Could do but your vertical pivot point is no longer at the centre of the arm wand diameter which is another great advantage of the terminator. I actually think turning the Ladergaard on 'its head" was a stroke of genius.. One development I would love to see is a dynamic solution to VTF via a spring or some such, that ol' diamond would stick to the grooves like **** to a blanket.

cheers fergs

cheers fergs

fergs1 said:One development I would love to see is a dynamic solution to VTF via a spring or some such, that ol' diamond would stick to the grooves like **** to a blanket.

cheers fergs

Hey, why use springs when we have air pumps going already!

Gentlemen,

The moving mass (horizontal, tracking across the record) is your enemy. That aluminum angle stock is heavier than you think... are you sure you want to move it with the stylus and cantilever of ur MC cartridge?

What about with a record with an off center hole?

If you hunt around you can likely find a friendly machinist who can work wonders...

Graphite rod? Fishing pole, golf club... are arrows controlled weapons in Ireland??

_-_-bear

The moving mass (horizontal, tracking across the record) is your enemy. That aluminum angle stock is heavier than you think... are you sure you want to move it with the stylus and cantilever of ur MC cartridge?

What about with a record with an off center hole?

If you hunt around you can likely find a friendly machinist who can work wonders...

Graphite rod? Fishing pole, golf club... are arrows controlled weapons in Ireland??

_-_-bear

looking at Inertia a little closer....

First, the side of the arm that the counter-weight is on has a higher Inertia for any given accelerations so it resists changes more than the stylus side of the arm.

Secondly, the arm doesn't care where it rotates. Yes, rotating about the centre of the arm appears more elegant, but again, due to Inertia, it is of no consequence. The arm should remain very stable. The acceleration required to overcome yhe counterweight's mass is very large compared to that which the stylus cantilever can provide.

There is however an inherent stability to any "under-hung" arrangement.

I'll do a few sketches to illustrate the point

stew

First, the side of the arm that the counter-weight is on has a higher Inertia for any given accelerations so it resists changes more than the stylus side of the arm.

Secondly, the arm doesn't care where it rotates. Yes, rotating about the centre of the arm appears more elegant, but again, due to Inertia, it is of no consequence. The arm should remain very stable. The acceleration required to overcome yhe counterweight's mass is very large compared to that which the stylus cantilever can provide.

There is however an inherent stability to any "under-hung" arrangement.

I'll do a few sketches to illustrate the point

stew

cid a couple of sketches....

the result? less than a .84% difference in the effective length from the location of the moment to the stylus tip. Pretty sure there are other things to consider before trying to kill off the source of a relatively minor issue. As I stated, a hanging arm is inherently stable, and the round "hanging" arm has fewer parts, so in theory the source for erroneous machining is reduced, and hence the accuracy of said device.

stew

the result? less than a .84% difference in the effective length from the location of the moment to the stylus tip. Pretty sure there are other things to consider before trying to kill off the source of a relatively minor issue. As I stated, a hanging arm is inherently stable, and the round "hanging" arm has fewer parts, so in theory the source for erroneous machining is reduced, and hence the accuracy of said device.

stew

Thinking out loud - I'm wondering if a way of producing a tight fit between a tube air manifold and it's circular sliding air bearing would be to dip the arm in some sort of melted plastic which would surround the tube & harden when cold. Any clearance could be chosen by using something like aluminium foil to wrap the tube in prior to dipping and removing after hardening. So tight tolerances could be achieved this way, I imagine?

The resultant sliding section would be light-weight & closely matched to the tube. As long as the tube was perfectly cylindrical to start with there should be no problem.

Is there anything I'm missing? What would be a good material to use for this?

The resultant sliding section would be light-weight & closely matched to the tube. As long as the tube was perfectly cylindrical to start with there should be no problem.

Is there anything I'm missing? What would be a good material to use for this?

Poul Ladegaard suggested epoxy for matching angles, I don't know why that couldn't be used with tubes. You would have to figure out what release material you can use to get the tubes apart afterward, but I'm sure that's well known (to those in the know). maybe a thin layer of white glue or something like that. Heck I'm a mac user; I'm much better at guessing what to do then to find the right manual, and actually read it!

