I have listed above or maybe replace the 4 x 6 with the 5 x 7...

It will cost you $102 with a max of $204 (+P&H and some MDF) and you will have your HE lens for a fraction of the price of a commercial equivalent...I've spent well over 5 times that just getting this far...

Do a "paper test" outlined in the beginning few pages of this thread to confirm your sizes. Remember, shorter throws need larger prisms and you want (need) so room to move so don't just go for the smaller prism if it look OK on paper, as the front prism has to be set at quite a steep angle, so the light will be wide there...

You need two of each if you want to build a 4 prism lens.

Also can you PLEASE find out how much P&H would be to Australia, becuase I want a set, and I sure that I can find few others that want them too...

I used the links and didn't even get a response to email inquiries, so if you can source them, then NO they are not too much...

Remeber I got a quote for optic prisms and it came back at $10.5K for 4 prisms...

Mark

crystal prism

Hi Mark,

How about this?

They are 170mm x 140mm and $ 88 AUD from Evright in Adelaide. See:

http://www.evright.com/showproduct.asp?P=CB8A

I have tried to contact the NZ agent but got voicemail.

Greg

Hi Mark,

How about this?

They are 170mm x 140mm and $ 88 AUD from Evright in Adelaide. See:

http://www.evright.com/showproduct.asp?P=CB8A

I have tried to contact the NZ agent but got voicemail.

Greg

http://www.evright.com/contact.asp

Email: sales@evright.com

Head Office (Australia)

208 Gouger Street

Adelaide, South Australia, 5000

Phone: +61-8-8231-2746

Fax: +61-8-8221-6355

ABN 88 365 825 639

Email: sales@evright.com

Head Office (Australia)

208 Gouger Street

Adelaide, South Australia, 5000

Phone: +61-8-8231-2746

Fax: +61-8-8221-6355

ABN 88 365 825 639

Thanks Fisher.

I used the link and found a contact number, called them and ordered a pair.

They should be here next week 🙂

If they work out as a 2 prism lens, I will order another set and build a 4 prism lens. The only problem is that they come in one size only (not really a problem for me) so it will effect the overall size of the lens...

We have to be aware that these are not BK7, but a crystal, so it will be interesting to see (yes pun intended) how they look 🙂

Getting exciting now - stay tunned...

Mark

I used the link and found a contact number, called them and ordered a pair.

They should be here next week 🙂

If they work out as a 2 prism lens, I will order another set and build a 4 prism lens. The only problem is that they come in one size only (not really a problem for me) so it will effect the overall size of the lens...

We have to be aware that these are not BK7, but a crystal, so it will be interesting to see (yes pun intended) how they look 🙂

Getting exciting now - stay tunned...

Mark

- Home

- General Interest

- Everything Else

- The Moving Image

- Optics

- DIY anamorphic lens