PS. Nice draw vs Italy yesterday (in case you care...)

PS. Nice draw vs Italy yesterday (in case you care...)

jkeny said:Thinking out loud - I'm wondering if a way of producing a tight fit between a tube air manifold and it's circular sliding air bearing would be to dip the arm in some sort of melted plastic which would surround the tube & harden when cold. Any clearance could be chosen by using something like aluminium foil to wrap the tube in prior to dipping and removing after hardening. So tight tolerances could be achieved this way, I imagine?

The resultant sliding section would be light-weight & closely matched to the tube. As long as the tube was perfectly cylindrical to start with there should be no problem.

Is there anything I'm missing? What would be a good material to use for this?

Thanks Stagerlee,

I did watch the game but although the win was a good result both teams were bad & I'm afraid that with this team Ireland is not near being a contender.

Epoxy, aha a good idea, I'm glad you brought it up - so some material which would provide clearance (Airtangent use 25 micron gap all round the tube) & release from the tube. I guess the gap only determines the pressure needed from the air pump. I'm wondering if film negative would provide such a smooth thin homogenous film which wouldn't be attacked by the epoxy & would be easy to release from it?

I did watch the game but although the win was a good result both teams were bad & I'm afraid that with this team Ireland is not near being a contender.

Epoxy, aha a good idea, I'm glad you brought it up - so some material which would provide clearance (Airtangent use 25 micron gap all round the tube) & release from the tube. I guess the gap only determines the pressure needed from the air pump. I'm wondering if film negative would provide such a smooth thin homogenous film which wouldn't be attacked by the epoxy & would be easy to release from it?

jkeny said:I'm wondering if film negative would provide such a smooth thin homogenous film which wouldn't be attacked by the epoxy & would be easy to release from it?

A stretched balloon? A eh umm hrmmm nevermind....

On the subject of the mass and the stylus being under pressure. I did a quick and dirty eyperiment using a verve record with an odd lead out groove where the lead out groove runs the stylus in and out over the entire lead out area - its kind of hard to explain - but if you9ve ever seen one you know what I mean.

Anyway, on that fairly tough test, I could not see any deflection of the stylus as it moved the whole arm in and out repeatedly at the end of record. I think I used it in one of the youtube vids I posted back up aways.

Don,t think its a concern anymore.

Fran

Anyway, on that fairly tough test, I could not see any deflection of the stylus as it moved the whole arm in and out repeatedly at the end of record. I think I used it in one of the youtube vids I posted back up aways.

Don,t think its a concern anymore.

Fran

Any clearance could be chosen by using something like aluminium foil to wrap the tube in prior to dipping and removing after hardening.

And

A stretched balloon? A eh umm hrmmm nevermind....

Well, epoxy won't stick to plastic food wrap (e.g., Saran Wrap) and that would probably be about the right thickness; and I understand the food wrap can also be used for hrmmm nevermind purposes, though I can't vouch for it myself.

Regards.

Aengus

Having researched a bit more it seems that the terminator style air bearing is a more stable, lower pressure solution than the tube based type such as airtangent, etc. Lower pressure means less pump noise & less turbulence in the air cushion, so all-in-all a good thing.

I see that MKIII of the Terminator has been released which includes on-the-fly VTA adjustment with digital readout: http://video.aol.com/video-detail/t...arm-on-the-fly-vta-adjustment-demo/4079376636

Edit: I can't hear any difference in the video when he's adjusting the VTA while playing but that could have something to do with the music. How do you know the correct VTA adjustment?

I see that MKIII of the Terminator has been released which includes on-the-fly VTA adjustment with digital readout: http://video.aol.com/video-detail/t...arm-on-the-fly-vta-adjustment-demo/4079376636

Edit: I can't hear any difference in the video when he's adjusting the VTA while playing but that could have something to do with the music. How do you know the correct VTA adjustment?

Here's a suggestions for quiet air pump:

- a medical pump from Medo USA - low noise (40dB), & there's a range of them to suit either high pressure/low airflow or low pressure/high air flow - best bit is they come up on ebay for about $30 (there's a pair of Medo vacuum pump listed, at the moment, for $30 - item number 330317109281)

Medo http://www.medousa.com/en/product/default.asp?prd_ln=lpac

Thread on ET Tonearm about the pump: http://www.stevehoffman.tv/forums/showpost.php?p=1675170&postcount=16

Has anybody tried these?

As Fran says the biggest deterrent to building this TT arm is the noise of the pump so a search for a reasonable priced quiet pump is worth pursuing

Edit: I've seen a reference to a 32dB air pump somewhere which I'm trying to find

- a medical pump from Medo USA - low noise (40dB), & there's a range of them to suit either high pressure/low airflow or low pressure/high air flow - best bit is they come up on ebay for about $30 (there's a pair of Medo vacuum pump listed, at the moment, for $30 - item number 330317109281)

Medo http://www.medousa.com/en/product/default.asp?prd_ln=lpac

Thread on ET Tonearm about the pump: http://www.stevehoffman.tv/forums/showpost.php?p=1675170&postcount=16

Has anybody tried these?

As Fran says the biggest deterrent to building this TT arm is the noise of the pump so a search for a reasonable priced quiet pump is worth pursuing

Edit: I've seen a reference to a 32dB air pump somewhere which I'm trying to find

Just my opinions...

Remote the pump, long hose, use a reservoir to kill the pulse of the pump (tank), and if you have a large enough tank, there is no need to run the pump most of the time, use a regulator out.

The lower the moving mass the better. Nanook, the moving horizontal mass is dominated by the counterweight in a very GOOD air bearing arm, but not in one where the rest of the moving parts weigh more than the counterweight. I vote for reducing the total moving mass as much as possible.

As far as "seeing" the cantilever move, once you get the arm in motion, its own inertia is trying to "throw it" to the inside of the record. The flex will take place on the take off where the slope of the groove suddenly increases. Might take a slow mo camera to see it with the eye...

In the meantime, the arm is constantly being pushed toward the inside of the record by the outside of the groove - assuming the TT and arm are level. There is no other mechanism by which it can be made to travel, it has to follow the groove. By contrast, the standard arm wants to travel to the center, so we apply "anti-skate" to keep it centered in the groove. (another approximate solution) So again I vote for the arm that can change direction the fastest, and that will be the one with the lowest total overall moving mass.

This is why - in part - that several very smart designers of linear tracking arms have made the part that moves very light, and the length of the "arm" that holds the cartridge very short...

Of course ymmv.

As far as getting a precision fit? Read up on lapping for machine tools and lathes, milling machines. Or as I suggested at another time find urself a local machinist to do the precision part. They tend to have CNC stuff that works to 0.0001" these days, and precison grinders that do that and better... A good machinist really won't charge you all that much, but you have to shop around a little for someone who likes to help and do neat little projects.

Dorking with fillers (epoxy) and shims (aluminum foil or mylar) is going to be very very difficult to make work well... maybe you can perfect the technique. I wouldn't want to try getting it flat and square myself... stock extrusions just are not smooth nor flat, nor very straight....

_-_-bear

Edit: Oh, VTA effects the stereo spread, and the way that highs sound...

Remote the pump, long hose, use a reservoir to kill the pulse of the pump (tank), and if you have a large enough tank, there is no need to run the pump most of the time, use a regulator out.

The lower the moving mass the better. Nanook, the moving horizontal mass is dominated by the counterweight in a very GOOD air bearing arm, but not in one where the rest of the moving parts weigh more than the counterweight. I vote for reducing the total moving mass as much as possible.

As far as "seeing" the cantilever move, once you get the arm in motion, its own inertia is trying to "throw it" to the inside of the record. The flex will take place on the take off where the slope of the groove suddenly increases. Might take a slow mo camera to see it with the eye...

In the meantime, the arm is constantly being pushed toward the inside of the record by the outside of the groove - assuming the TT and arm are level. There is no other mechanism by which it can be made to travel, it has to follow the groove. By contrast, the standard arm wants to travel to the center, so we apply "anti-skate" to keep it centered in the groove. (another approximate solution) So again I vote for the arm that can change direction the fastest, and that will be the one with the lowest total overall moving mass.

This is why - in part - that several very smart designers of linear tracking arms have made the part that moves very light, and the length of the "arm" that holds the cartridge very short...

Of course ymmv.

As far as getting a precision fit? Read up on lapping for machine tools and lathes, milling machines. Or as I suggested at another time find urself a local machinist to do the precision part. They tend to have CNC stuff that works to 0.0001" these days, and precison grinders that do that and better... A good machinist really won't charge you all that much, but you have to shop around a little for someone who likes to help and do neat little projects.

Dorking with fillers (epoxy) and shims (aluminum foil or mylar) is going to be very very difficult to make work well... maybe you can perfect the technique. I wouldn't want to try getting it flat and square myself... stock extrusions just are not smooth nor flat, nor very straight....

_-_-bear

Edit: Oh, VTA effects the stereo spread, and the way that highs sound...

Bear,

Not everybody can site the pump remotely & have a tube running into the room with the TT. WAF is an issues also. Here's the one at @ 30dB http://www.silentaire.com/silentaire/chart_choice.asp although significantly more expensive at $600

Not everybody can site the pump remotely & have a tube running into the room with the TT. WAF is an issues also. Here's the one at @ 30dB http://www.silentaire.com/silentaire/chart_choice.asp although significantly more expensive at $600

Not sure why... the tubing can be thin and flexible... hide against a wall... a closet works... but I suppose the WAF might be an issue.

Ah ha! I see why those compressors are as "silent as a refrigerator"! They are refrigerator type units!

Not bad, but I still don't want a refrigerator running in my room while playing - but if you can charge up a storage tank that ought to work... give enough play time between recharges.

_-_-bear

Edit: I am wondering if there will be WAF with one of those things in the LR??

Ah ha! I see why those compressors are as "silent as a refrigerator"! They are refrigerator type units!

Not bad, but I still don't want a refrigerator running in my room while playing - but if you can charge up a storage tank that ought to work... give enough play time between recharges.

_-_-bear

Edit: I am wondering if there will be WAF with one of those things in the LR??

Ah now, I didn't think of that - a reclaimed fridge compressor - must be lots of these to be had!

How big a tank is needed to give 1 hr of playing time. I'm sure there's a formula but I can't begin to put one together.

This would probably be the ideal solution - charge up a tank (if it's small enough) with a quiet pump(if it only takes a short time) - then turn off during playback - pressure in tank providing silent air through a regulator to air bearing arm.

Edit: What's the LR?

How big a tank is needed to give 1 hr of playing time. I'm sure there's a formula but I can't begin to put one together.

This would probably be the ideal solution - charge up a tank (if it's small enough) with a quiet pump(if it only takes a short time) - then turn off during playback - pressure in tank providing silent air through a regulator to air bearing arm.

Edit: What's the LR?

LR = Living Room

or if you are lucky = Listening Room

The problem with stock refrigeration compressors is that they do not last long running on air... so these are likely modified to do the job properly...

Otoh if they are almost free and you can get a bunch, it shouldn't matter if they sieze up after a while...

The relationship between the tank and the arm is going to be CFM at some pressure. The tank is a fixed Cu Ft (or Cu Meters) at some pressure... there is a conversion formula online somewhere that takes CF at some PSI and converts it to CFM at some other PSI, that's all you need.

I don't know what it is...

_-_-bear

or if you are lucky = Listening Room

The problem with stock refrigeration compressors is that they do not last long running on air... so these are likely modified to do the job properly...

Otoh if they are almost free and you can get a bunch, it shouldn't matter if they sieze up after a while...

The relationship between the tank and the arm is going to be CFM at some pressure. The tank is a fixed Cu Ft (or Cu Meters) at some pressure... there is a conversion formula online somewhere that takes CF at some PSI and converts it to CFM at some other PSI, that's all you need.

I don't know what it is...

_-_-bear

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

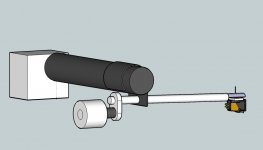

- DIY Air bearing tangent tone arm